Patents

Literature

59results about How to "Guaranteed beat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

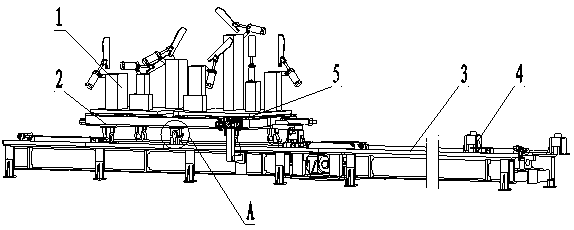

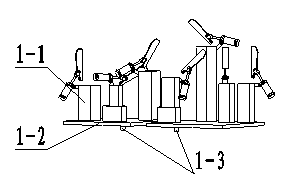

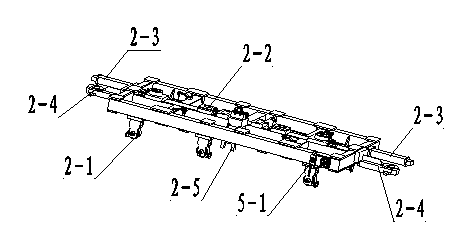

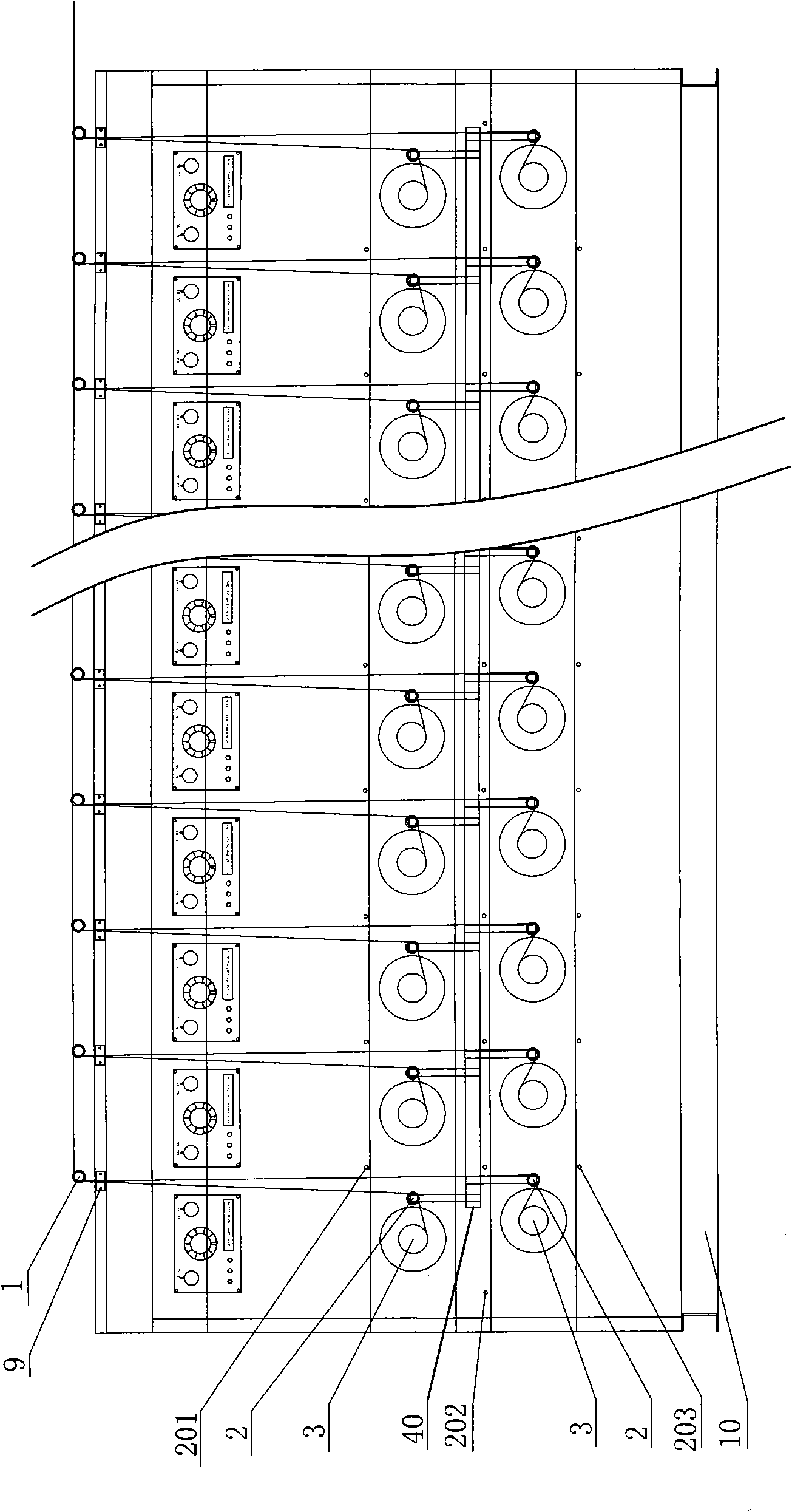

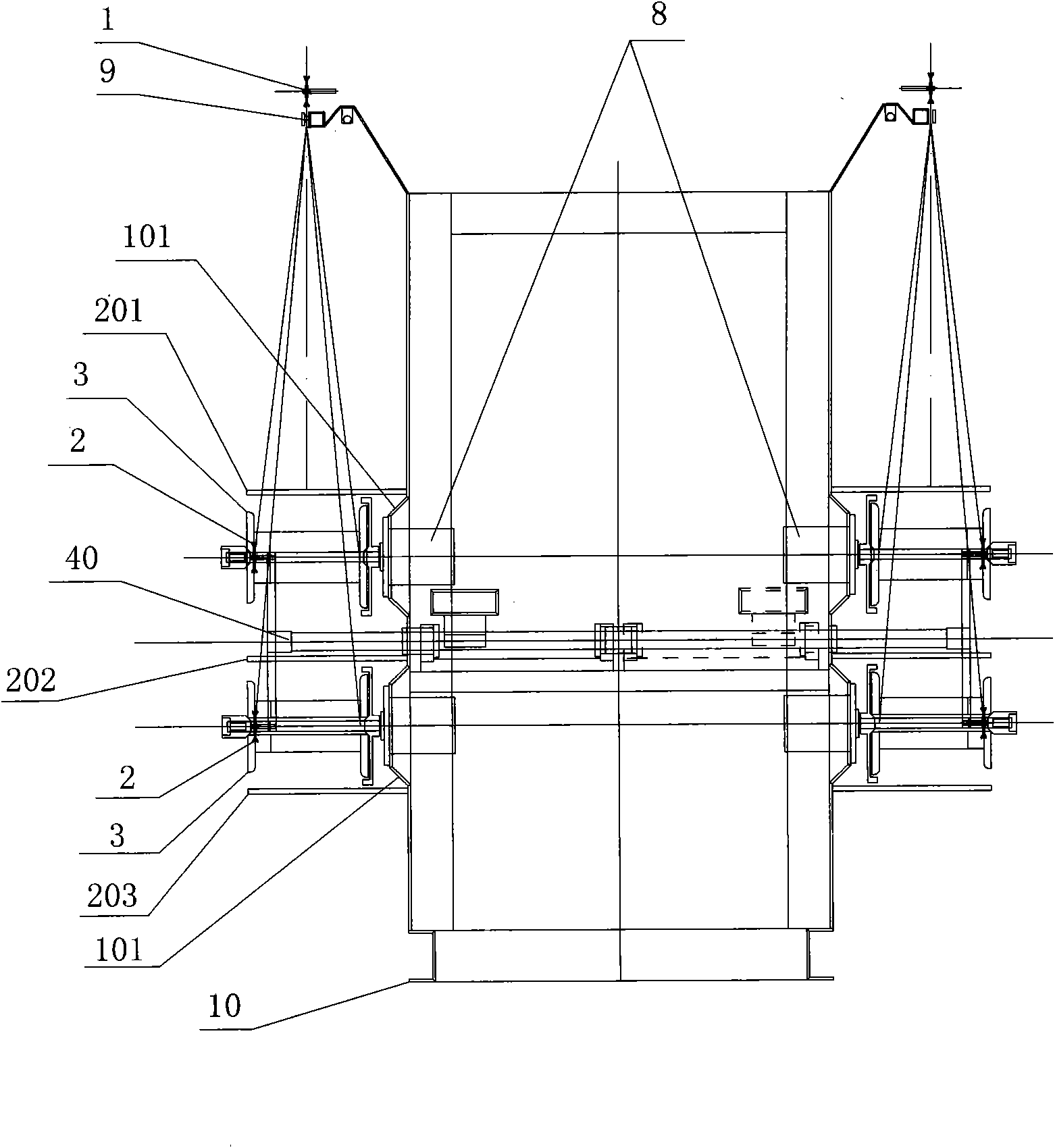

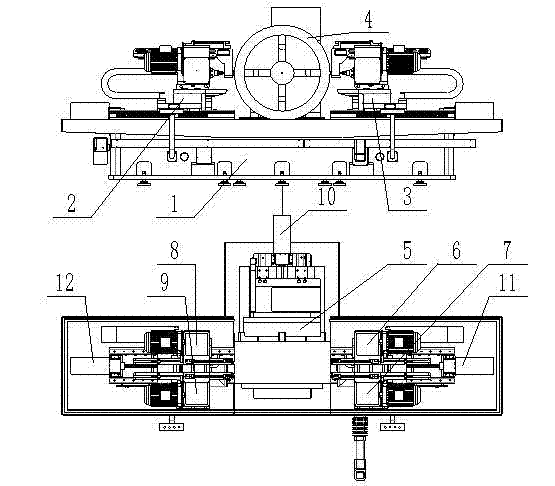

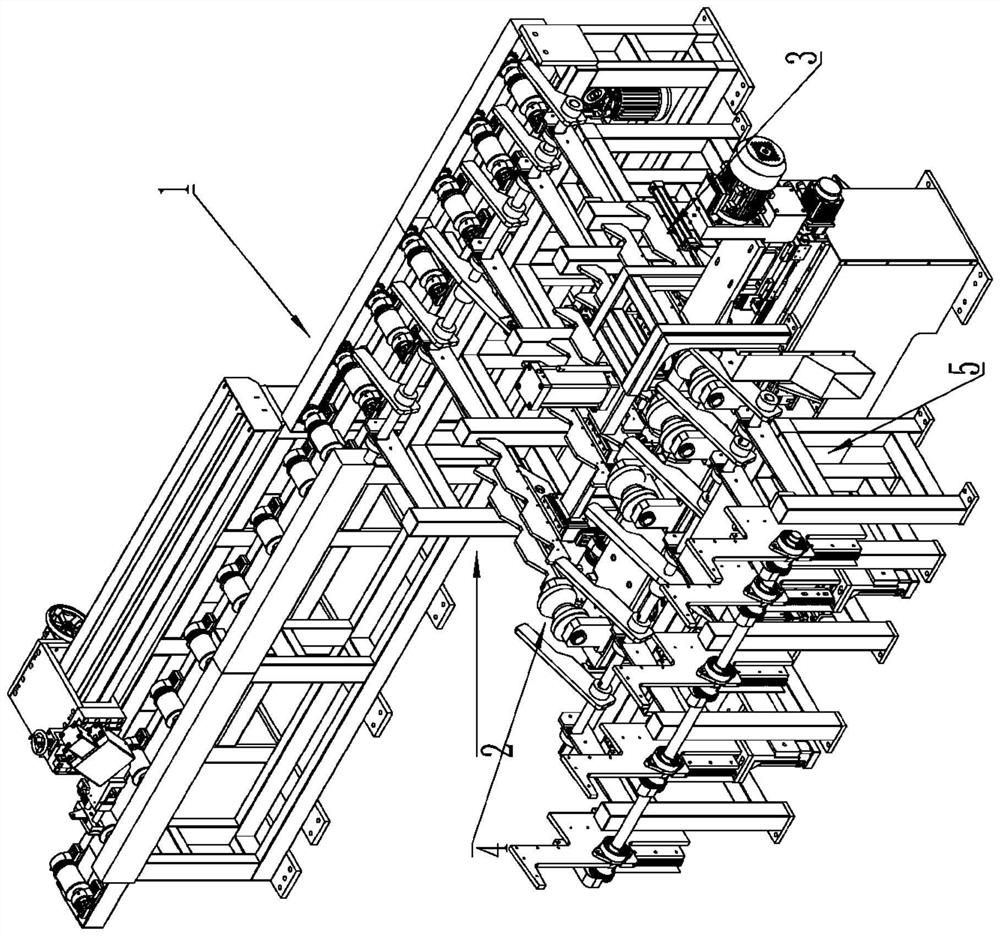

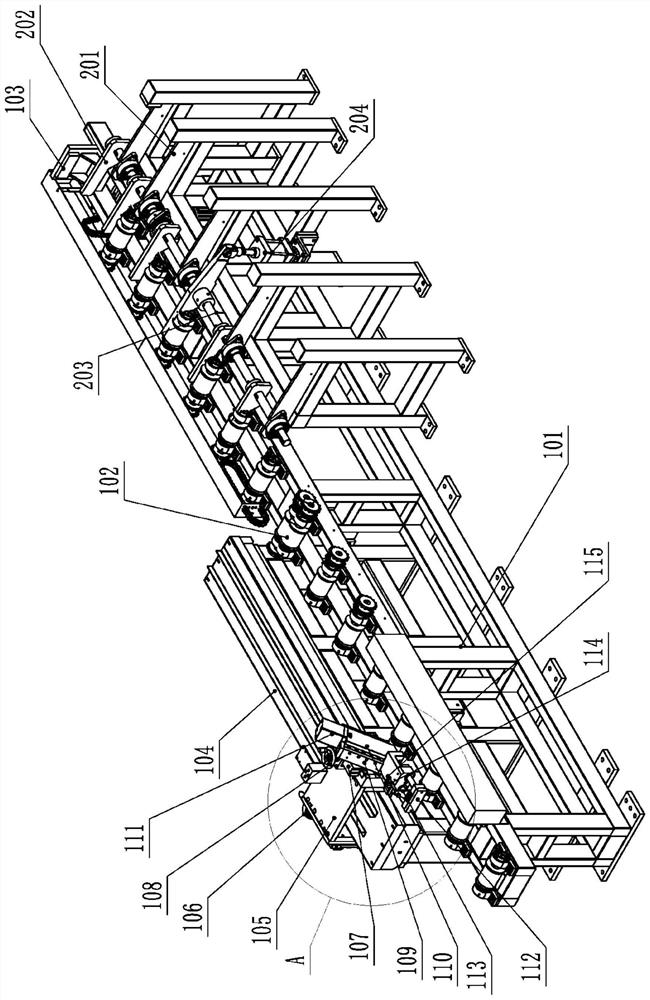

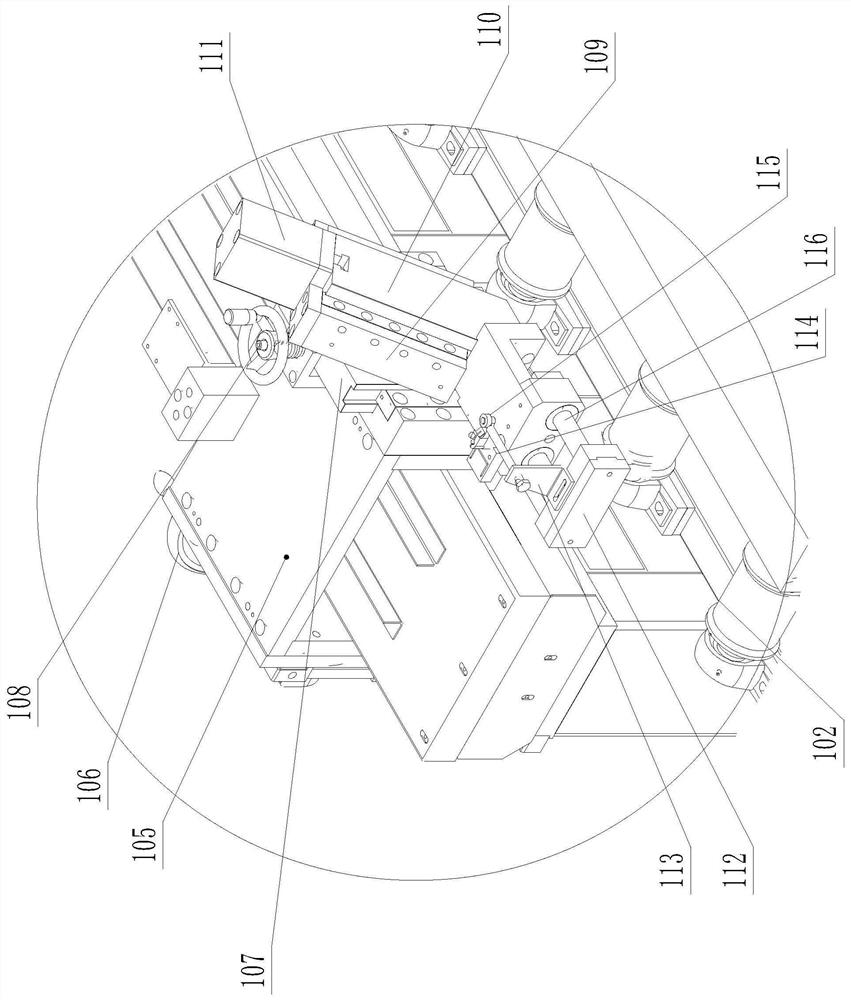

Flexible welding production line for side wall plate of automobile

ActiveCN102699585AImprove flexible production capacityImproved flexible production capacityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineProgrammable logic controller

The invention relates to a flexible welding production line for a side wall plate of an automobile, which is used for improving the flexible production capacity of an autobody welding line body, and comprises a clamp body, a trolley, a frame, a drive mechanism and a PLC (programmable logic controller) control system. The clamp body is installed on the trolley which is connected with the drive mechanism. The trolley is controlled by the PLC control system and dragged by the drive mechanism to reciprocate on a track of the frame to convey the clamp and workpiece of the welding line body. The drive mechanism is arranged on the frame which is fixed on the level ground. The flexible welding production line for the side wall plate of the automobile provided by the invention has the advantages of stable performance, strong universality and high degree of automation, and according to the flexible welding production line, not only is the work efficiency of the welding operation improved remarkably and the production pace of the factory is ensured, but also the flexible production capacity of the welding line body is improved, the capital investment on devices is lowered, the period of new products in batch production is shortened, and large economic benefits is brought for enterprises.

Owner:长城汽车股份有限公司平湖分公司

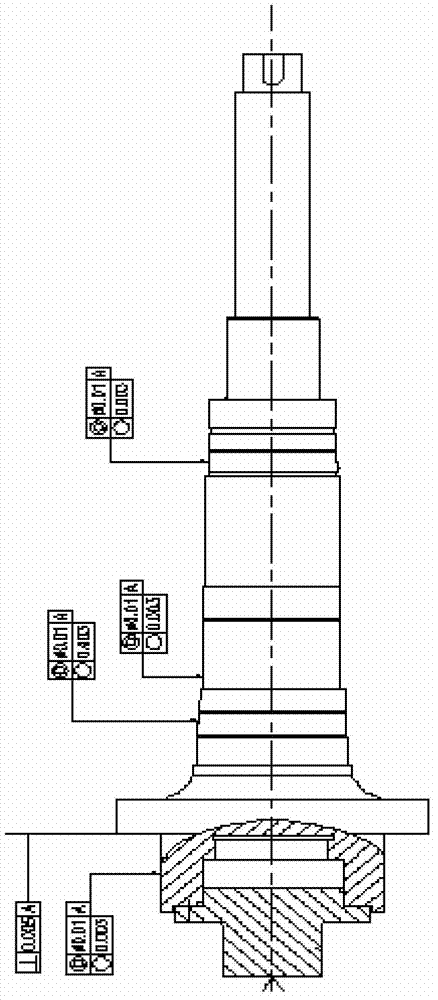

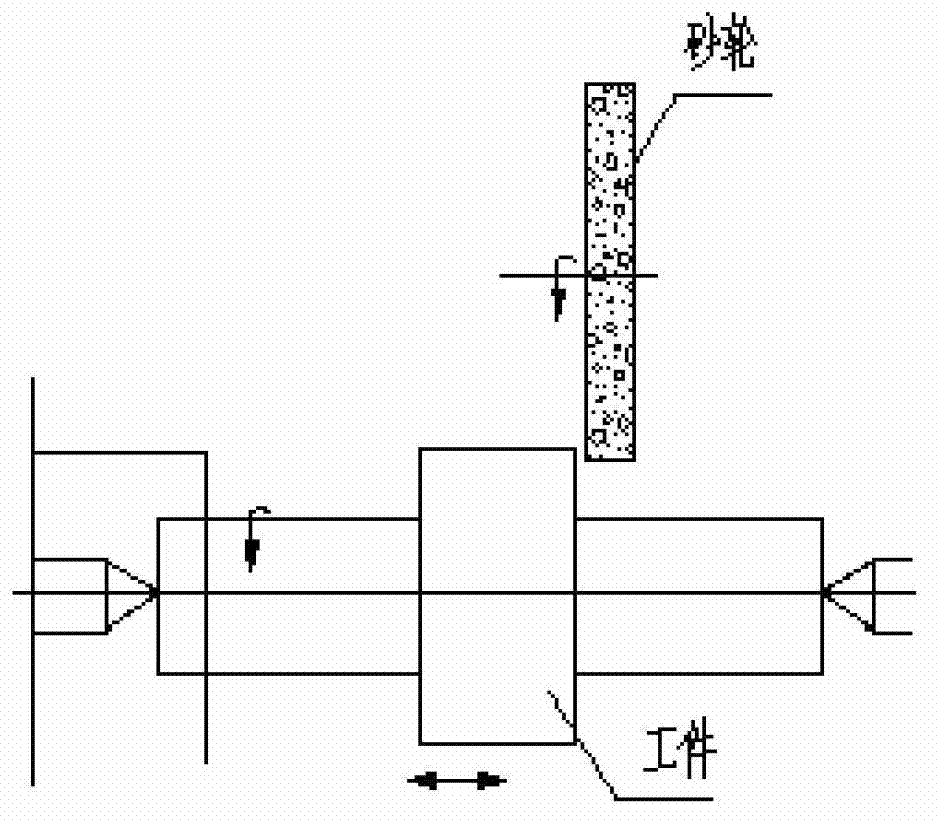

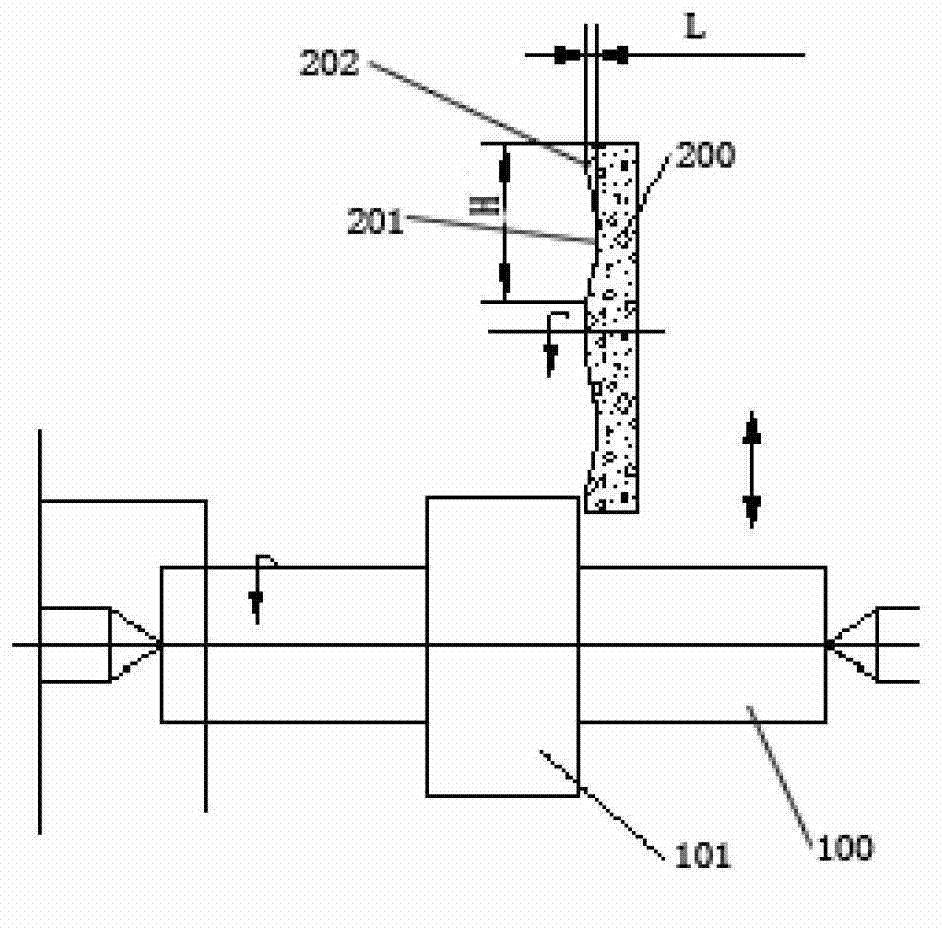

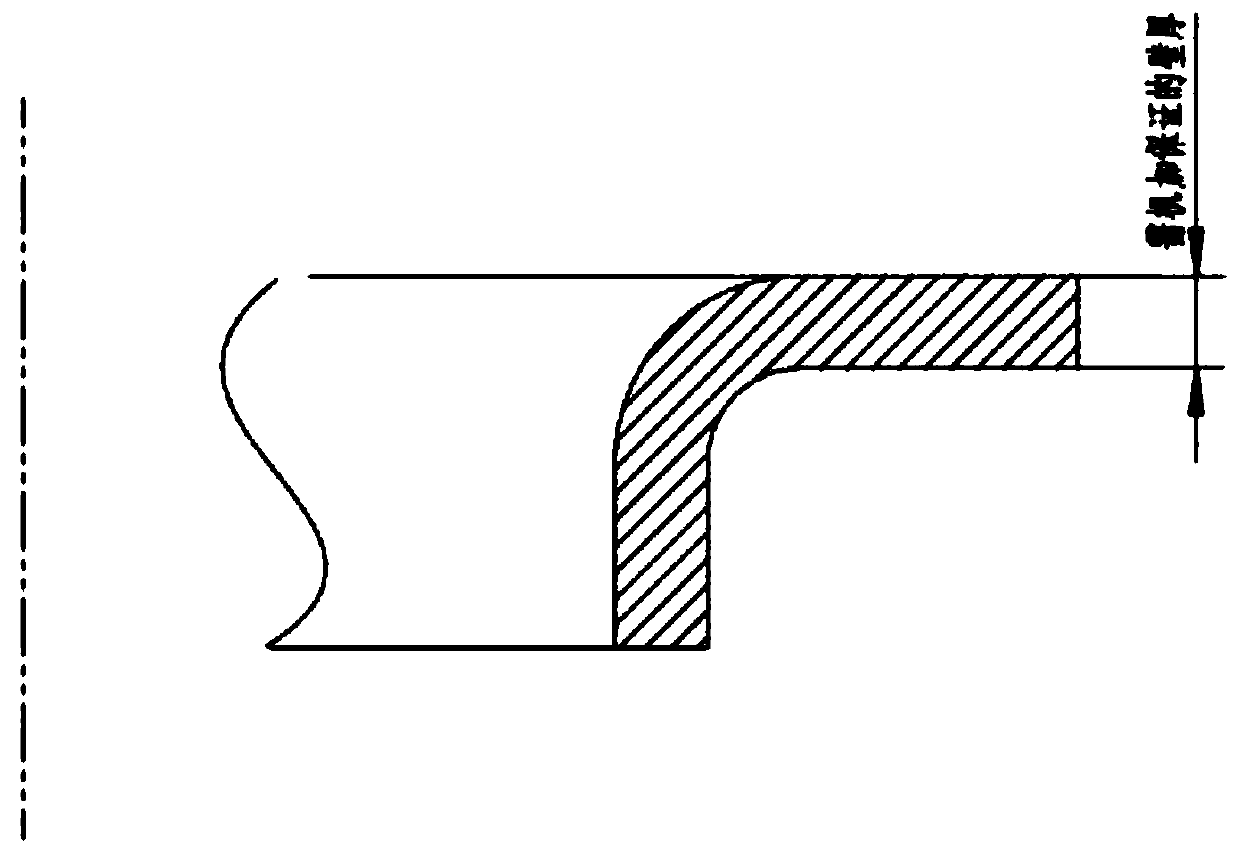

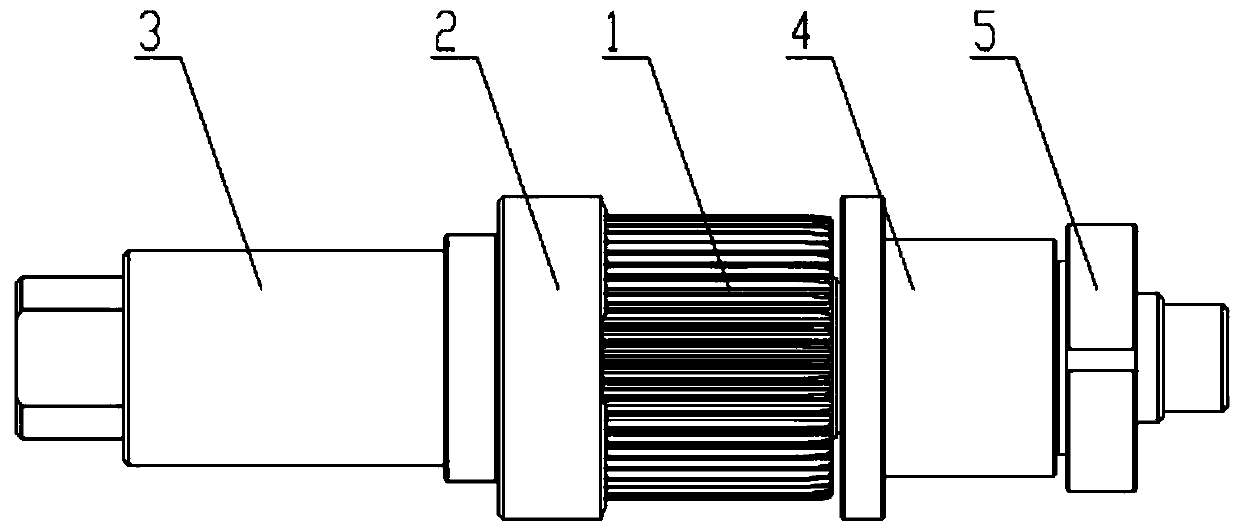

Machining method of high-accuracy cutter shaft of rotary shear

ActiveCN102825515AGuaranteed beatGuaranteed meshing accuracyPlane surface grinding machinesCircular discResonance

The invention discloses a machining method of a high-accuracy cutter shaft of a rotary shear. The machining method is sequentially performed according to the following steps of: 1, forging a blank and normalizing; 2, performing rough turning; 3, performing hardening and tempering, i.e., performing quenching and high-temperature tempering treatment on the cutter shift; 4, performing semi-fine turning; 5, performing semi-fine milling; 6, performing fine turning; and 7, performing fine milling, i.e., milling a main outer circle and a taper of the cutter shaft, and meanwhile, arranging a groove in a middle part of an axial end face of a milling grinding wheel, wherein a part which is clamped between the groove and the circumferential surface of the grinding wheel is a milling part of the grinding wheel, so that the milling part of the grinding wheel in a rotation process is used for milling an end face of a cutter shaft shoulder which is kept in the rotation process after being clamped on a machine tool, and the grinding wheel does reciprocating motion in the radial direction of the cutter shaft in a milling process. According to the machining method, a contact area of the grinding wheel and the shaft shoulder can be reduced, jumping of a grinding wheel and aggravation of jumping of the shaft by resonance of an end face of the shaft shoulder and the grinding wheel in a milling process are prevented, and the milling accuracy of the axial end face is guaranteed to be within 0.005 mum.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

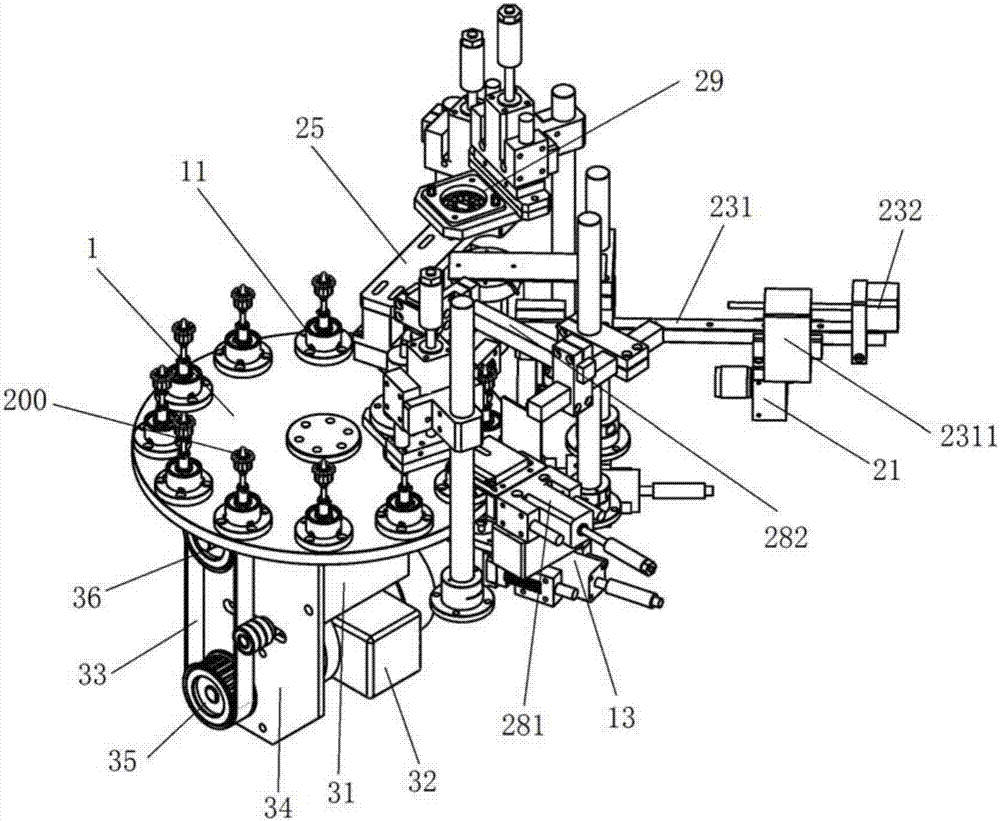

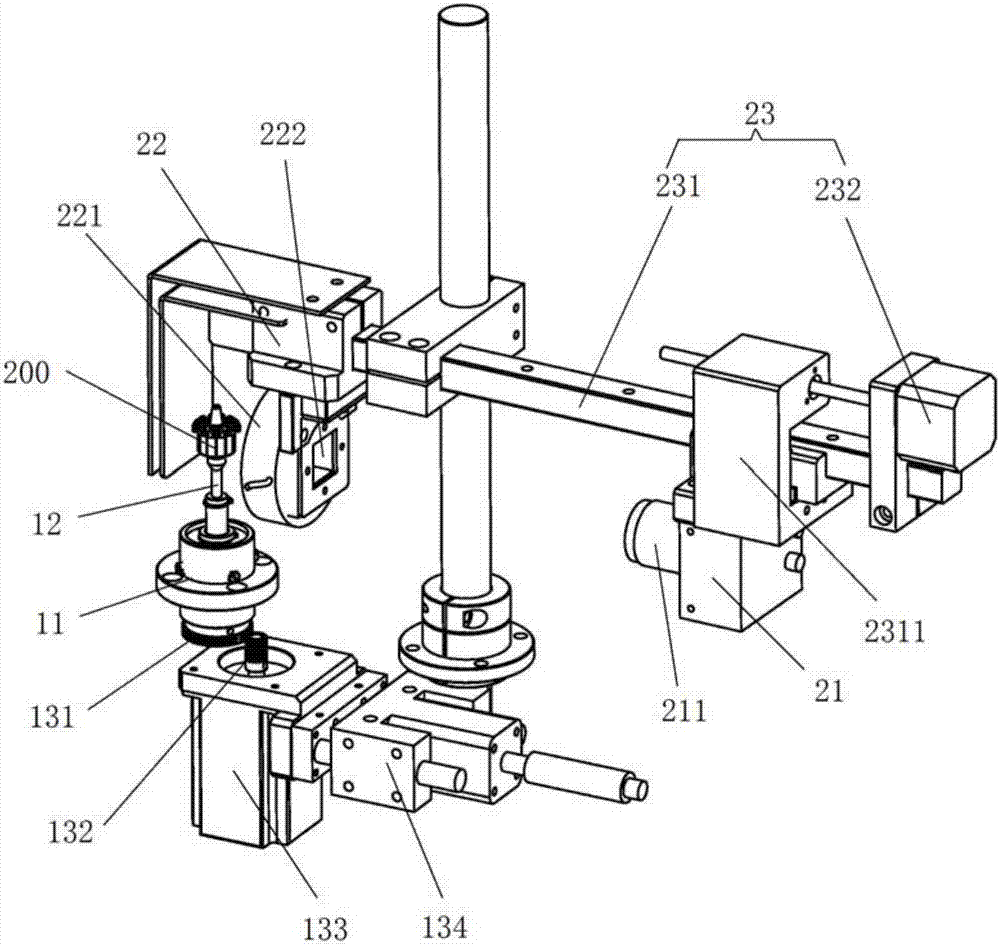

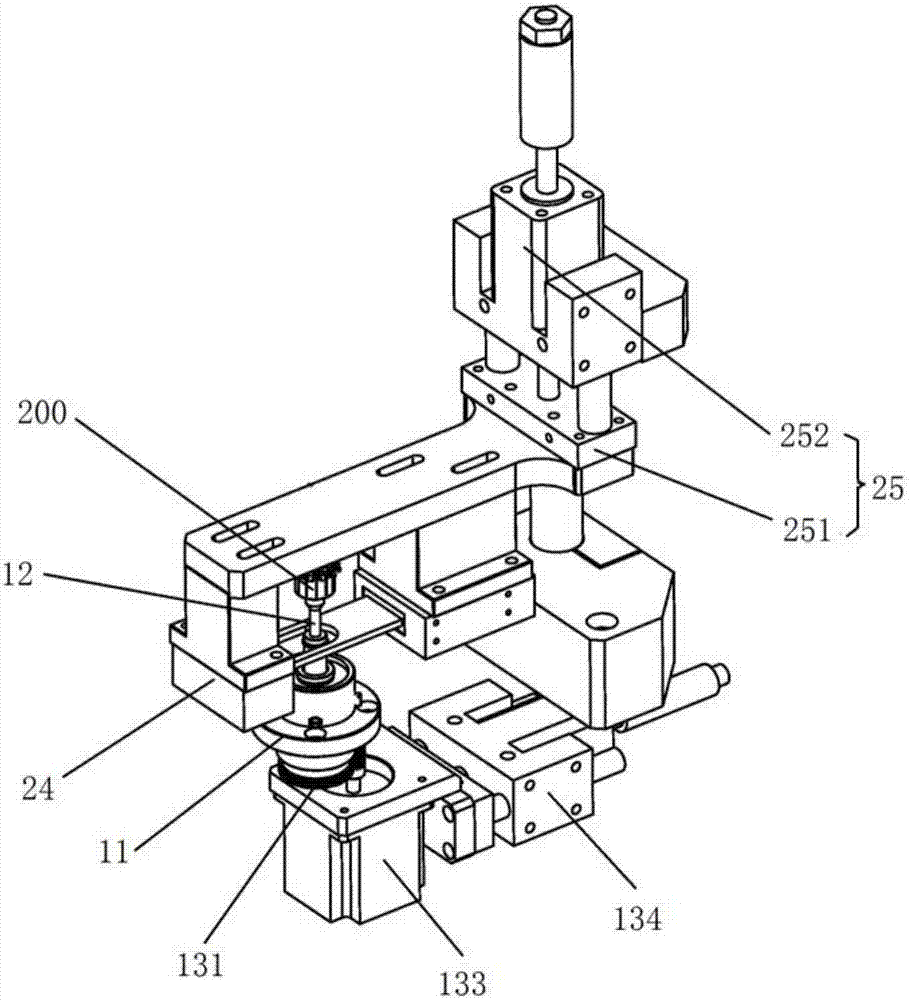

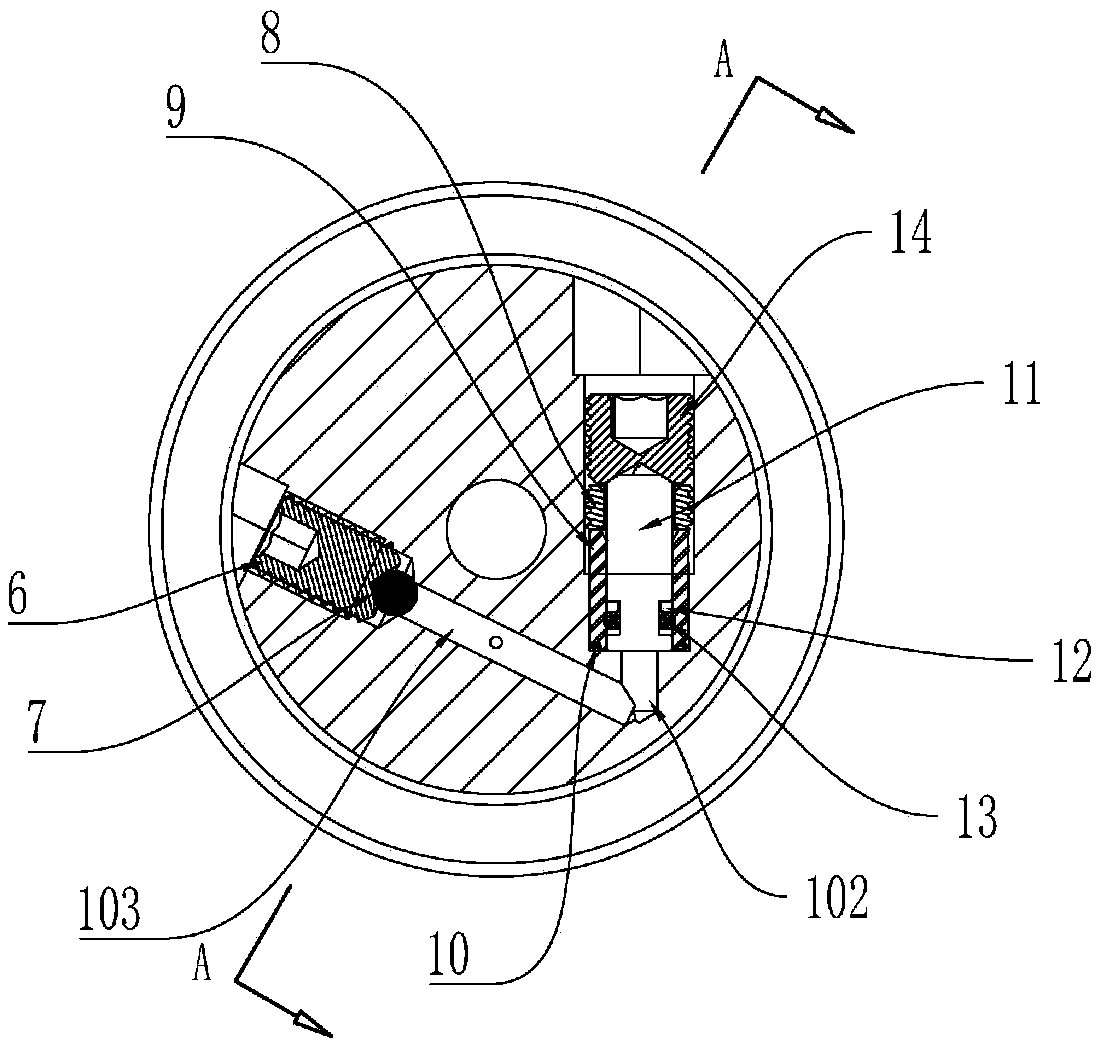

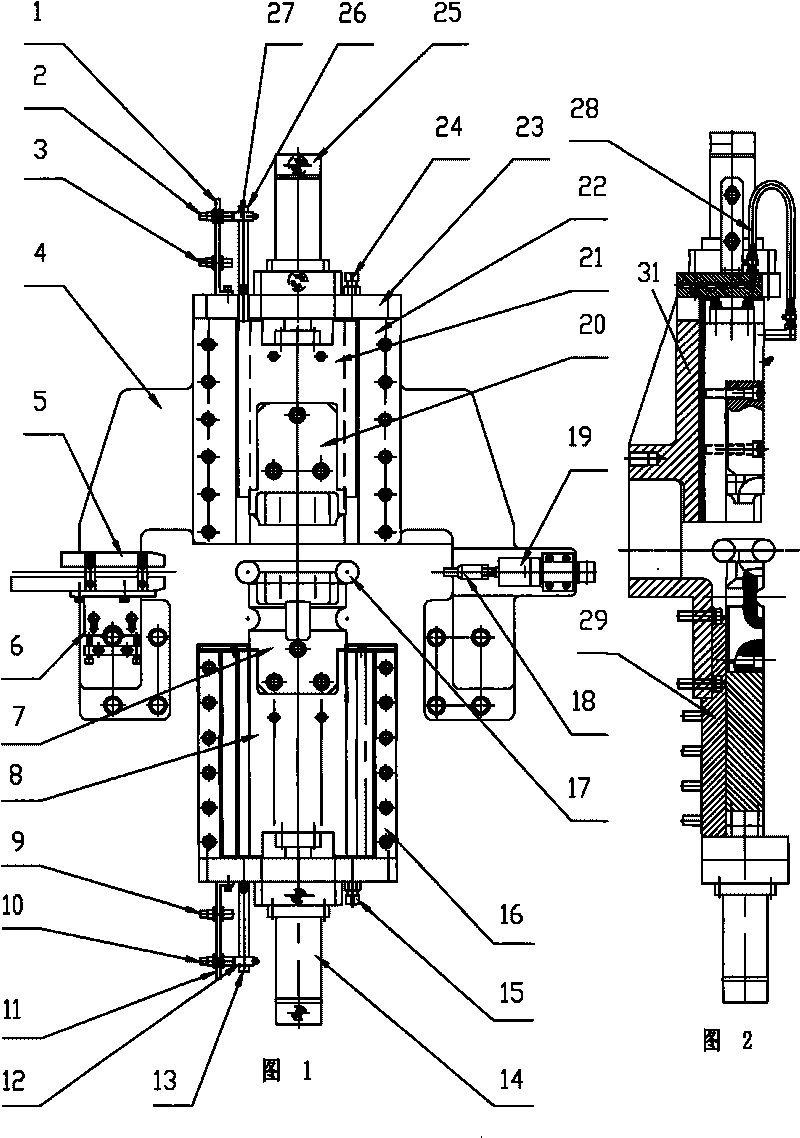

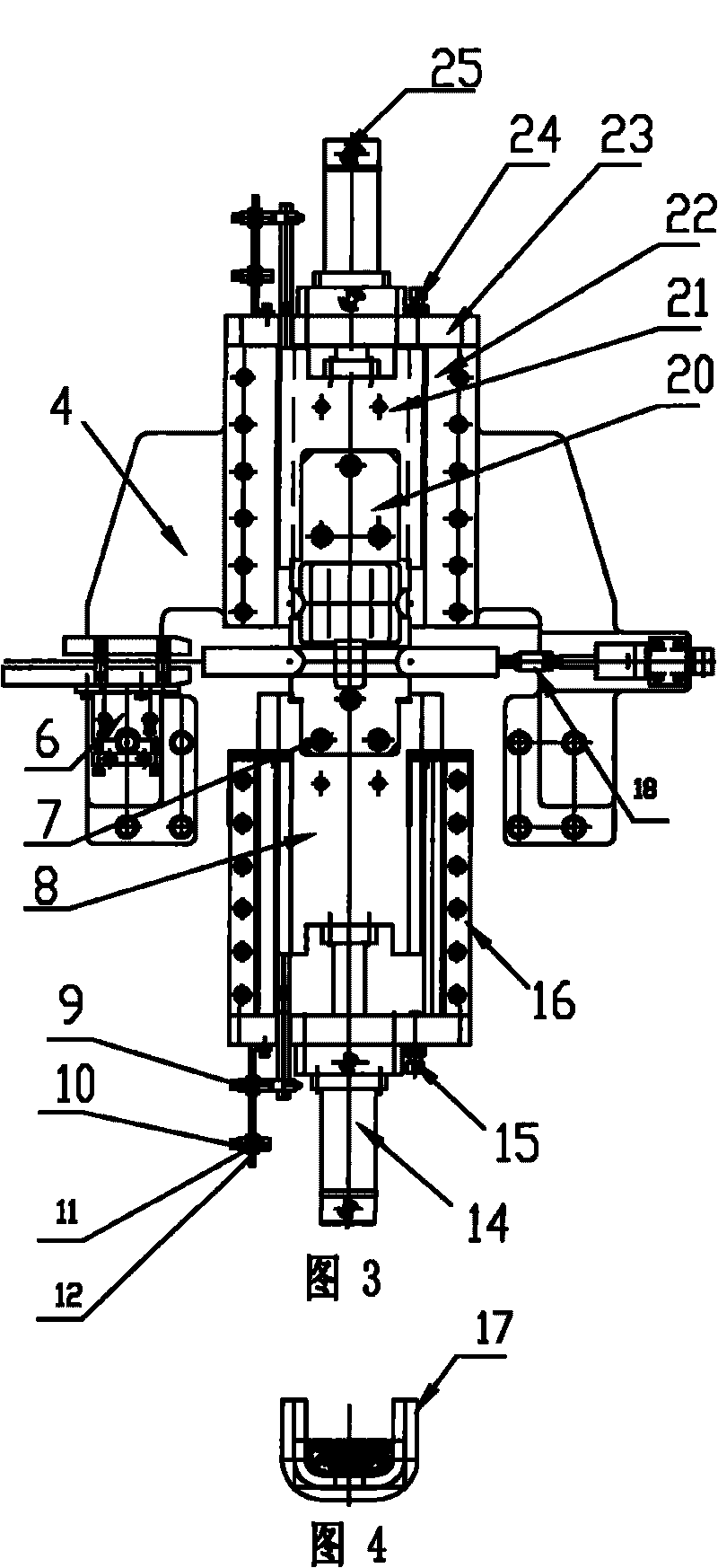

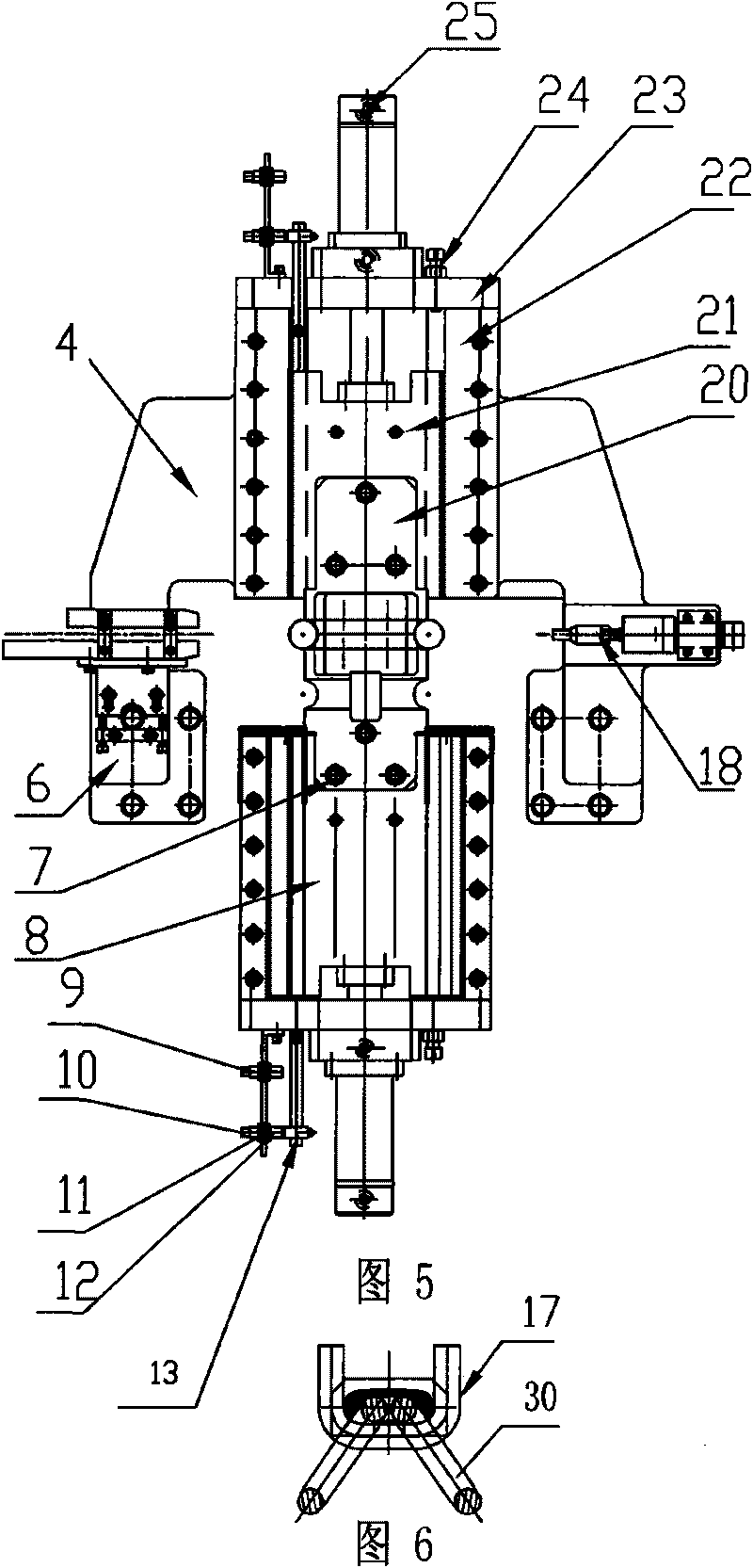

Multifunctional appearance detection device

PendingCN107218972AGuaranteed beatGuaranteed detection effectMeasurement devicesFree rotationEngineering

The invention provides a multifunctional appearance detection device, which comprises a rotating plate, a detection system, a driving device and an installation rack, and is characterized in that the rotating plate can rotate freely, the rotating plate is provided with a plurality of detection stations used for placing workpieces, each detection station is provided with a detection core shaft which can rotate freely and is used for arranging a workpiece in a sleeved manner; the detection system comprises a shooting device used for detecting the outer surface of the workpiece, and the shooting device is arranged at the periphery of the rotating plate along the radial direction of the detection core shaft; the driving device is arranged below the rotating plate so as to drive the rotating plate to rotate intermittently in a stepping manner; the rotating plate, the detection device and the driving device are installed on the installation rack, the pace of detection for each workpiece is guaranteed through driving the rotating plate to rotate intermittently in a stepping manner, and the detection efficiency is improved; and meanwhile, the shooting device is arranged at the periphery of the rotating plate along the radial direction of the detection core shaft so as to detect the peripheral surface of each workpiece, and is enabled to detect the peripheral surface of each workpiece in an omnidirectional manner by being matched with free rotation of the detection core shaft, so that the detection accuracy is greatly improved.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

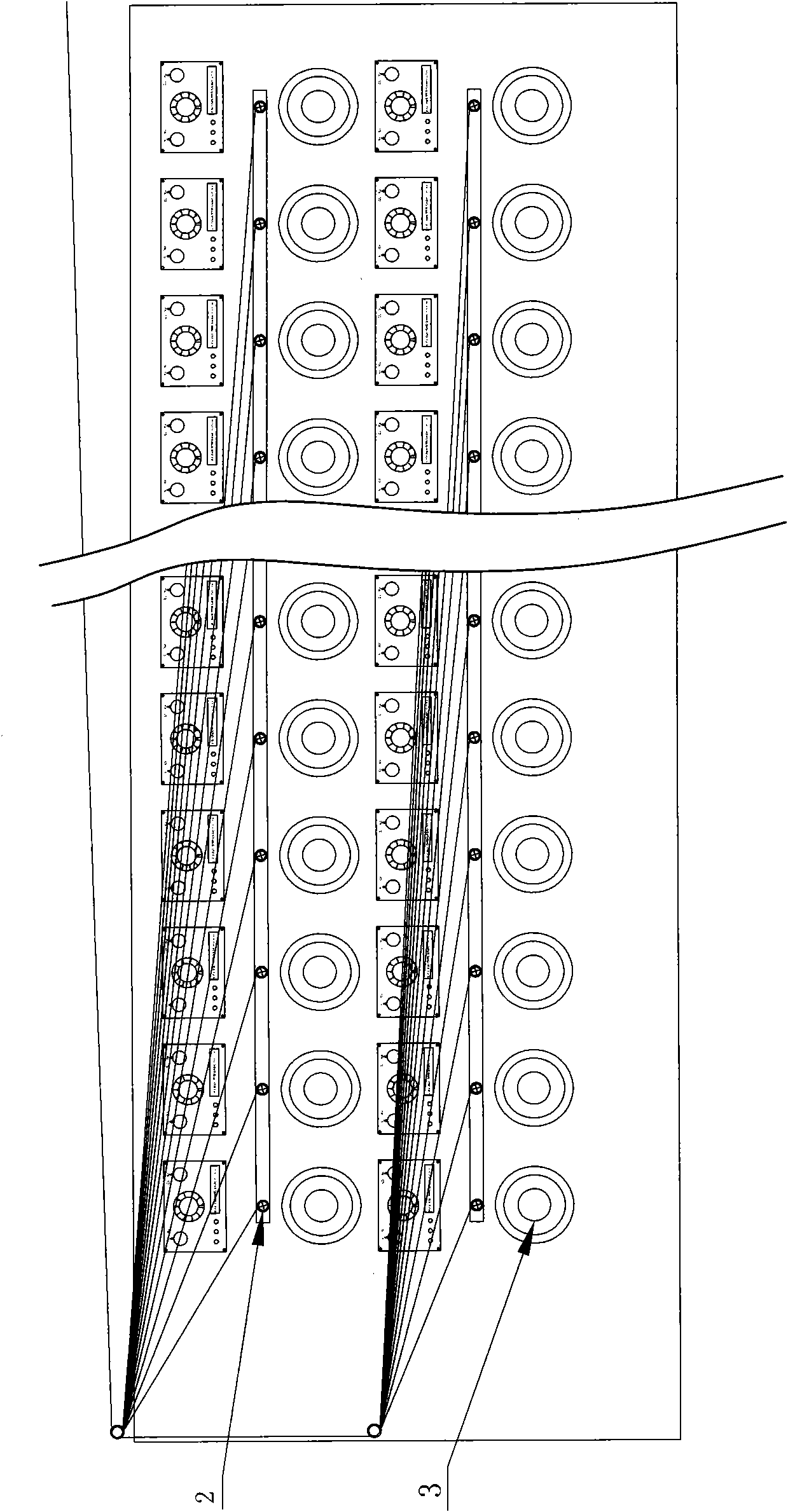

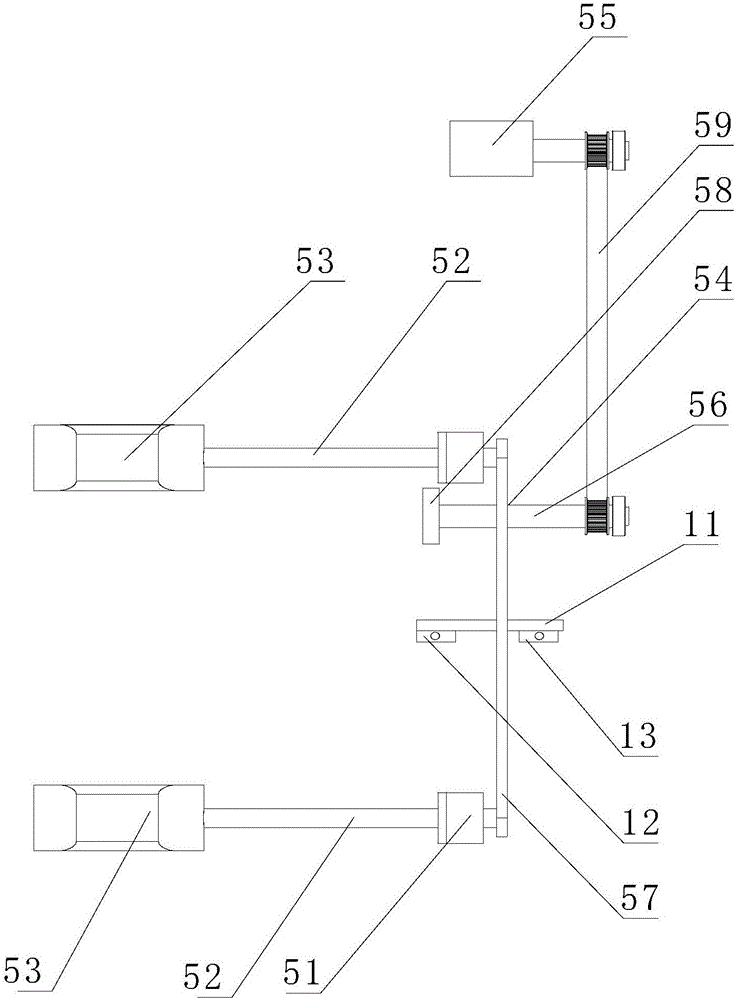

Wire-arranging mechanism of multi-head wire-rewinding machine and numerical control wire-arranging method

InactiveCN101863398AReduce distractionsReduce production capacityFilament handlingManufacturing cost reductionNumerical control

The invention relates to the field of wire-arranging technology of a multi-head wire-rewinding machine, in particular to a wire-arranging mechanism of the multi-head wire-rewinding machine and a numerical control wire-arranging method. The wire-arranging mechanism of the multi-head wire-rewinding machine comprises a stander, a PLC controller, a screw rod driving device, wire-arranging guide wheels, a reversing guide wheel and a wire-arranging guide wheel driving device, wherein the wire-arranging guide wheel driving device is connected with the wire-arranging guide wheels; the screw rod driving device comprises a screw rod, a screw rod nut, an approach switch, two screw rod bearing seats, two synchronous belt pulleys, a synchronous belt and a constant speed motor, wherein the screw rod nut is connected with the wire-arranging guide wheel driving device; the PLC controller is connected with the approach switch and the constant speed motor; and the PLC controller is provided with a forward rotation monitoring timer, a reverse rotating monitoring timer, a millisecond-level reversing timer and a speed increasing and reducing timer. The invention not only reduces the interference amongwires and the production accidents and improves the wire-arranging quality and finished product wire quality, but also simplifies the structure, is easy for operation and reduces the manufacturing and maintaining costs.

Owner:东莞市康汇聚线材科技有限公司

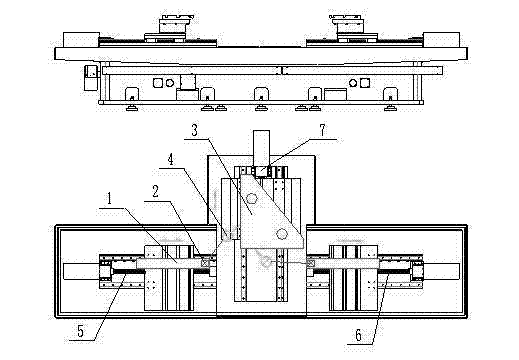

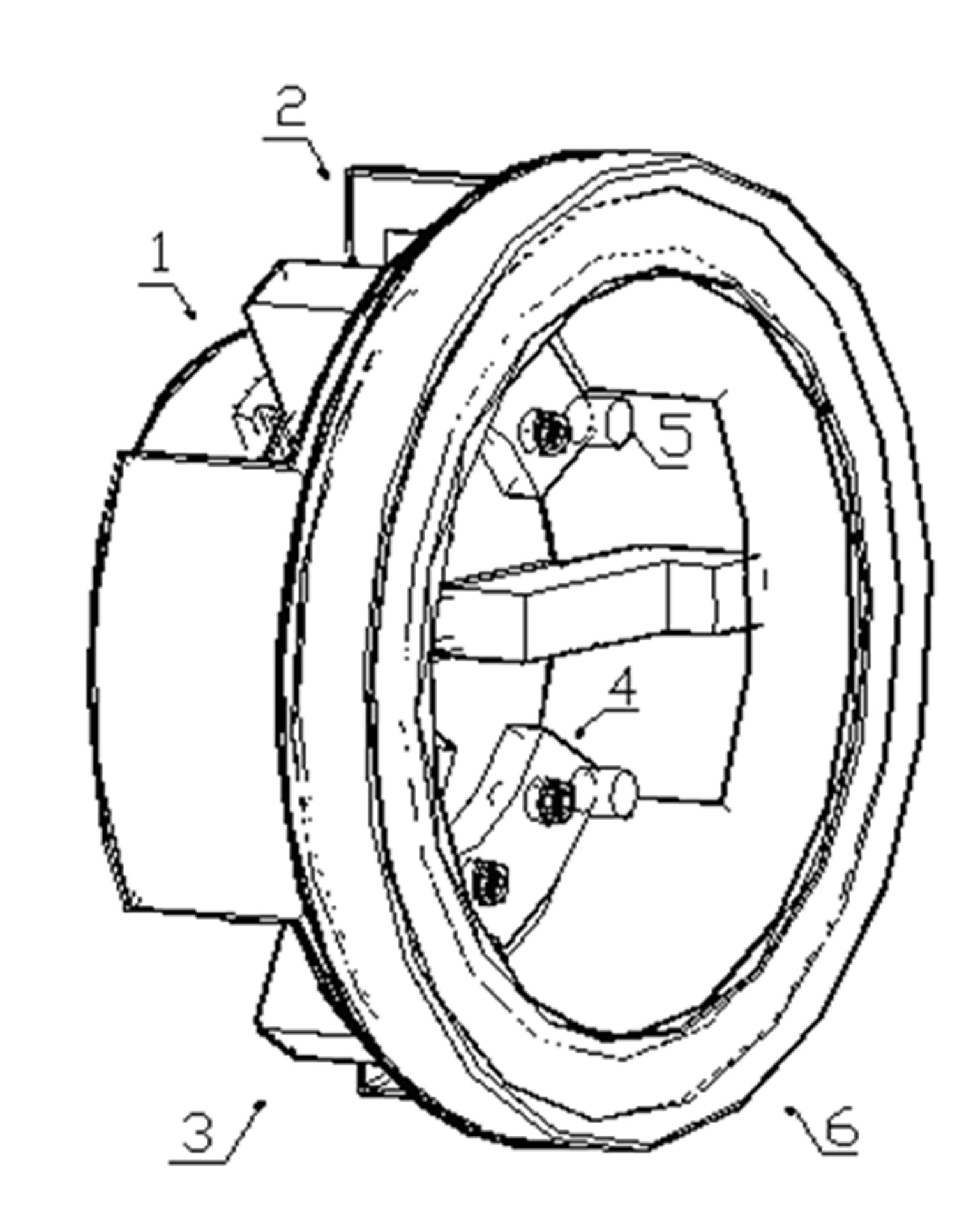

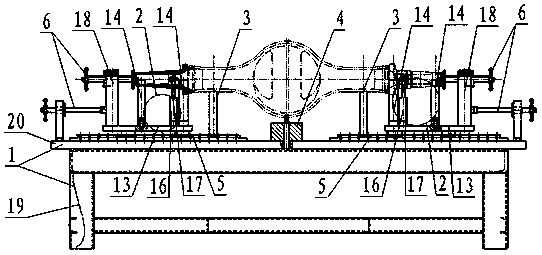

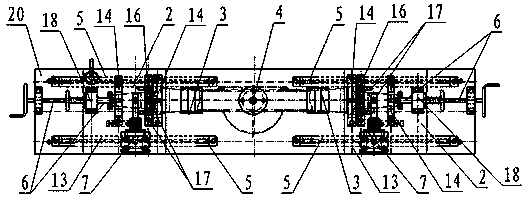

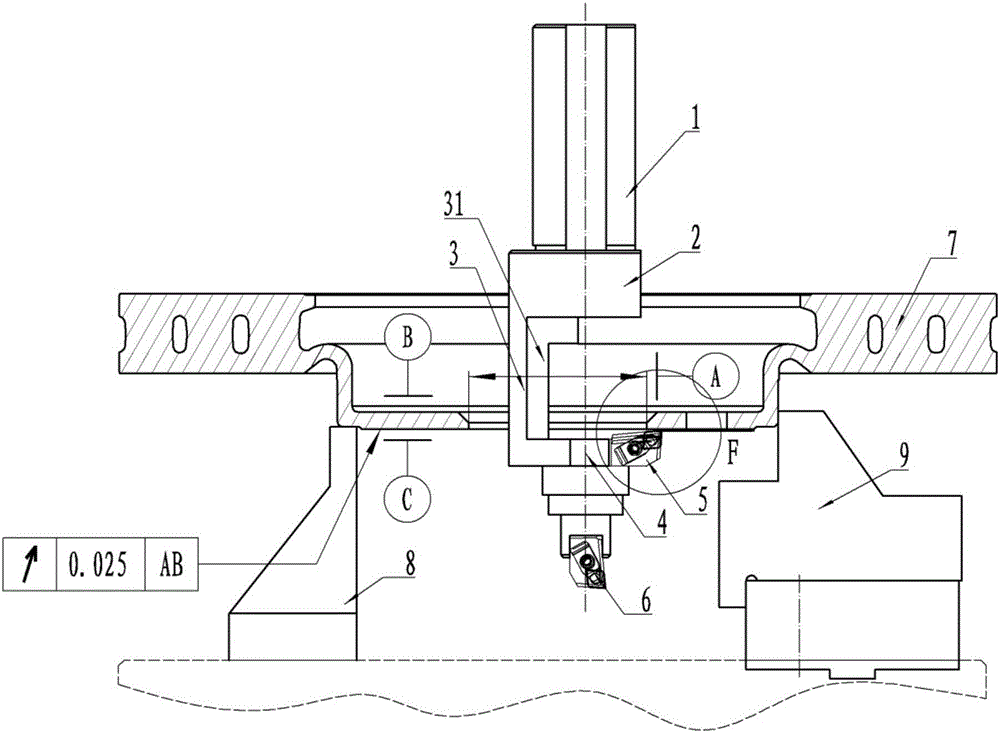

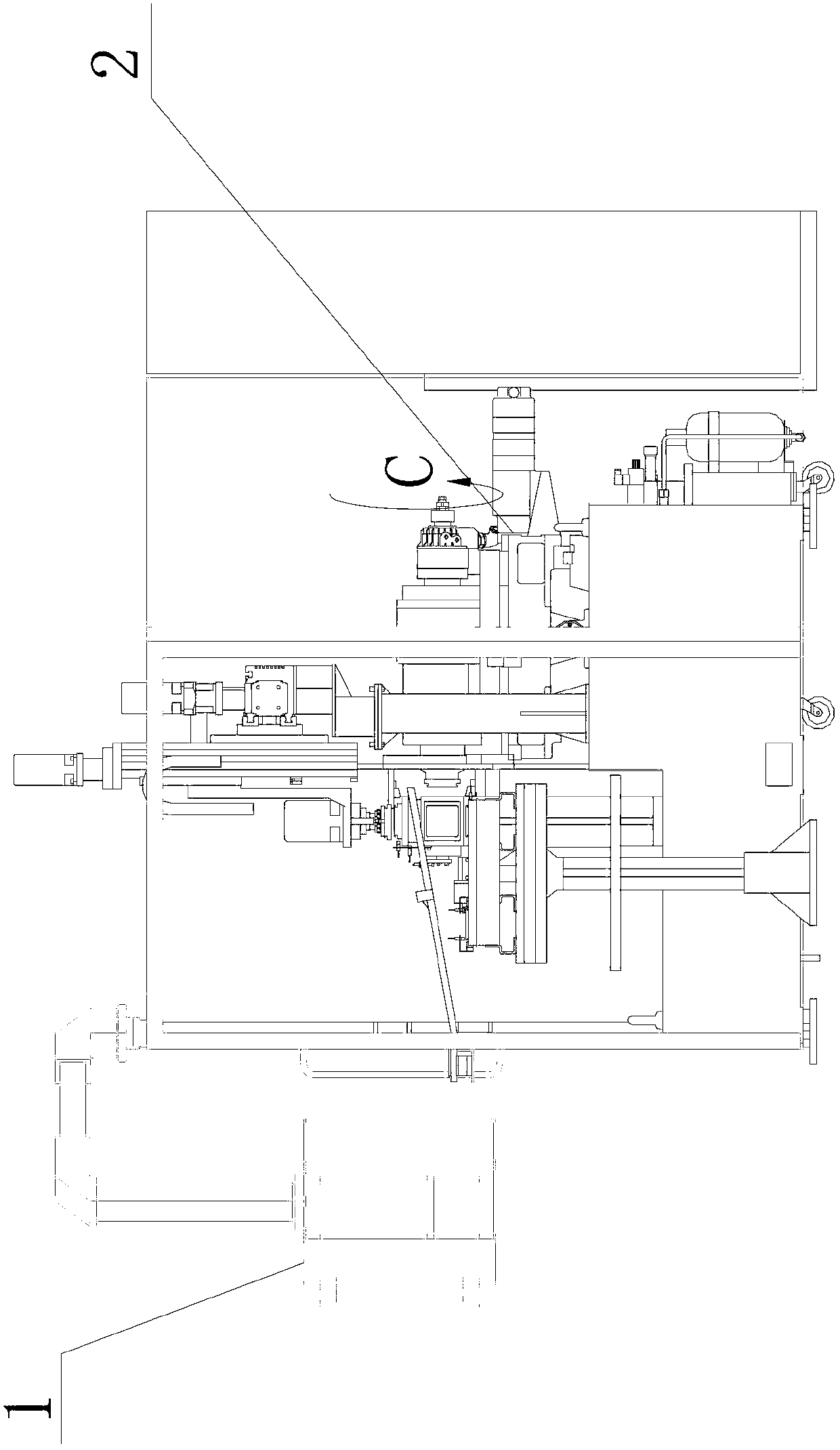

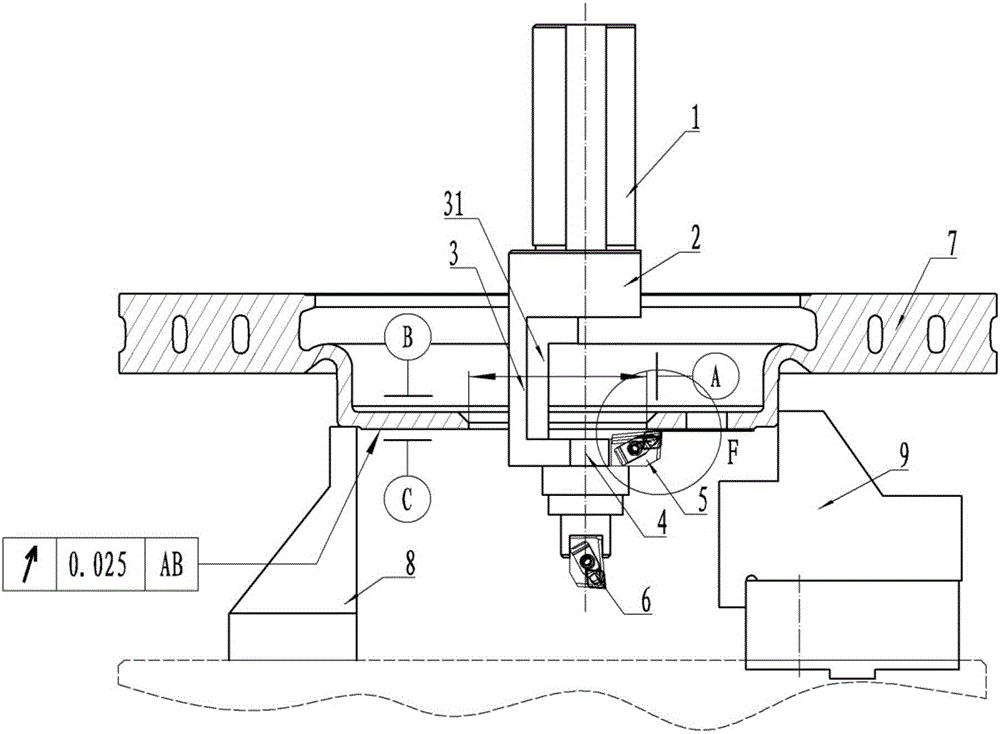

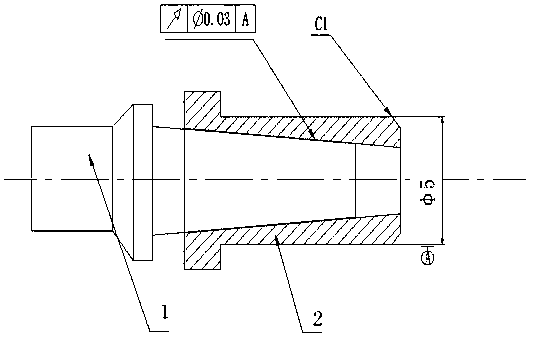

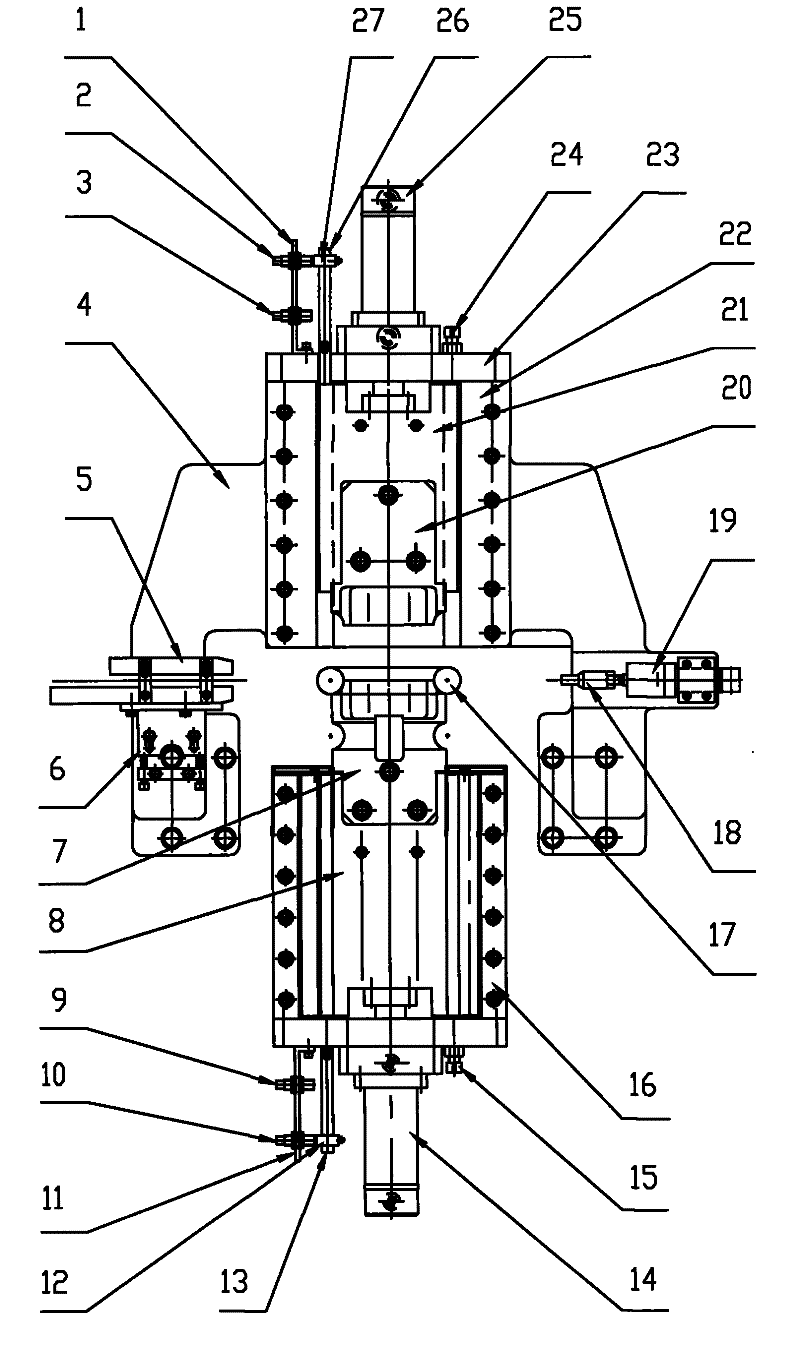

Method of assembly and precision calibration of numerical control four-axis ring die deep hole drill machine tool

ActiveCN103157825AGuaranteed runoutGuaranteed beatBoring/drilling machinesNumerical controlBall screw

The invention discloses a method of assembly and precision calibration of a numerical control four-axis circular ring die deep hole drill machine tool. The machine tool is used for machining a stainless steel ring die in a feeding stuff granulator, a vertical type rotary working platform is adopted in the middle of the machine tool, and four-axis double-station deep hole main shafts are adopted on two sides of the machine tool. When the machine tool machines, a workpiece is installed on a numerical control index table, a four-claw chuck is used for clamping a ring die of the workpiece, and the situation that the outer circle of the ring die beats and the end face of the ring die beats is guaranteed. Numerical control sliding tables are symmetrically arranged at the left and the right, and ball screws and ball guide rails are installed on the sliding tables. The machine tool is controlled by a servo motor to move front and back so as to enable a main shaft guide sleeve box to move, when the machine tool works, guide holes are tightly attached to the surface of the workpiece, and when moving cuttings are carried out, the machine tool moves on the ball guide rails to achieve the machining of holes in the outer circle of the ring die.

Owner:浙江宁锐精密机械有限公司

Machining tool for brake drum

The invention discloses a machining tool for a brake drum. The machining tool comprises a three jaw chuck and a locking cap, wherein the axis of the locking cap is the same as that of the three jaw chuck; the locking cap is connected with the body of the three jaw chuck through a half sleeve; a space enclosed by the locking cap, the body of the three jaw chuck and the half sleeve has a shape corresponding to the appearance of a machined brake drum; and the surface of the body of the three jaw chuck is provided with positioning columns corresponding to screw holes on the machined brake drum. Through experimental production, the entire production line has stable quality and stable yield after the bottleneck problem of a lathed braking surface is solved.

Owner:溧阳市虹翔机械制造有限公司

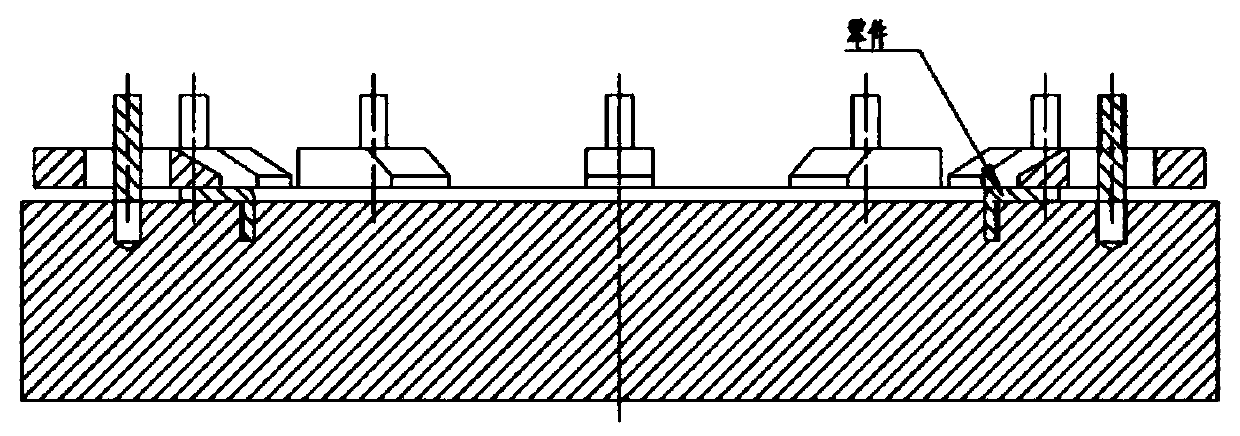

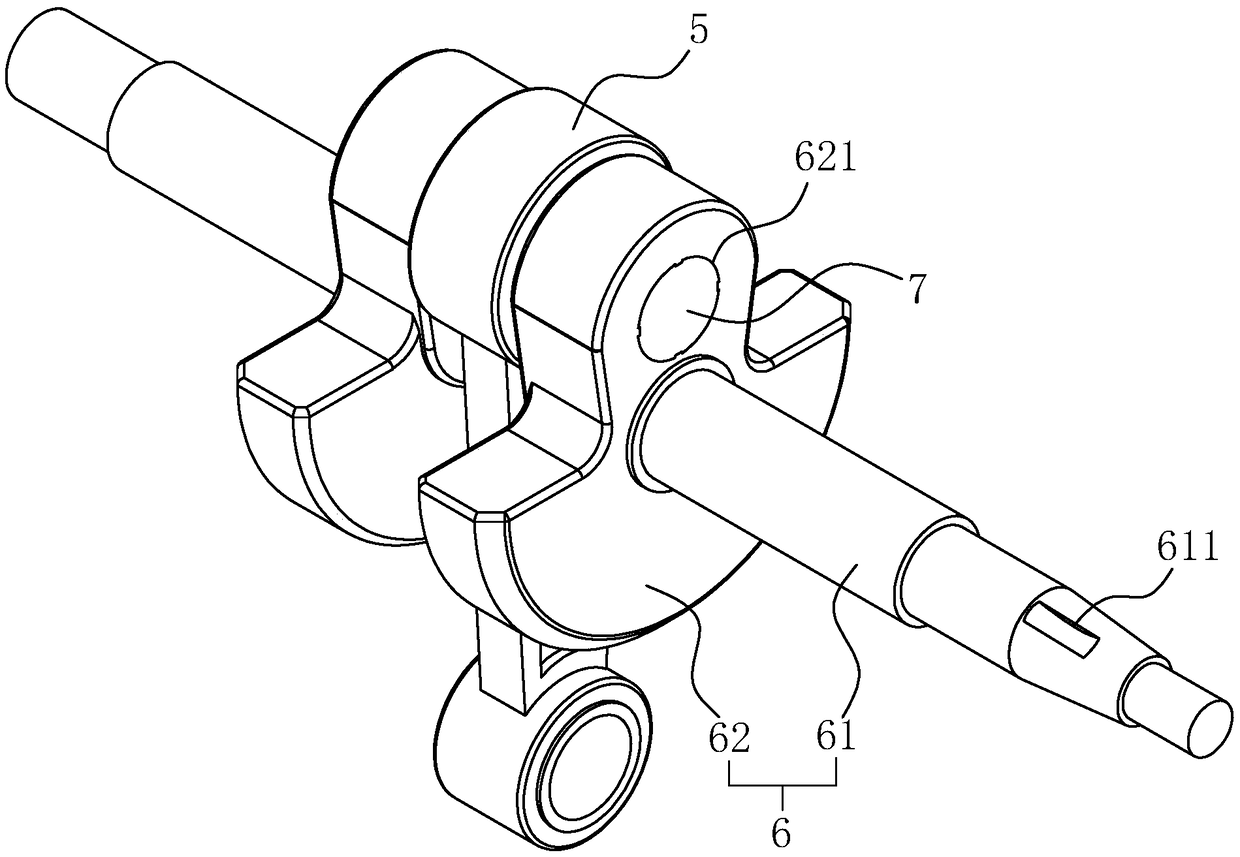

Length-adjustable and flange-plate-angle-adjustable clamp for track welding of finished shaft heads

PendingCN107627059AGuaranteed length design requirementsReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a length-adjustable and flange-plate-angle-adjustable clamp for track welding of finished shaft heads. The clamp comprises a table (1). The table is characterized in that flange plate and shaft head positioning assemblies (2), axle housing two-end square-portion leveling devices (3), axle housing oil drainage hole positioning pins (4), linear sliding rails (5), lead screw moving assemblies (6) and cylinder pressers (7) are arranged on the table (1); the flange plate threaded hole angles of the finished shaft heads are positioned by the flange plate and shaft head positioning assemblies (2), and the total length of axle housing assemblies is adjusted by moving the flange plate and shaft head positioning assemblies (2) by means of the lead screw moving assemblies (6).The length-adjustable and flange-plate-angle-adjustable clamp is suitable for axle housing products, the application range is wide, it can be guaranteed that the coaxiality of the axle housing assembly single-side finished shaft heads obtained after shaft head bodies, flange plates and axle housing bodies are welded is within 0.2 mm, the run-out range of the finished shaft heads on the two sidesis within 0.5 mm, and the flange plate threaded hole angles of the finished shaft heads on the two sides are consistent, the quality is stable, the structure is simple, the production efficiency is high, and the production cost is lowered.

Owner:SHANDONG PENGXIANG AUTOMOBILE

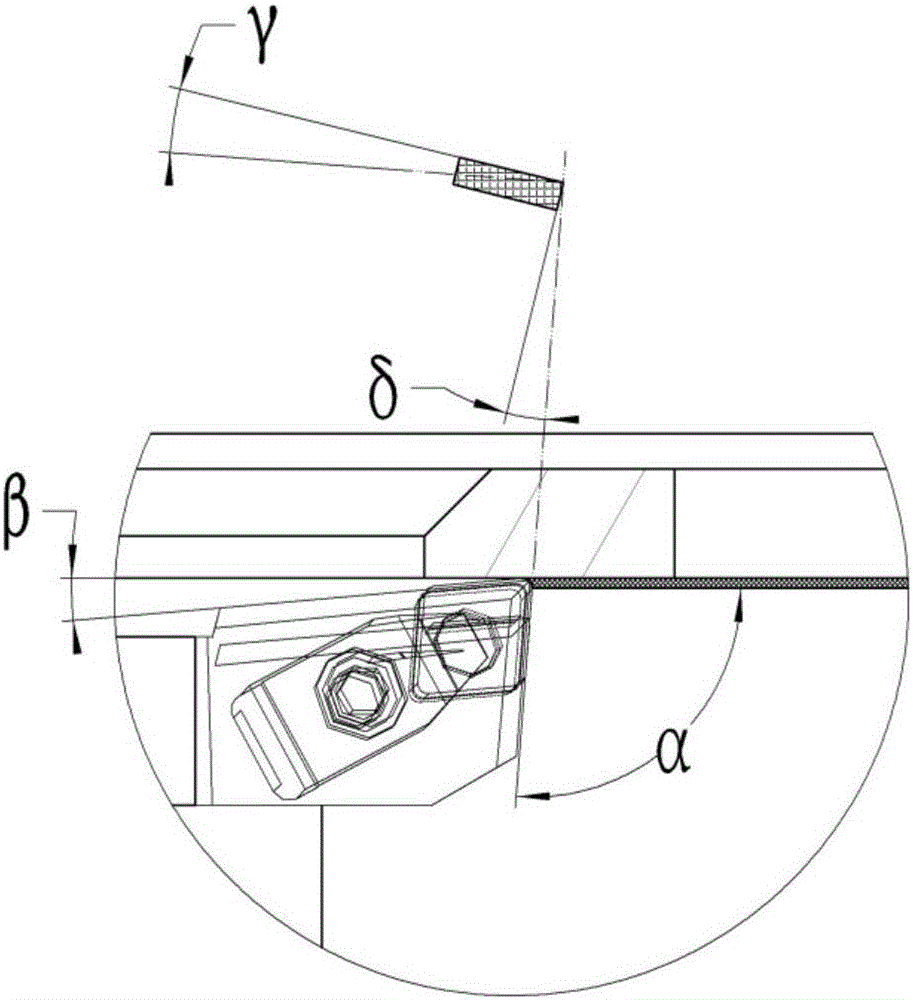

Brake disc machining knife and machining method thereof

A brake disc machining knife comprises a knife rod, a transition hook and a knife body. The knife rod is of a structure of a round rod, three vertical clamping faces in clamp fit with the knife rod machined on a cylindrical face of the round rod, the transition hook comprises a connecting disc, a side column and an underframe which are integrally machined, the connecting disc is coaxially fixed at the lower end of the knife rod, the side column is smoothly connected at the outer edge of the connecting disc and extends downward, the underframe is connected at the lower end of the side column and is a cylinder coaxial with the connecting disc and provided with a knife body mounting groove, the knife body comprises a radial knife radially mounted on the underframe, and a knife tip of the radial knife is positioned on one side opposite to the side column and points above. By using the brake disc machining knife, a measuring reference and a measuring plane are machined in a same process according to a same machining reference, machining accuracy is improved, and errors caused by repeated clamping during machining in different processes are avoided.

Owner:布雷博惠联(廊坊)制动系统有限公司

Workpiece-dropping device of automatic spot-welding equipment

ActiveCN103028872AReduce bump damageRealize automatic droppingWelding/cutting auxillary devicesAuxillary welding devicesSlide plateEngineering

The invention discloses a workpiece-dropping device of automatic spot-welding equipment, which is used for solving the problem on quick drop of a welding tool. The device comprises a driving mechanism, a rotating mechanism, a rotation limit mechanism, a workpiece positioning tool, a discharge slide plate and workbench brackets, wherein the driving mechanism is connected with the rotating mechanism through a shaft; the rotation limit mechanism is matched with the rotating mechanism; the workpiece positioning tool and the rotating mechanism are fixedly arranged; the discharge slide plate is positioned below the workpiece positioning tool; the workbench brackets are arranged on the two sides of the workpiece positioning tool; and the driving mechanism, the rotation limit mechanism and the rotating mechanism are fixedly arranged on the workbench brackets. The workpiece-dropping device has the characteristics of high automation degree, stable performance and low manufacturing cost, a welded workpiece can quickly drop, the rhythm of welding production is ensured, and the production efficiency is improved.

Owner:长城汽车股份有限公司平湖分公司

Automatic drilling device of short material sawing and drilling all-in-one machine

PendingCN112676841AEasy to sendAchieving lateral transferMeasurement/indication equipmentsOther manufacturing equipments/toolsStructural engineeringMechanical engineering

The invention discloses an automatic drilling device of a short material sawing and drilling all-in-one machine. The automatic drilling device comprises a sawing, discharging and conveying device, a transverse material turning and temporary storage device, a transverse stepping feeding device, a drilling device and a drilling discharging device, wherein the sawing, discharging and conveying device is used for longitudinally conveying sawn bars; the transverse material turning and temporary storage device is used for transversely turning and conveying the longitudinally-placed bars to a temporary storage material frame; the transverse stepping feeding device is used for feeding the bars on a material taking station to a drilling supporting station in a stepping mode; the drilling device comprises a drilling machine base and a drilling supporting device, the drilling supporting device is used for supporting the bars conveyed by the transverse stepping mechanism, and a drill bit component and a drilling clamping device are longitudinally arranged on the drilling machine base in a sliding mode; and the drilling discharging device is used for discharging the bars on the drilling supporting device. According to the automatic drilling device, the bars can be automatically conveyed to the drilling device one by one to be drilled after the bars are sawn, so that the production efficiency is improved, and meanwhile, the occupied area of the whole equipment is smaller.

Owner:SUZHOU KINKALTECK MACHINERY TECH

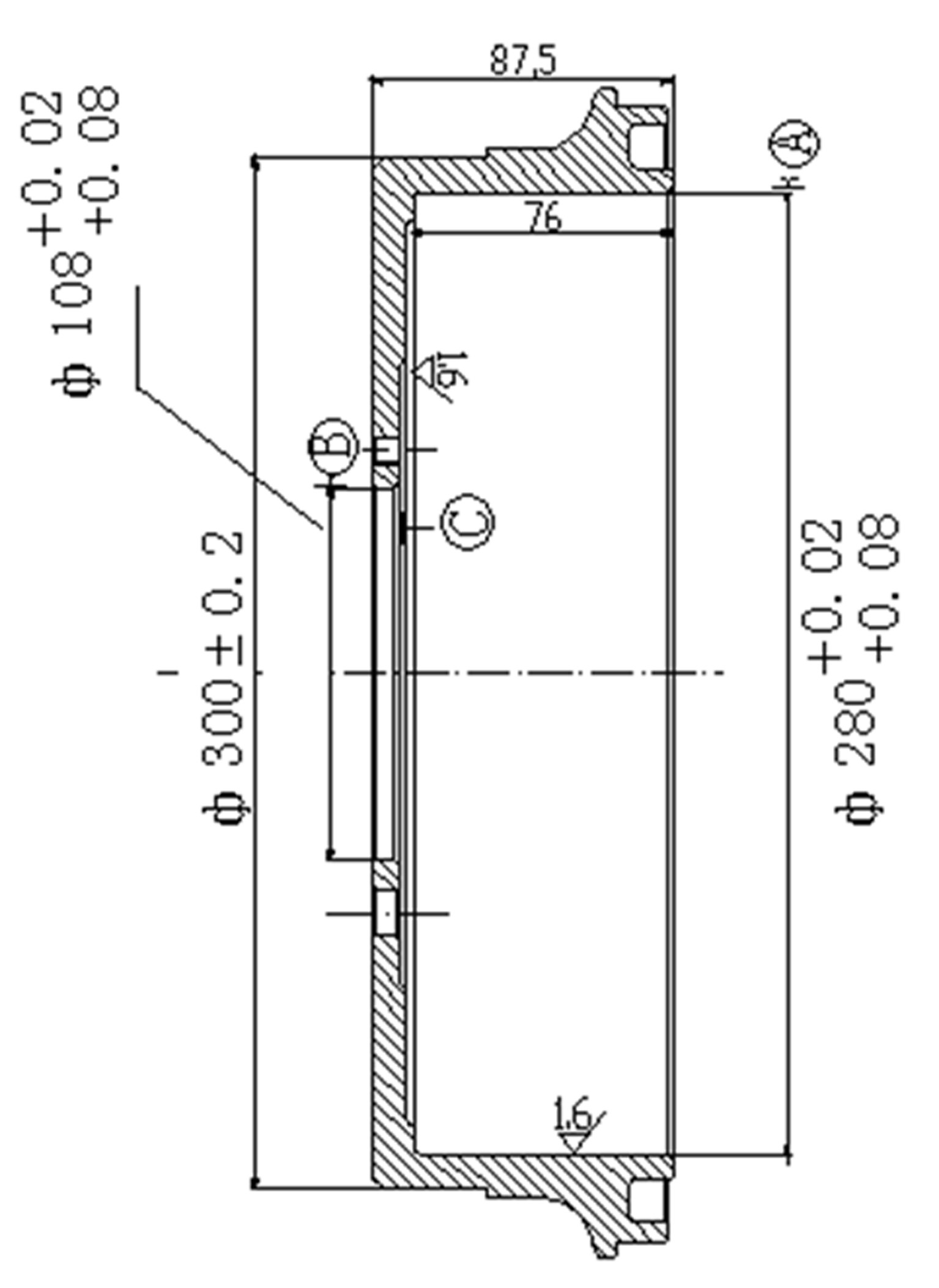

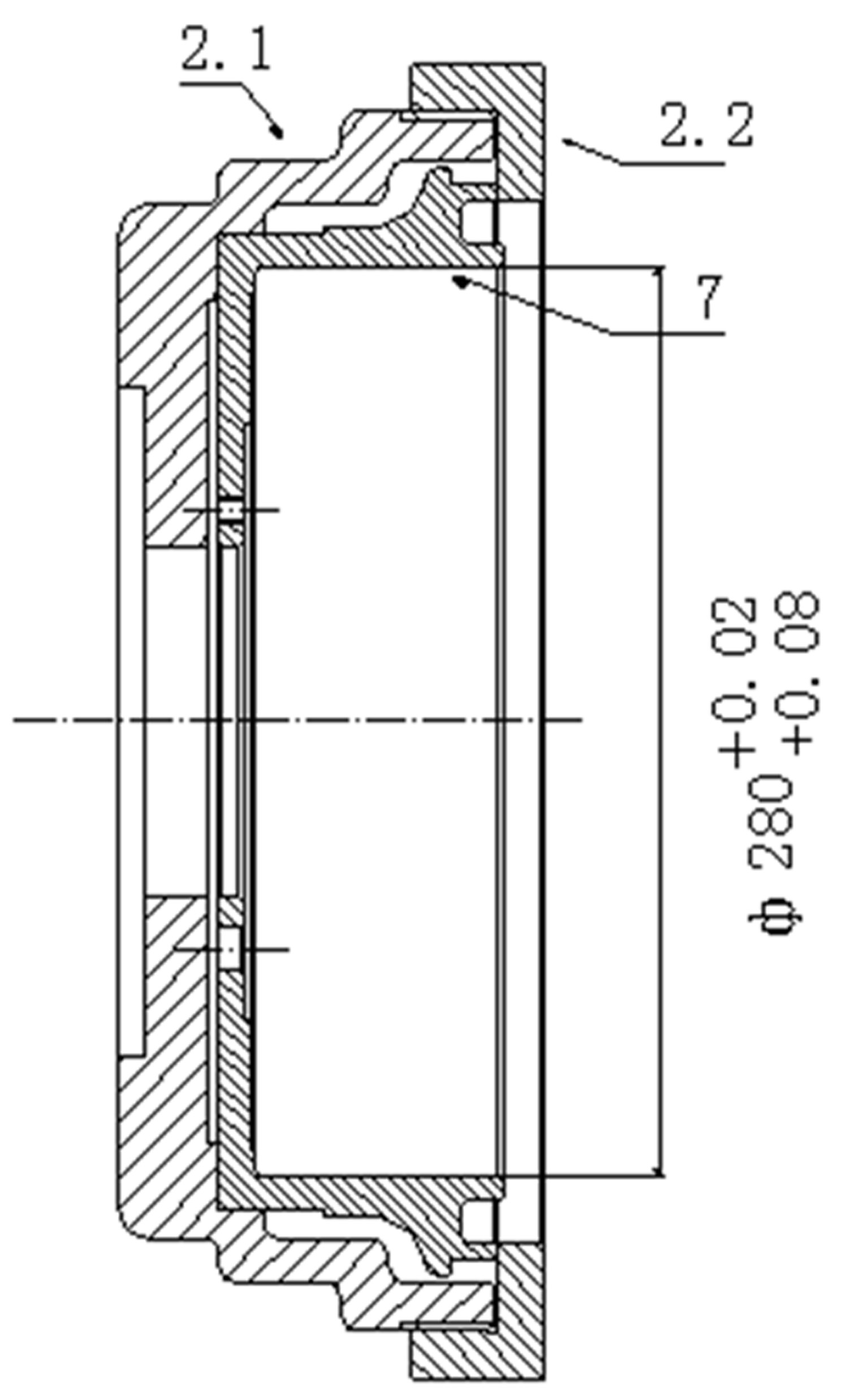

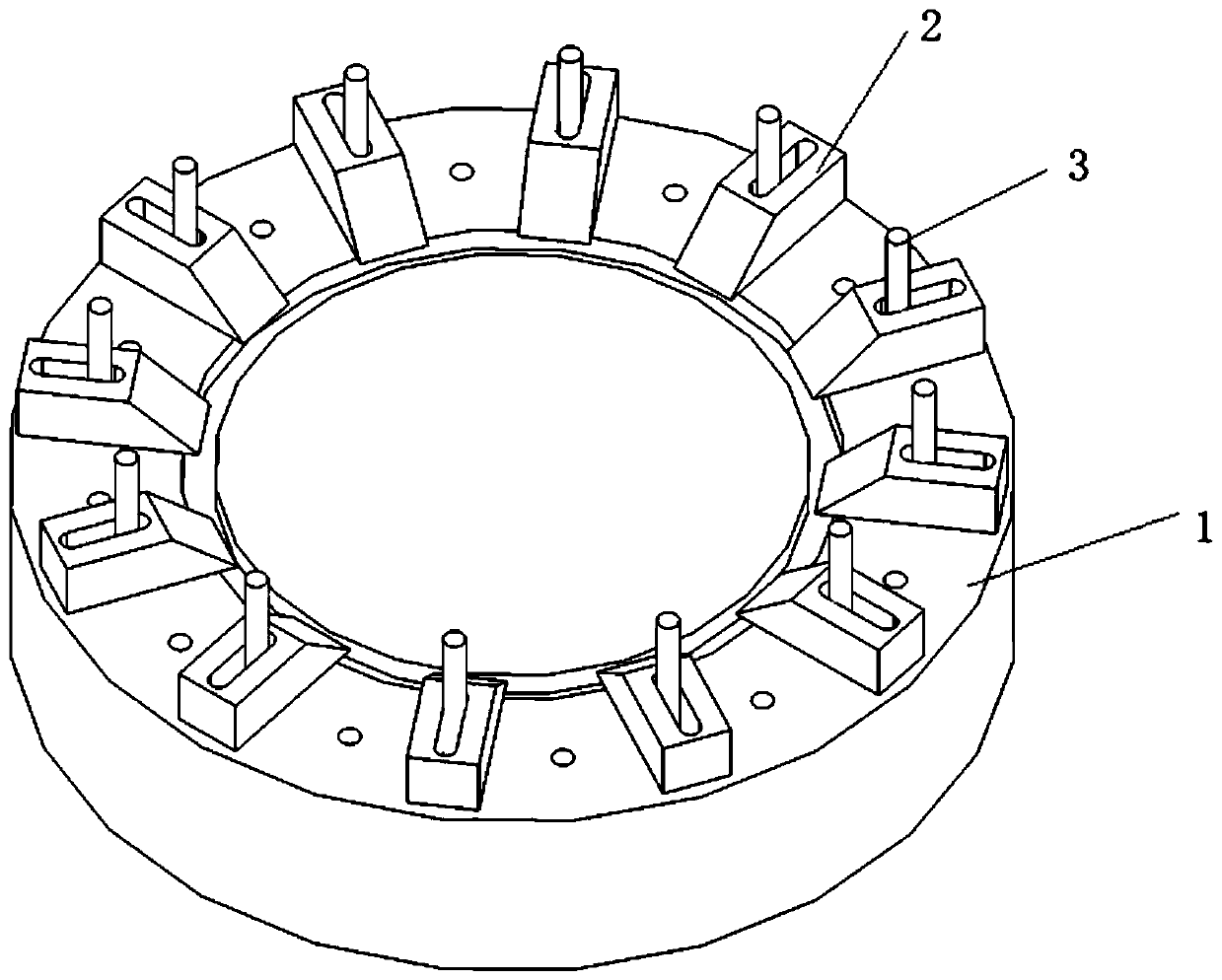

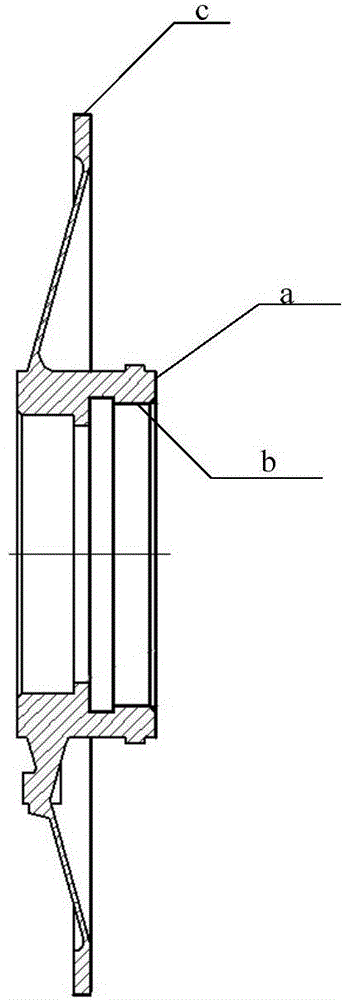

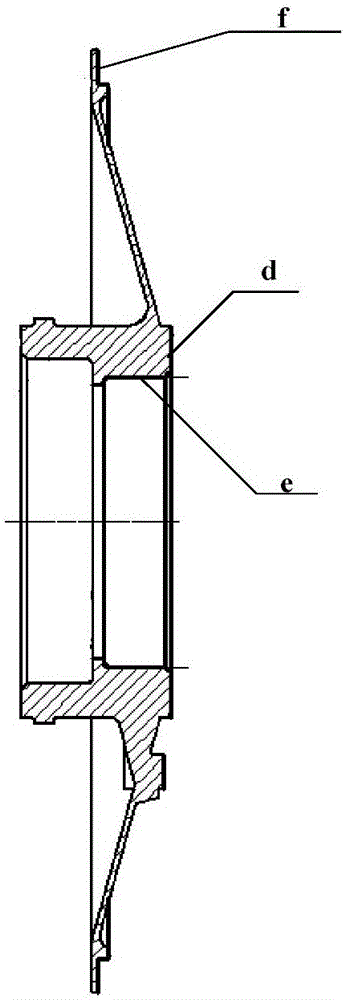

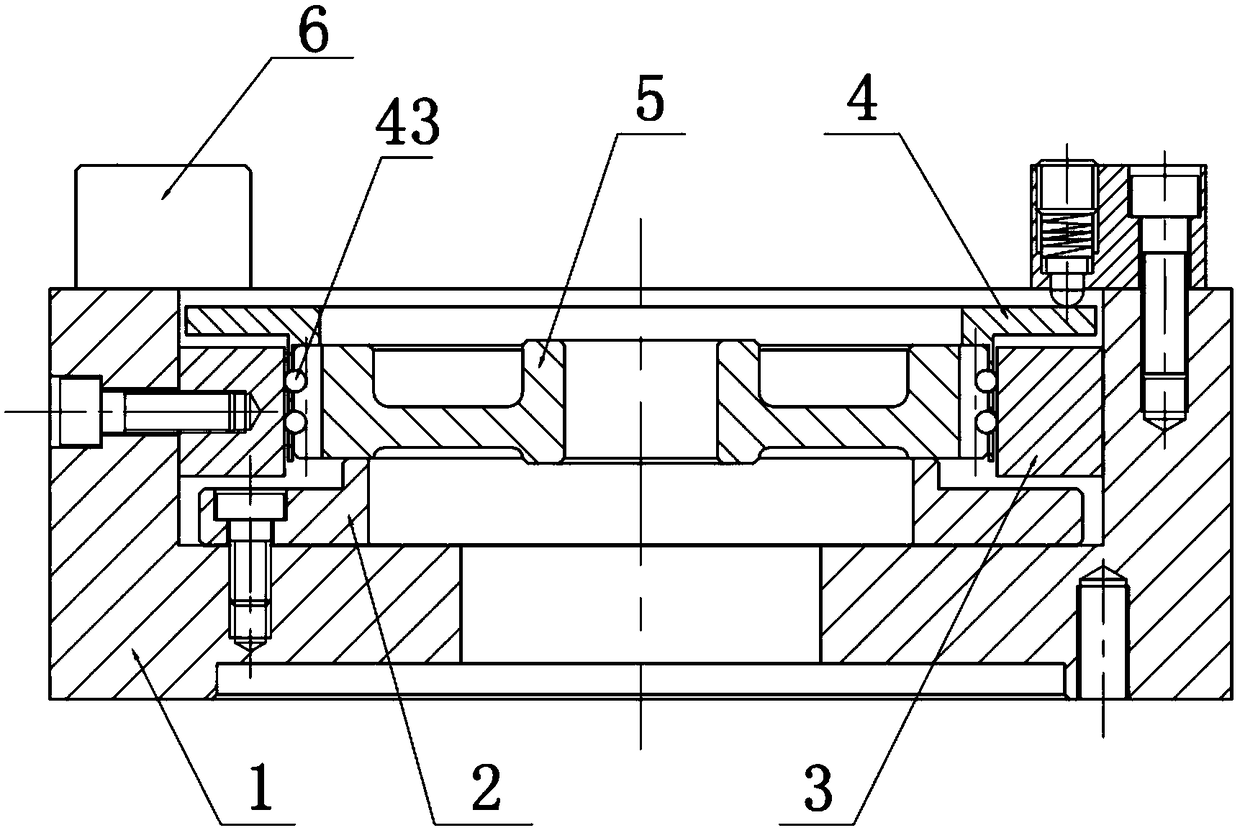

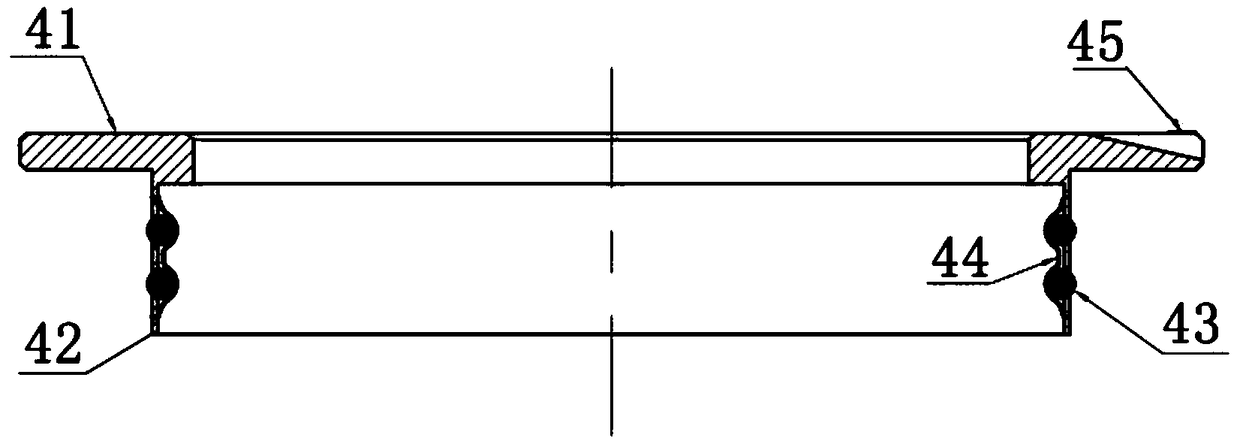

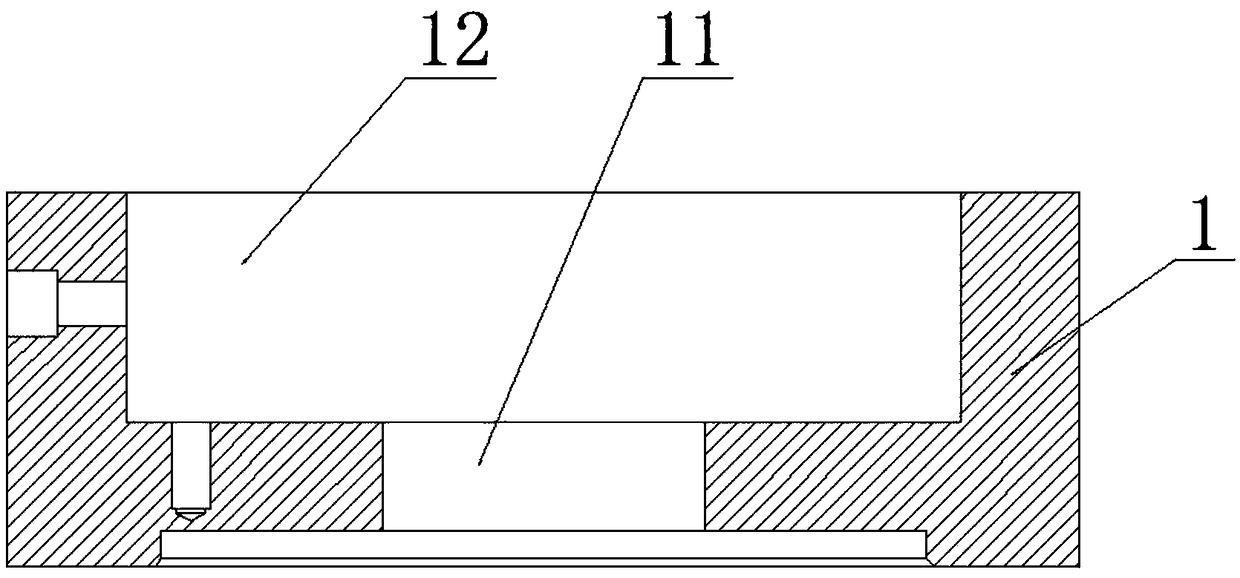

Method and device used for guaranteeing wall thickness of metal plate forming thin-wall ring part

ActiveCN110315361AAvoid deformationEasy to adjustPositioning apparatusMetal-working holdersThin walledEngineering

The invention discloses a method and device used for guaranteeing the wall thickness of a metal plate forming thin-wall ring part. The device comprises a ring body (1) and a pressing plate (2); the upper end face of the ring body (1) is a plane which is provided with an annular groove; the cross section shape of the annular groove is consistent with the cross section shape of the non-machining portion of the thin-wall ring part; the pressing plate (2) is located above the annular groove; and the bottom face of the pressing plate (2) is a plane, and the pressing plate (2) can move in the axialdirection and the radial direction of the ring body (1). During machining, firstly, the planeness standard exceeding position of the to-be-machined portion of the metal plate forming thin-wall ring part is compressed, and after it is guaranteed that the planeness of the portion is qualified, then remaining non-compressed positions are machined to the required thickness; and then the positions machined to the required thickness are compressed, and after it is guaranteed that the planeness of the portions is qualified, remaining non-compressed positions are machined to the required thickness.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

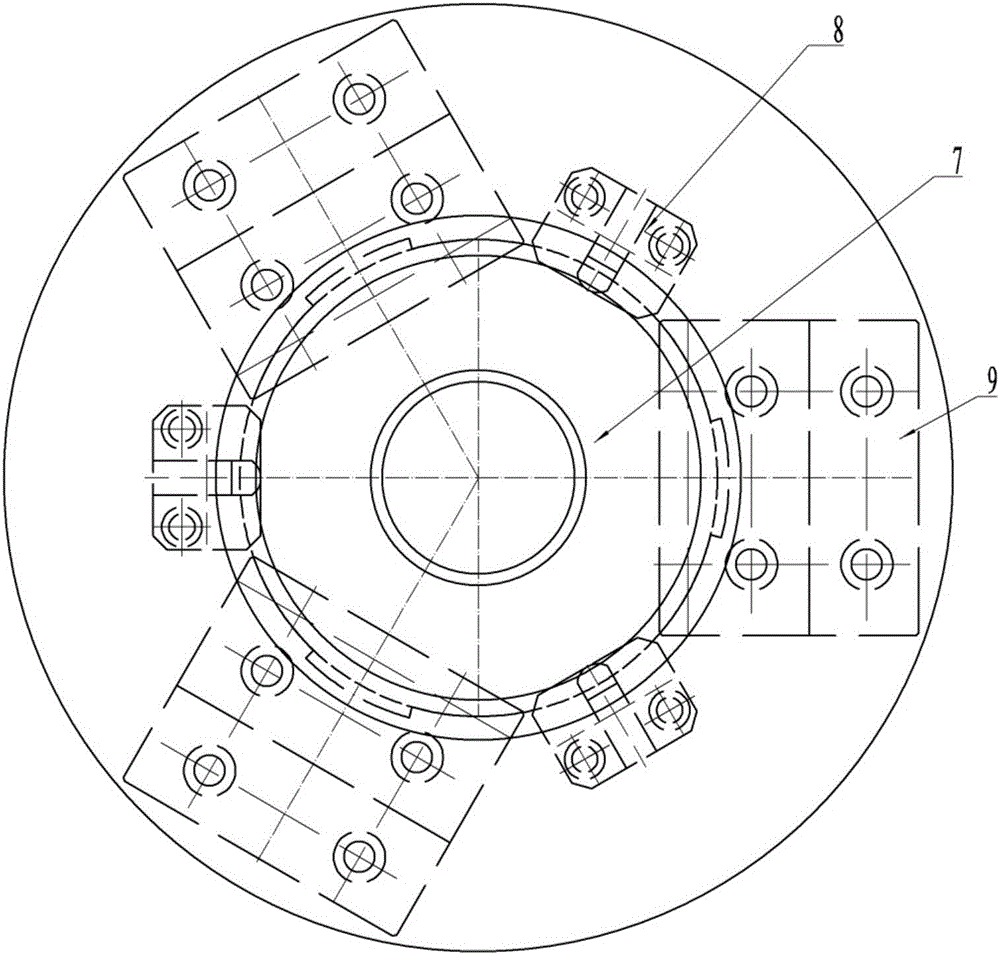

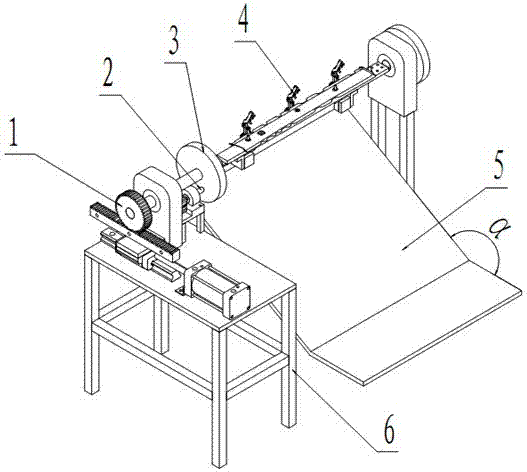

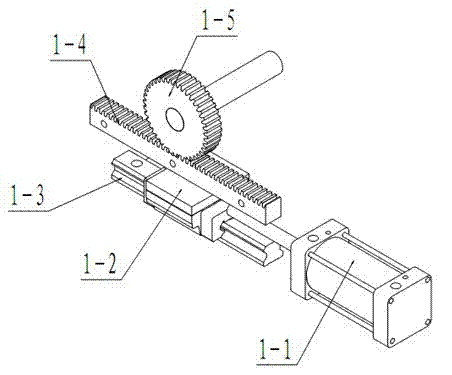

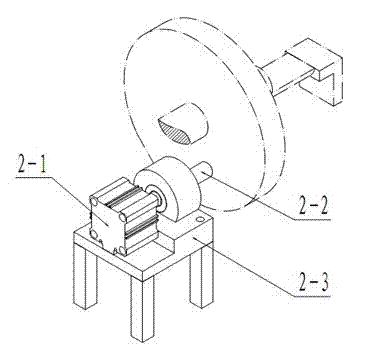

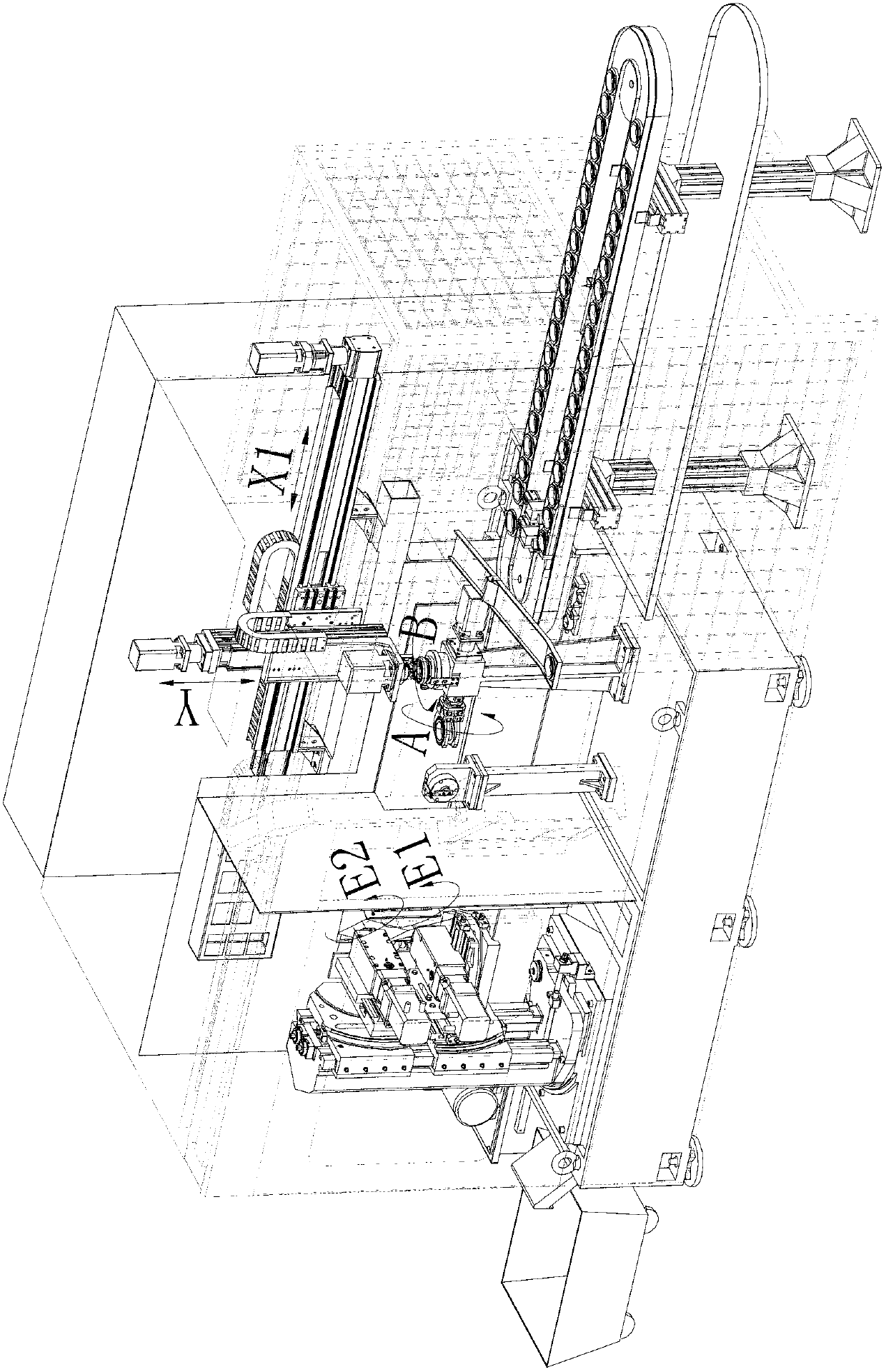

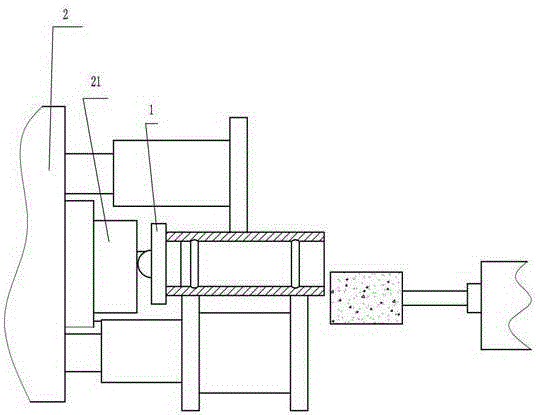

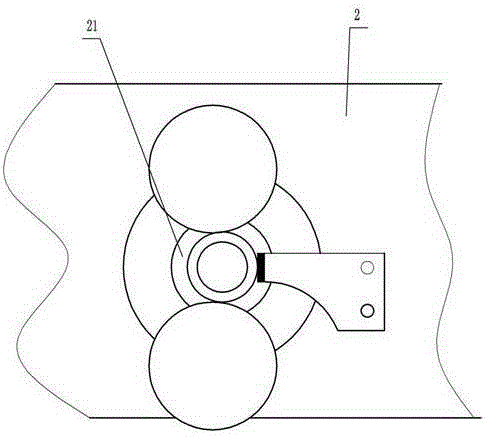

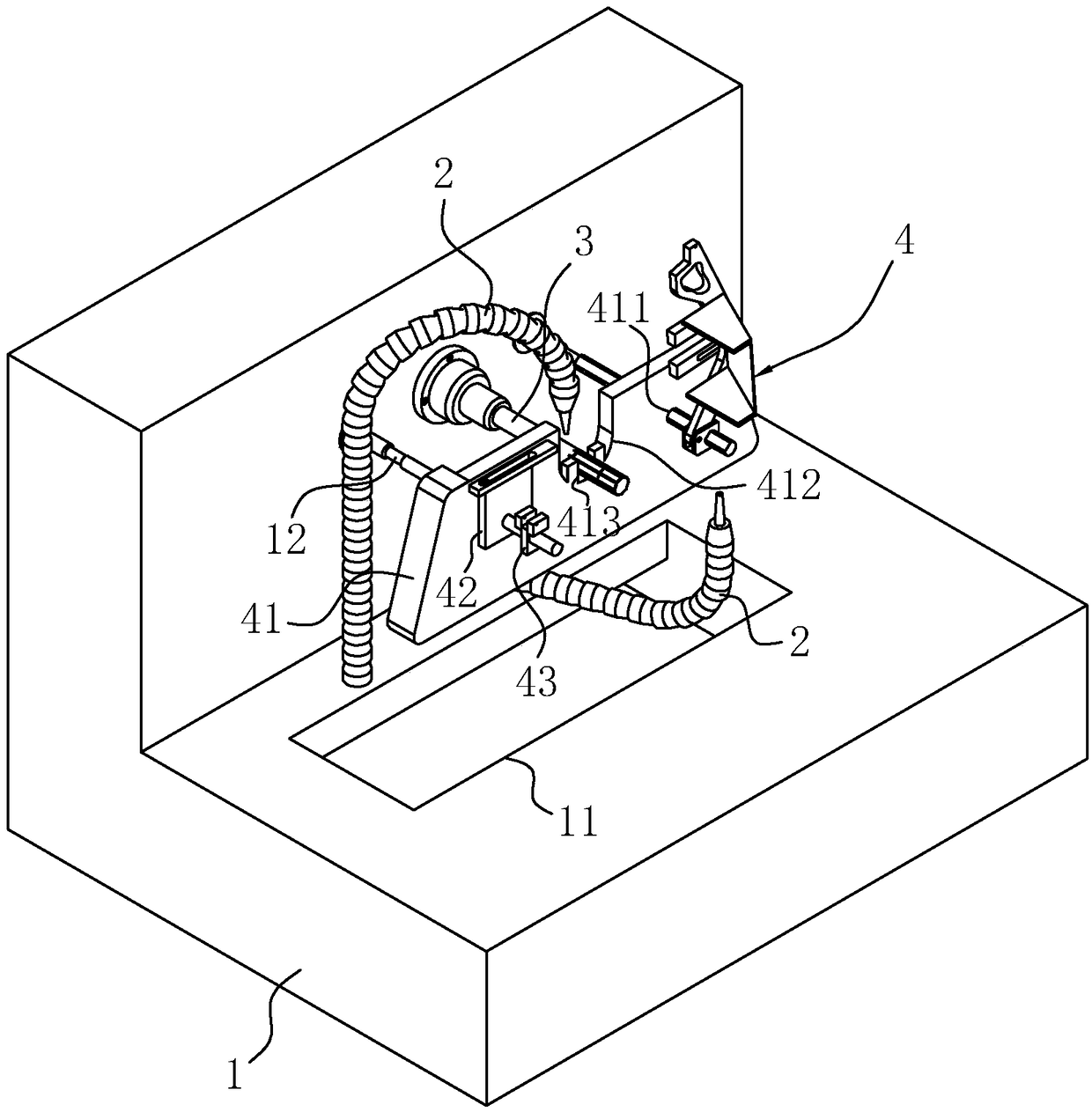

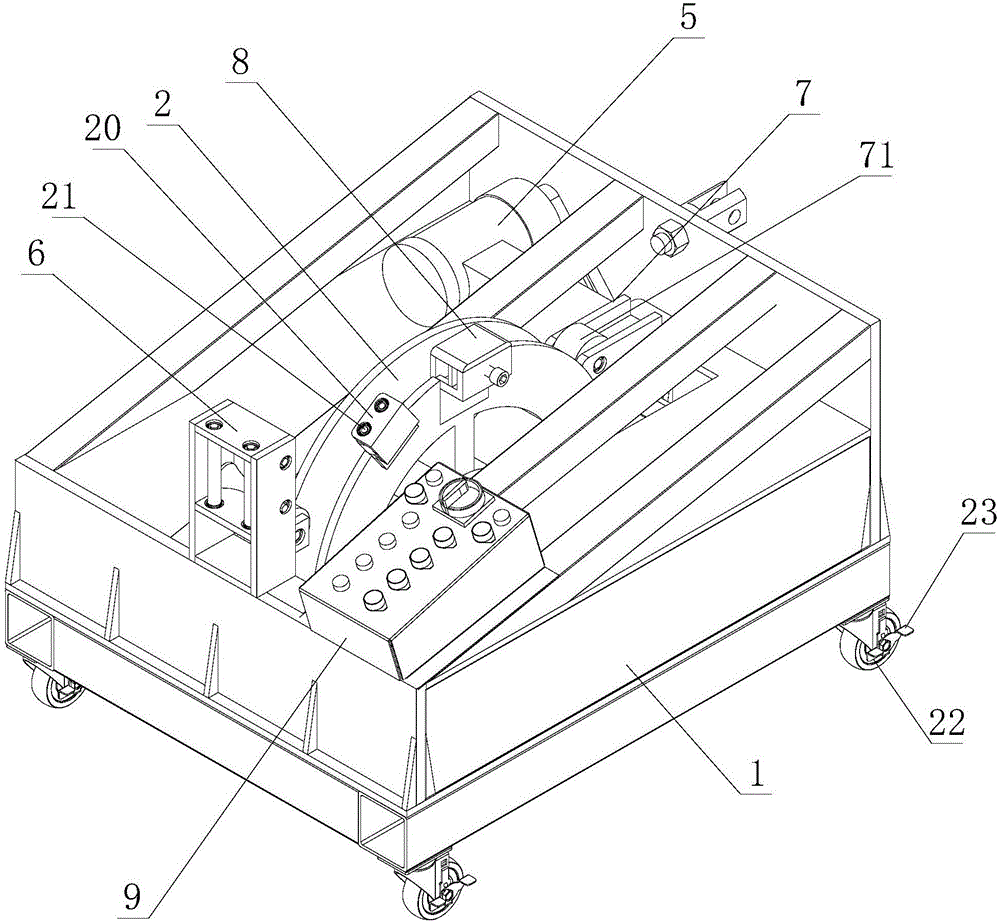

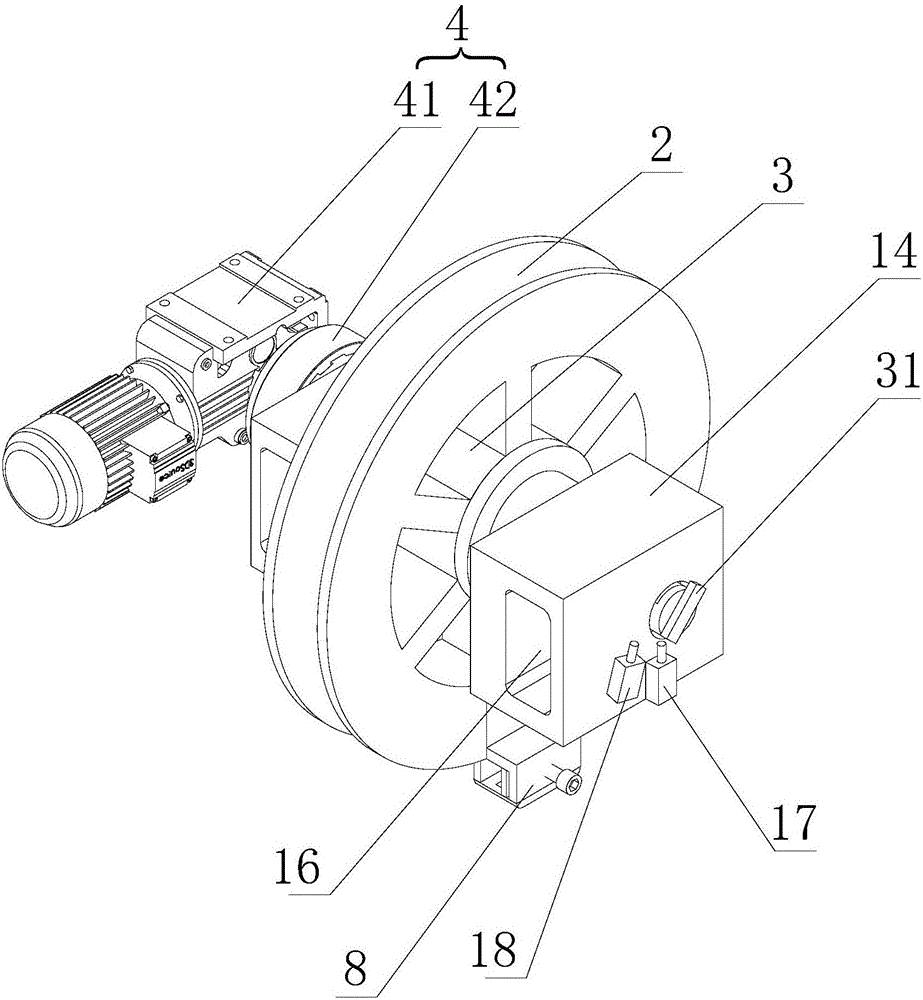

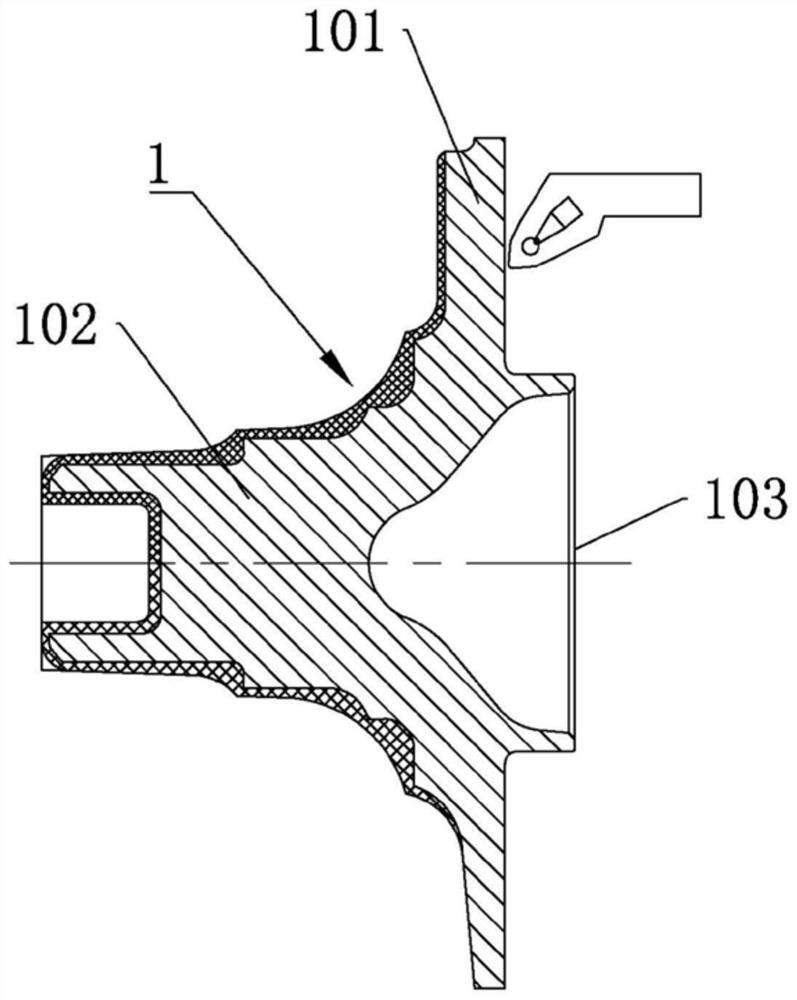

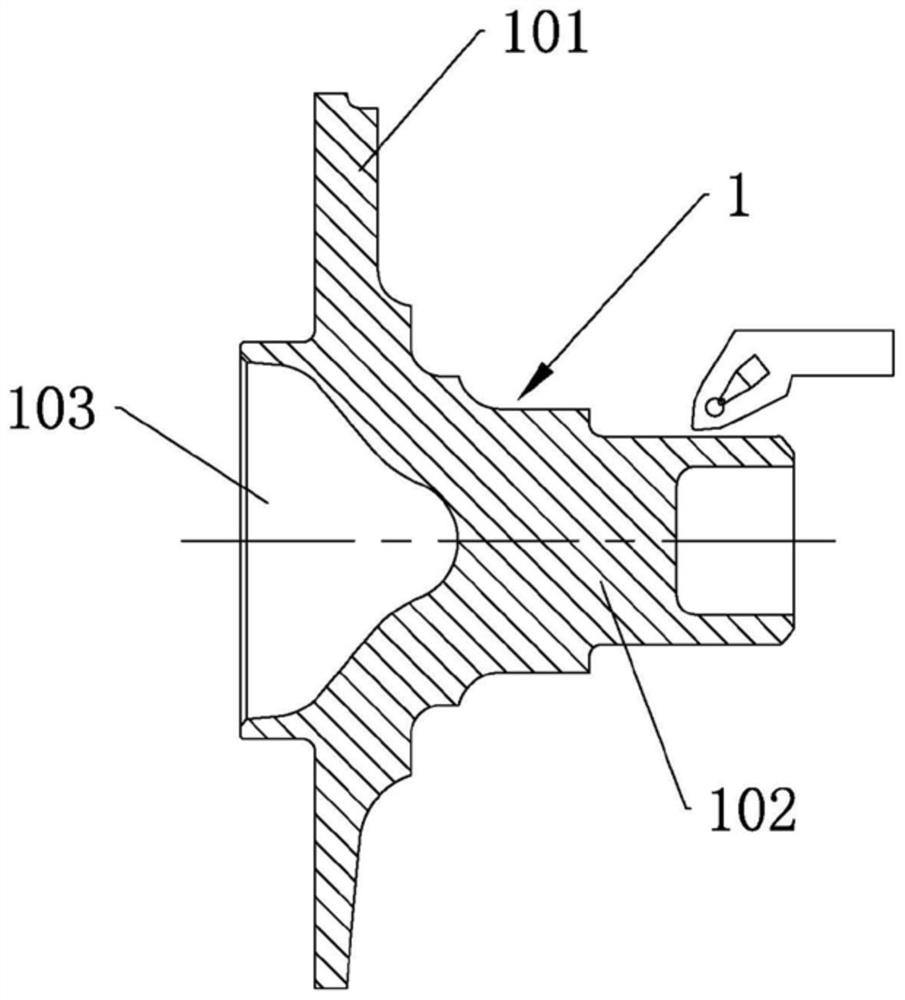

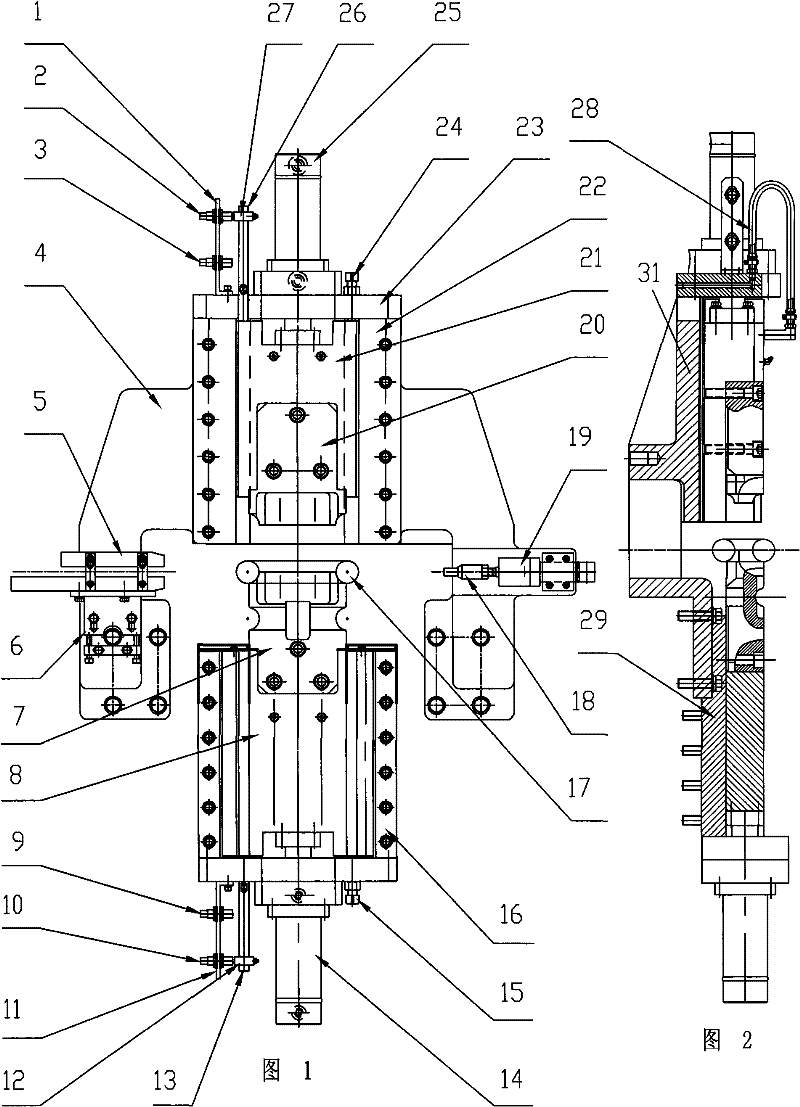

Whirlwind chamfering machine with automatic material feeding and discharging function

ActiveCN103128377AGuaranteed beatGuaranteed machining accuracyMeasurement/indication equipmentsFeeding apparatusHigh volume manufacturingEngineering

The invention provides a whirlwind chamfering machine with an automatic material feeding and discharging function. The whirlwind chamfering machine with the automatic material feeding and discharging function comprises a lathe bed, a workpiece box system, a cutter shaft system, a positioning turning mechanism, a conveyor line mechanism, a material feeding and discharging mechanism and an order leaking detection mechanism. The lathe bed is in a horizontal type structure. The workpiece box system, the cutter shaft system, the positioning turning mechanism and a support frame are installed on the lathe bed. The whirlwind chamfering machine with the automatic material feeding and discharging function has the advantages that machining rhythms of a wheel gear are guaranteed. Labor intensity of operators is greatly relieved. Machining precision of the wheel gear is guaranteed. The whirlwind chamfering machine with the automatic feeding and material discharging function has the advantages of being wide in the chamfering machining type, high in automation degree, high in efficiency, high in precision and high in stability. Trial-production of small quantities of new products and production on a large scale can be achieved.

Owner:天津精诚机床股份有限公司

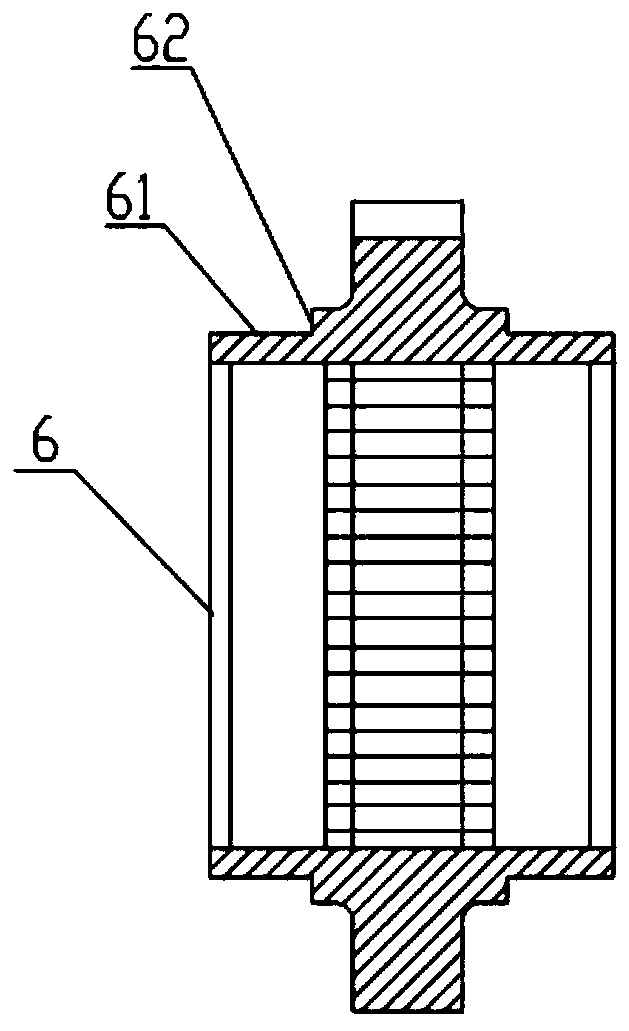

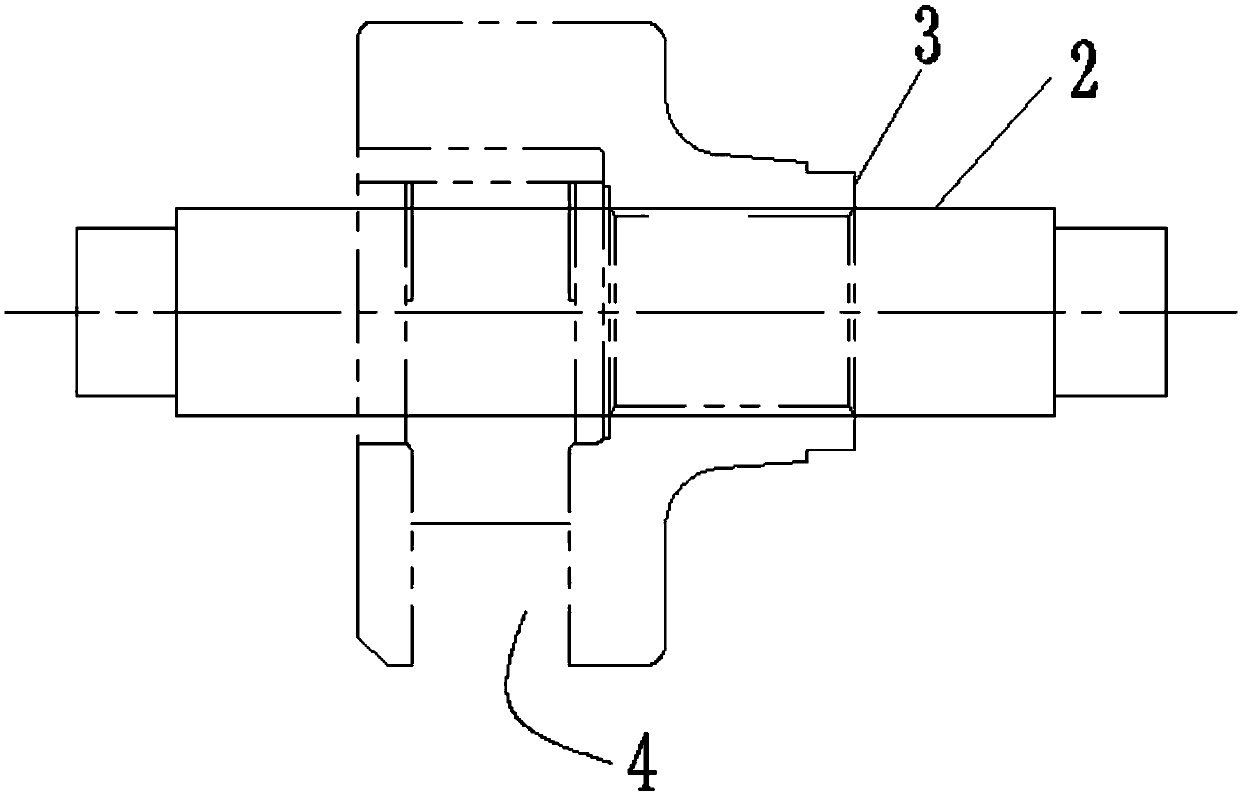

Chain wheel outer circle and end surface grinding tool

PendingCN110549174AGuaranteed Runout ToleranceAchieving Runout ToleranceRevolution surface grinding machinesGrinding work supportsInterference fitSprocket

The invention belongs to the technical field of machining, and in particular, relates to a chain wheel outer circle and end surface grinding tool. The tool comprises a mandrel, an end surface polishing sleeve, a centering sleeve spline sleeve, a pressing sleeve and a flower nut; the end surface polishing sleeve, the centering sleeve spline sleeve, the pressing sleeve and the flower nut sleeve theouter side of the mandrel in sequence side by side; the end surface polishing sleeve and a positioning sleeve spline sleeve are in inference fit with the mandrel; the maximum outer diameter of the tail end part of the end surface positioning sleeve is larger than the maximum outer diameter of the positioning sleeve spline sleeve; an involute spline is arranged at the outer periphery of the positioning sleeve spline sleeve, and is matched with a center inner spline of a chain wheel to be machined; the pressing sleeve is in clearance fit with the mandrel; an external thread is arranged on the outer side wall, near the tail end direction, of the middle end of the mandrel; and the flower nut is connected with the thread of the mandrel. The tool realizes once clamping and grinding, prevents accumulated errors caused by multiple times of clamping, and guarantees the run-out tolerance of end surfaces relative to the involute spline, the run-out tolerance of outer circles relative to the involute spline, the coaxiality tolerance of the outer circles and all size tolerances.

Owner:QINGDAO CHOHO IND CO LTD

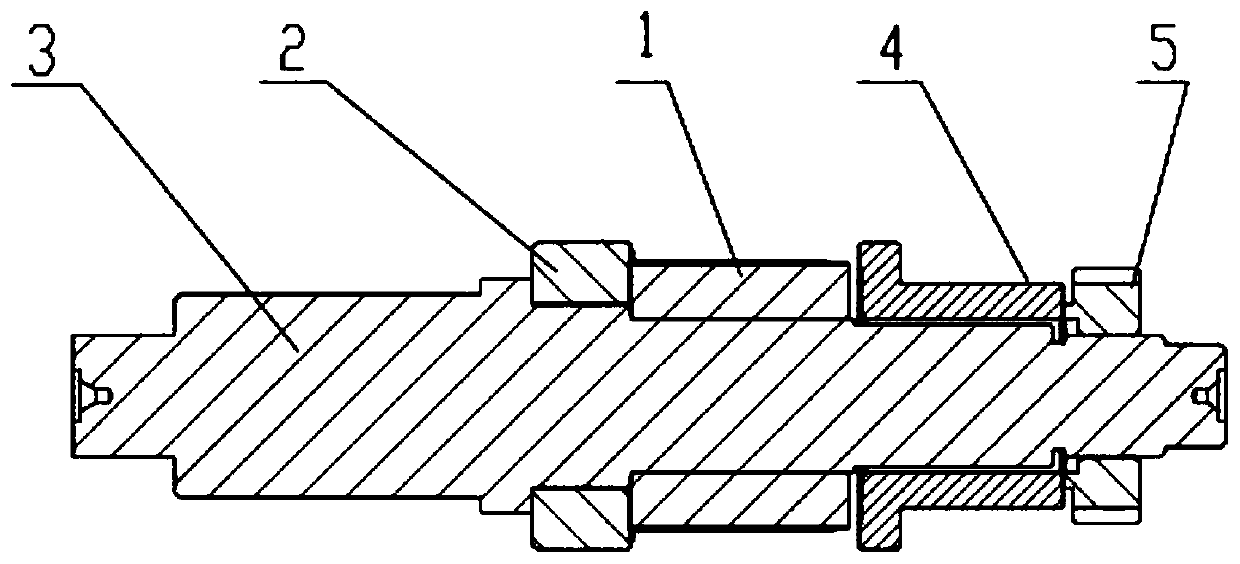

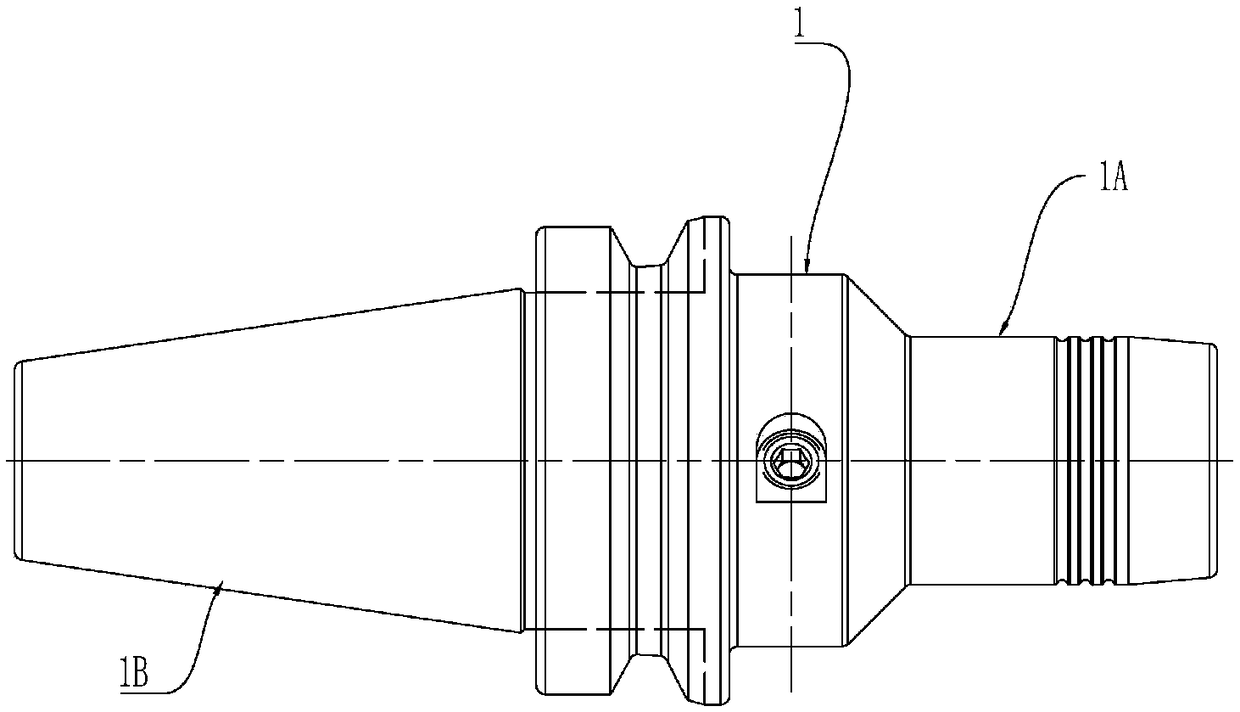

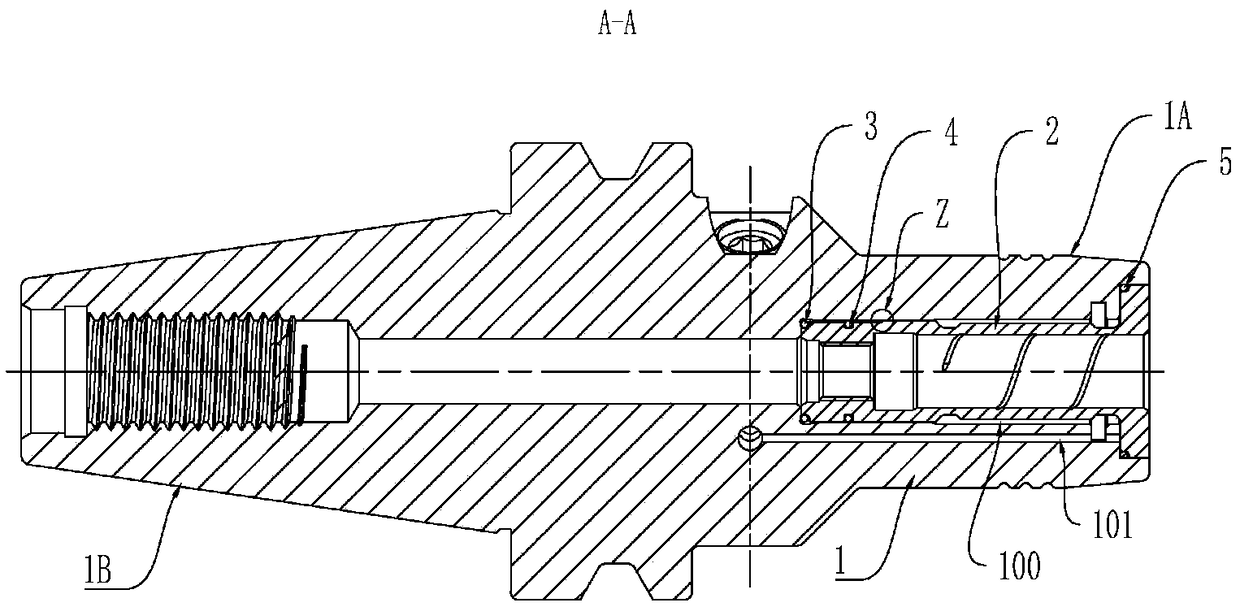

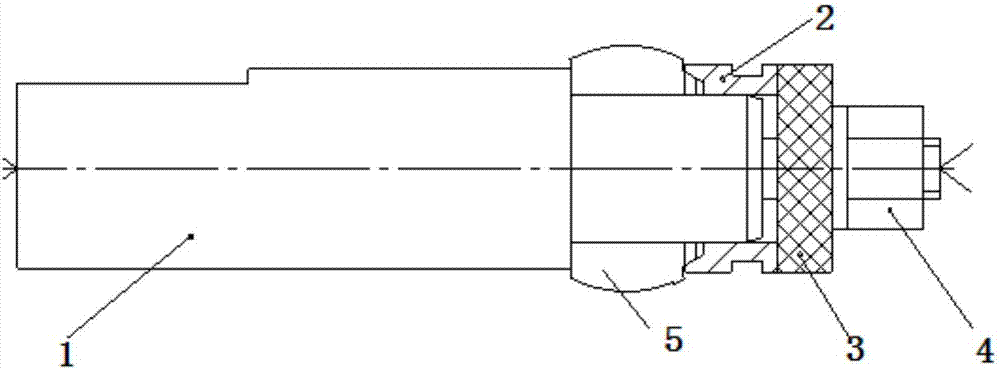

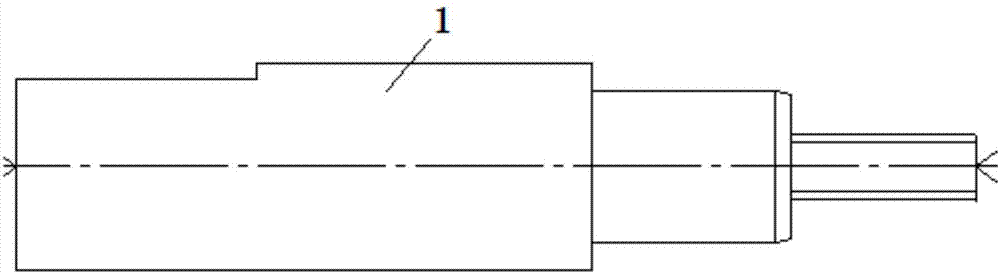

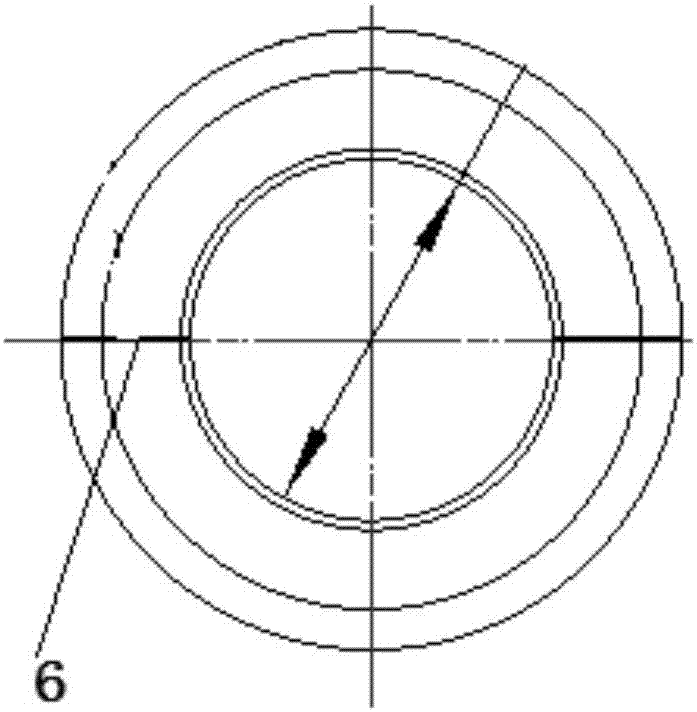

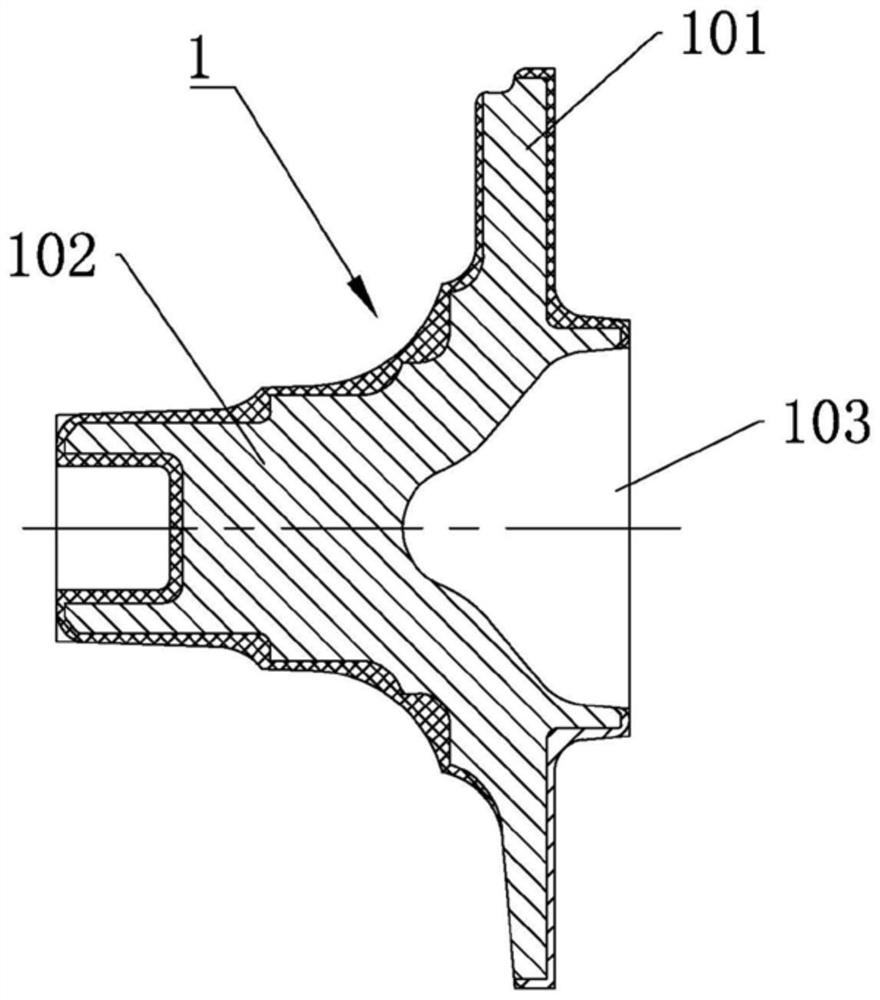

Composite connection type hydraulic knife handle

PendingCN108907776AImprove overall strengthPrevent extravasationPositioning apparatusMetal-working holdersThin walledEngineering

The invention relates to a composite connection type hydraulic knife handle. The composite connection type hydraulic knife handle comprises a main knife handle body and an elastic thin-wall inner ringarranged in the main knife handle body, wherein a hydraulic oil cavity is arranged between the main knife handle body and the elastic thin-wall inner ring; the elastic thin-wall inner ring is arranged as a barrel thin-wall structure with two thick ends and a thin middle part; and the side outer rings of the two ends of the elastic thin-wall inner ring make contact with the support surfaces of inner holes of the main knife handle body. The main knife handle body and the elastic thin-wall inner ring are fixed in a manner of combining brazed connection and interference fit connection, the effectof stress on the connection performance of the main knife handle body and the elastic thin-wall inner ring is reduced, the joint of the main knife handle body and the elastic thin-wall inner ring isprevented from tear under the high pressure state, and therefore the service life of the hydraulic knife handle is prolonged. Meanwhile, by improving the structure of a piston rod and the structure ofa piston sleeve, the piston sleeve is quickly maintained, the overall sealing performance of a hydraulic access is improved, and the overall strength of the hydraulic knife handle is improved.

Owner:成都成林数控刀具股份有限公司

Method for machining end faces of connecting shaft bearing outer ring

InactiveCN105196121AGuaranteed beatRealize automatic processingPlane surface grinding machinesEngineeringBall joint

The invention discloses a method for machining end faces of a connecting shaft bearing outer ring. The method comprises the following steps of grinding the double end faces of the connecting shaft bearing outer ring obtained after quenching, conducting accurate grinding on the end faces of the connecting shaft bearing outer ring after the double end faces are ground, wherein a special rolling wheel clamp is adopted for conducting clamping in the process of conducting accurate grinding on the end faces, machining a cutting edge out of the end face of a grinding wheel, and by controlling axial movement of the grinding wheel, conducting accurate grinding machining on the end faces of the connecting shaft bearing outer ring by means of the grind wheel end face where the cutting edge is located. The special rolling wheel clamp comprises a ball-shaped backer and a rolling wheel clamp body, the rolling wheel clamp body is connected with a lathe head of a grinding lathe, when a workpiece is clamped, the ball-shaped backer is sleeved into an inner hole of the connecting shaft bearing outer ring through the boss end, and a ball joint at the other end abuts against the magnetic pole of the lathe head and the plane of a plane backer assembly. The method has the advantages of being high in machining precision and efficiency.

Owner:HENGYANG TEXTILE MACHINERY MANUFACTORY

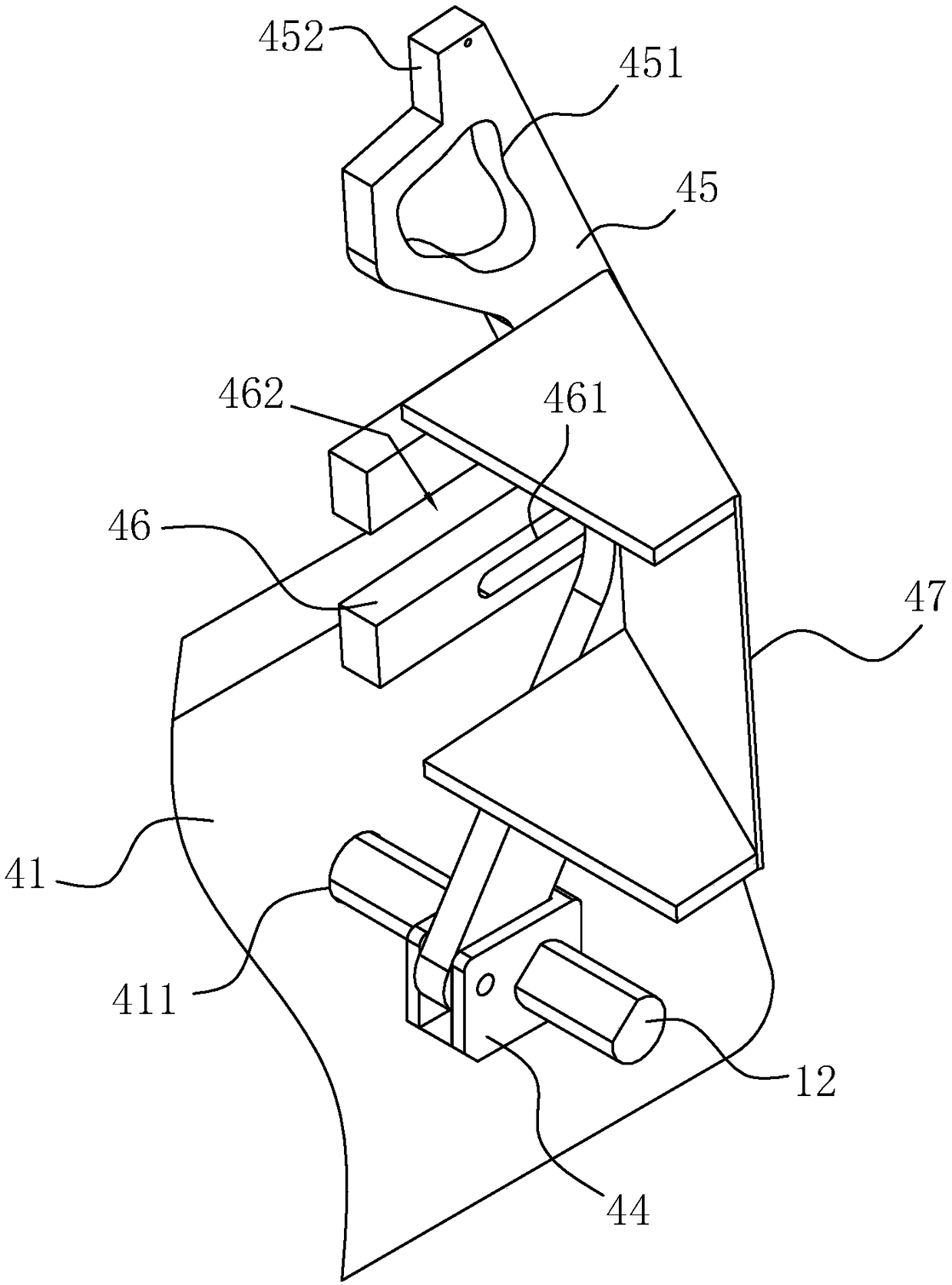

Connecting rod pin hole fine grinding equipment and crankshaft production process

ActiveCN109108751AImprove working precisionImprove work performanceCrankshaftsRevolution surface grinding machinesEngineeringCrankshaft

The invention discloses connecting rod pin hole fine grinding equipment and a crankshaft production process and relates to the technical field of crankshaft machining. According to the main points ofthe technical scheme, the connecting rod pin hole fine grinding equipment comprises a rack and a grinding shaft installed on the rack horizontally rotationally. A driving mechanism drive the grindingshaft is connected to one end of the grinding shaft. A cooling pipe is connected to the rack and is provided with a nozzle extending to the grinding shaft. A vertically arranged installing plate is fixed to the rack through a strut. A U-shaped groove is formed in the middle of the installing plate, and the grinding shaft can penetrate through the U-shaped groove. A jacking block and a clamping block are fixed to one end of the installing plate. The jacking block is located on one side of the U-shaped groove and extends in the axial direction of the grinding shaft. The clamping block is provided with a clamping groove. A limiting plate is connected to the other end of the installing plate. The limiting plate rotates around the axis perpendicular to the installing plate and relative to the installing plate. The end, away from the rotation axis, of the limiting plate is provided with a clamping connection part matched with the clamping groove. Through the connecting rod pin hole fine grinding equipment and the crankshaft production process, the problem of high circle jumping in the use process due to low precision of existing crankshaft machining is solved, a shaft rod of a crank is centered, fine grinding is conducted on a connecting rod, and thus precision of the crankshaft is improved.

Owner:青岛锦瑞特园林工具有限公司

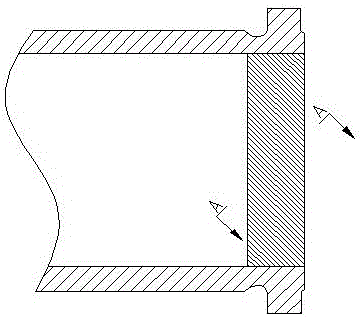

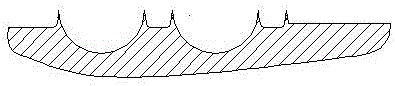

Tool and method for machining comb lines on inner wall of cylinder liner

The invention discloses a tool and method for machining comb lines on an inner wall of a cylinder liner, and belongs to the field of machining. The tool for machining the comb lines on the inner wall of the cylinder liner comprises a knife holder and a comb line knife. The comb line knife comprises a hilt, a crossbeam, auxiliary hilts and rollers, a U-shaped groove is formed in each auxiliary hilt, and directions of openings of the U-shaped grooves in the two auxiliary hilts are opposite to each other. Each U-shaped groove is connected with the corresponding roller through a corresponding hinge pin, and outer circle surfaces of the two rollers are higher than the tops of the corresponding U-shaped grooves. A threaded rod is mounted in the middle of each of the two auxiliary hilts, and each auxiliary hilt is connected with the corresponding threaded rod through a corresponding fixing device. In addition, the method for machining the comb lines on the inner wall of the cylinder liner comprises the following steps: step A, mounting a clamp and a knife; step B, adjusting the clamp and the knife; step C, rolling the comb lines; step D, removing burrs; and step E, cleaning and polishing the comb lines. The special tool is used for machining the comb lines, damage to a machine tool is small, and machining steps are simple; and the machined cylinder liner can adsorb carbon deposits and is high in strength.

Owner:HEBEI HUABEI DIESEL ENGINE

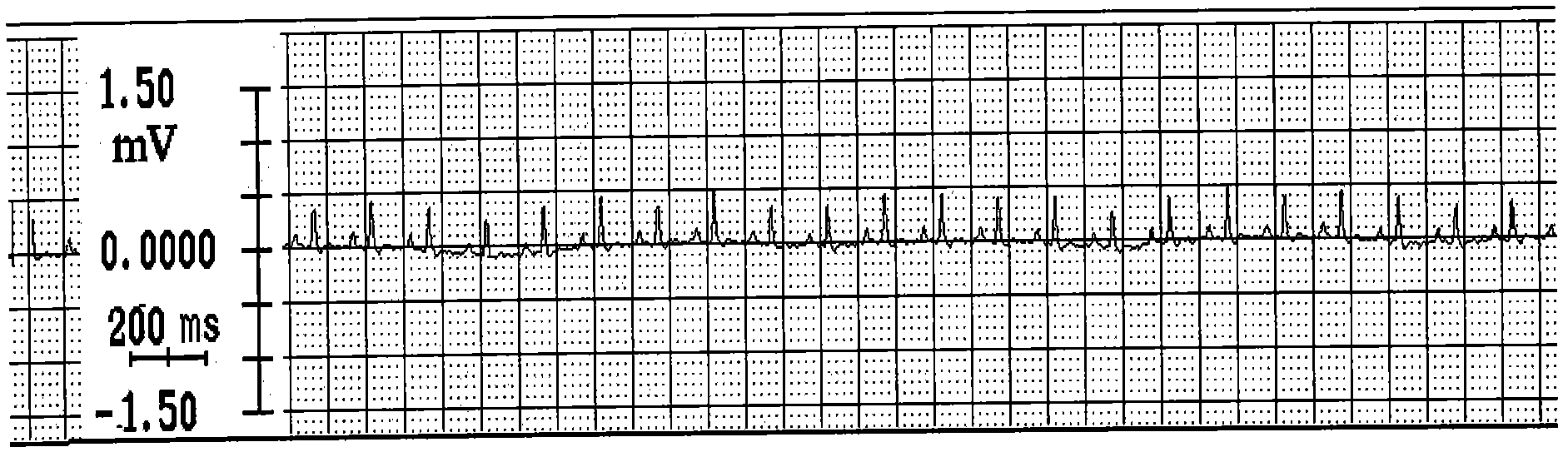

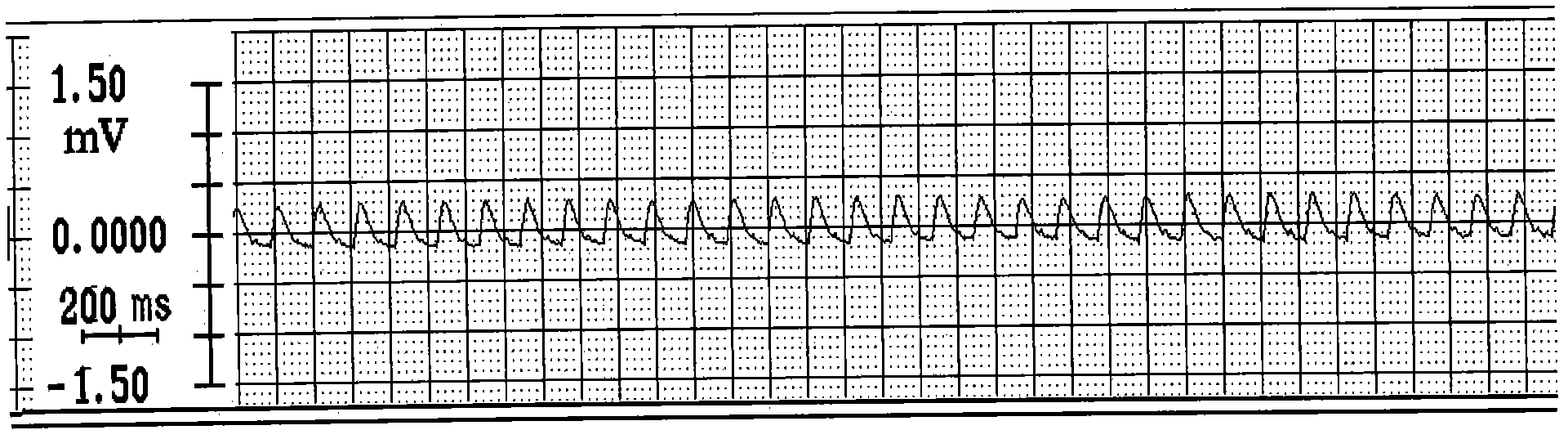

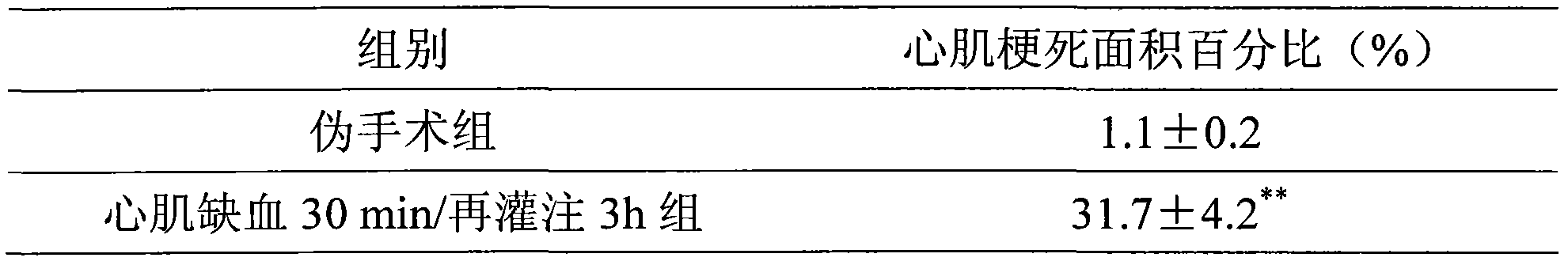

Preparation method of myocardial ischemia/reperfusion model in rats

InactiveCN102077807AAnesthesia is stableLittle side effectsSurgical veterinaryAnimal husbandryAnterior Descending Coronary ArteryIsoflurane

The invention relates to a preparation method of myocardial ischemia / reperfusion model in rats. The preparing method comprises the following steps in turn: I, anesthetizing, namely placing rats in an induction box, performing inhalation anesthesia by using 2 to 3 percent isoflurane, taking the rats out of the induction box, allowing the rats to continuously inhale isoflurane under a mask to maintain anesthesia; II, cutting off the chest skin and extruding the heart, disinfecting the chest skin, cutting off the chest skin, expanding the subcutaneous muscle to enter the chest, and directly extruding the heart out of the intercostals; III, ligating the left anterior descending coronary artery, ligating a starting end of the left anterior descending coronary artery by using a slipknot, sending the heart back to the chest after ligation, making one end of the ligating line positioned out of the chest, sewing and closing the chest; and IV, loosening the ligating line after ischemia is finished, directly loosening the ligating line exposed out of the chest, and restoring blood supply in the coronary. The invention is simple in operation, short in time consumption and relatively high in survival rate of the rats.

Owner:TAIYUAN IRON & STEEL GROUP

Two-station mandrel mechanism for serially connected knitting of metal ring chain

ActiveCN101693280AGuaranteed beatCompact and reasonable structureMetal chainsEngineeringProcedural approach

The mechanism of the invention relates to a two-station mandrel device for completing the serially connected knitting of a metal ring chain at a same station, in particular to a two-station mandrel mechanism for serially connected knitting of the metal ring chain. The method comprises the following steps: an upper mandrel cylinder works to lead an upper mandrel to be at an upper position, a lower mandrel cylinder works simultaneously to lead a lower mandrel to be also at the upper position, so that a U-shaped ring is knitted; the upper mandrel cylinder works inversely to lead the upper mandrel to be at a lower position, the lower mandrel cylinder works inversely simultaneously to lead the lower mandrel to be also at the lower position, thus knitting a ring chain in a serially connection manner; the upper mandrel cylinder works inversely once again to lead the upper mandrel to be at the upper position, the lower mandrel is still at the lower position, then, other auxiliary mechanisms accomplish the action of taking out the knitted ring chain; and the processes are repeated automatically. The mechanism of the invention combines the two-station mandrel device with a knitting mainframe and other auxiliary mechanisms, and PLC conducts automatic procedure control, so that two stations for bar material forming and serially connected knitting are automatically accomplished on a same mandrel mechanism. The two-station mandrel mechanism is characterized by compact and reasonable structure, high production efficiency, high automation degree, stable production process and safety and reliability.

Owner:王洪军

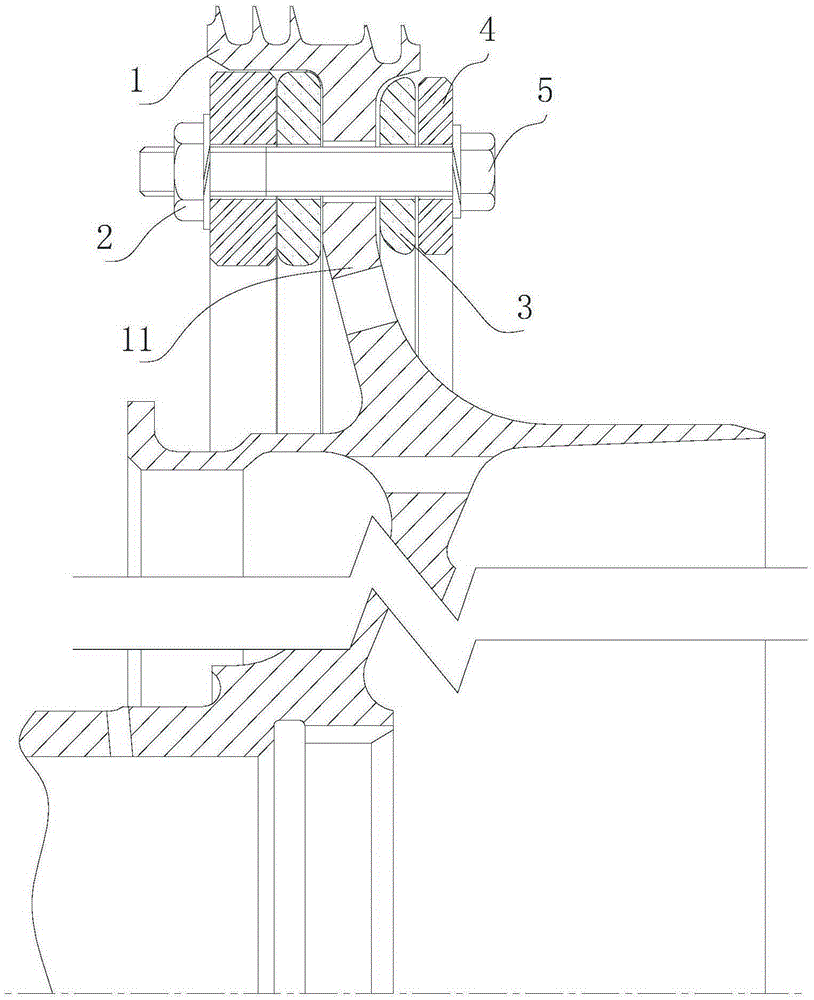

Machining device used for split-type ball bearing and machining method thereof

InactiveCN107570973AGuaranteed beatBeating meetsLarge fixed membersPositioning apparatusBall bearingGasket

The invention discloses a machining device used for a split-type ball bearing. A core shaft with one end being a stepped shaft is arranged, and a to-be-machined part, a limiting ring, a gasket and a nut are sequentially mounted on the stepped shaft of the core shaft; one end of the to-be-machined part makes contact with the end face of a shaft shoulder of the core shaft, and the other end of the to-be-machined part makes contact with one end of the limiting ring; and the other end of the limiting ring makes contact with the gasket, and the other end of the gasket makes contact with one end ofthe nut. Two to-be-machined semi-ball bearings are simultaneously clamped by the core shaft with the stepped shaft and then are closely combined through the limiting ring to ensure that jumping of theparts conforms to machining requirements. According to the machining device used for the split-type ball bearing, machining of the two semi-ball bearings in pairs is achieved, the machining device isreliable and safe in using, so that machining efficiency is doubled, and the material utilization of products is increased by one time.

Owner:AECC AVIATION POWER CO LTD

A brake disc processing tool and processing method thereof

A brake disc machining knife comprises a knife rod, a transition hook and a knife body. The knife rod is of a structure of a round rod, three vertical clamping faces in clamp fit with the knife rod machined on a cylindrical face of the round rod, the transition hook comprises a connecting disc, a side column and an underframe which are integrally machined, the connecting disc is coaxially fixed at the lower end of the knife rod, the side column is smoothly connected at the outer edge of the connecting disc and extends downward, the underframe is connected at the lower end of the side column and is a cylinder coaxial with the connecting disc and provided with a knife body mounting groove, the knife body comprises a radial knife radially mounted on the underframe, and a knife tip of the radial knife is positioned on one side opposite to the side column and points above. By using the brake disc machining knife, a measuring reference and a measuring plane are machined in a same process according to a same machining reference, machining accuracy is improved, and errors caused by repeated clamping during machining in different processes are avoided.

Owner:布雷博惠联(廊坊)制动系统有限公司

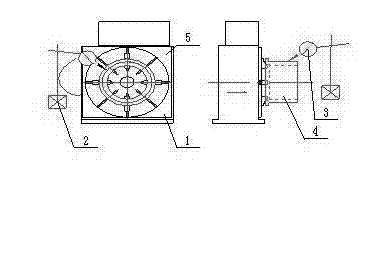

Stranded wire full-automatic tensioning experiment device based on spoked wheel structure

PendingCN106840881APrevent wrong rotationAchieve windingMaterial strength using tensile/compressive forcesProgramme control in sequence/logic controllersClassical mechanicsStructural engineering

The invention relates to a stranded wire full-automatic tensioning experiment device based on a spoked wheel structure. The device comprises a frame and a spoked wheel, wherein the spoked wheel is rotatably connected to the frame through a first rotating shaft, a driving component connected with the first rotating shaft is arranged on the frame, a locking device for locking the first rotating shaft is arranged on the frame, a compressing component for compressing a stranded wire is arranged on the spoked wheel, and a guide component facilitating the outgoing and incoming of the stranded wire is arranged on the frame. The stranded wire full-automatic tensioning experiment device has the advantages that the first rotating shaft is driven to rotate through the driving component so as to drive the spoked wheel to rotate, so that the stranded wire can wind on the spoked wheel, and a tensioning experiment of the stranded wire in the process of bending is realized; the first rotating shaft is locked through the locking device, so that the spoked wheel can be locked on the frame during the experiment, mistaken rotating of the spoked wheel during the experiment can be prevented effectively, the reliability of the experiment is guaranteed, and the stability of experiment data is improved; the stranded wire is compressed on the spoked wheel through the compressing component, so that jumping of the stranded wire during the experiment can be prevented, and the safety of the experiment is improved.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST

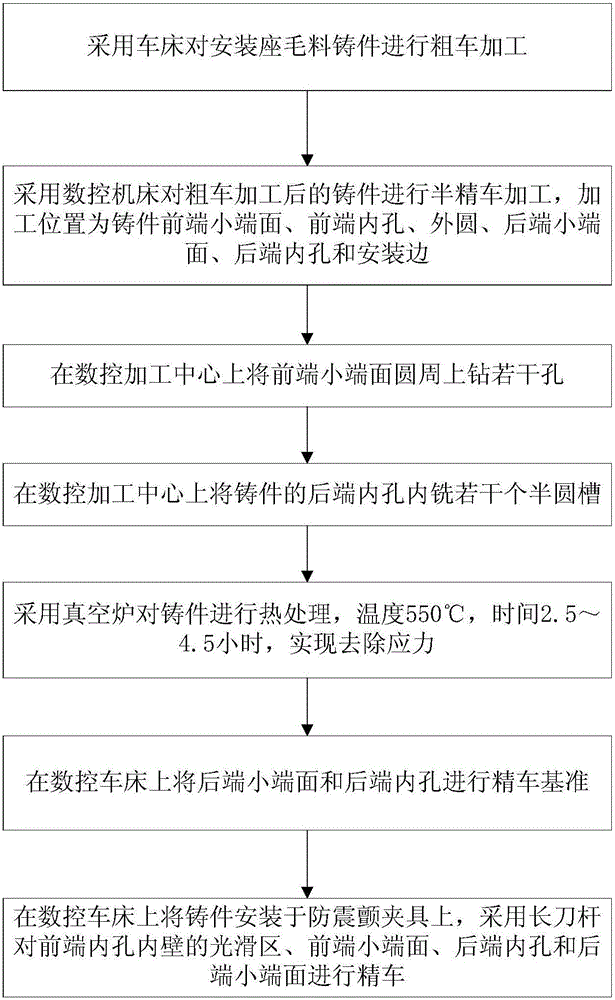

Processing method to prevent deformation of mounting edge of high-precision large-scale titanium alloy thin-walled casting

InactiveCN103551856BSolve the deformationSolve the deformation problem caused by chatterOther manufacturing equipments/toolsPositioning apparatusNumerical controlTitanium

The invention provides a machining method for preventing high-precision large titanium alloy thin-wall casting mounting edge deformation and belongs to the technical field of titanium alloy machining. The method has the advantages that process routes are adjusted, drilling and arc-shaped groove milling are performed in advance, stabilization is added, and machining stress can be reduced; manual machining is changed into numerical control machining, the numerical control program not intervened the whole process is used, allowance is removed evenly, and large machining stress caused by manual cutter compensation can be avoided; a lengthened cutter rod is used, two inner holes and the small end face are machined simultaneously, and coaxiality of the two inner holes and jump of the small end face are guaranteed; the clamping scheme of a clamp is modified, deformation caused by part oscillation during machine can be avoided, the technical bottleneck of large titanium alloy thin-wall casting mounting edge deformation is broken through, and design requirements of parts are satisfied.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

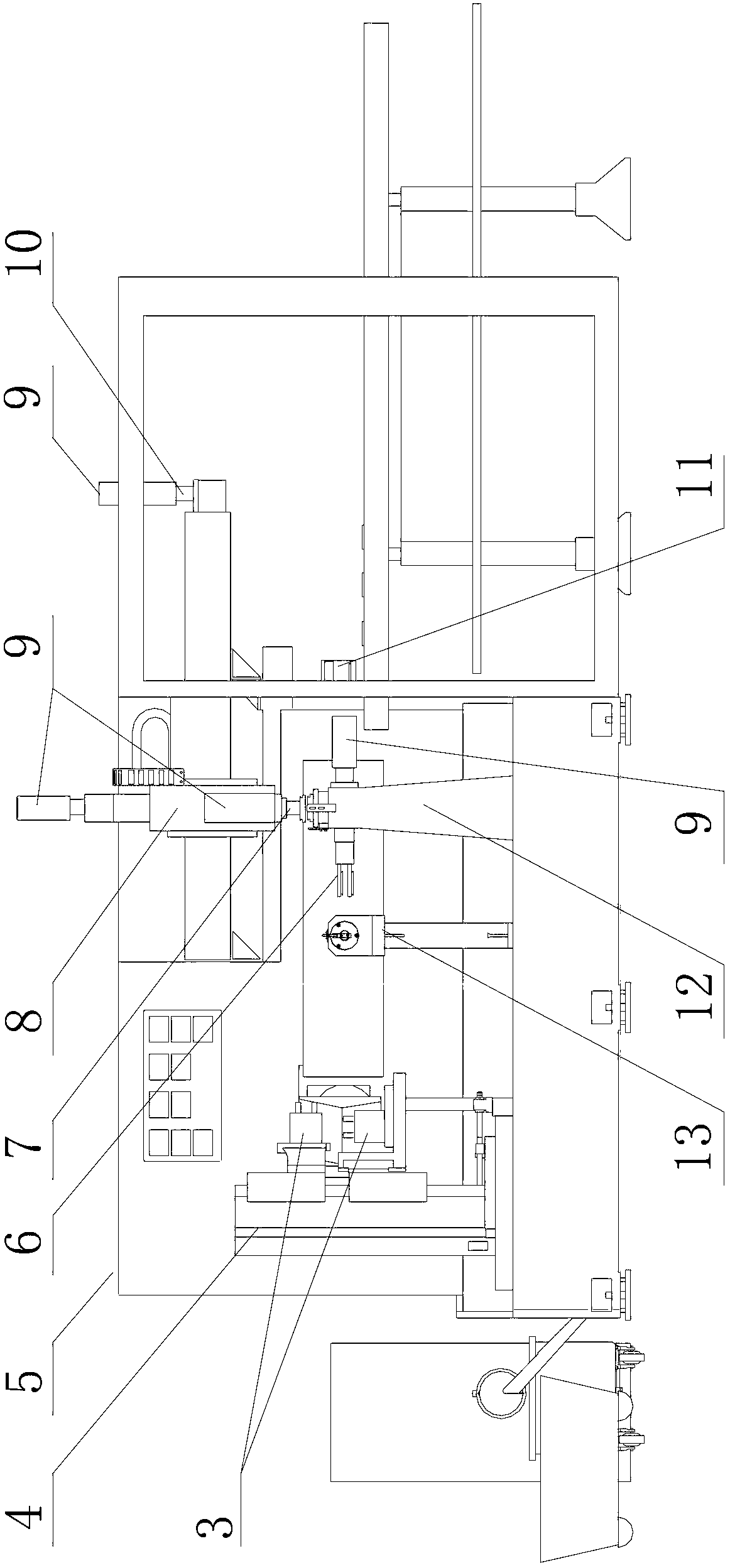

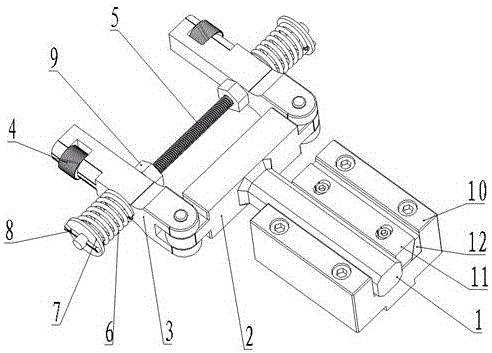

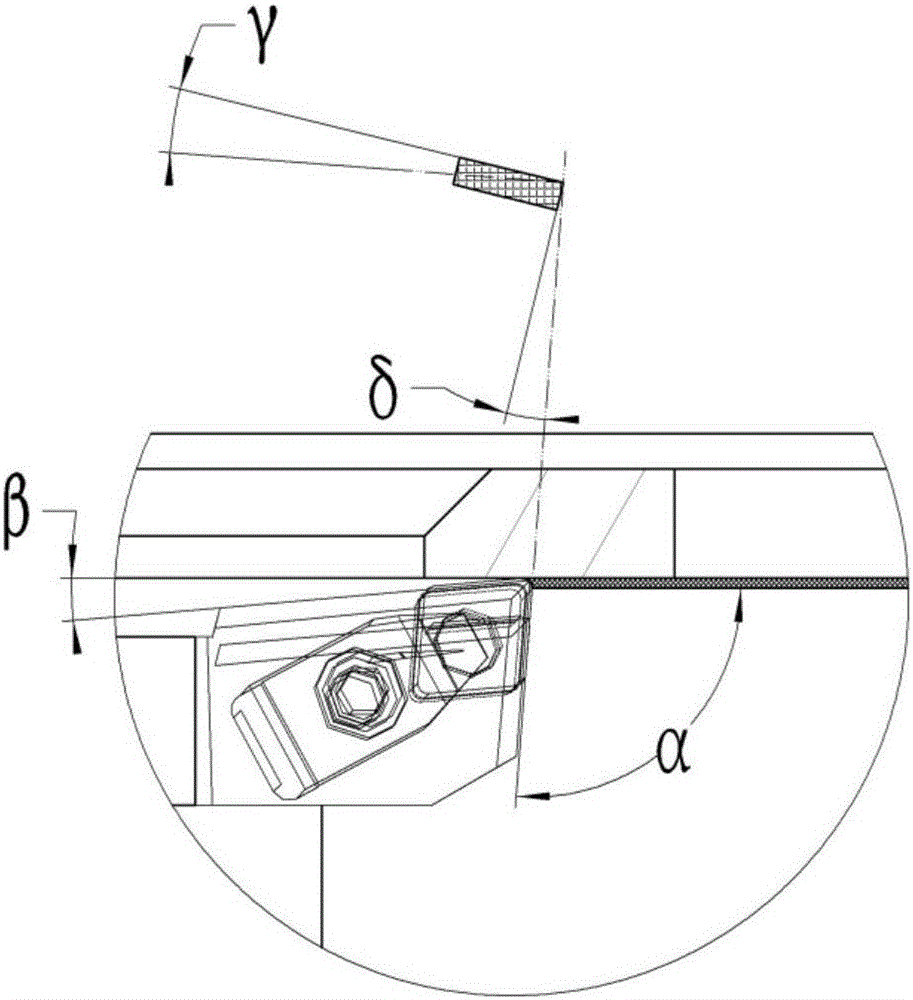

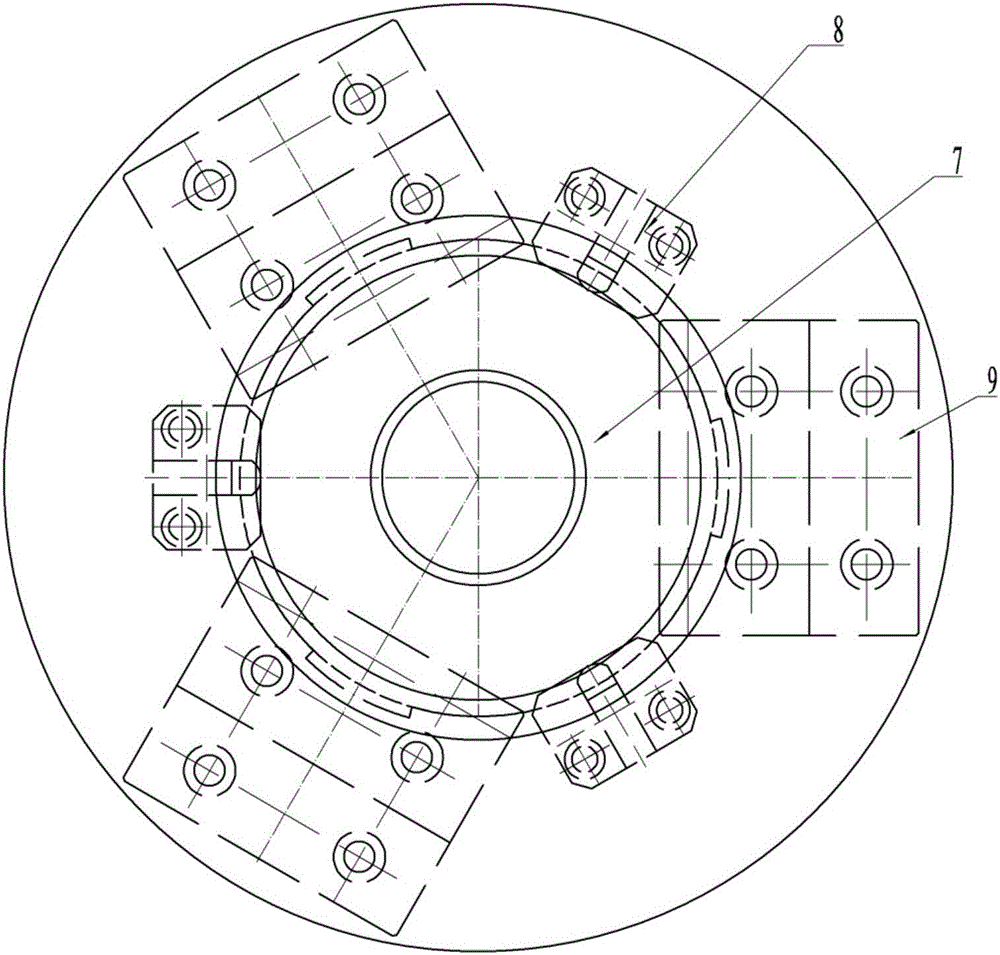

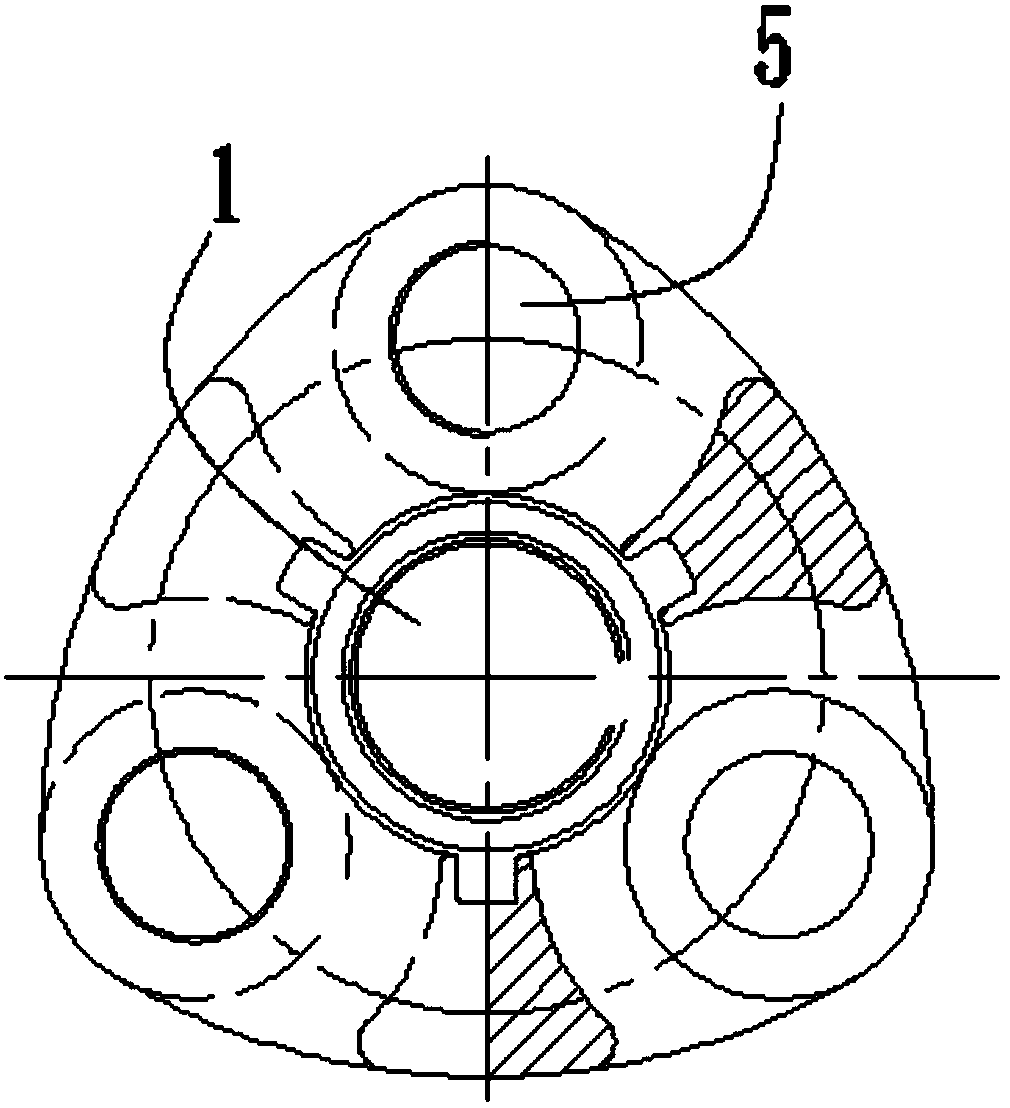

Positioning tool for gear pitch circle clamp

PendingCN109382676AMeet the precision requirementsGuaranteed beatPositioning apparatusMetal-working holdersHigh volume manufacturingGear wheel

The invention provides a positioning tool for a gear pitch circle clamp. The positioning tool comprises a clamp body; the upper end of the clamp body is provided with a gear workpiece mounting groove;the clamp body is provided with a positioning disc on the end face of a gear workpiece at the lower end of the gear workpiece mounting groove; the clamp body is provided with a plurality of wedge blocks at the periphery of the gear workpiece mounting groove; the clamp body is provided with a retainer at the upper portion of the gear workpiece mounting groove, the retainer comprises a pressing plate pressed on the gear workpiece, and ball structures are arranged at the portions, corresponding to the wedge blocks, of the lower end of the pressing plate and comprise balls which are in contact fit with the two toothed surfaces of the pitch circle of the gear workpiece and the end surfaces of the wedge blocks respectively; the upper end of the retainer is provided with a plurality of elastic pressing structures fixed to the clamp body. The positioning tool can realize a deep molten salt pump test under the action of variable liquid. The positioning tool meets the precision requirement of agear at first, then improves the working efficiency and is suitable for mass production; finally, the tool is convenient to disassemble and assemble and easy to understand.

Owner:PANZHIHUA RUNYING GEAR CO LTD

Vibration absorbing structure for thin-wall support of auxiliary plate of shaft part and vibration absorbing method thereof

InactiveCN105328467ASmall sizeGuaranteed beatWork clamping meansPositioning apparatusThin walledFastener

The invention discloses a vibration absorbing structure for a thin-wall support of an auxiliary plate of a shaft part and a vibration absorbing method thereof. The vibration absorbing structure comprises rubber rings which are arranged at two sides of the auxiliary plate of the part, wherein bakelite plates cover the outer sides of the rubber rings; the rubber rings and the bakelite plates are correspondingly fixed to two sides of the auxiliary plate through fasteners and can be fixed to the auxiliary plate by bolts which correspondingly pass through mounting holes in the rubber rings and the bakelite plates. The method is characterized in that the mounting holes in the manufactured bakelite plate and the rubber ring at one side of the part are aligned, then the bakelite plate and the rubber ring are positioned on the part, and the mounting holes are aligned to through holes in the auxiliary plate; the processed mounting holes in the bakelite plate and the rubber ring at the other side of the part are aligned, and then the bakelite plate and the rubber ring are positioned to the part; the bakelite plates and the rubber rings are locked through the through holes in the auxiliary plate, so as to achieve the auxiliary supporting effect. The vibration absorbing structure and the vibration absorbing method are applicable to the processing of sealing teeth and threads in thin-wall supporting parts of various shaft parts of aircraft engines, and the vibration caused by poor support stiffness in the processing process can be effectively prevented.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

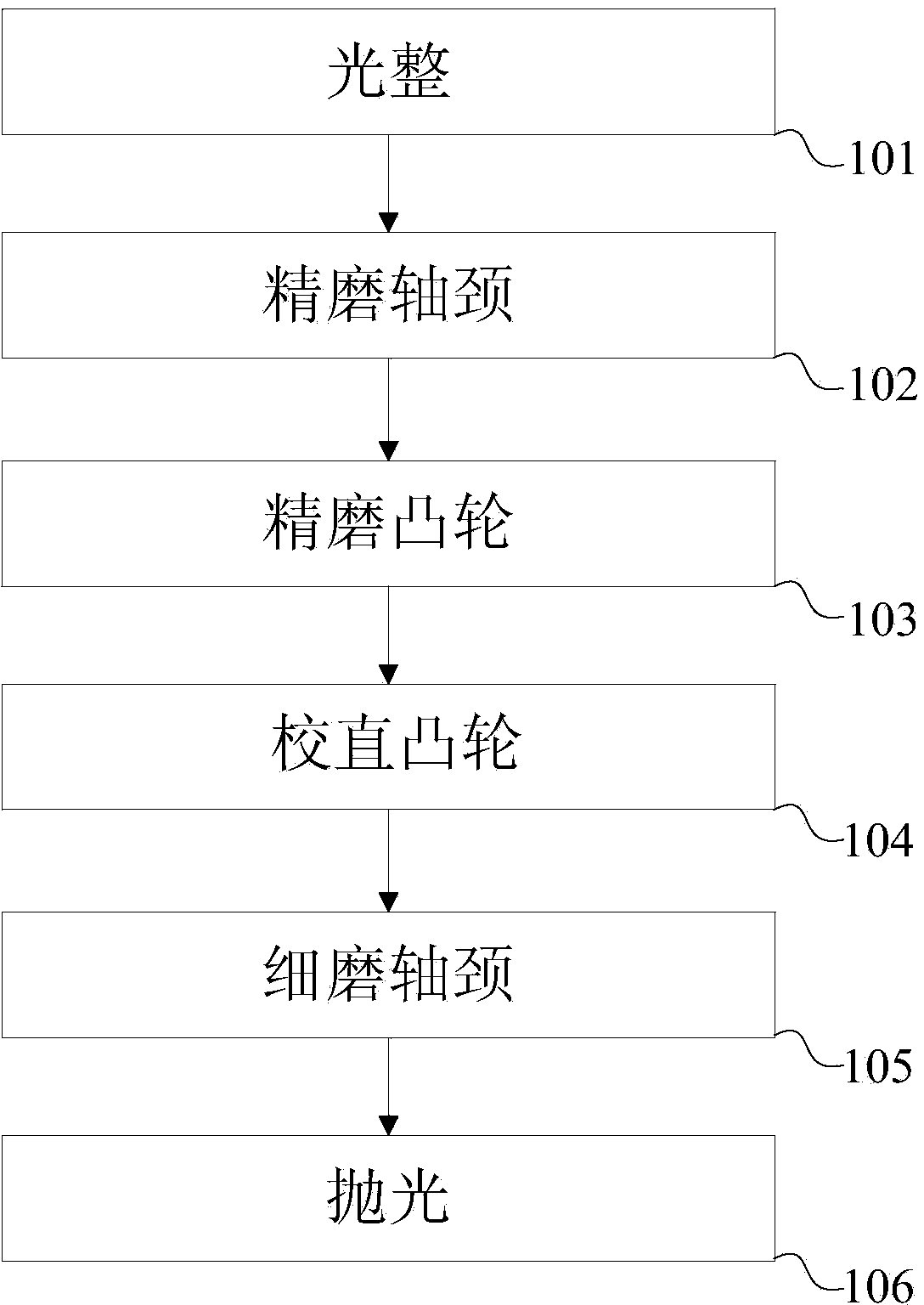

Finish machining method of camshaft

The invention discloses a finish machining method of a camshaft. The finish machining method sequentially comprises the following steps that first, finishing is conducted on a workpiece; second, a shaft neck and a cam are accurately ground, wherein shaft neck allowance is reserved in the shaft neck accurate grinding process; third, the shaft neck at the farthest end of the workpiece which is completed in the second step is used as a supporting point to straighten the cam; fourth, fine grinding is conducted on the shaft neck. By the adoption of the method, it is guaranteed that cam base circle run-out of the camshaft can meet requirements, and therefore the machining precision of the camshaft is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

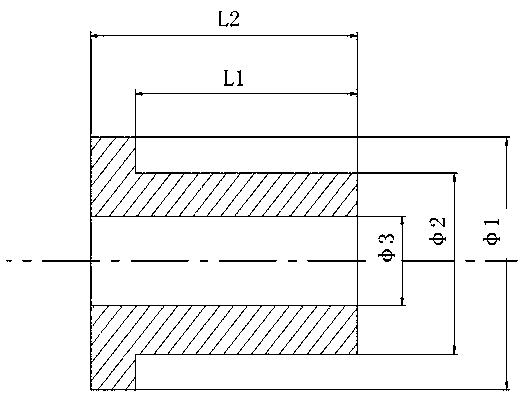

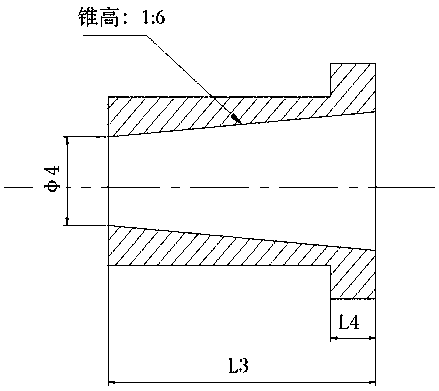

Technology for machining bushing with conical hole

The invention discloses a technology for machining a bushing with a conical hole. The technology for machining the bushing with the conical hole comprises the following steps that firstly, a bar material corresponding to the material designation is received; secondly, 100% light splitting inspection is conducted as required; thirdly, end faces are planed smooth by using a turning tool, rough turning is conducted on a large-diameter outer circle, a small-diameter outer circle and an inner hole; fourthly, heat treatment is conducted as required, and the strength of heat treatment is requested to reach the formula that sigma b is equal to 1175 + / - 100 MPa; fifthly, the small-diameter outer circle end is clamped, end surfaces are planed smooth, and finish turning is conducted on the conical hole; sixthly, the turning tool is turned round, locating is conducted according to the conical hole, and finish turning is conducted on the big-diameter outer circle and the small-diameter outer circle; seventhly, heat treatment is conducted as required, and low temperature tempering is conducted; and eighthly, a bushing is delivered for inspection. According to the technology for machining the bushing with the conical hole, finish turning is conducted on the conical hole firstly, then finish turning is conducted on the outer circles, circular run-out can be effectively guaranteed, technological requirements are met, and the part quality is also guaranteed; and the technological scheme conforms to reality, the operation is convenient, the technology is popular and easy to understand, and the machining method is easy to learn and popularize.

Owner:JIANGXI HONGDU AVIATION IND GRP

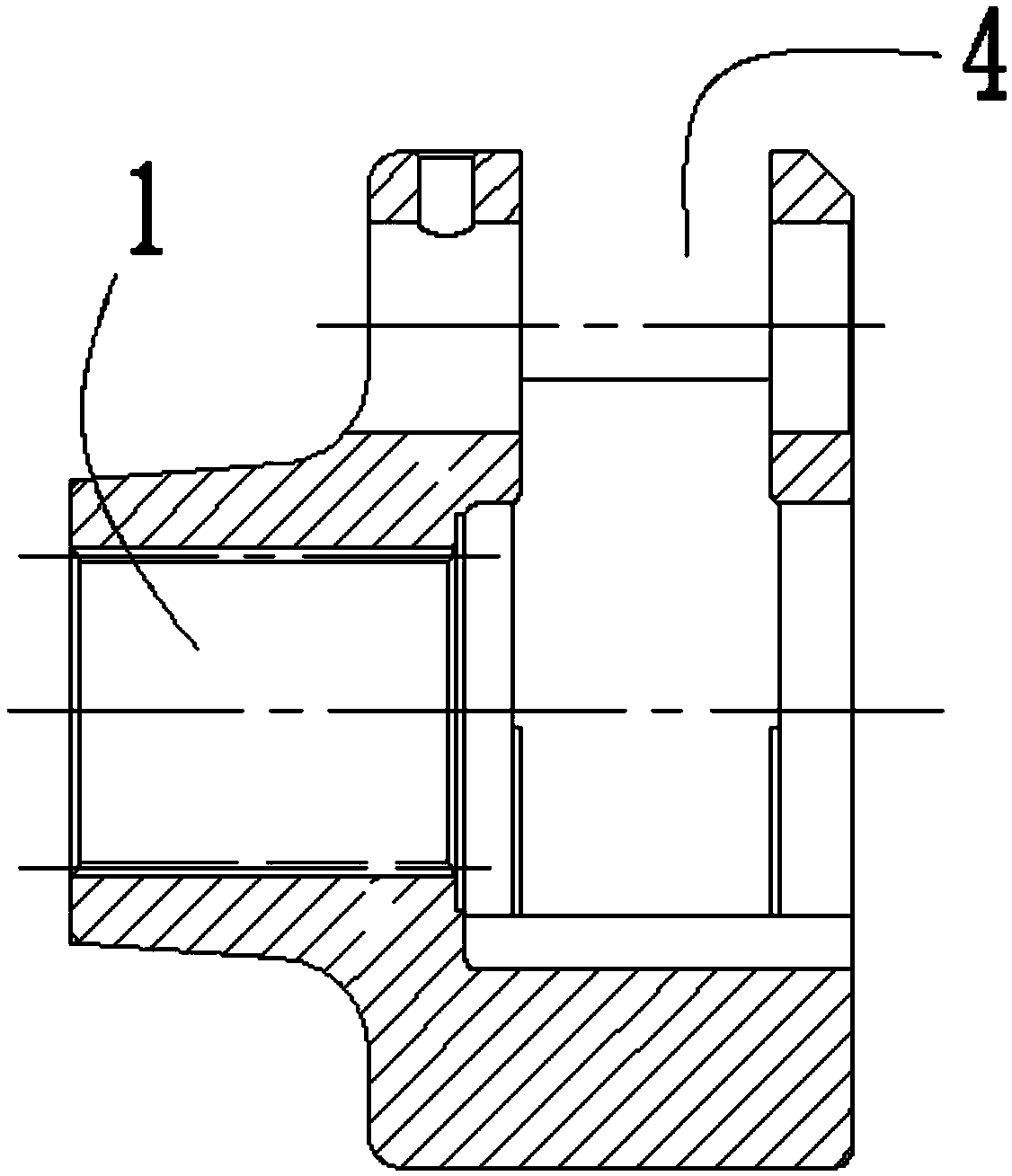

Processing method for planet carrier

PendingCN108788656AGuaranteed beatGuaranteed positioning accuracyPositioning apparatusMetal-working holdersEngineeringPlanet

The invention relates to a processing method for a planet carrier. The processing method comprises the following steps that (1), after the planet carrier is subjected to rough processing, a splined hole is formed in a vertical broaching machine in a broaching manner; (2), the planet carrier is inserted into a high-precision-taper spline mandrel, axially and tightly wedging is performed by means ofthe taper, a jacking tip of a numerically controlled lathe tightly jacks center holes in the two ends of the spline mandrel, and a small end face of the planet carrier is subjected to finish turning;(3), the small end face of the planet carrier is placed on a bottom plate, positioning is performed through the splined hole and the small end face, the splined hole serves as the positioning benchmark, three planetary gear mounting holes are formed in a vertical machining centre, and the relative positions of the three planetary gear mounting holes are guaranteed by equipment precision; (4), thesplined hole and the small end face serve as the positioning benchmark, and processing of three blank portions is completed. Positioning is performed through the splined hole, the positioning benchmark is consistent with the design benchmark, the position precision is effectively guaranteed, the main precision is guaranteed by a high-precision fixture and the equipment precision of the machiningcenter, less human factors exist, and quality stability is high.

Owner:青岛华瑞汽车零部件股份有限公司

Flange plate turning process and machining equipment

InactiveCN112756641AGuaranteed accuracyReduce waiting timeAuxillary equipmentMetal working apparatusEngineeringMachine tool

The invention relates to a flange plate turning process and machining equipment. The flange plate turning process comprises the following steps that firstly, rough turning is conducted on the rear end face and the peripheral face of a flange plate body and a second flange base body through a first lathe; secondly, rough turning is conducted on the front end face of the flange plate body and a first flange base body through a second lathe; and thirdly, finish turning is conducted on the front end face of the flange plate body and the first flange base body through a third lathe. Rough turning and finish turning are separated, only the size of a finish turning part needs to be emphatically controlled, and the precision of a finish turning machine tool can be effectively guaranteed through separation of rough turning and finish turning; and the rough turning time of the first lathe and the second lathe is shorter than the finish turning time of the third lathe, so that the beats among the procedures can be effectively ensured, the waiting time of the machine tool is reduced, and the production efficiency is improved.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD +1

Two-station mandrel mechanism for serially connected knitting of metal ring chain

ActiveCN101693280BGuaranteed beatCompact and reasonable structureMetal chainsEngineeringProcedural approach

The mechanism of the invention relates to a two-station mandrel device for completing the serially connected knitting of a metal ring chain at a same station, in particular to a two-station mandrel mechanism for serially connected knitting of the metal ring chain. The method comprises the following steps: an upper mandrel cylinder works to lead an upper mandrel to be at an upper position, a lowermandrel cylinder works simultaneously to lead a lower mandrel to be also at the upper position, so that a U-shaped ring is knitted; the upper mandrel cylinder works inversely to lead the upper mandrel to be at a lower position, the lower mandrel cylinder works inversely simultaneously to lead the lower mandrel to be also at the lower position, thus knitting a ring chain in a serially connection manner; the upper mandrel cylinder works inversely once again to lead the upper mandrel to be at the upper position, the lower mandrel is still at the lower position, then, other auxiliary mechanisms accomplish the action of taking out the knitted ring chain; and the processes are repeated automatically. The mechanism of the invention combines the two-station mandrel device with a knitting mainframe and other auxiliary mechanisms, and PLC conducts automatic procedure control, so that two stations for bar material forming and serially connected knitting are automatically accomplished on a same mandrel mechanism. The two-station mandrel mechanism is characterized by compact and reasonable structure, high production efficiency, high automation degree, stable production process and safety and reliability.

Owner:王洪军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com