Double-step floating burr removing device of crankshafts and machining method

A technology for deburring and crankshafts, which is applied to grinding drives, metal processing equipment, manufacturing tools, etc., can solve the problems of the tool without radial floating function, unstable quality, low efficiency, etc., to achieve a simplified structure and avoid rigidity. Contact, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

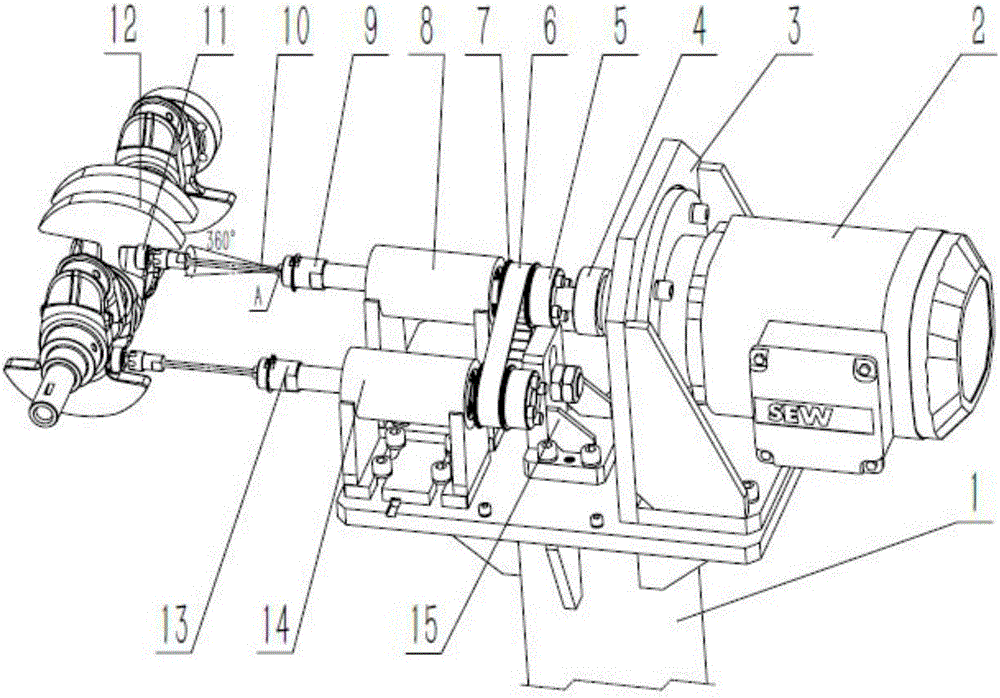

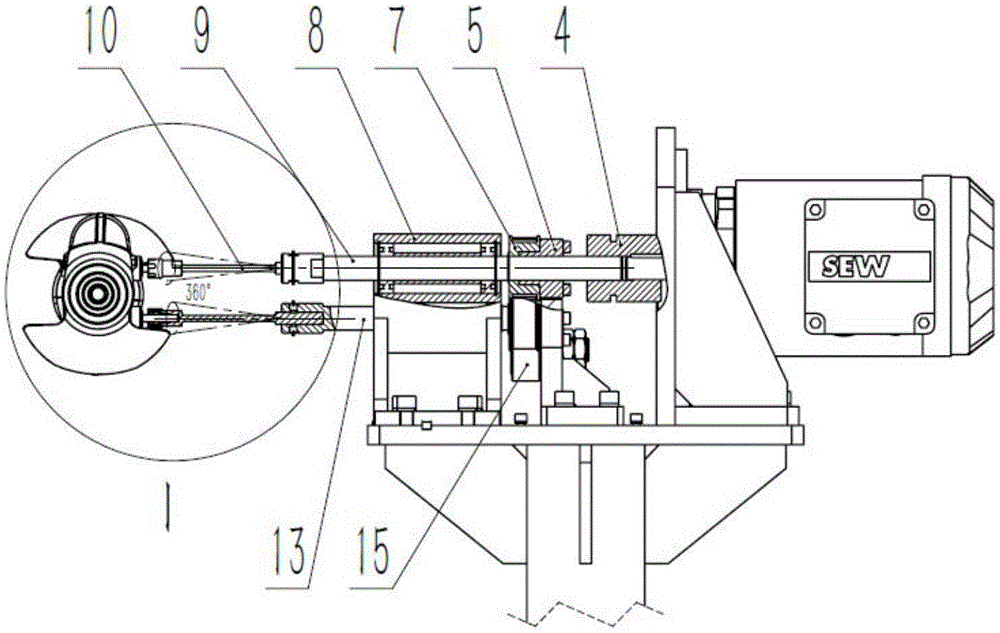

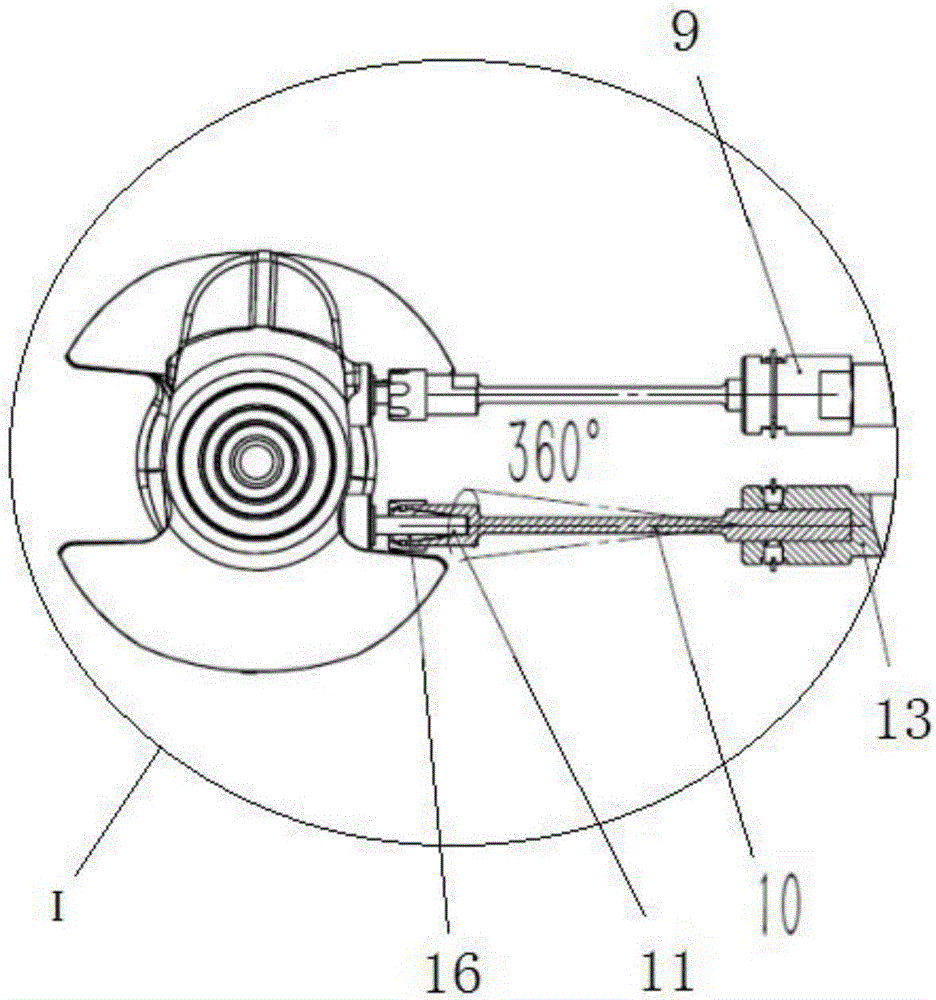

[0042] refer to figure 1 , the preferred embodiment of the present invention provides a crankshaft double-step floating deburring device, including a base 1, a geared motor 2, a motor seat 3, a coupling 4, an expansion sleeve 5, a synchronous belt 6, and a synchronous pulley 7. Main transmission shaft seat 8, main transmission shaft 9, elastic knife bar 10, hair brush 11, auxiliary transmission shaft 13, auxiliary transmission shaft seat 14, tensioning wheel assembly 15 and elastic collet 16.

[0043] The main transmission shaft seat 8 , the auxiliary transmission shaft seat 14 , the motor seat 3 and the tensioning wheel assembly 15 are fixedly installed on the base 1 .

[0044] The geared motor 2 is fixedly installed on the motor base 3 .

[0045] The main transmission shaft 9 is installed on the main transmission shaft seat 8 through a rolling bearing, and its input end is connected with the output shaft of the reduction motor 2 through a shaft coupling 4, and an elastic kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com