Method and device used for guaranteeing wall thickness of metal plate forming thin-wall ring part

A technology for circular parts and thin walls, which is applied in positioning devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of inconsistent wall thickness and flatness of thin-walled circular parts formed by sheet metal, and achieve convenient adjustment, Effects of preventing deformation and facilitating positioning of references

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

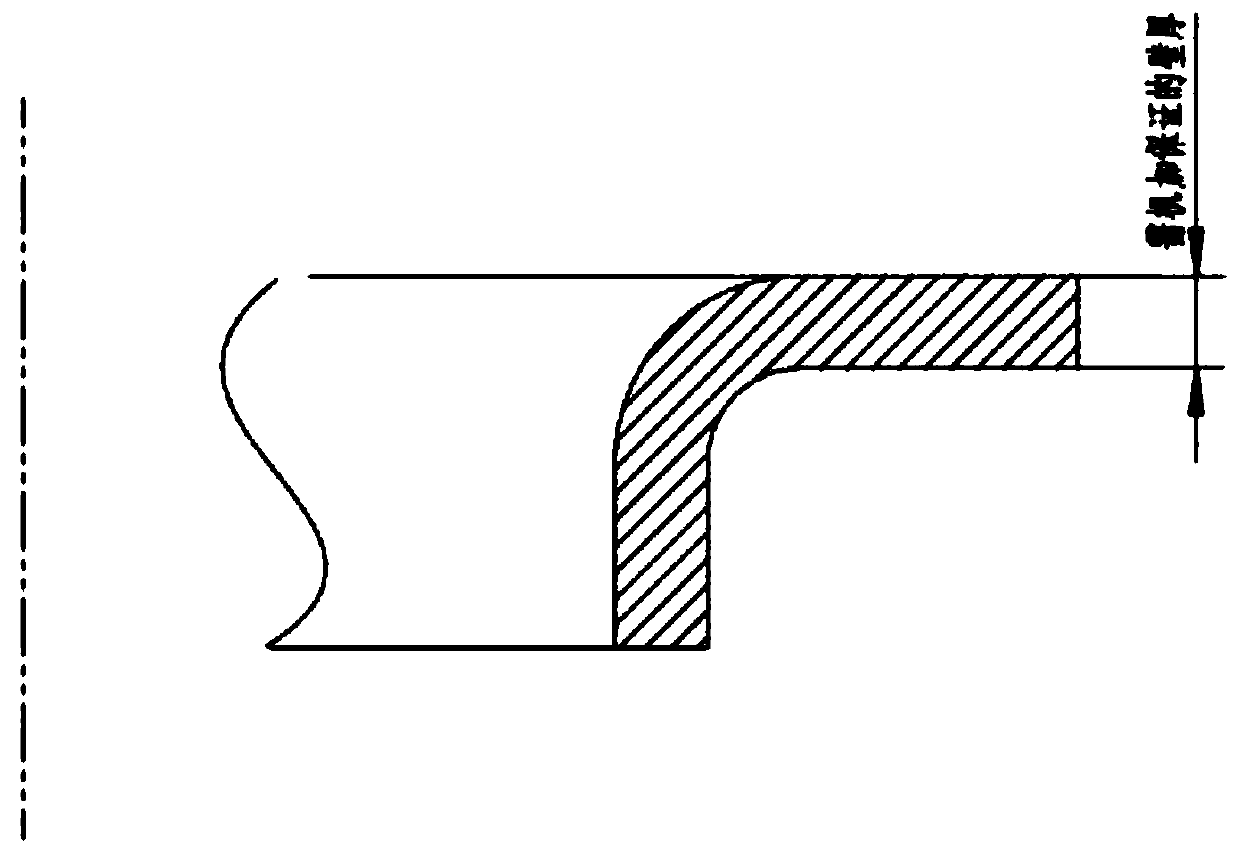

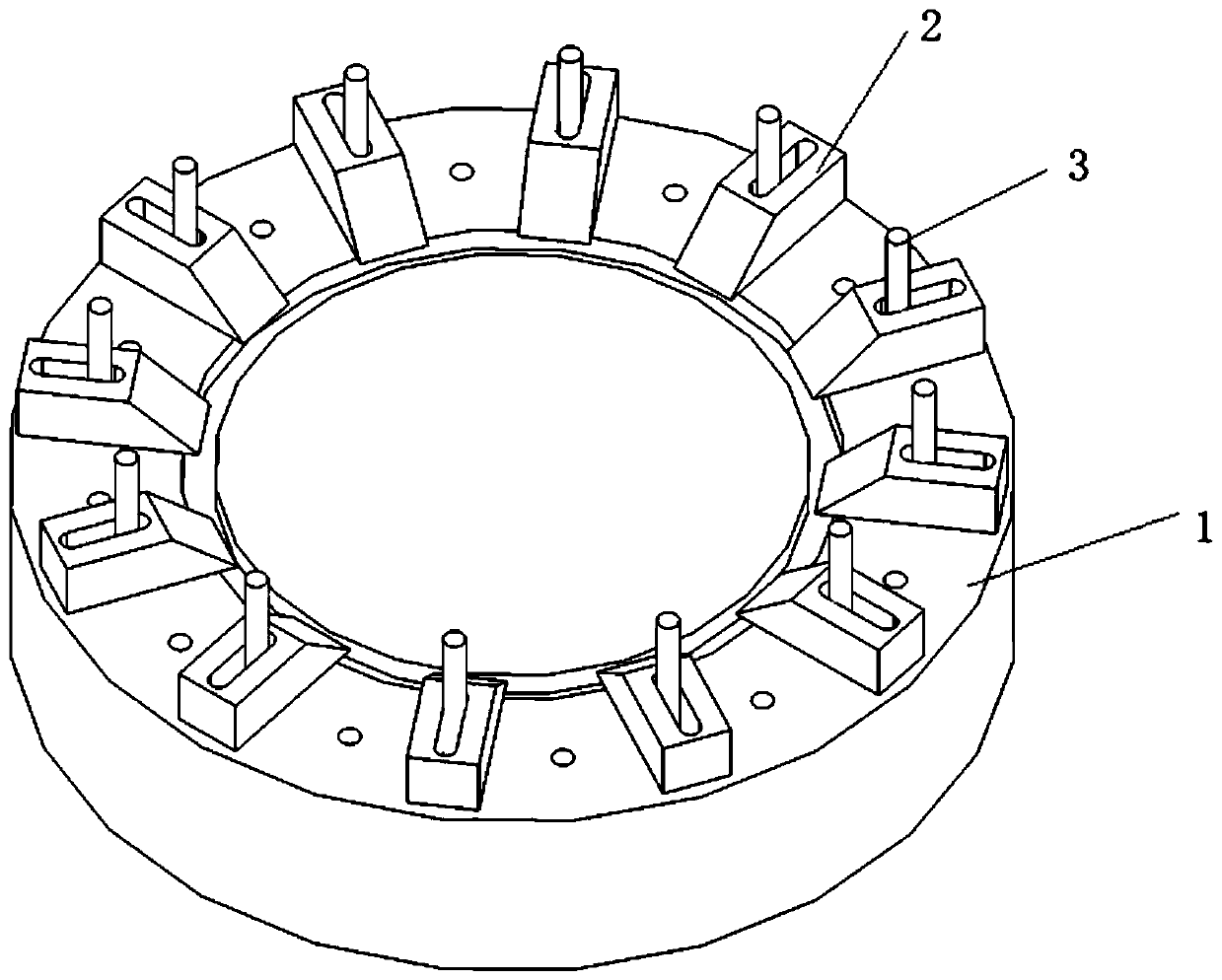

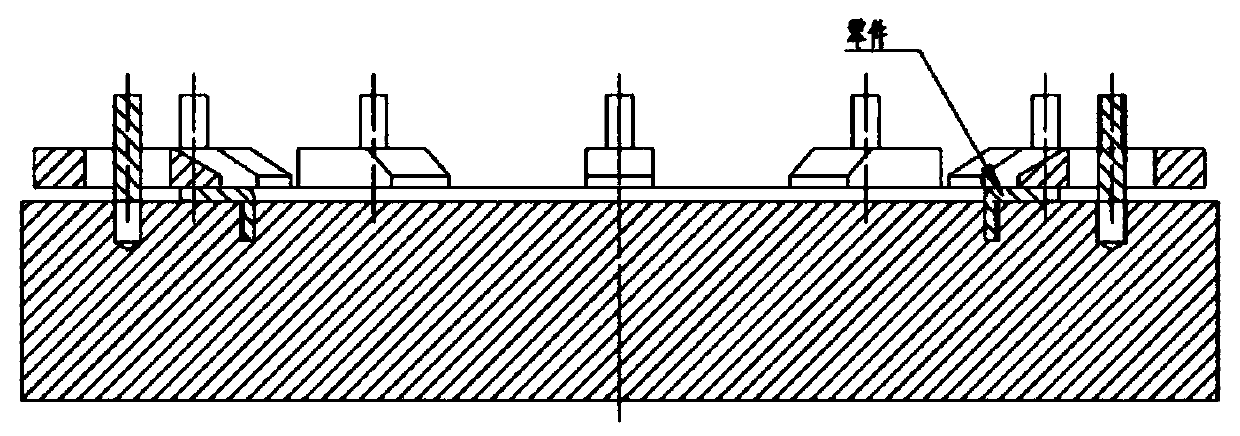

[0029] Such as figure 2 and image 3 , the device used to ensure the wall thickness of sheet metal forming thin-walled circular parts includes a ring body 1, a pressure plate 2, and a screw rod 3; wherein the ring body 1 is the main component: there is an annular groove on the ring body 1, and the cross-sectional shape of the annular groove is according to the specific Part design (specifically, the non-machining part of sheet metal formed thin-walled ring parts) is mainly used to tighten the inner circle of the thin-walled ring part, and on the other hand, it is used to place the main body of the ring part to ensure that the end surface of the part is in full contact with the ring body 1 ( image 3 ), and the flatness of the ring body 1 is required to be better; there are 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com