Flange plate turning process and machining equipment

A technology of processing equipment and technology, which is applied in the field of flange turning technology and processing equipment, can solve the problems of large machining allowance in the rough turning part, affecting the machining accuracy of the finishing turning part, and damage to the accuracy of the machine tool, so as to reduce waiting time and improve Production efficiency, guaranteed beat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

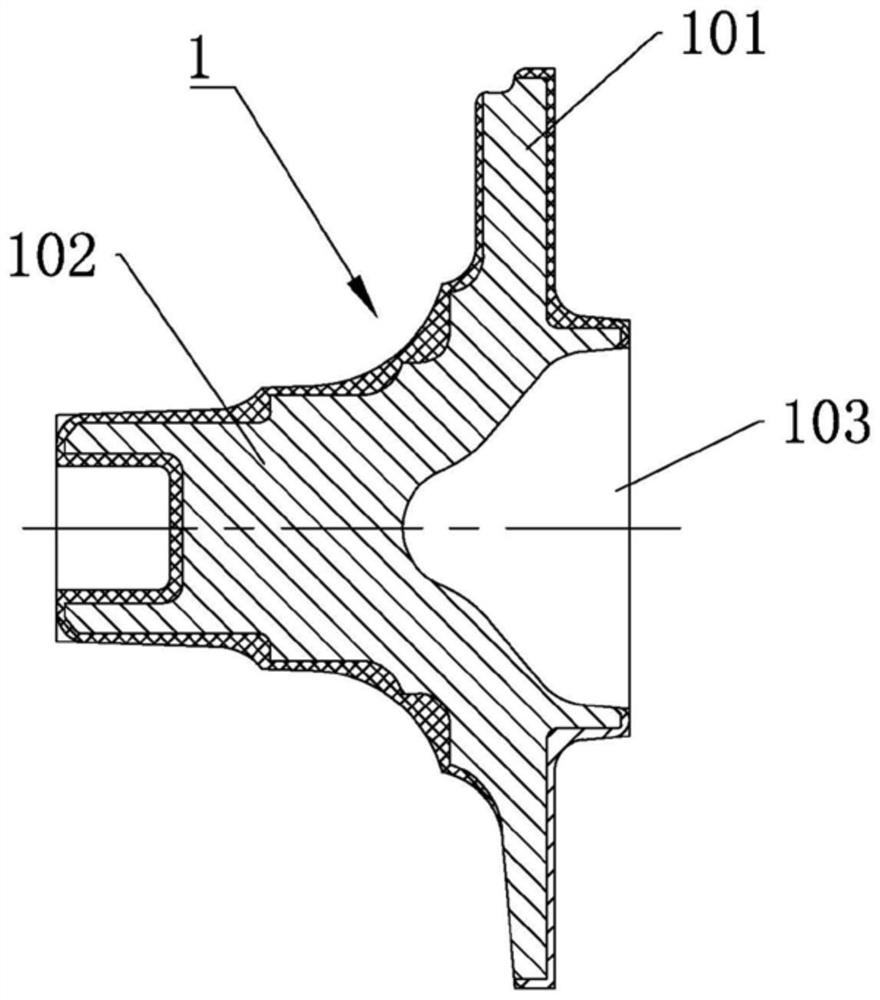

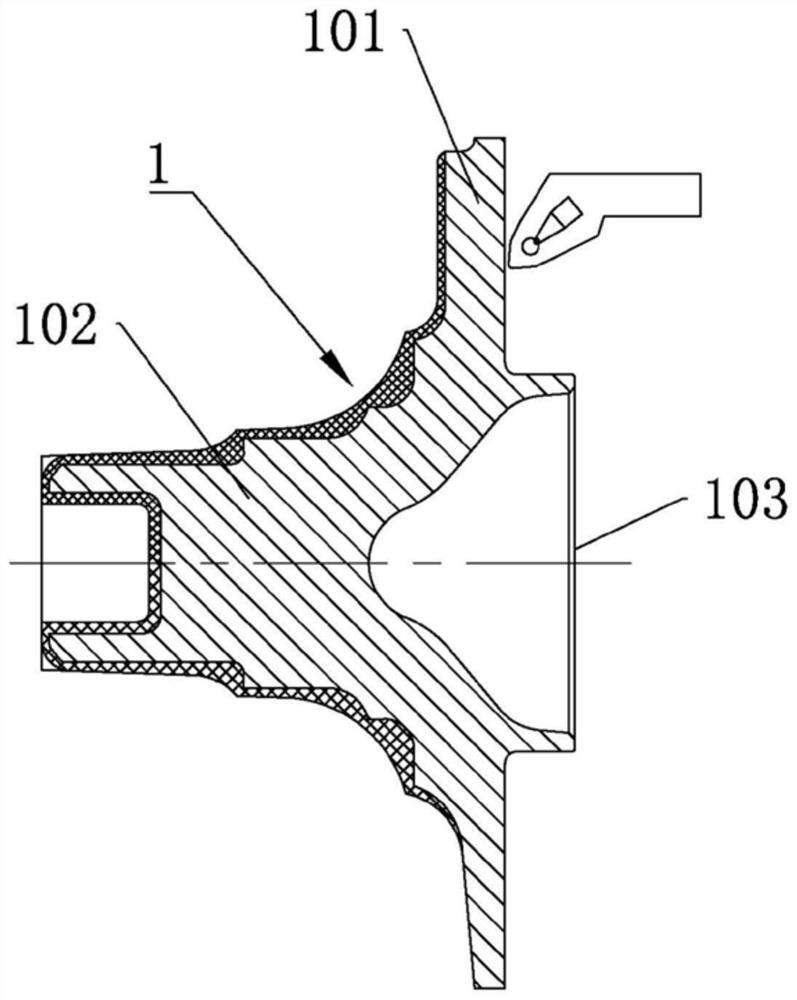

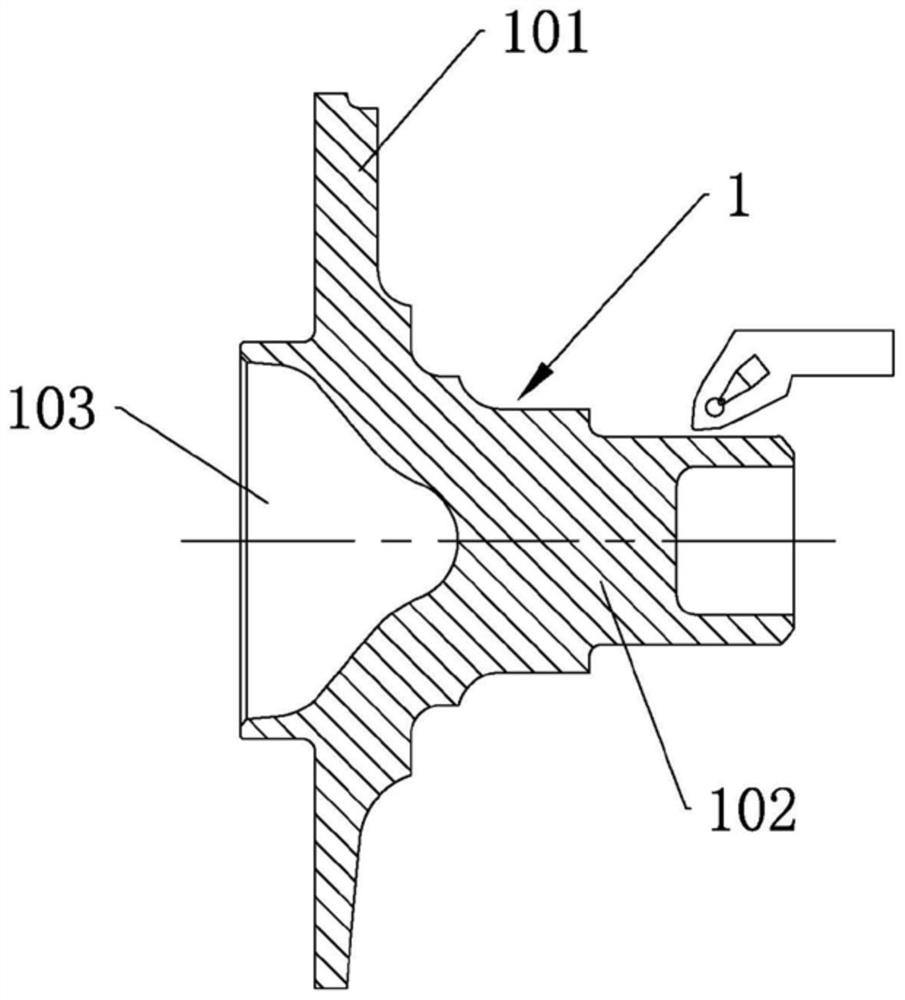

[0027] Example: such as figure 1 As shown, the flange 1 includes a flange body 101, a first flange base 102 disposed on the front end of the flange body 101, and a second flange base 103 disposed on the rear end of the flange body 101 , The flange plate body 101, the first flange base body 102 and the second flange base body 103 are coaxially arranged.

[0028] A processing equipment for flange turning process, including the first lathe 2, the second lathe 3, the third lathe 4, the truss 6 and the manipulator 7, the first lathe 2, the second lathe 3 and the third lathe 4 are set Below the truss 6 and along the longitudinal direction of the truss 6 , they are distributed sequentially at intervals. The manipulator 7 is movably arranged on the truss 6 and moves along the truss 6 between the first lathe 2 , the second lathe 3 and the third lathe 4 . There are two groups of manipulators 7, which can move along the truss 6 independently.

[0029] Such as Figure 4 As shown, a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com