Processing method to prevent deformation of mounting edge of high-precision large-scale titanium alloy thin-walled casting

A technology of thin-walled castings and processing methods, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of no processing technology, achieve the effects of reducing cutting heat, reducing machine stress, and solving deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

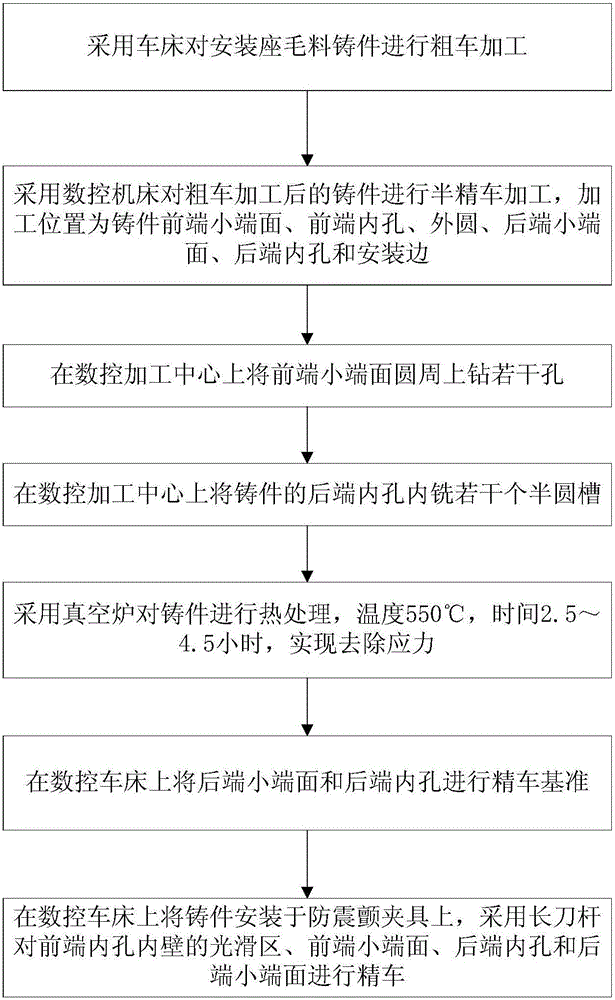

[0021] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

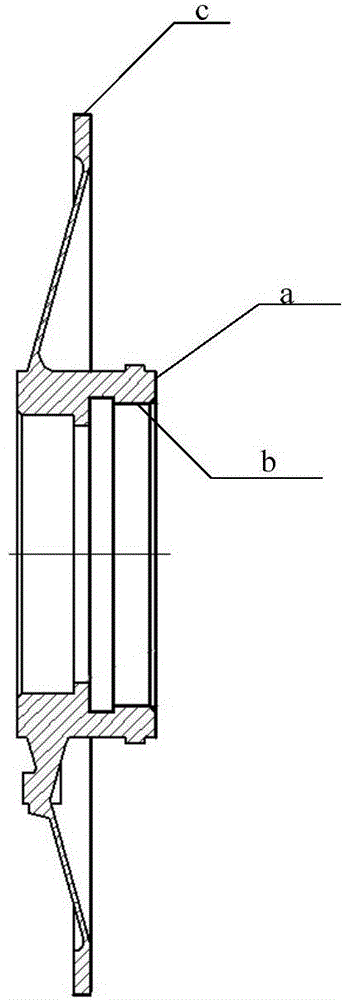

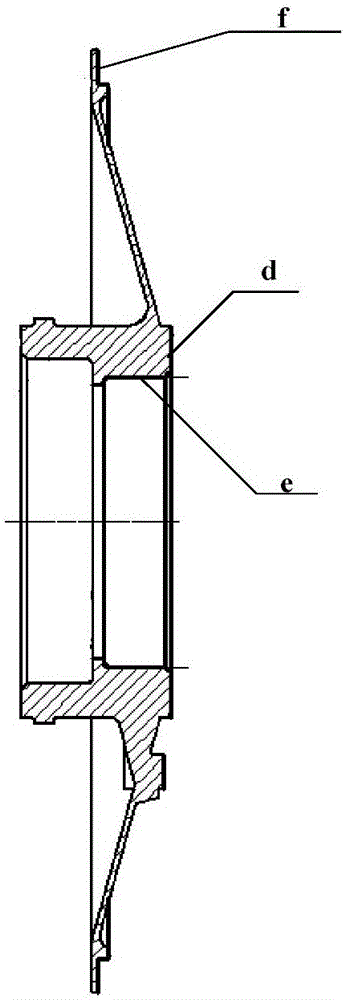

[0022] In the embodiment of the present invention, the mounting seat is a large thin-walled titanium alloy part with a complex structure, with a maximum diameter of φ560, which not only requires extremely high dimensional accuracy and shape and position tolerance, but also has 55 uniformly distributed φ6 holes on the periphery of the φ184 inner hole. Small holes, the wall thickness of the thinnest part is only 3mm, and the total length is 85. Bore size for mounting bearings Inner hole size for installing graphite ring The coaxiality between the two inner holes is 0.03, the runout of the bearing rib to the inner hole is 0.015, and the reference of the outer circle of the inner hole of the bearing is The coaxiality is 0.03, and the outer circle reference of the installation side The beat is 0.03.

[0023] A processing method for preventing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com