Vibration absorbing structure for thin-wall support of auxiliary plate of shaft part and vibration absorbing method thereof

A technology of shaft parts and auxiliary plates, applied in metal processing machinery parts, supports, maintenance and safety accessories, etc., can solve the problems of tool damage, parts deformation, unqualified surface finish, and achieve the effect of preventing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

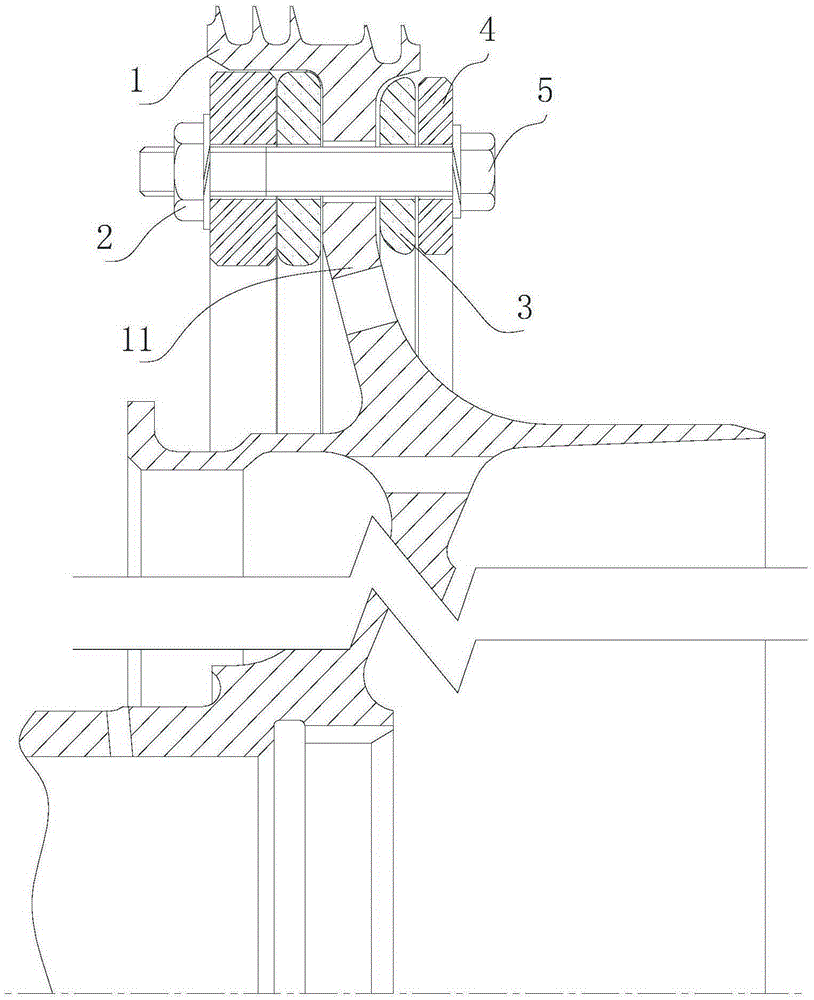

[0017] Such as figure 1 As shown in the present invention, a thin-walled support shock absorbing structure for an auxiliary plate of a shaft part includes rubber rings 3 arranged on both sides of the auxiliary plate 11 of the part 1, and the outer side of the rubber ring 3 is covered with bakelite boards 4, The rubber ring 3 and the bakelite board 4 are fixed on the two layers of the auxiliary board 11 by fasteners. With this technical solution, when processing the part 1, the rubber rings 3 on both sides are attached to the part 1, so that it is evenly stressed in the clamped state, and the effect of clamping deformation is reduced; then the bakelite board 4 is covered on the The outer side of the rubber ring 3 plays the purpose of fixing and strengthening the strength of the auxiliar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com