Dustproof film for furniture and preparation method thereof

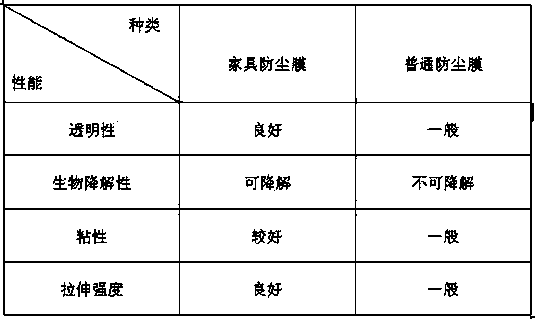

A dust-proof film and furniture technology, applied in the field of furniture dust-proof film and its preparation, can solve the problems of non-degradable materials, environmental problems, high cost, etc., and achieve good plasticizing effect, short degradation time and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of preparation method of furniture dust-proof film, comprises the following steps:

[0032] 1. Alkaline modification of konjac glucomannan: Weigh 2g of konjac glucomannan, add 100mL water to a conical flask, stir in a 50°C water bath with a magnetic stirrer at 3000r / min for 10min, and use 0.1mol / L Ca(OH) 2 solution, adjust the pH value to 10, and then stir with a magnetic stirrer at 3000r / min for 1h to obtain deacetylated konjac glucomannan sol;

[0033] 2. Blending: Prepare a glacial acetic acid solution with a weight concentration of 5% to 20%, add chitosan at a weight ratio of 1.5% to 2.5%, stir in a magnetic stirrer at 3000r / min for 10 minutes, and then add the glacial acetic acid solution Stearic acid with a weight ratio of 0.05% to 0.1% to obtain a glacial acetic acid mixed solution, take 70g of glacial acetic acid mixed solution, add 30g of deacetylated konjac glucomannan sol, and mix to obtain a mixed glue. Add 6g of paraffin and 5g of gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com