Whirlwind chamfering machine with automatic material feeding and discharging function

A cyclone chamfering machine, automatic loading and unloading technology, applied in the direction of components with teeth, gear cutting machines, mechanical equipment, etc., can solve the problems of complex adjustment, easy to turn out burrs, low production efficiency, etc. The effect of reducing labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

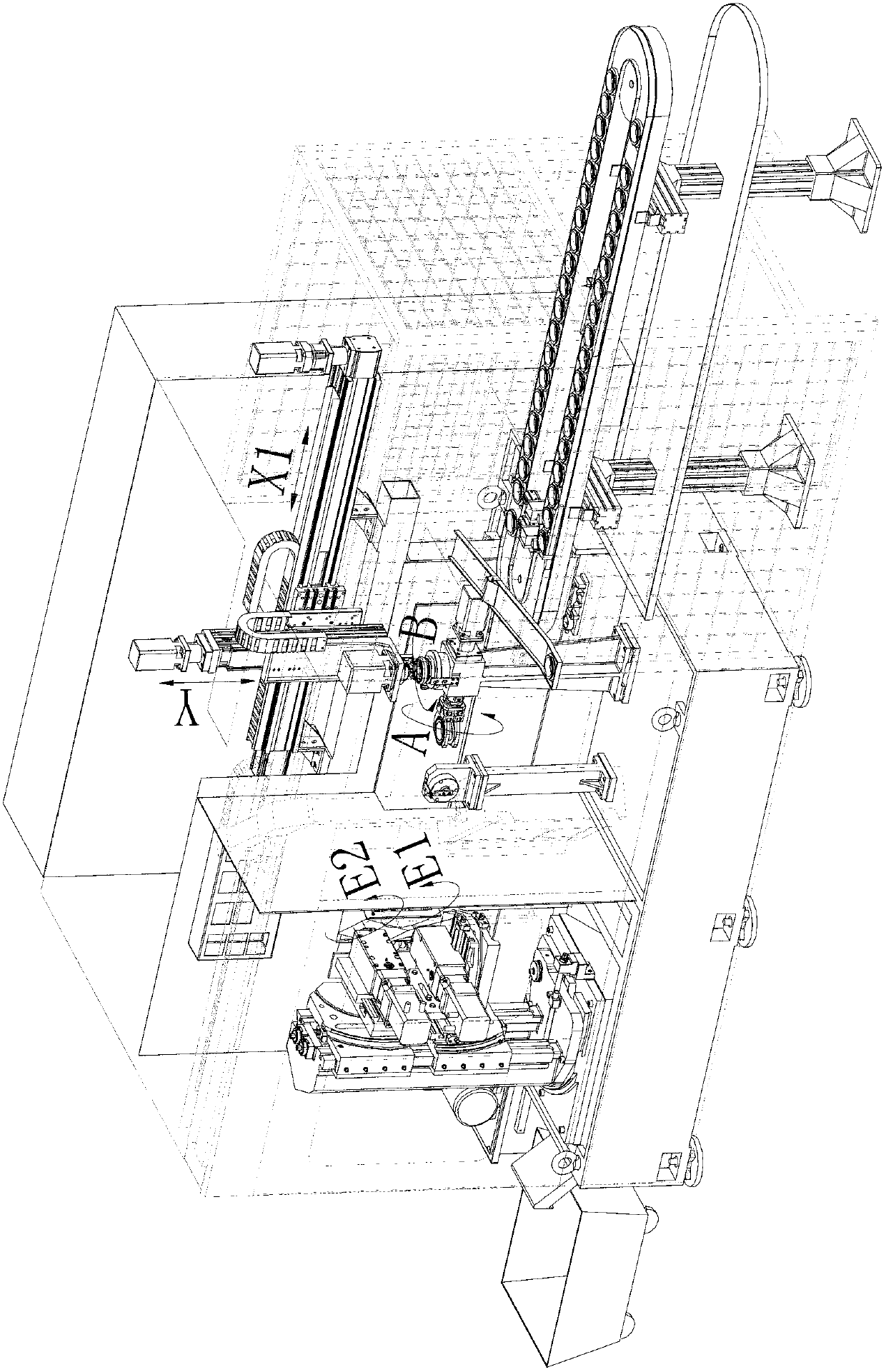

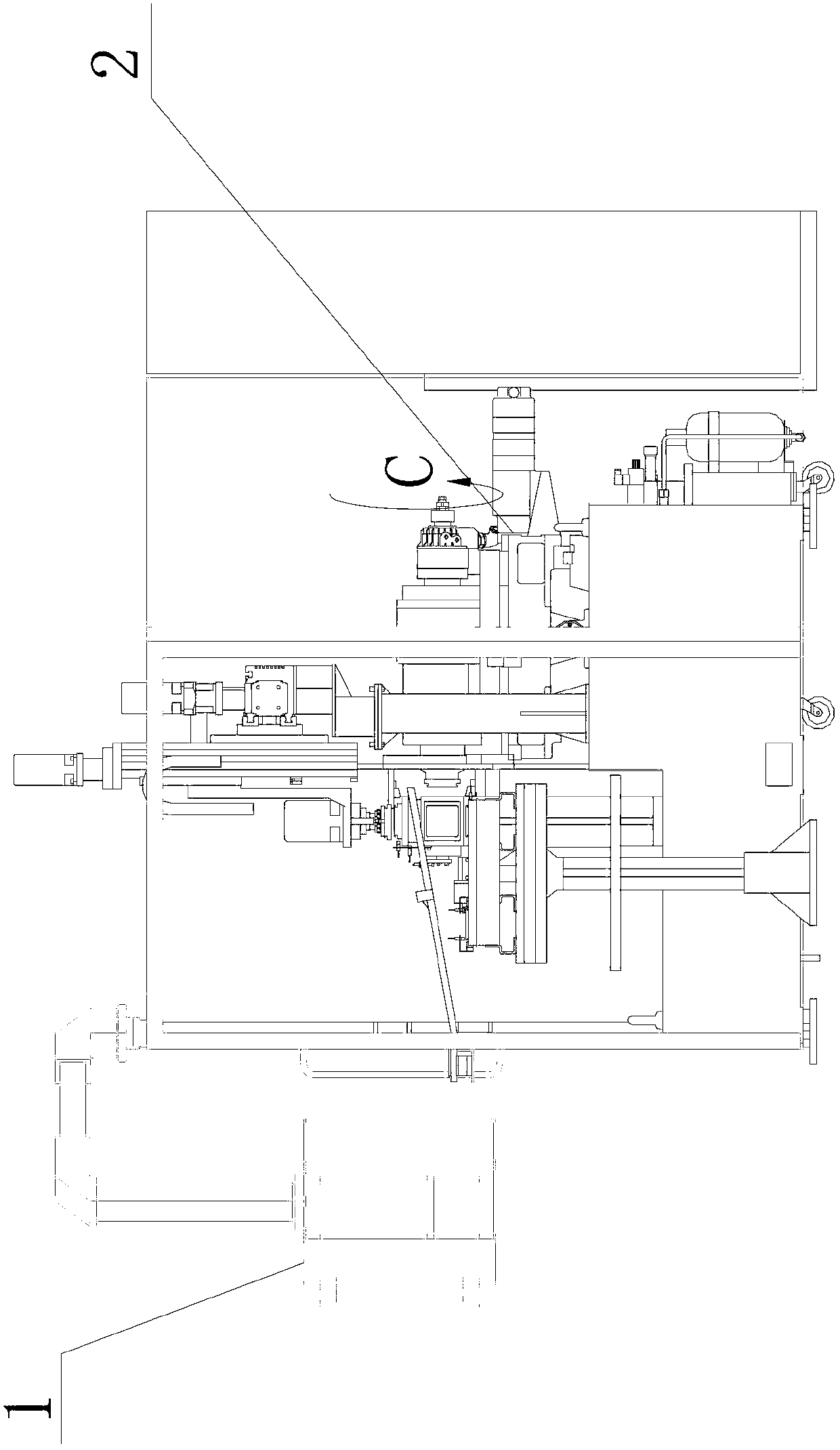

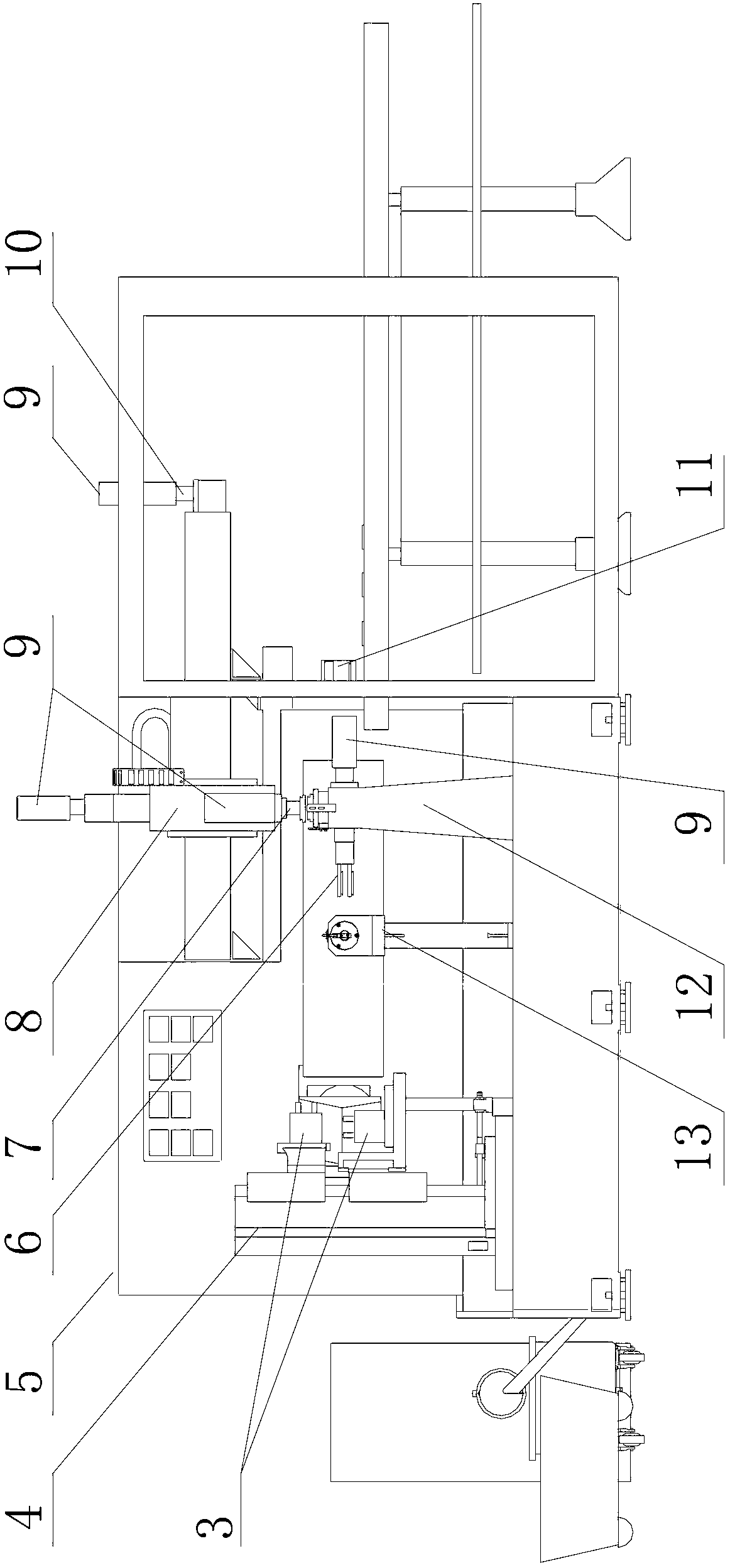

[0038] Such as Figure 1 to Figure 4 As shown, the present invention is a cyclone chamfering machine with automatic loading and unloading functions, including a bed 21, a workpiece box 18, a cutter shaft system 4, a conveyor line mechanism 23, a loading and unloading mechanism 8, and a positioning and turning mechanism 12. The machine tool bed 21 has a horizontal layout. The workpiece box 18 and the cutter shaft system 4 are installed on the bed 21. The machine tool is driven by nine servo motors.

[0039] Lateral movement of the workpiece box 18 on the bed 21 (X direction), feed movement of the workpiece box (Z direction), continuous indexing of the workpiece spindle (C direction), rotation of the two tool spindles (E1 direction and E2 direction) . Fixtures for positioning and clamping workpieces are also installed on the workpiece box 21 . A linear guide rail is set on the bed 21, and the linear guide rail is connected with the slide plate. The workpiece box 21 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com