Two-station mandrel mechanism for serially connected knitting of metal ring chain

A metal ring and two-station technology, applied in the direction of metal chains, etc., can solve the problems of difficult maintenance and replacement of parts, large device volume, complex structure, etc., and achieve the effects of reducing labor intensity of workers, high production efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

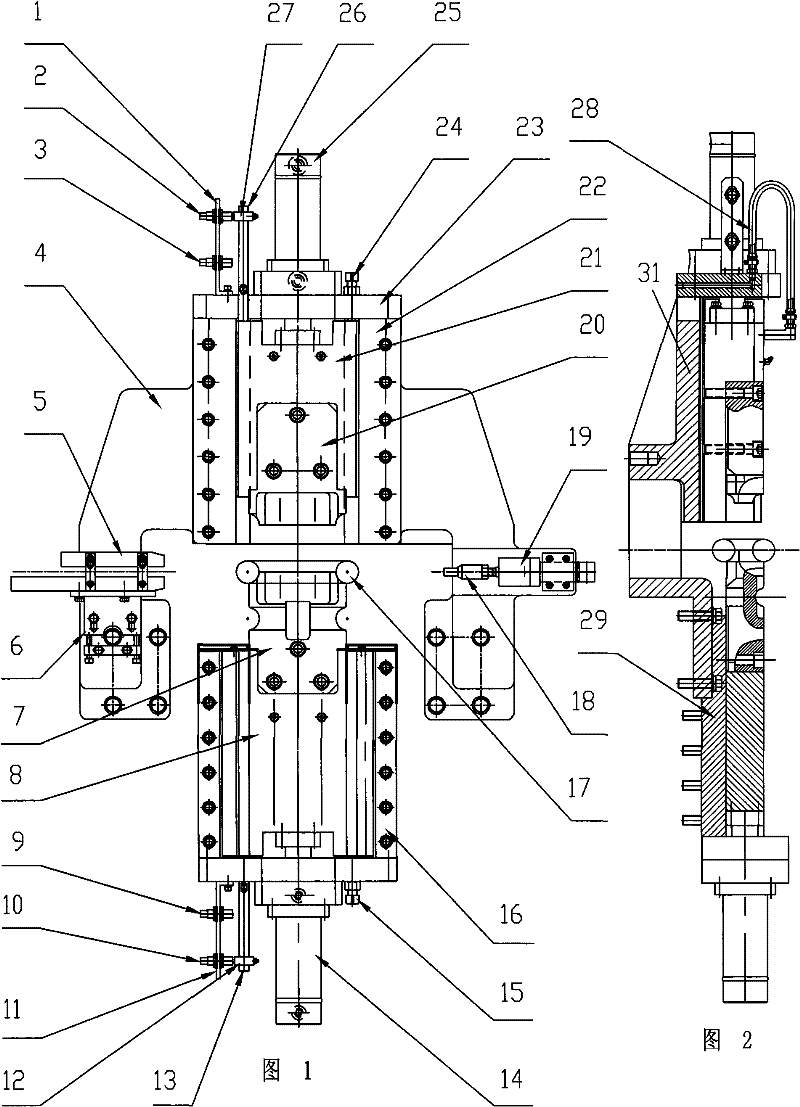

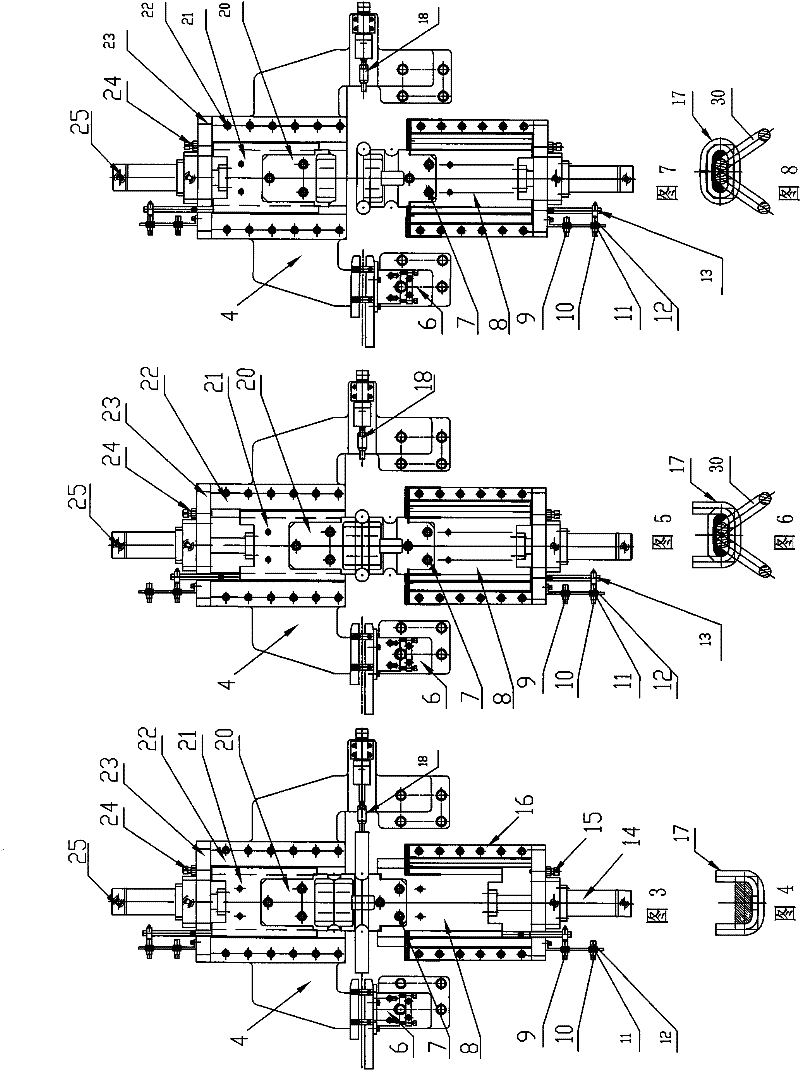

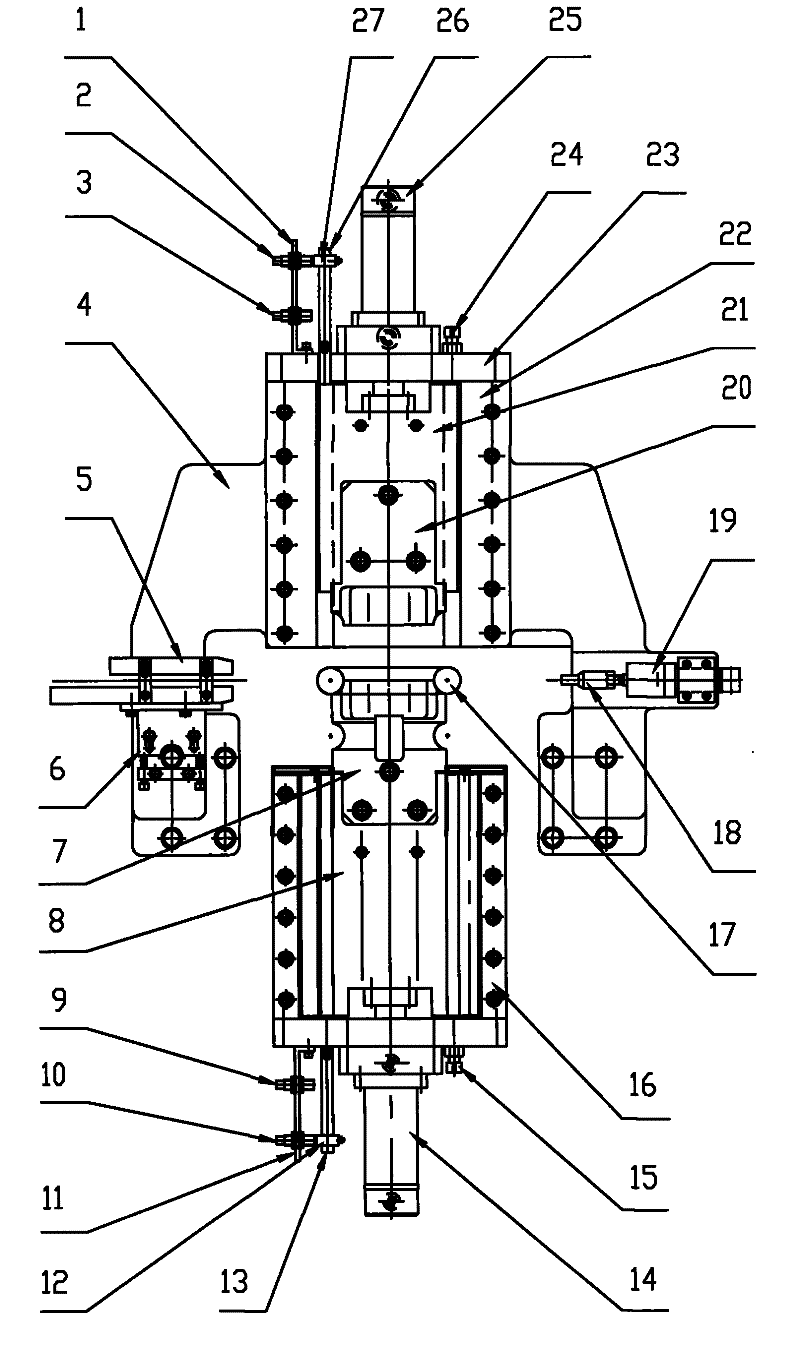

[0021] Such as figure 1 Shown: The two-station mandrel mechanism for braiding metal ring chains in series is composed of three parts. It includes: an upper mandrel device; a special lower mandrel device; a gantry bracket for fixing the upper mandrel device is fixed on the front upper part of the main body of the chain knitting equipment.

[0022] The gantry support for fixing the upper mandrel device includes a gantry support 4, a limit guide plate 5, a guide adjustment plate 6, a positioning block 18, a positioning oil cylinder 19, etc. The gantry support 4 is fixed on the front upper part of the main body of the equipment, and the upper sliding seat 21 is embedded in the chute on the upper sliding seat body 31 on the gantry support 4; the limit guide plate 5 and the guide adjustment plate 6 are fixed on the left feeding position of the gantry support 4, and the positioning block 18 and the positioning cylinder 19 are fixed on the gantry The right stopper position of bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com