Patents

Literature

109results about How to "Guaranteed Design Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

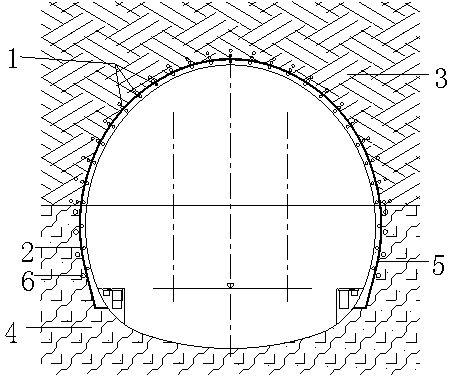

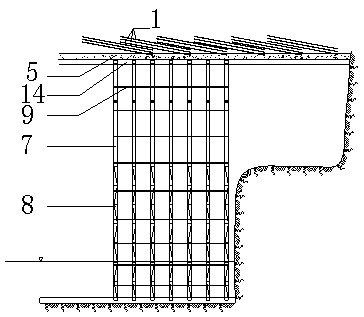

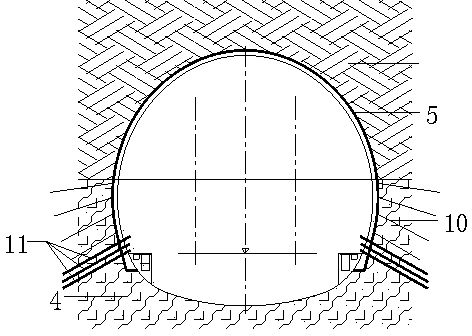

Preliminary bracing construction method for tunnel with surrounding rocks containing collapsible loess and soft rocks

InactiveCN103410527AEasy to operateEconomically reasonableUnderground chambersTunnel liningShotcreteMesh reinforcement

The invention discloses a preliminary bracing construction method for a tunnel with surrounding rocks containing collapsible loess and soft rocks. The method includes the following steps that a plurality of layers of advanced pipe sheds are arranged on a collapsible loess layer, and a single layer of advanced pipe shed is arranged on a soft rock layer; after the advanced pipe shed is set up, a working face is closed through sprayed concrete, a system anchor bolt is arranged on the soft rock layer, a foot locking small guide pipe is arranged at the arch springing position of the tunnel, and grouting is conducted on the rocks through permeation of the system anchor bolt and the foot locking small guide pipe; a pre-fabricated reinforcing mesh is paved on a concrete initial spraying layer formed by concrete initial spraying in a fluctuation mode, and a reinforcing mesh arranged at the collapsible loess layer is encrypted; a steel arch support is set on the collapsible loess layer, a reinforcing steel bar grid is set up at the soft rock layer, and the connecting position of the reinforcing steel bar grid and the steel arch support is welded; repeated spraying is conducted by adopting concrete spraying, and construction of tunnel preliminary bracing is finished. By means of the method, stress releasing and deformation coordination of two layers of surrounding rocks can be well controlled, operability is good, construction cost is low, and the safety is good.

Owner:CENT SOUTH UNIV

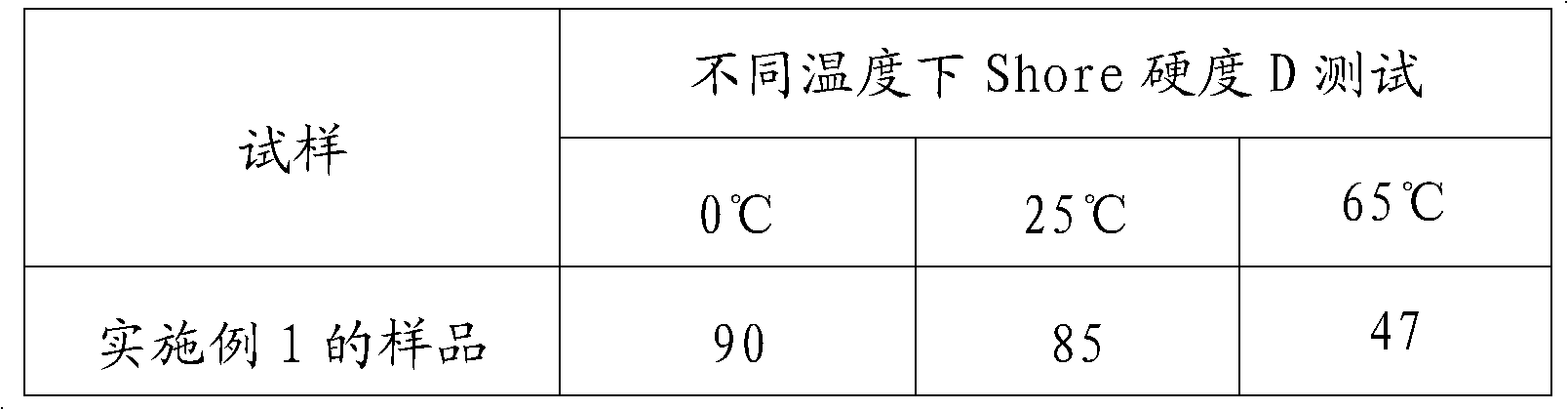

Flexibility-regulable epoxy resin adhesive and preparation method thereof

InactiveCN102604577AImprove toughnessSolve the problem of high brittleness and weak impact resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxySilanes

The invention relates to a flexibility-regulable epoxy resin adhesive, which consists of component A and component B; the component A consists of the following materials in percentage by weight: 30 to 60 percent of toughened epoxy resin, 1 to 5 percent of thinning agent, 30 to 60 percent of filler, 0 to 1 percent of silane active coupling agent, 0 to 1 percent of dye, 1 to 10 percent of toughener and 0 to 1 percent of defoaming agent; and the component B consists of the following materials in percentage by weight: 40 to 99 percent of curing agent, 0 to 60 percent of filler, 0 to 1 percent of dye, 0 to 10 percent of toughener and 0 to 1 percent of defoaming agent. The invention solves the problems of cured epoxy resin, i.e. high brittleness and weak impact resistance, the modulus is not lost on the basis of toughening, moreover, the bonding reliability of the cured system is high, and the application range is wide.

Owner:YANTAI DARBOND TECH

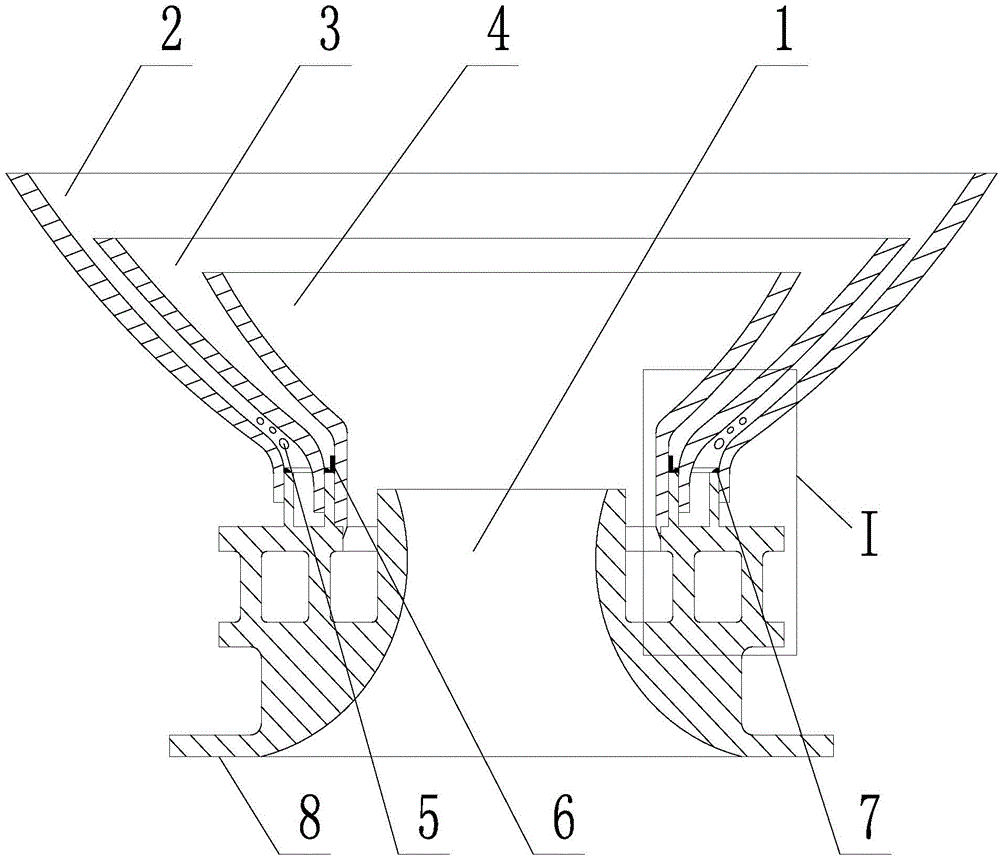

Flame tube head assembly brazing method

ActiveCN104475909APrevent oxidationStrong maneuverabilityContinuous combustion chamberHeating appliancesEngineeringBrazing

The invention discloses a flame tube head assembly brazing method and belongs to the technical field of aero-engine part manufacturing. In a brazing method of a traditional flame tube head assembly, an assembly substrate at a positioning welding point is oxidized due to the fact that a tube front section and a splash pan are positioned through argon arc welding, so that during brazing, brazing filter metal cannot moisten the substrate at the positioning welding point, the brazing seam is not continuous, and a design requirement of a continuous brazing seam cannot be achieved, and after brazing, a cold air hole is blocked by the brazing filter metal, the brazed rate between a sleeve and a swirler cannot achieve a design requirement of more than 80%. The flame tube head assembly brazing method has the advantages that the assembly substrate at the positioning welding point is avoided from being oxidized due to positioning through energy storage spot welding, enabling the paste brazing filter metal to moisten the substrate at the positioning welding point and guaranteeing the continuous brazing seam design requirement; enabling a to-be-welded position on the internal side of the sleeve to satisfy the brazed rate requirement and avoiding the brazing filter metal blocking the cold air hole during the brazing process due to the fact that check soldering flux pains inside the cold air hole; the operability is strong and production costs are obviously reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

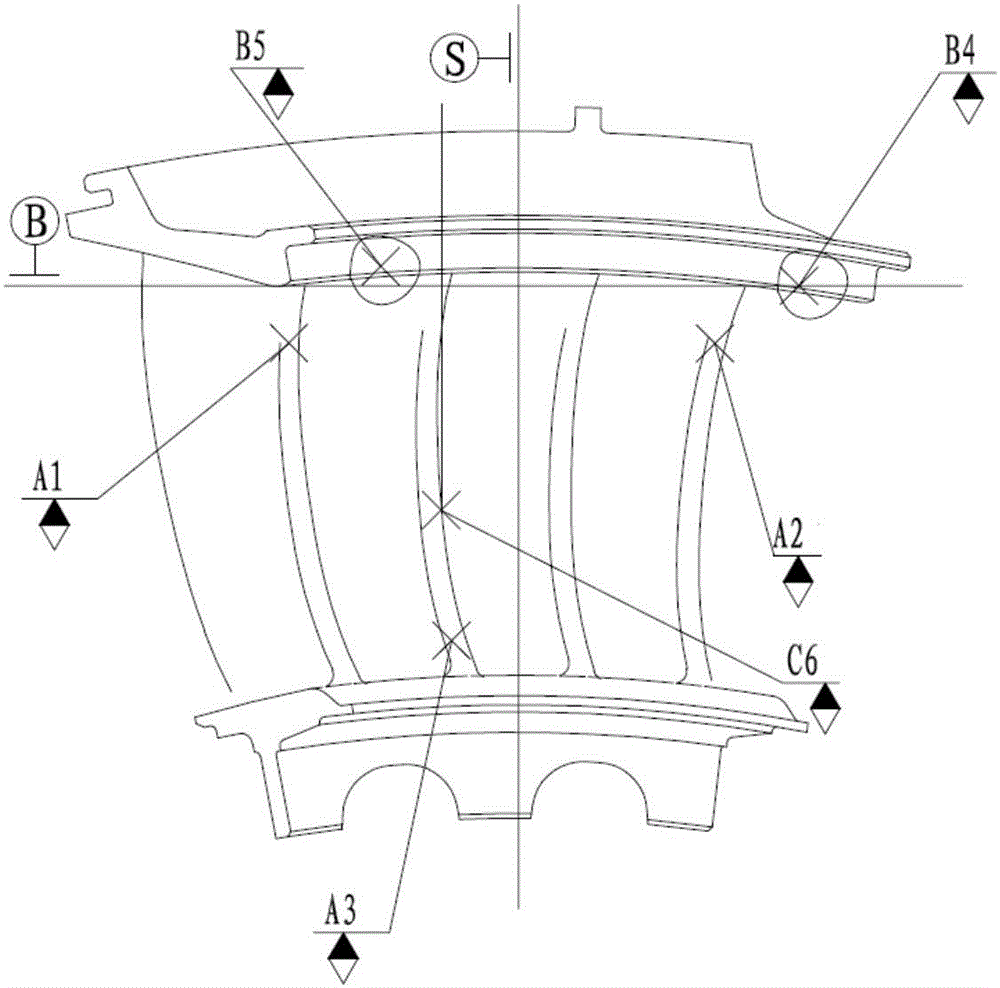

Machining process for low-pressure first-stage stationary blades of gas turbines

ActiveCN103028917AGuaranteed Design RequirementsGuaranteed assembly qualityWire cuttingRadial surface

The invention discloses a machining process for low-pressure first-stage stationary blades of gas turbines, which belongs to the technical field of blade machining. The machining process for low-pressure first-stage stationary blades of gas turbines includes: step 1: a Z-shaped blade blank is formed by wire cutting; step 2: auxiliary heads are respectively welded on the inner and outer rings of the blade; step 3: rough machining is carried out; step 4: semifinishing is carried out; step 5: four times of finish machining are carried out on the air passage part, and finish machining is carried out on the radial face of the blade; step 6: the wire cutting method is adopted to remove the auxiliary heads of the outer and inner rings, and the inner ring surface, the outer ring surface and the inner radial surface of the blade are then machined. Under the premise of guaranteeing product design requirements and assembly quality, the machining process for low-pressure first-stage stationary blades of gas turbines strive for strict process control, a complete machining process, simple machining operation, integrated difficult point machining and critical control on key factors, thus effectively guaranteeing the quality of products and increasing the production efficiency.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

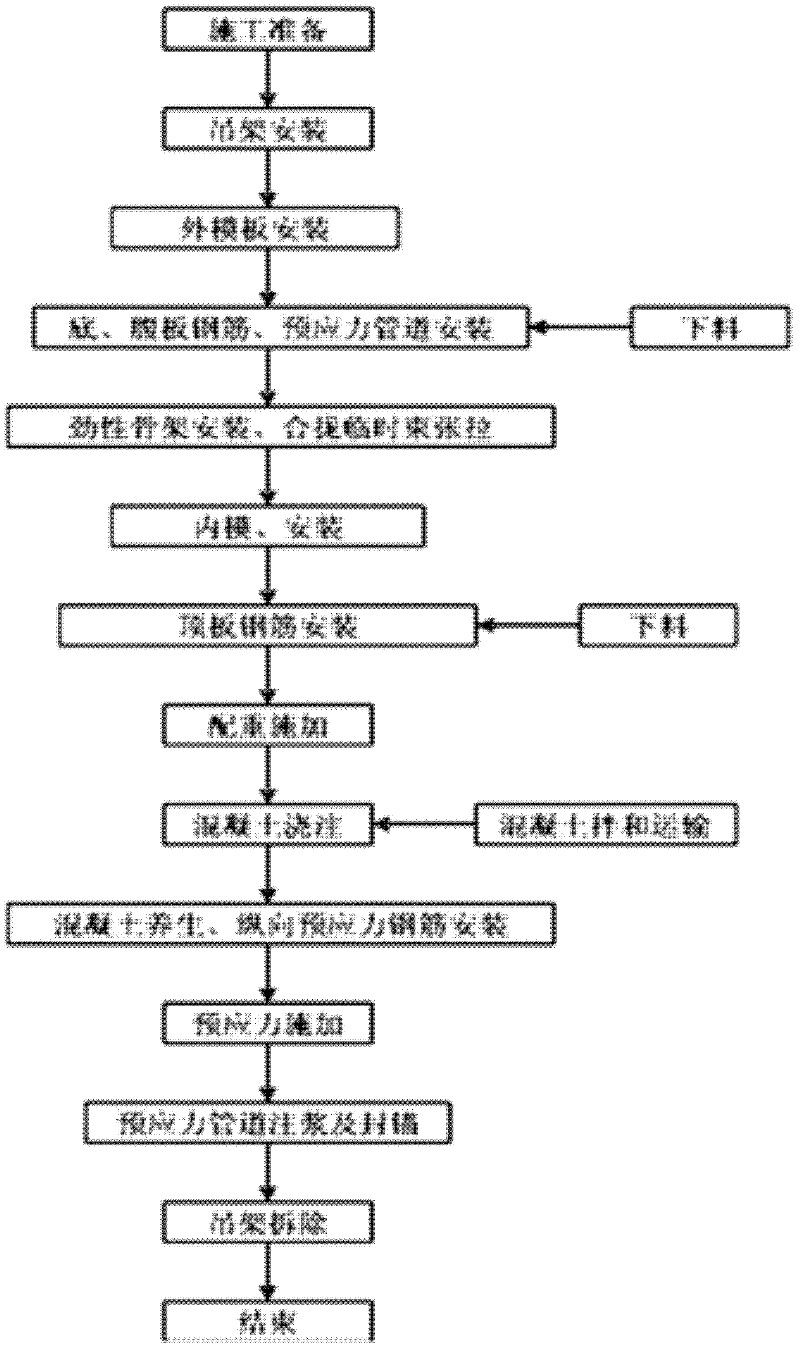

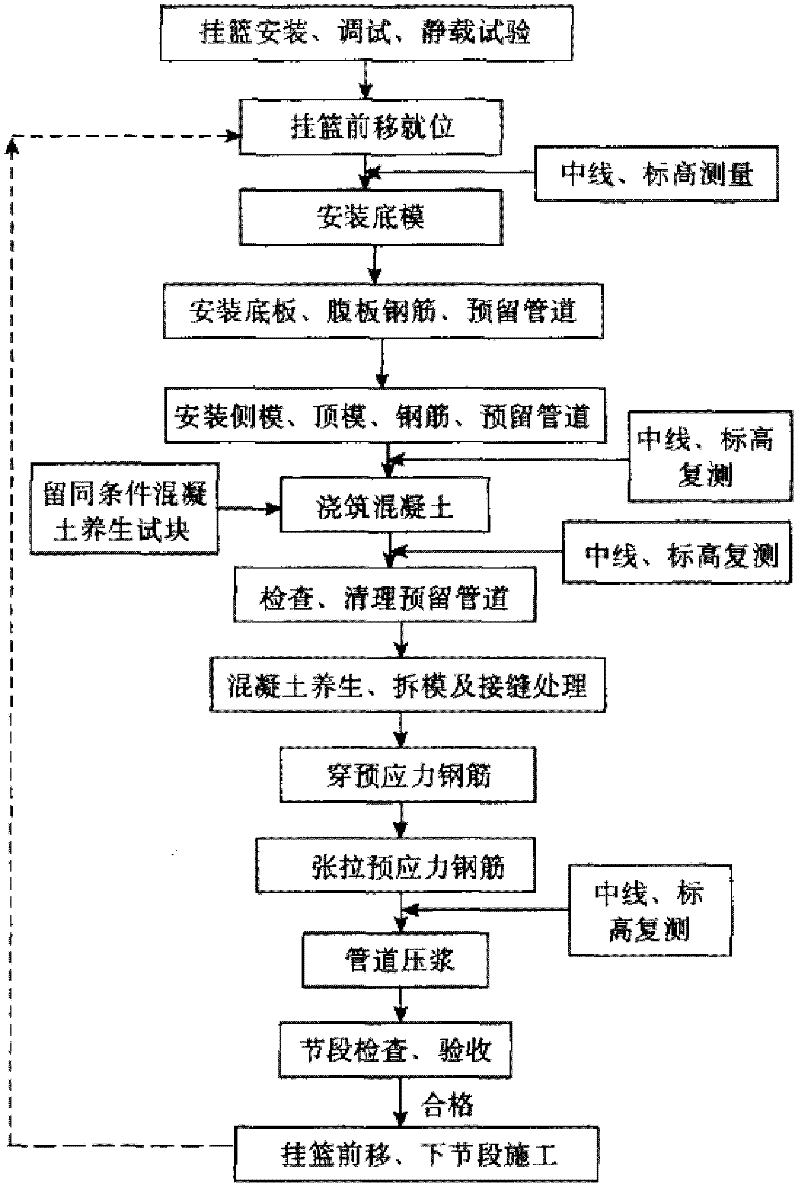

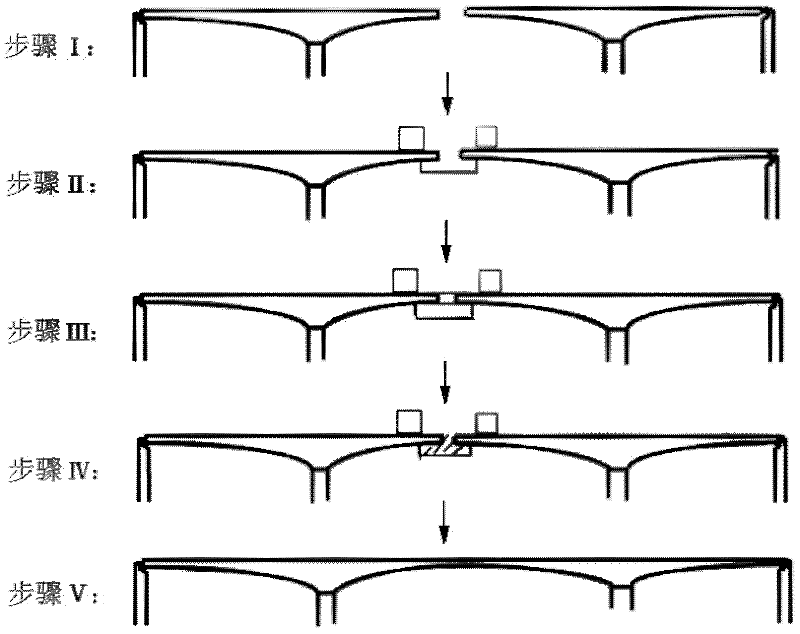

Construction method for midspan closure segment of longspan continuous rigid frame bridge

The invention discloses a construction method for the midspan closure segment of a longspan continuous rigid frame bridge, which is characterized by comprising the following steps: (a) adopting a hanging basket cantilever pouring method, and constructing a cantilever beam section in front of the closure segment; (b) disassembling the hanging basket, manufacturing components disassembled from the hanging basket into a cradle, and installing the cradle on the two beam sections of the midspan closure; (c) carrying out equivalent counterweight; and (d) supporting the beam. The traditional hanging basket is utilized in the closure process instead of manufacturing the cradle again. After the traditional hanging basket system is disassembled and combined again, the closure cradle is formed, thereby guaranteeing the design requirement, improving the working efficiency and saving fund. The construction method for the midspan closure segment is suitable for constructing of the same type of suspended irrigation closure. The traditional hanging basket is modified without additionally adding the cradle, the self weight is lightened, and the problem that the upper limit requirement of the total amount of the additional loading amount of the closure segment is exceeded if the hanging basket is directly used for closure.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

Machining method of wave spring

The invention provides a machining method of a wave spring. A strip the same as a finished wave spring in thickness, length and width is obtained, a remelting layer of the strip is polished out through crocus paper, and a planar wave spring blank is made; the wave spring blank is fixed in a tool at room temperature and is subjected to cooling sizing; vacuum sizing processing is conducted, wherein hot sizing processing is conducted in an aging sizing mode, a clamp is detached, then the part shape is reserved, and forming processing of the spring is completed; the part is preformed through the fixing function of technological equipment, then elastic deformation stress is eliminated through aging hot processing, and the accurate machining shape of the part is reserved. It is ensured that the geometrical size and waveform of the wave spring meet the design requirements; the machining problem of strip-shaped wave springs is solved; it is ensured that the spring meets the design requirements.

Owner:AECC AVIATION POWER CO LTD

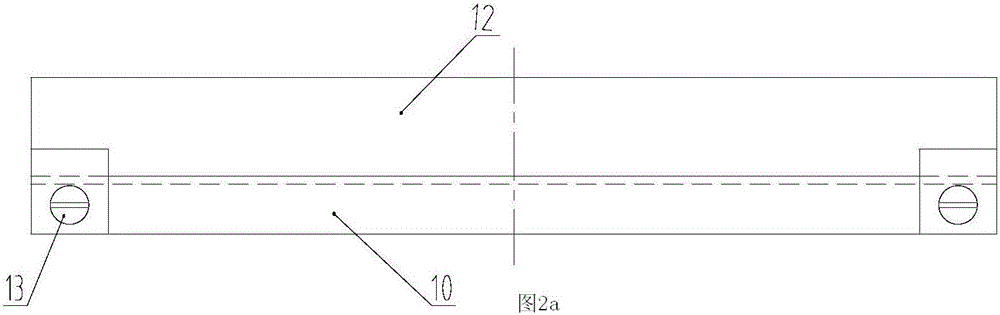

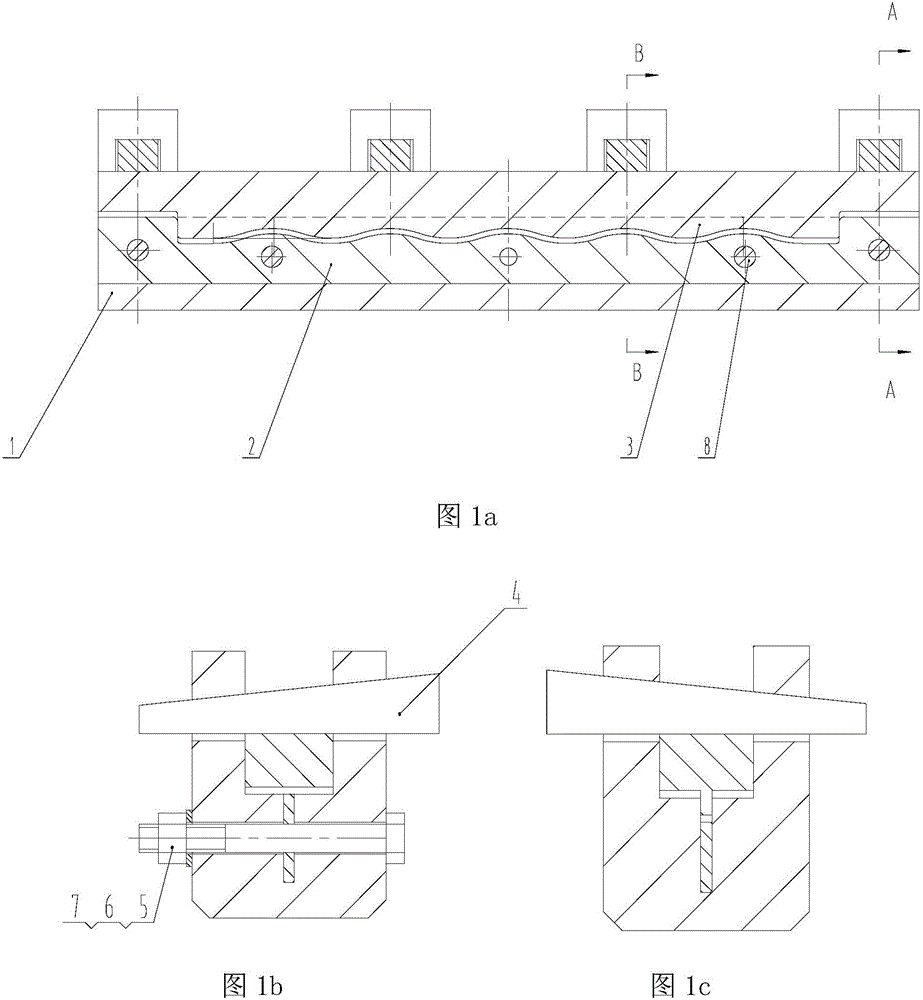

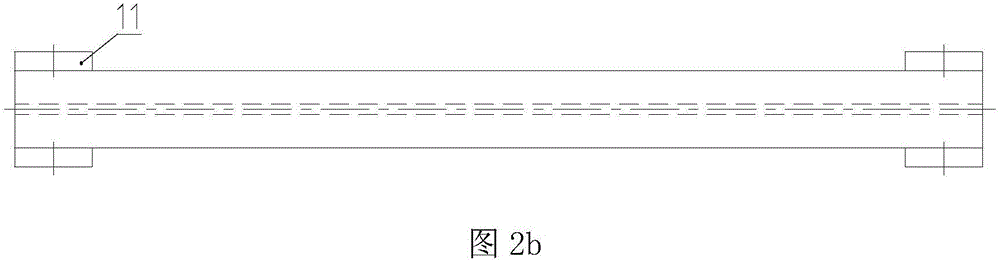

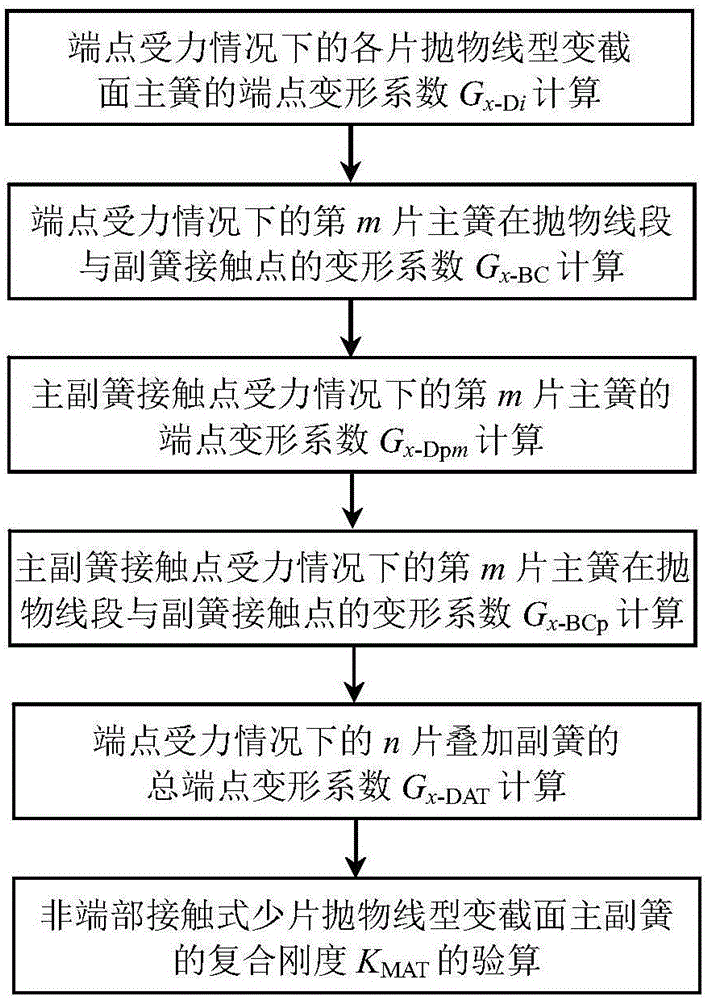

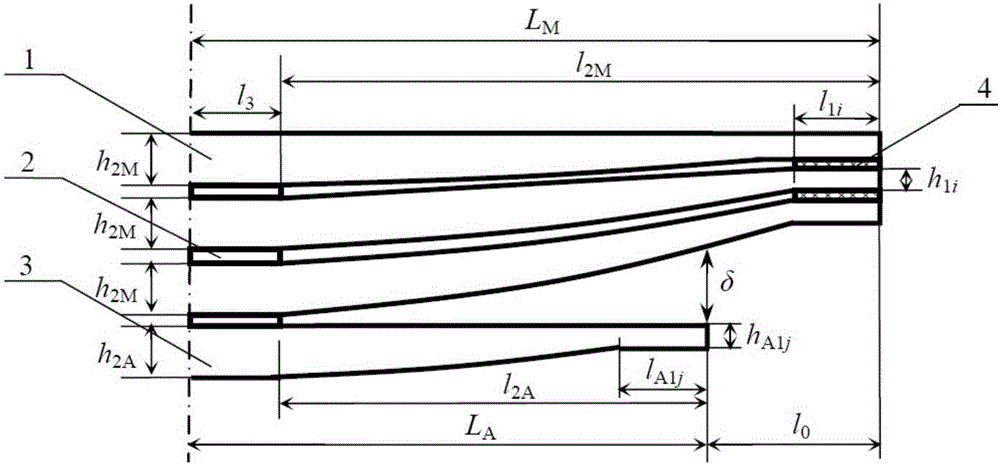

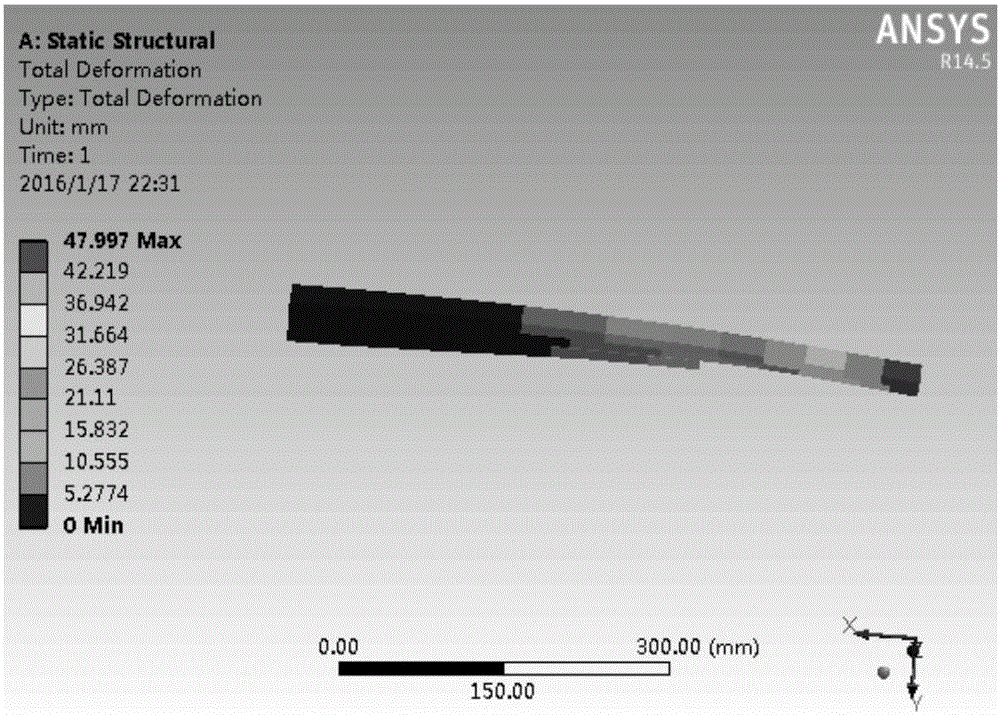

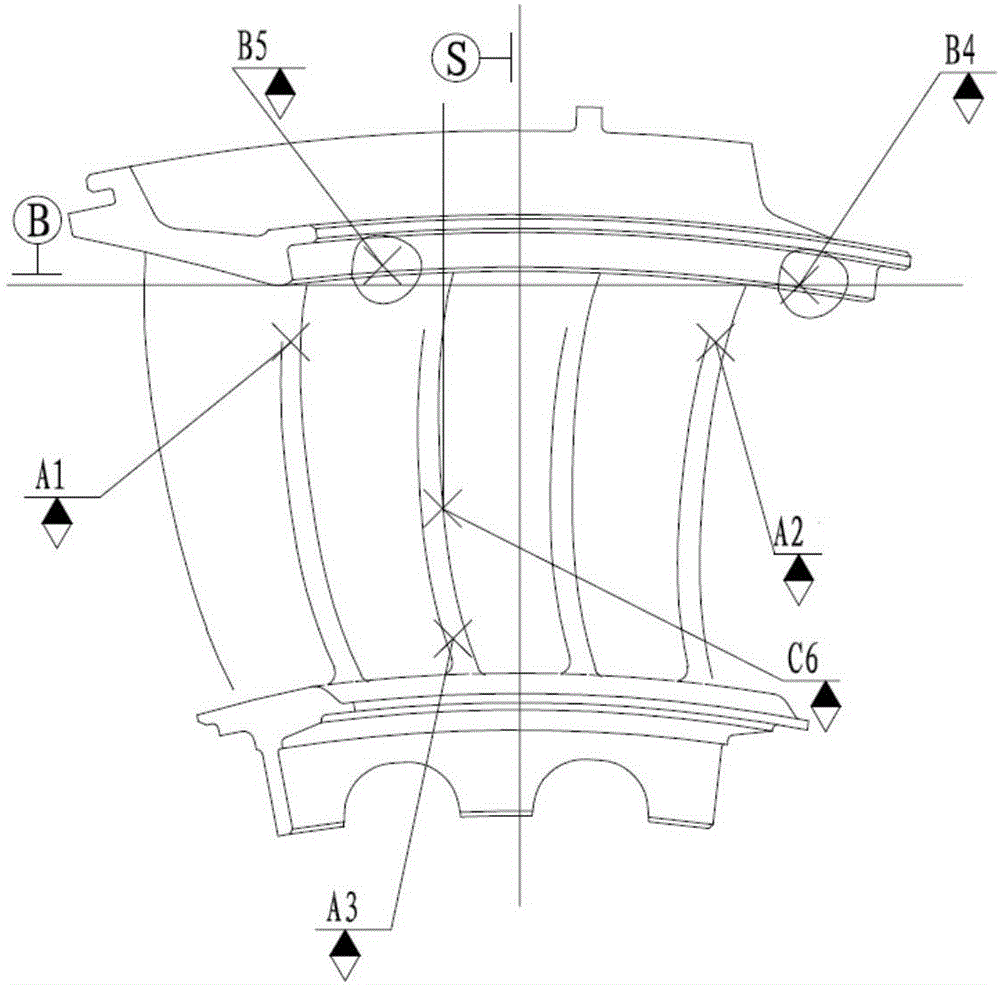

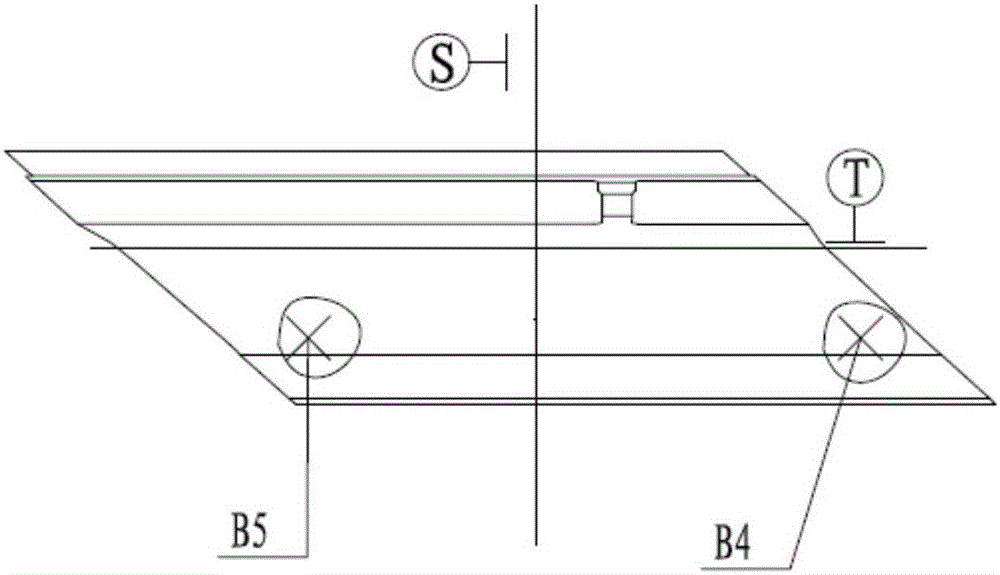

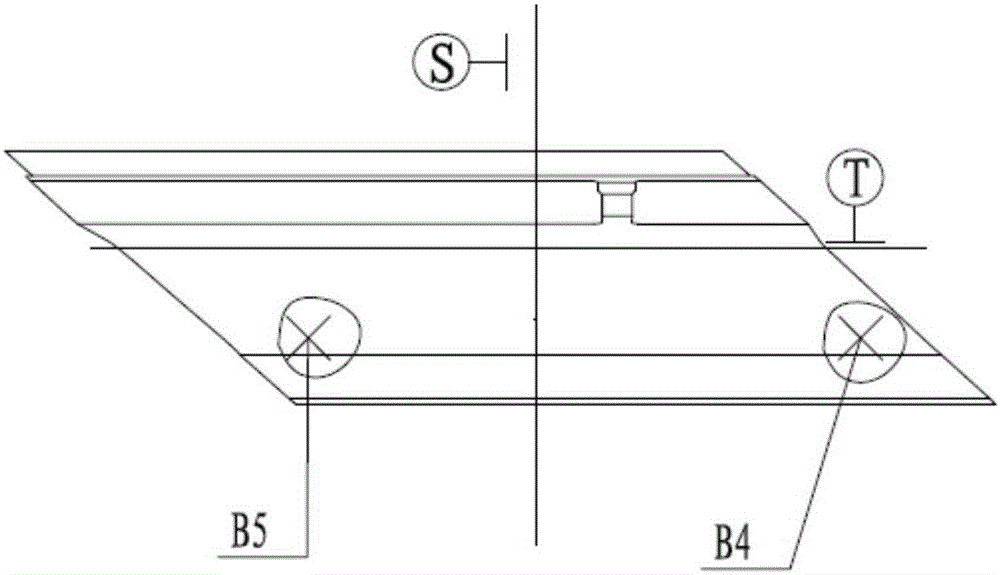

Checking computation method for composite stiffness of non-end contact type few-leaf parabolic main and auxiliary spring

InactiveCN105956223AAccurate Composite Stiffness Check ValueReliable Composite Stiffness Check ValueGeometric CADDesign optimisation/simulationEngineeringContact type

Belonging to the technical field of suspension steel plate springs, the invention relates to a checking computation method for the composite stiffness of non-end contact type few-leaf parabolic main and auxiliary spring. According to the structural parameter and elastic modulus of each main spring leaf and each auxiliary spring leaf in the non-end contact type few-leaf parabolic tapered main and auxiliary spring, precise checking computation of the composite stiffness of the non-end contact type few-leaf parabolic tapered main and auxiliary spring carried out. By means of examples and ANSYS simulation verification, the checking computation method for composite stiffness of the non-end contact type few-leaf parabolic tapered main and auxiliary spring provided by the invention is correct, thus providing a reliable checking computation method for composite stiffness checking computation. The method can acquire an accurate and reliable composite stiffness checking calculation value of the non-end contact type few-leaf parabolic tapered main and auxiliary spring, ensures that the product can meet a design required value of a suspension for composite stiffness, thus enhancing the product design level and performance and vehicle travel riding comfort. At the same time, the method also can reduce the design and experiment test cost, and speeds up product development rate.

Owner:周长城

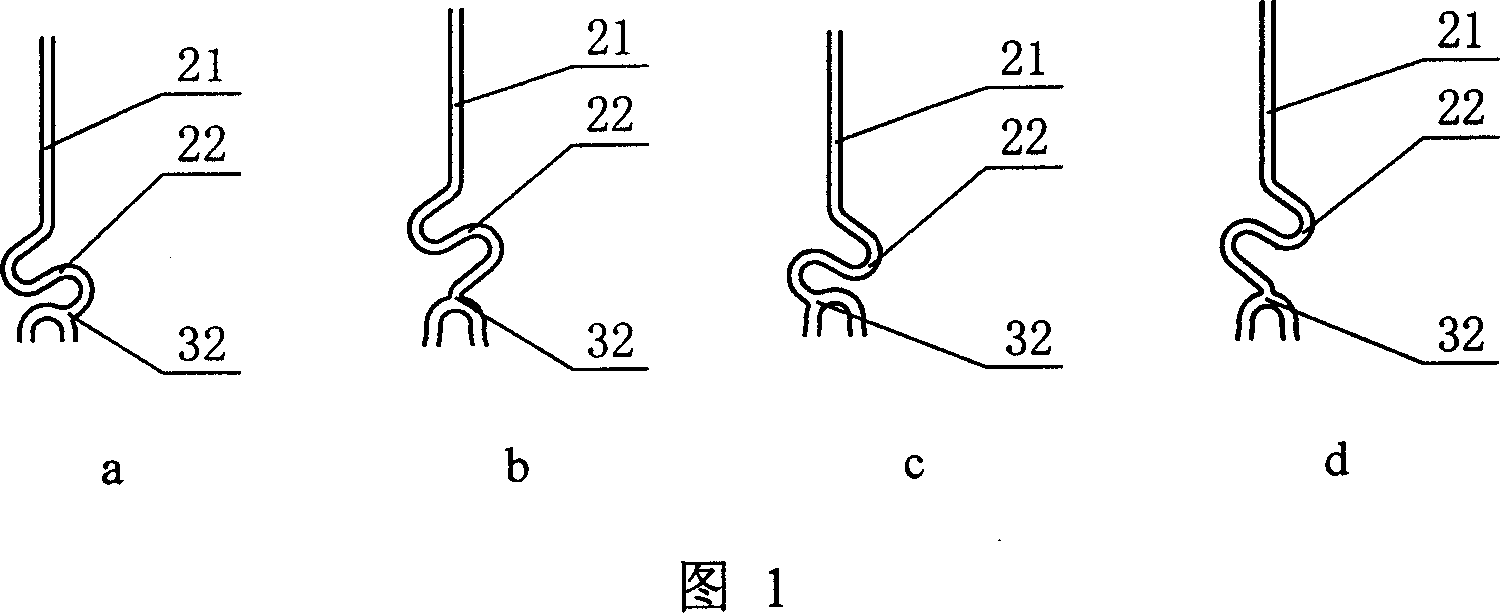

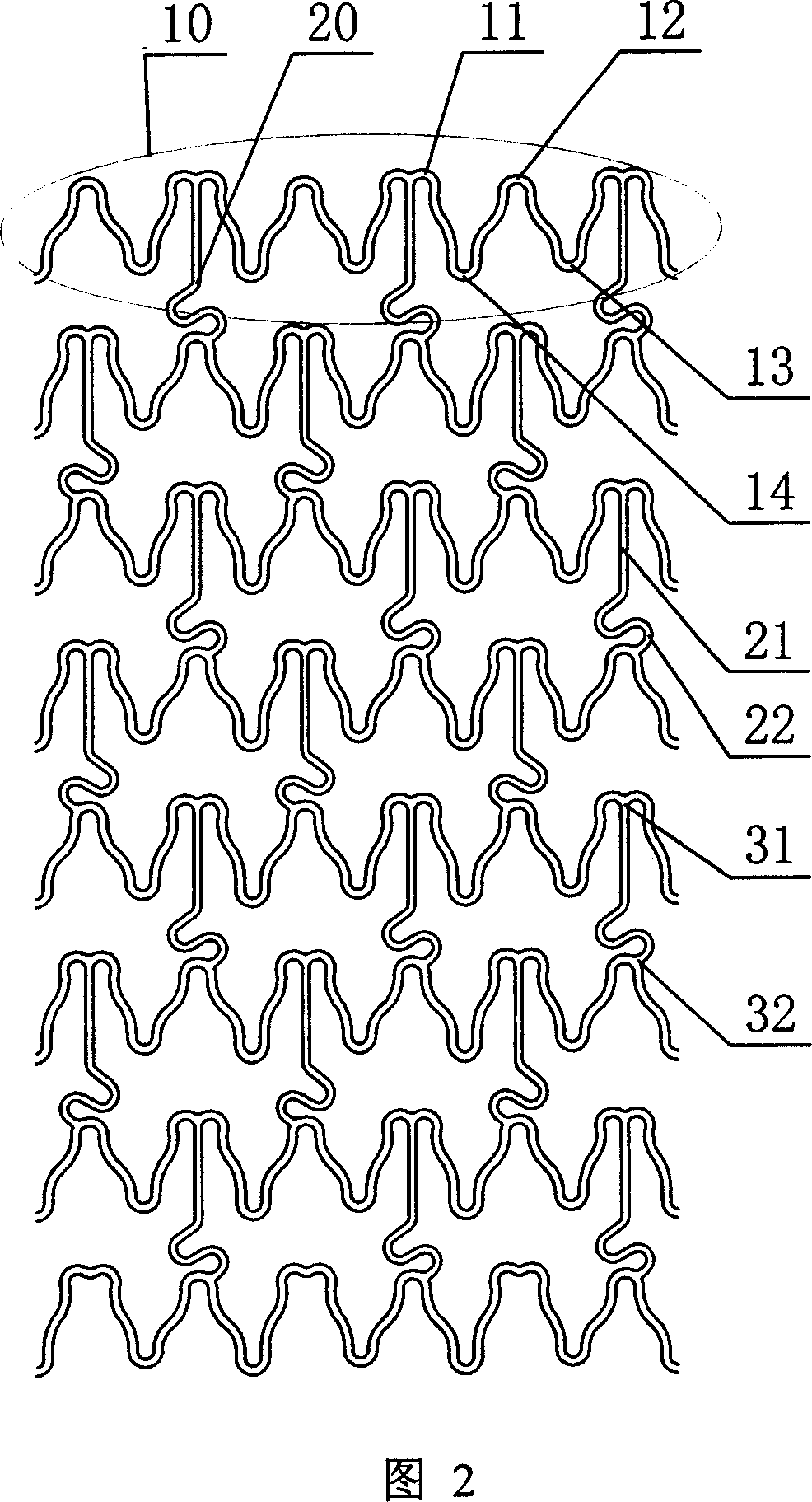

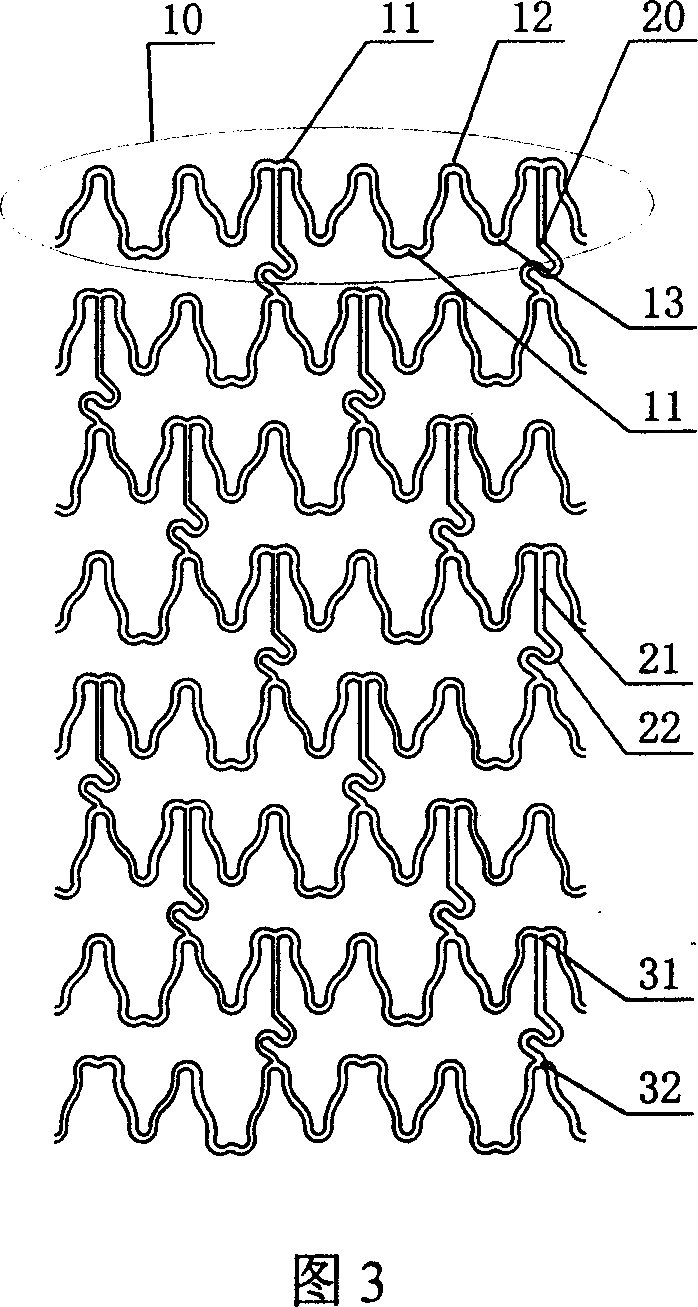

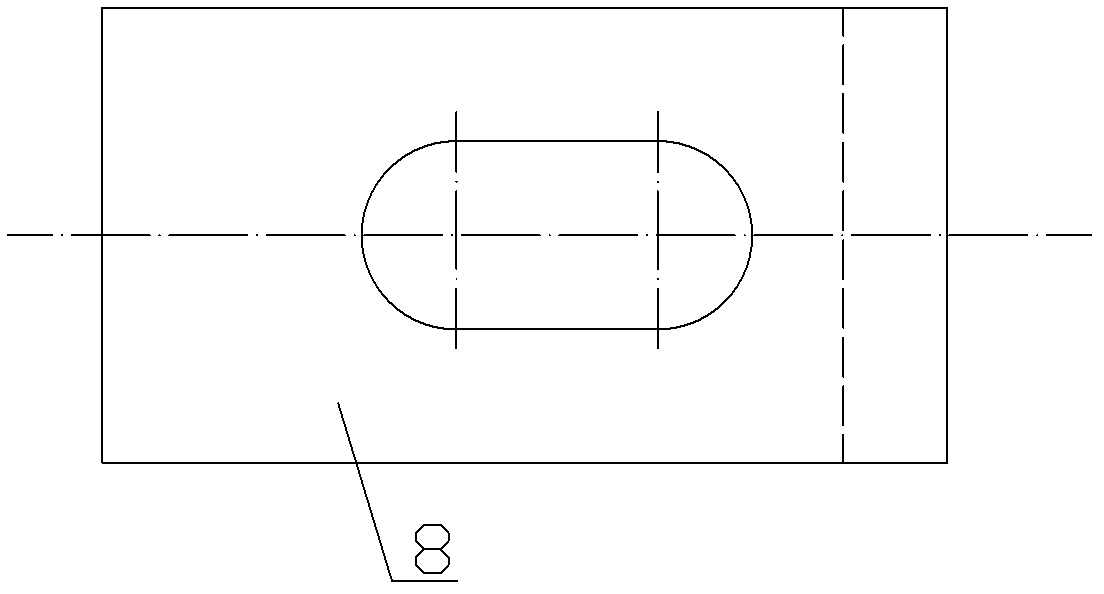

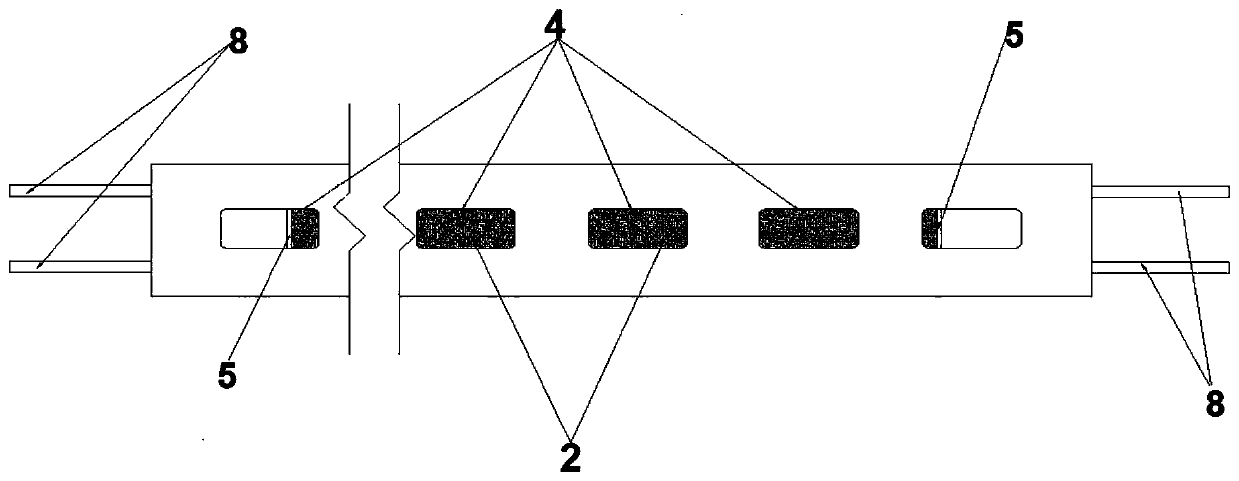

Blood vessel support bracket with little tissue prolapsus after implantation

InactiveCN1923154AEvenly distributedReduce prolapseStentsBlood vesselsBlood vessel occlusionReticular formation

The invention relates to a blood vessel support with less drop organism after being planted into organism, used to treat blood vessel block in puncture shaping surgery. Wherein, said support can be used in heart blood vessel, and outer blood vessels, via thin micro tube and laser to be carved into network structure; and the invention is formed by several groups of wave support rings (10) connected by connecting rods (20); each support ring (10) is formed by 2-5 groups of unit waves; nearby support rings (10) are connected by 2-10 connecting rods; the invention can avoid the support rod interfere the clamping and expanding, to improve flexibility, and the drug coat will not form web and the drug density will be uniform.

Owner:SOUTHEAST UNIV

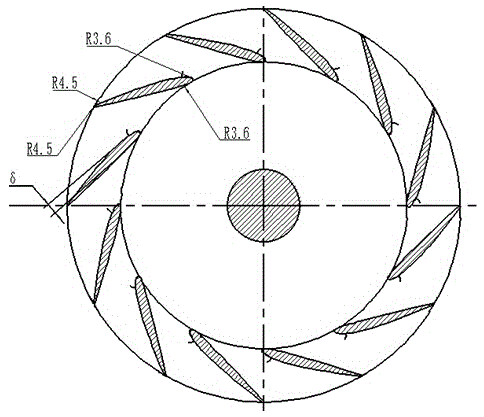

Process method for reducing corner-cleaning milling vibration of root part of integral closed impeller

InactiveCN104588750ARealize the improvement of manufacturing processGuarantee product qualityMilling cuttersWorkpiecesImpellerMilling cutter

The invention relates to a process method for reducing the corner-cleaning milling vibration of the root part of an integral closed impeller. According to the process method, milling processing is carried out on parts of various metal integral closed impeller systems, complex curved surface integral impellers and deep cavity curved surface system structures on five-shaft linked processing central equipment by adopting a rigid alloy milling cutter containing 0.2-0.8 micrometer superfine or extremely fine particles; and the process method is realized through the selection on a cutter structure, a cutter cutting locus, a cutter feeding method, a feeding direction, a cutting depth and a cutter shaft vector parameter, the setting of the processing allowance of rough processing and fine processing and the adoption of parameters. The process method disclosed by the invention can be used for carrying out the milling processing on the parts of the integral closed impeller systems, the complex curved surface integral impellers and the complex deep cavity curved surface system structures, thereby realizing the enhancement of a manufacturing process of a complex structural system part, ensuring the requirements for quality, property and design of a product and enhancing the stability of product property.

Owner:SHANGHAI INST OF TECH

Polyester/recycled cotton/colored flax blended knitting yarn and processing method

The invention relates to a polyester / recycled cotton / colored flax blended knitting yarn. The polyester / recycled cotton / color jute blended knitting yarn is produced from raw materials, namely dyed flax fibers (colored flax), recycled fibers (recycled cotton of rotor spinning) and polyester short fibers, by virtue of a cotton spinning production process. The characteristics of the three types of fibers are thoroughly developed in the blended knitting yarn; the formed clothing fabric is concave-convex, blinking, novel in style, hygroscopic and air permeable, antibacterial and bacteriostatic and fashionable to wear, and thus is an ideal fabric to produce various fashion clothes; the yarn produced by use of the structure of the three raw materials fills in the domestic gaps. The production processes of various steps are optimized, the technical problems such as poor fineness, high rigidity, no natural crimp, poor cohesive force between fibers and poor length uniformity of the flax fibers, many flock impurities and poor spinnability of the rotor spinning recycled cotton, and the influence caused by difficult control of the blending ratio and the color of the three types of fibers on the yarn forming quality and the style of the yarn are solved; the technique is mature and at the advanced level domestically.

Owner:江阴市茂达棉纺厂有限公司

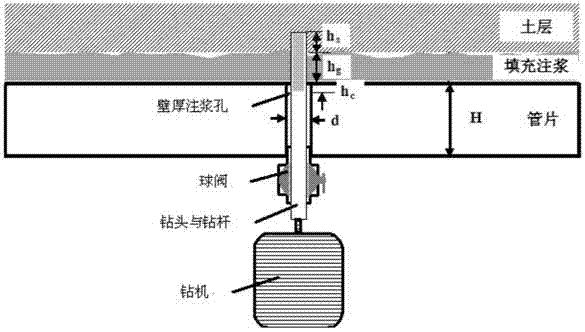

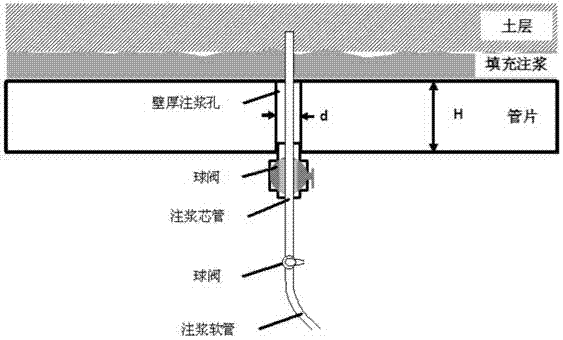

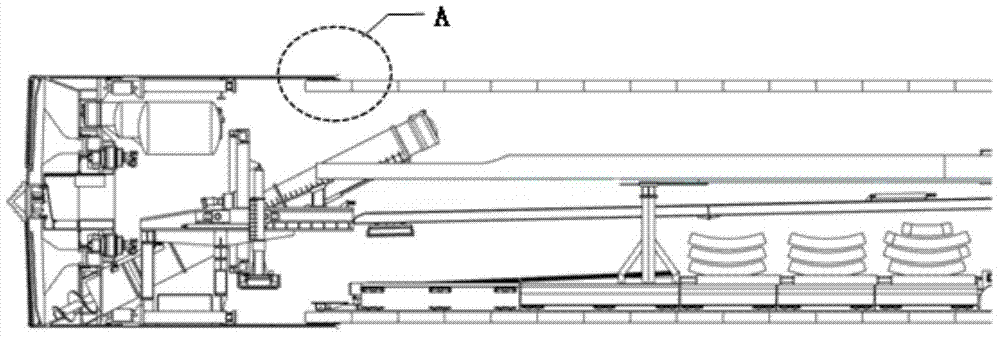

Shield tunnel grouting layer performance detection method

ActiveCN103573269ARealize detectionGuaranteed Design RequirementsTunnelsPetroleum engineeringDrill bit

The invention discloses a shield tunnel grouting layer performance detection method. The method comprises the following steps that firstly, a first ball valve is installed at a reserved grouting hole of a tunnel pipe piece, then a drill is positioned, and a drill bit and a drill rod are installed on the drill; the drill bit and the drill rod pass through the first ball valve, penetrate through the grouting hole, drill in the grouting layer, and continuously drill in the peripheral soil layer of a tunnel; the drill bit is taken out, and core samples are taken out and put into a sample cylinder; finally a grouting core pipe penetrates through the first ball valve and is inserted in a drill hole, and grouting, filling and blocking are conducted on the gap of the drilling position. According to the shield tunnel grouting layer performance detection method, the mode of drilling and taking out the core is used for achieving detection on samples extracted from the shield tunnel grouting layer, the detection to the shield tunnel grouting effect is achieved, and the purpose that a shield tunnel grouting layer reaches design requirements is ensured.

Owner:SHANGHAI JIANKE ENG CONSULTING

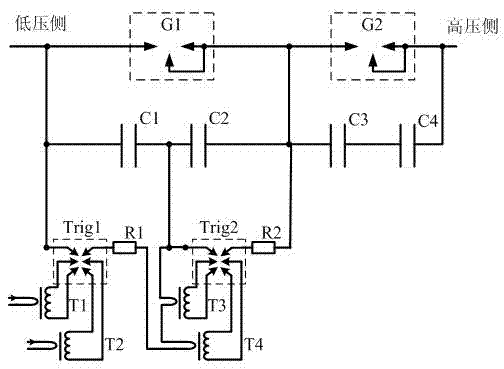

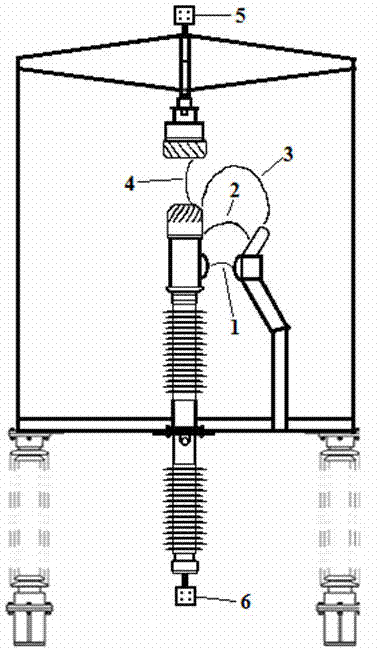

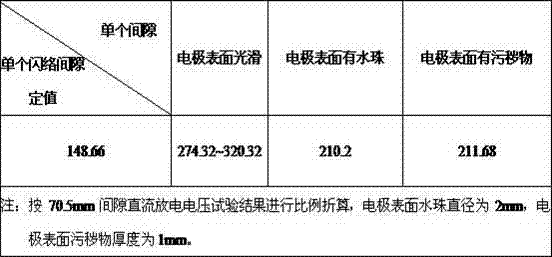

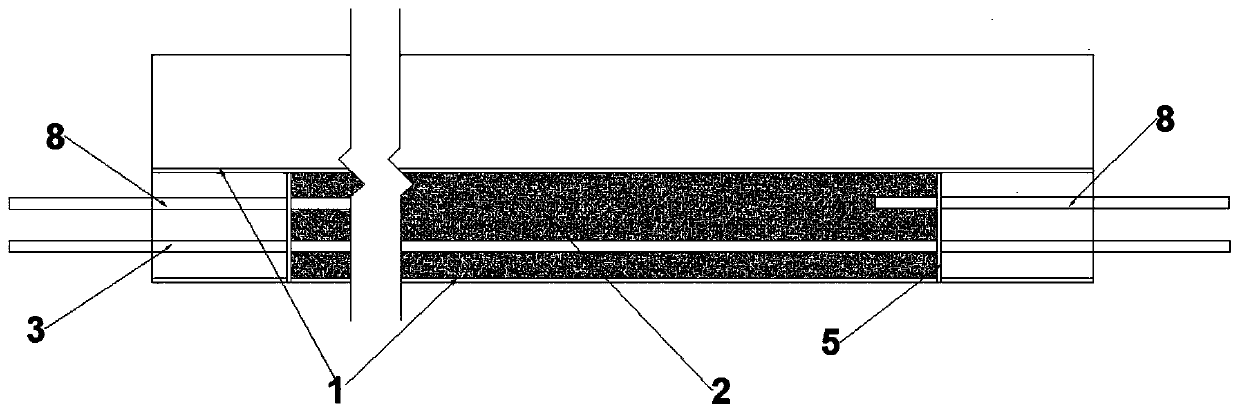

Self-triggering voltage setting method of spark gap of 500kV series compensation system

ActiveCN103579910AReduce false self-triggeringSolving self-triggering voltage dropsSpark gaps adjustmentGraphite electrodeCurrent limiting

The invention relates to a self-triggering voltage setting method of a spark gap of a 500kV series compensation system. The spark gap of the series compensation system structurally comprises a self-triggering main gap device G1, a self-triggering main gap device G2, a sealing gap device TRIG1, a sealing gap device TRIG2, a current limiting resistor R1, a current limiting resistor R2, a pulse transformer T1, a pulse transformer T3, a high-insulation pulse transformer T2, a high-insulation pulse transformer T4, a voltage-sharing capacitor C1, a voltage-sharing capacitor C2, a voltage-sharing capacitor C3 and a voltage-sharing capacitor C4. The self-triggering voltage setting method of the spark gap of the series compensation system includes the steps that the single flashover gap distance of the main gap device G1 and the single flashover gap distance of the main gap device G2 are adjusted according to 1.8p.u. series compensation rated voltages, and the flashover gap self-triggering voltages are made to be higher than the sum of the self-triggering voltages of two triggering gaps on a parallel branch. By means of the self-triggering voltage setting method of the spark gap of the 500kV series compensation system, self-triggering of the spark gap in the operating process of the series compensation system can be effectively reduced, the problem of self-triggering voltage reduction caused by dirt accumulation on the surface of a hemispherical flashover gap graphite electrode is solved, and thus the self-protection function of the self-triggering voltages of the series connection spark gap can be achieved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

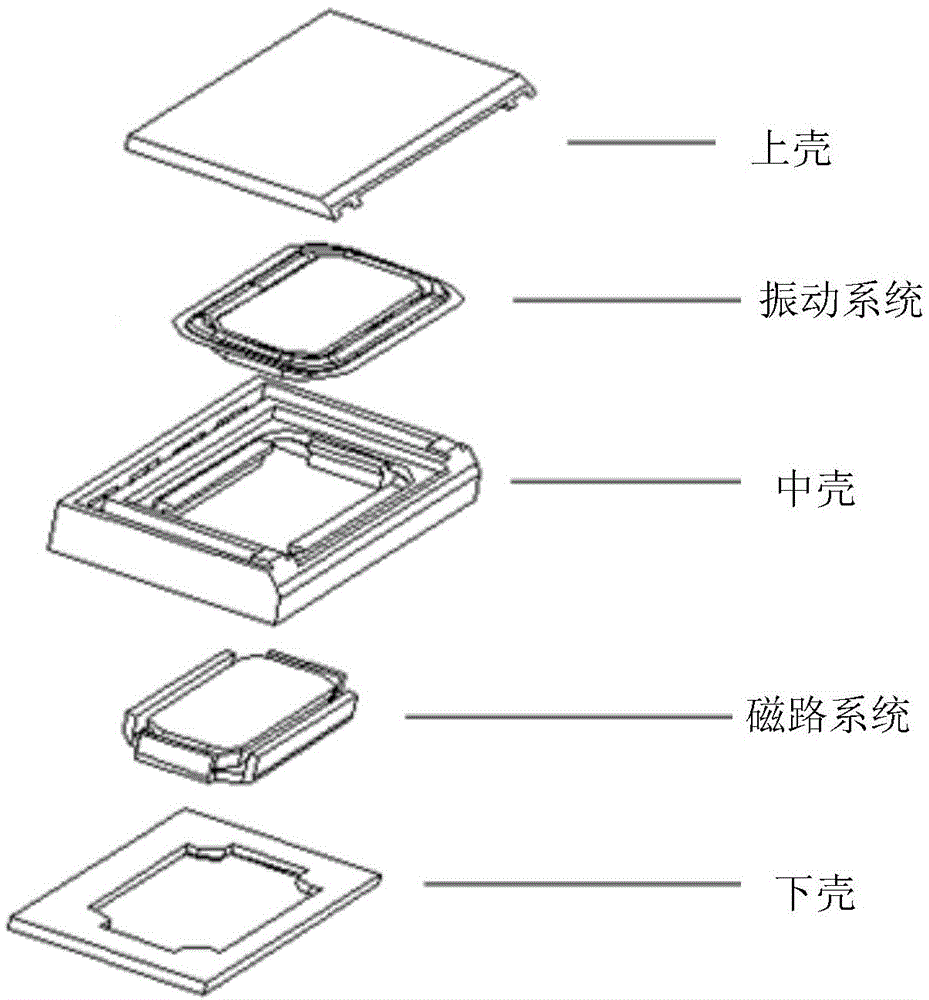

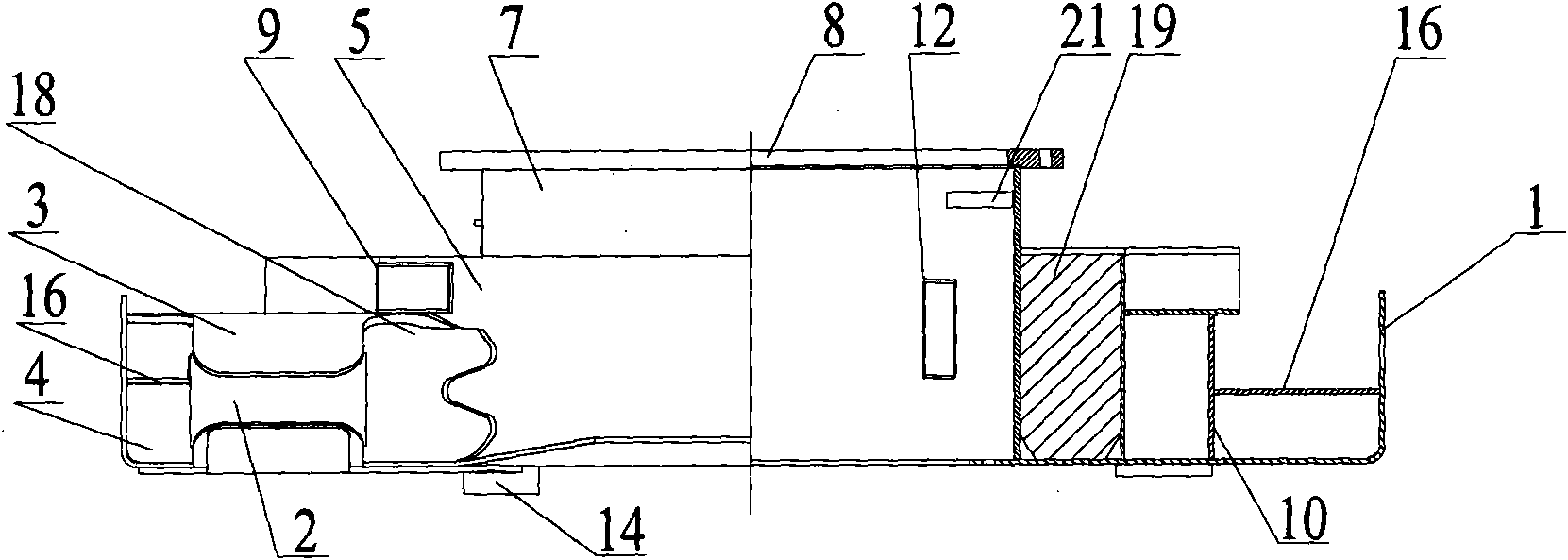

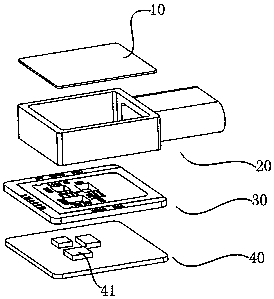

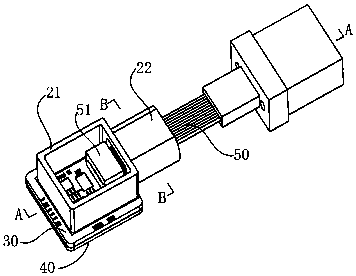

Micro loudspeaker module and design method thereof

ActiveCN104602168AGuaranteed Design RequirementsElectrical transducersSubstation speech amplifiersForming gasEngineering

The invention discloses a micro loudspeaker module and a design method thereof. The module comprises an upper casing, a vibration system, a middle casing, a magnetic circuit system and a lower casing from the top to the bottom successively. The vibration system is arranged in the middle casing and is in seamless connection with the middle casing, a front cavity and a rear cavity of the middle casing are isolated completely through the upper casing, and preset-shape holes are formed in the wall of the rear cavity, so that the rear cavity and the outside can form gas exchange during the vibration of the vibration system. By means of the module and the design method, the preset-shape holes are formed in the wall of the rear cavity of the middle casing, the rear cavity and the outside can form gas exchange by the aid of the holes, and accordingly, large enough gas exchange space is provided, the design requirement of the micro loudspeaker module is guaranteed, and the problem that design space for the micro loudspeaker module become smaller and smaller and cannot meet the micro loudspeaker module design requirement in the prior art is solved.

Owner:シェンジェンインムーテクノロジーシーオーエルティーディー

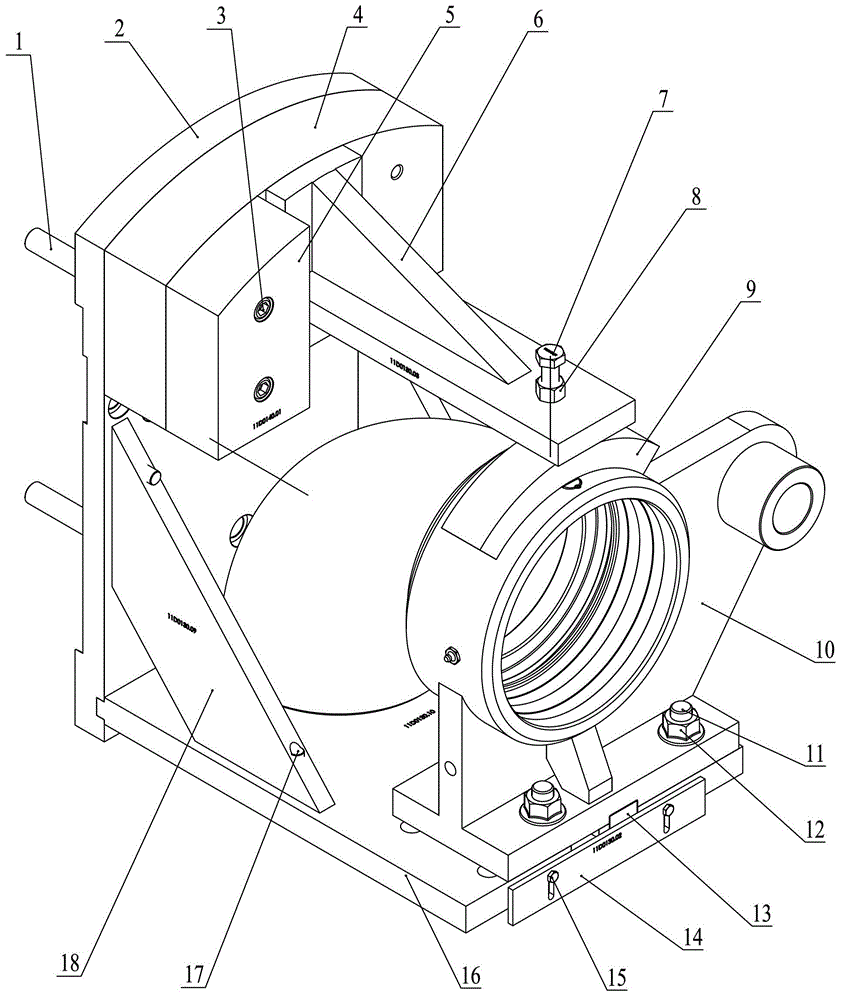

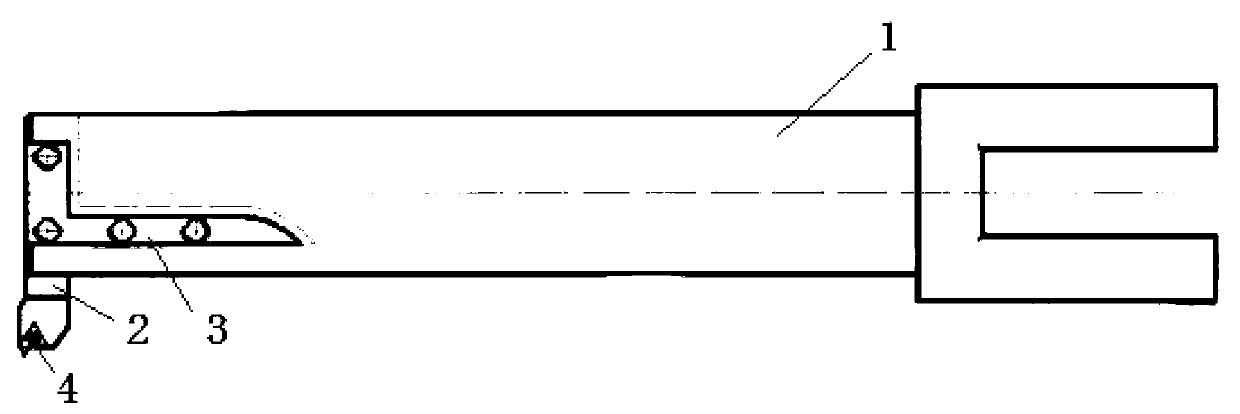

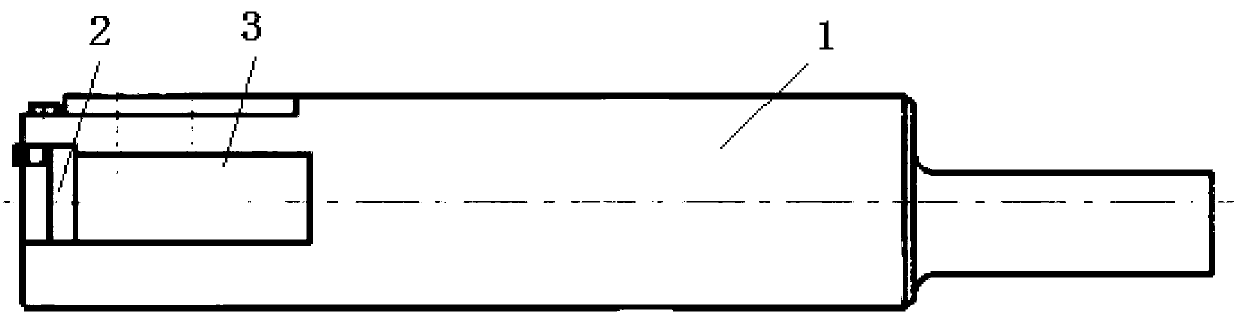

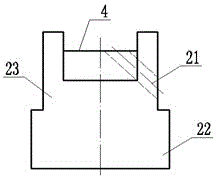

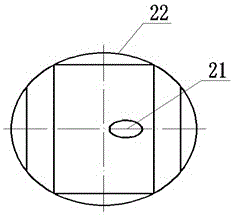

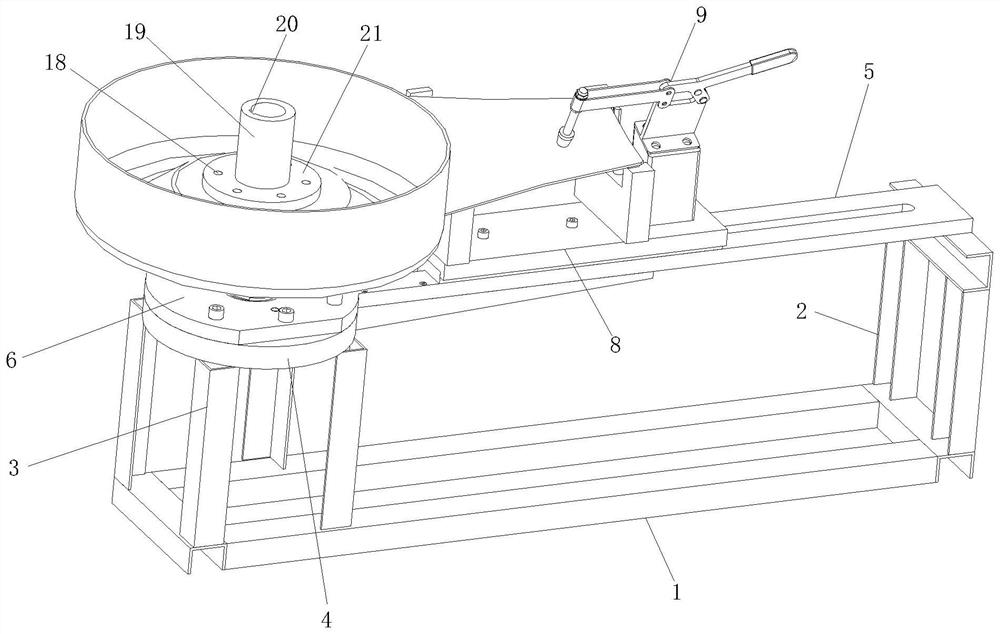

Specially-shaped body annular groove machining mechanism

ActiveCN102909574ATurn aroundSimple and flexible structurePositioning apparatusMaintainance and safety accessoriesMachine partsEngineering

The invention relates to a specially-shaped body annular groove machining mechanism, which is characterized in that a vertical plate is connected with a soleplate into a whole, the vertical plate is provided with a connecting bolt which is in fitting connection with a numerical-control lathe rotary main shaft chuck to be locked; a specially-shaped body to be machined is tightened onto the soleplate through a tightening screw and a hexagonal nut, and the soleplate is provided with a positioning key which enables the specially-shaped body to be machined to rotate concentrically with the numerical-control lathe rotary main shaft; and a pressure plate is installed on the upper part of the vertical plate, the front end of the pressure plate is provided with a pressure block for compressing the specially-shaped body to be machined through a compression screw, the pressure block can be compressed onto the specially-shaped body to be machined by screwing the compression screw, and the compression screw is provided with a locking nut. A machined part of the specially-shaped body can be rotated through rapid installation, clamping and positioning, and an ordinary tool is used for cutting a hole and an annular groove to be machined of the specially-shaped body, so that the auxiliary time is reduced, the machining efficiency is improved, and the investment cost of the equipment and forming tool can be greatly reduced.

Owner:TENGXUAN TECH

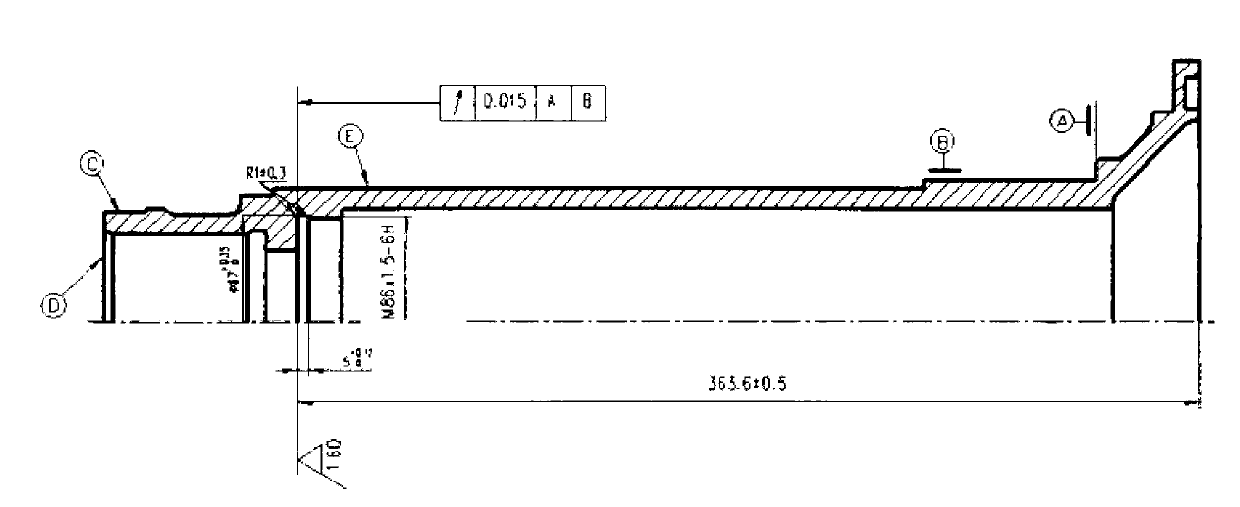

Heavy automobile two-segment drive bridge set collar processing method

The invention discloses a machining method of two-section drive bridge space ring for a heavy automobile, belonging to automobile fitting technique field. At first, determining required apparatus and model drawing for machining; based on the apparatus for machining, designing positioning fixtures of each procedure and required special tool; rough turning a front end face (4) and a half outer circle B(2) by a digital control lathes; rough turning a back end face (4) and a half outer circle A(1) by a digital control lathes; heat treating the workpiece outer circle, high frequency quench treating surface; turning groove by a lathe and chamfering edges; fine turning a middle inner plane D(5), an inner plane G(6) and an inner hole (7) by the digital control lathes and the special tool; machining the outer circle by the grinder. Using parts produced by the invention can reduce friction force, with high sealing performance, and while with less oil consume and conservation of energy; the invention has advantages of high production efficiency and quality guarantee and low cost.

Owner:JIANGSU HENGYI IND TECH CO LTD

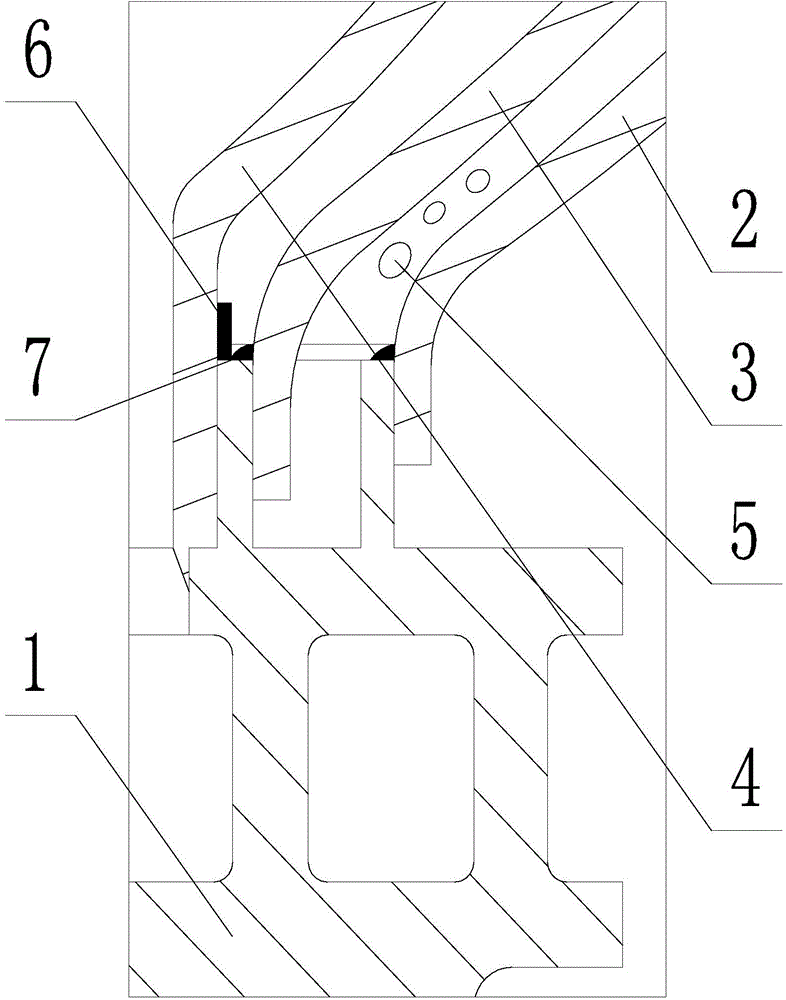

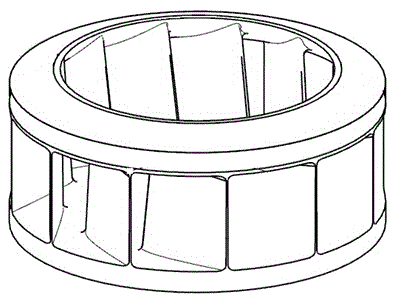

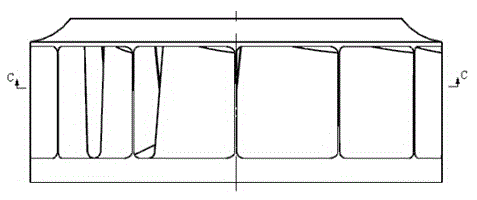

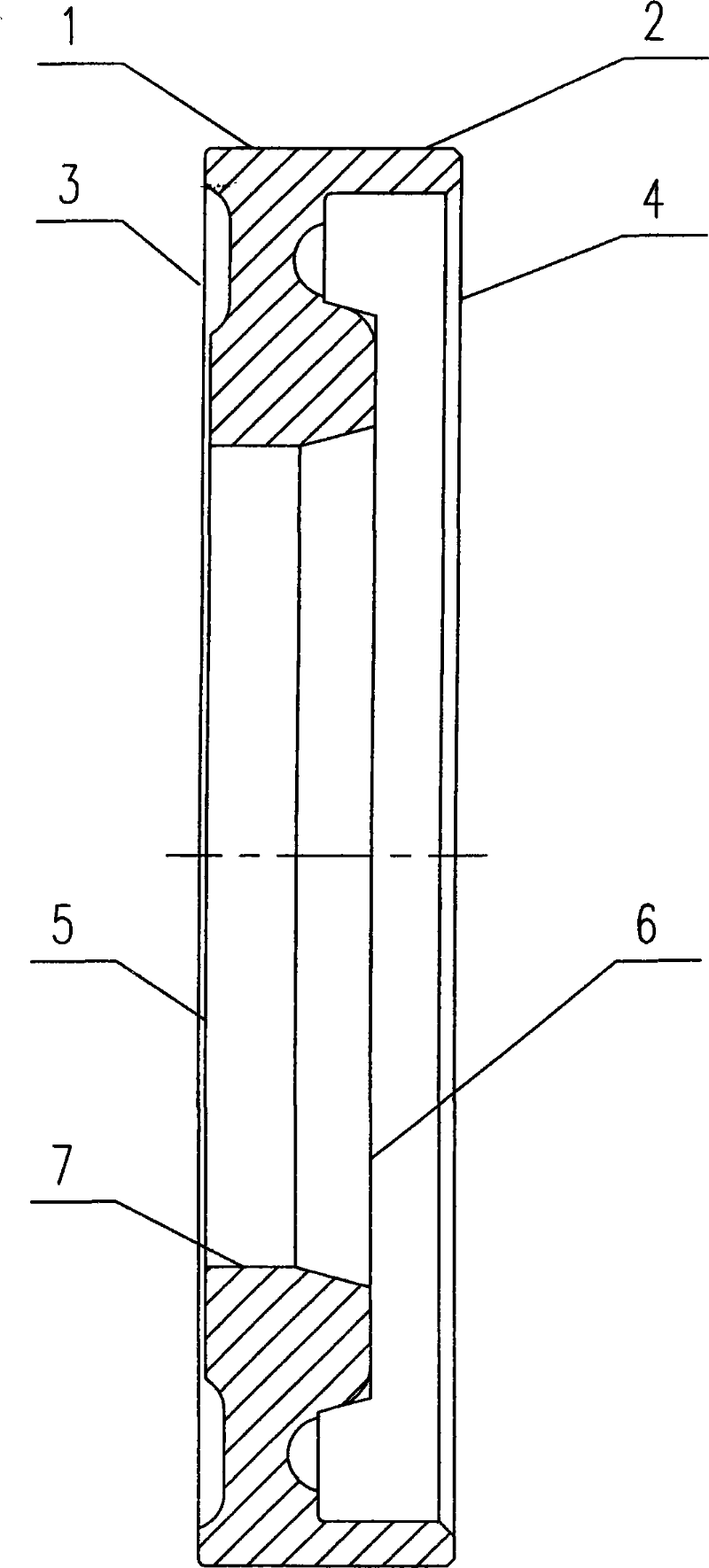

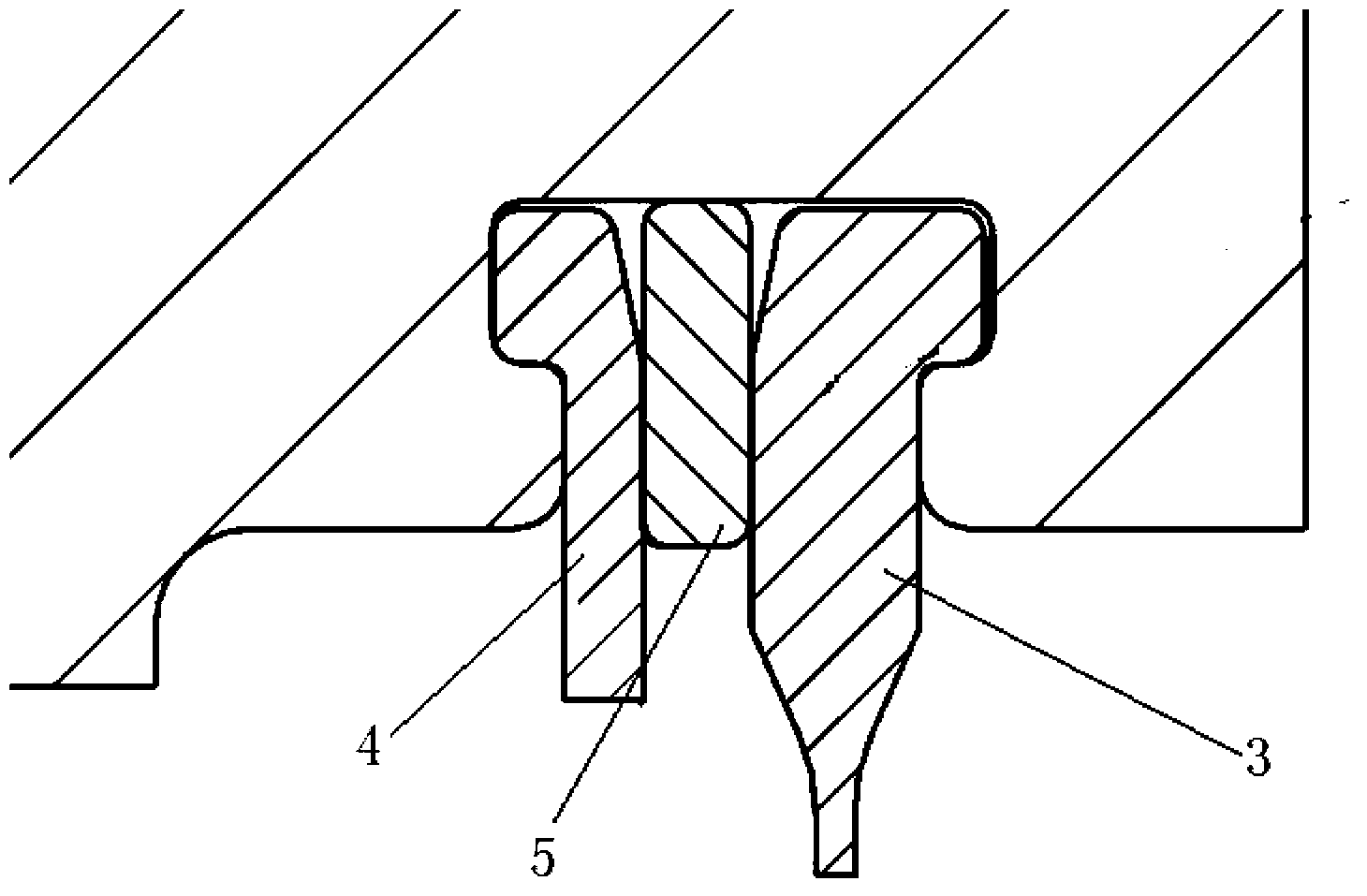

Steam sealing structure for steam turbines and assembling method thereof

ActiveCN102797512AImprove stabilityImprove reliabilityLeakage preventionMachines/enginesEngineeringSteam turbine

The invention provides a steam sealing structure for steam turbines. The steam sealing structure for steam turbines comprises a peripheral T-shaped slot, a steam sealing strip, a packing strip and a locking strip, wherein the steam sealing strip and the locking strip are arranged in a longitudinal clamping slot of the peripheral T-shaped slot, a first transverse elbow is clamped in a first transverse clamp slot, and a second transverse elbow is clamped in a second transverse clamp slot; and the packing strip is arranged between the steam sealing strip and the locking strip, the lower end of the locking strip is formed into a bent edge, and the bent edge is pressed on the lower surface of the packing strip. According to the steam sealing structure for steam turbines, the packing strip is arranged between the steam sealing strip and the locking strip, and through the packing strip, the steam sealing strip can be tensioned and tightly clamped in the peripheral T-shaped slot in the axial direction; and meanwhile, the bent edge formed at the lower end of the locking strip is pressed on the lower surface of the packing strip, so that the packing strip can be tightly compressed in the radial direction, in such a way, the steam sealing strip can be tightly fixed in the peripheral T-shaped slot, therefore, the occurrence of moving of the steam sealing strip can be effectively prevented, the assembling quality of the steam sealing strip can be ensured, and the operating stability and reliability of a steam turbine can be effectively improved.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

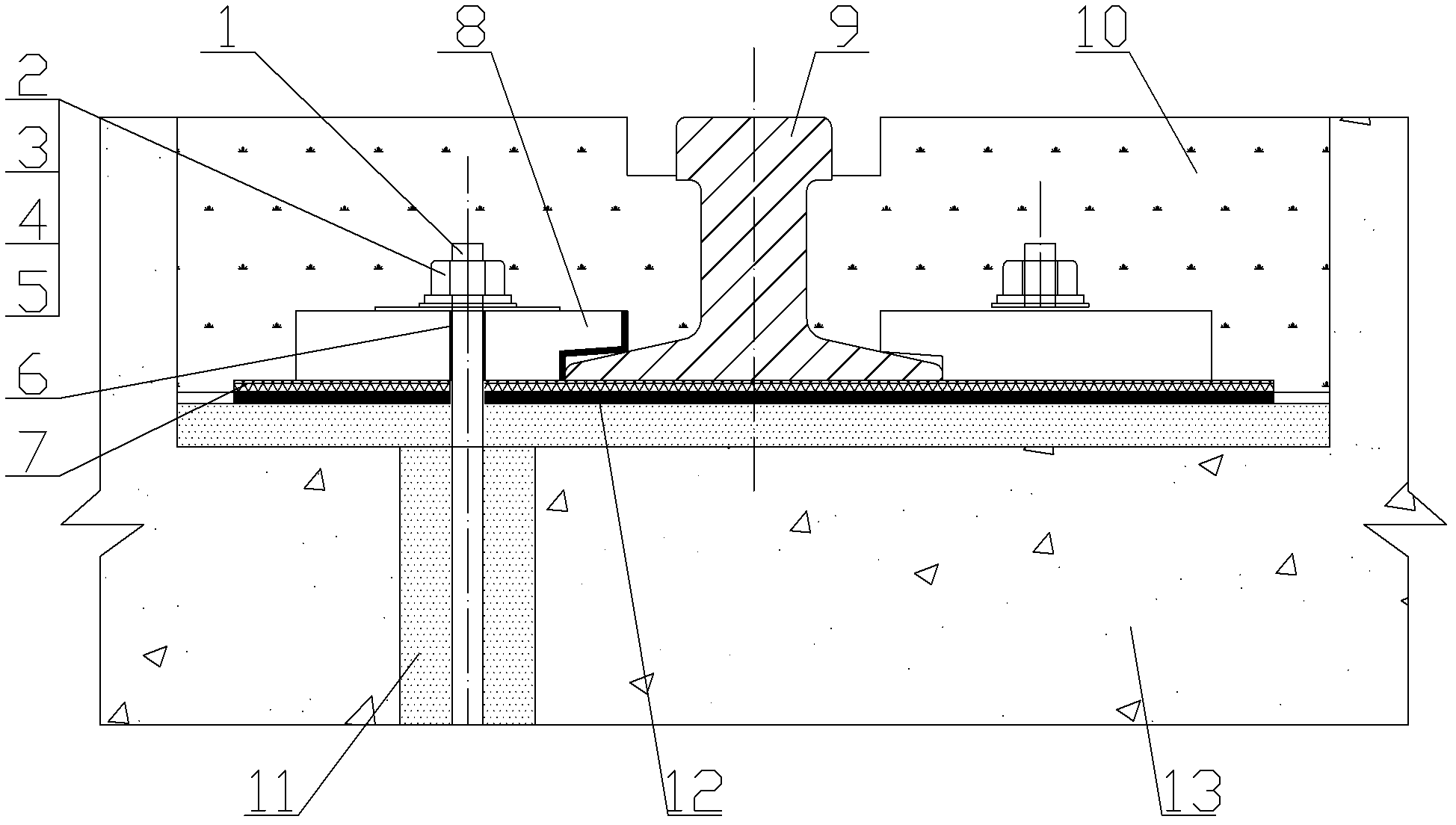

Insulation structure of ground power supply sliding contact wire of electric flat car and construction technology thereof

ActiveCN102529750AGuaranteed insulation resistanceGuaranteed Design RequirementsRail devicesRailway track constructionSliding contactPhenolic aldehyde

The invention discloses an insulation structure of a ground power supply sliding contact wire of an electric flat car and a construction technology thereof. Firstly, a layer of electro-insulating rubber of 2-5mm is additionally arranged at a contact port part of a pressing plate and a track; secondly, an insulation tube is sleeved on a foundation bolt, a phenolic aldehyde insulation plate is arranged between a steel washer of the foundation bolt and an insulation pressing plate; meanwhile, an elastic rubber base plate which is arranged below the track in the original design is reserved, and layers of insulation are formed between the insulation pressing plate and the track, between the insulation pressing plate and the bolt as well as between the track and a foundation; and finally, the design requirement of the insulation resistance of the track to the ground is also ensured. According to the insulation structure, a process of pouring the sulphur-bonded motar insulation foundation bolt is omitted, so the construction difficulty is greatly reduced; the construction quality and the progress are improved, and the construction technology is the insulation technology of a flat car track, which is more convenient, environmental-friendly, safer and more economic.

Owner:TIANJIN 20 CONSTR

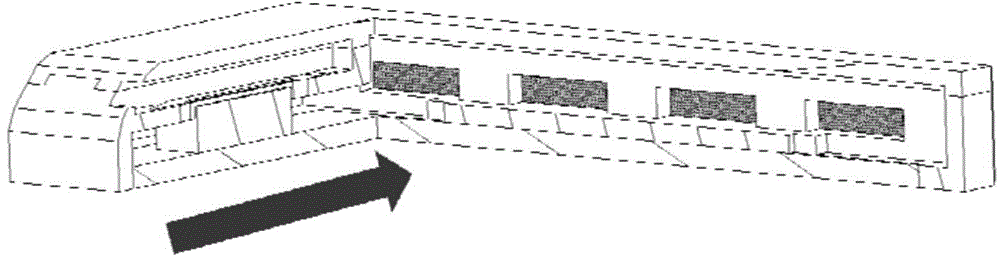

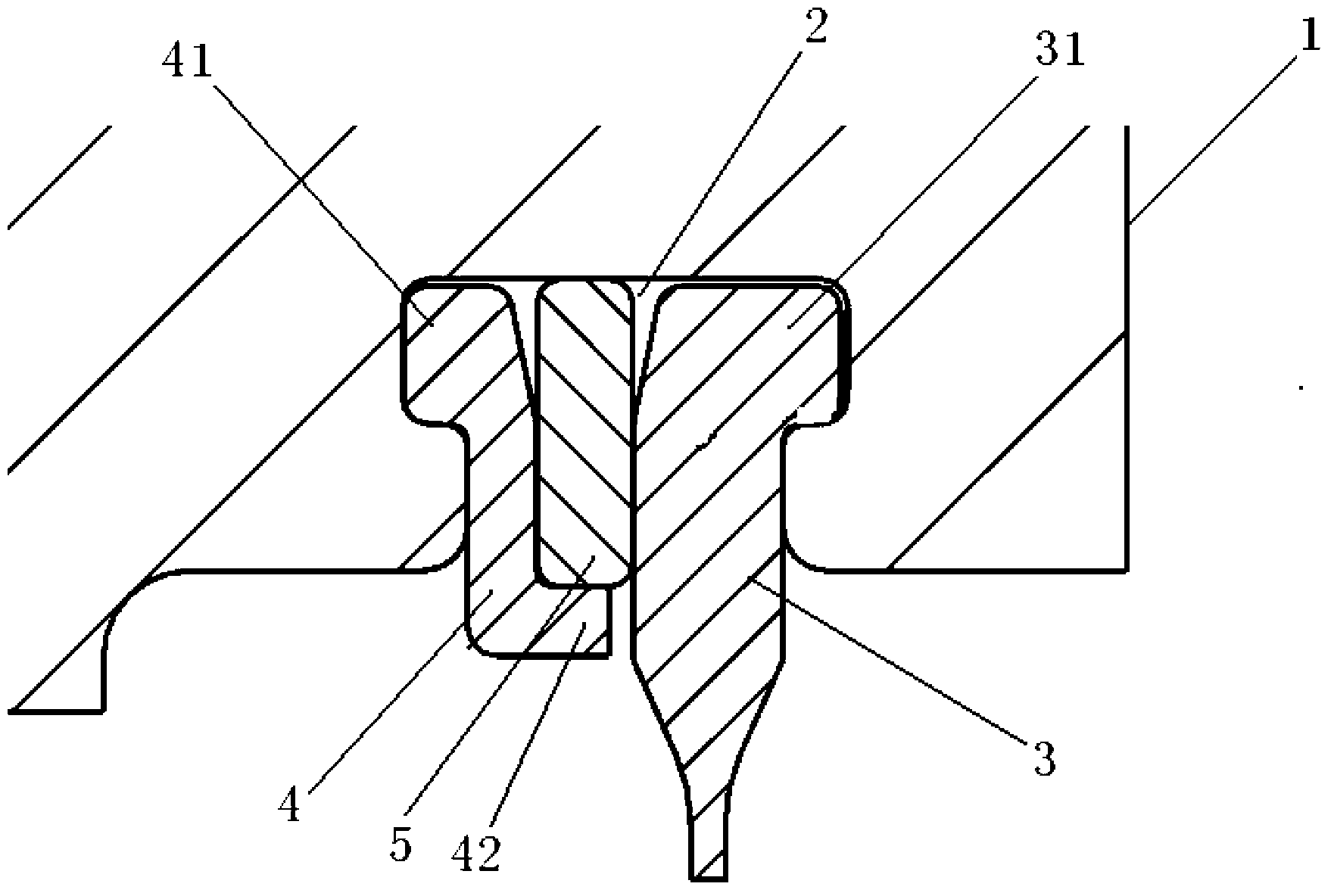

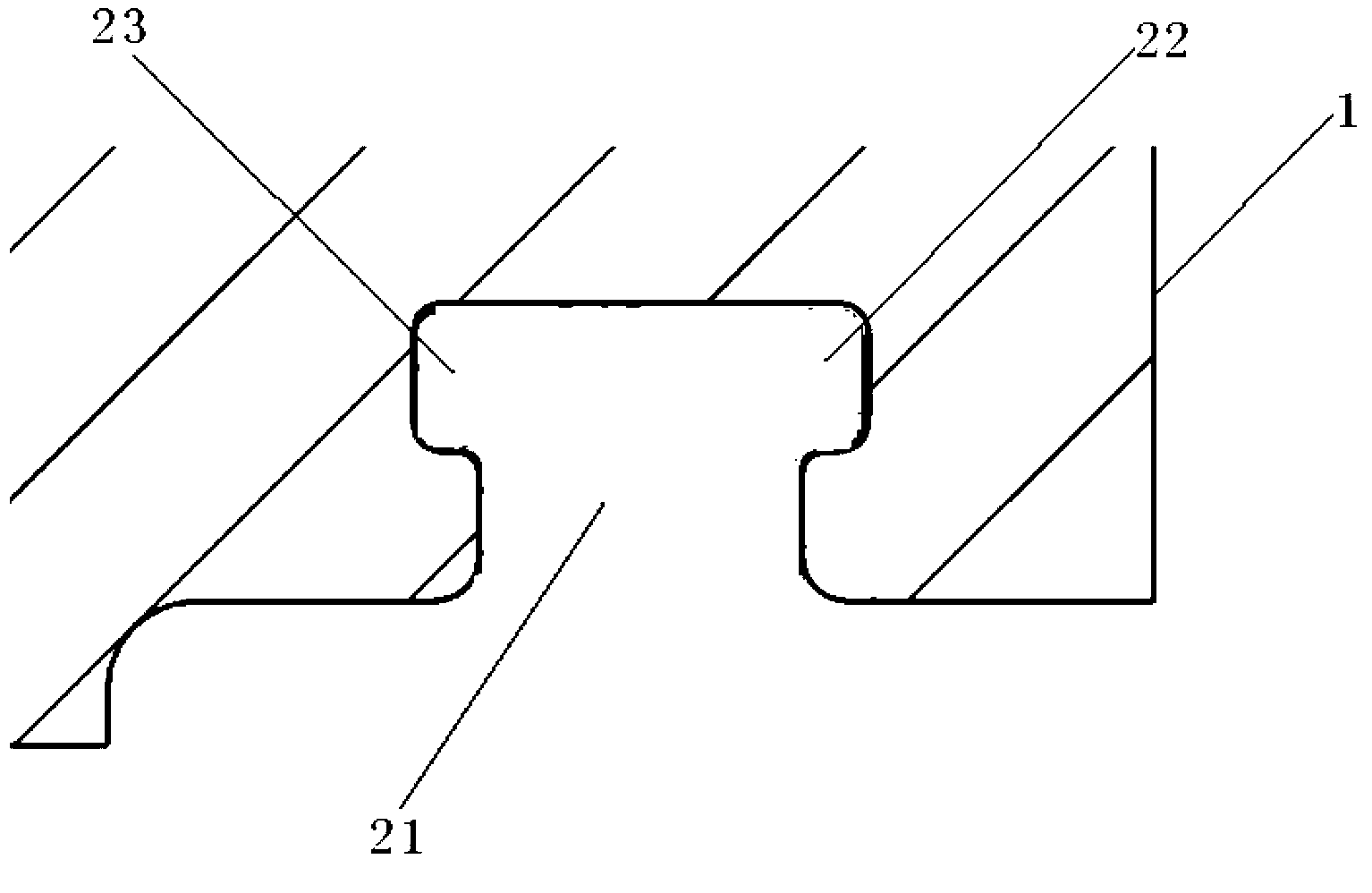

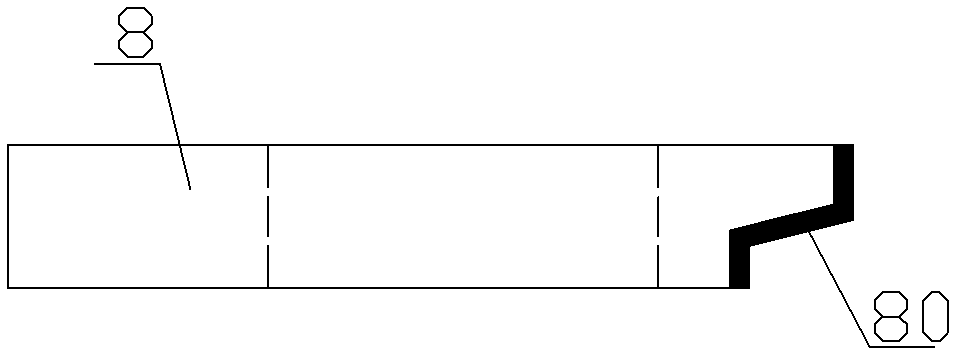

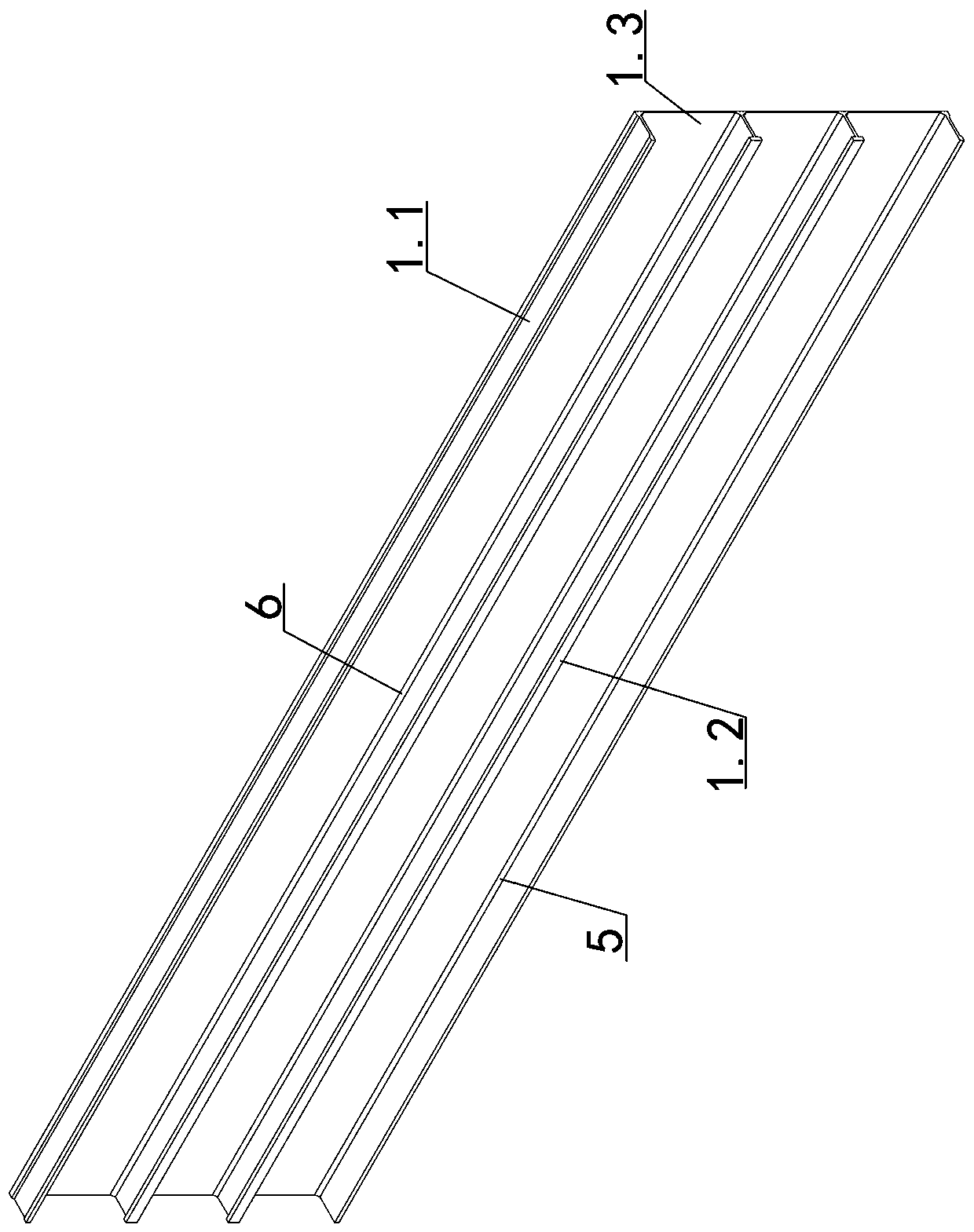

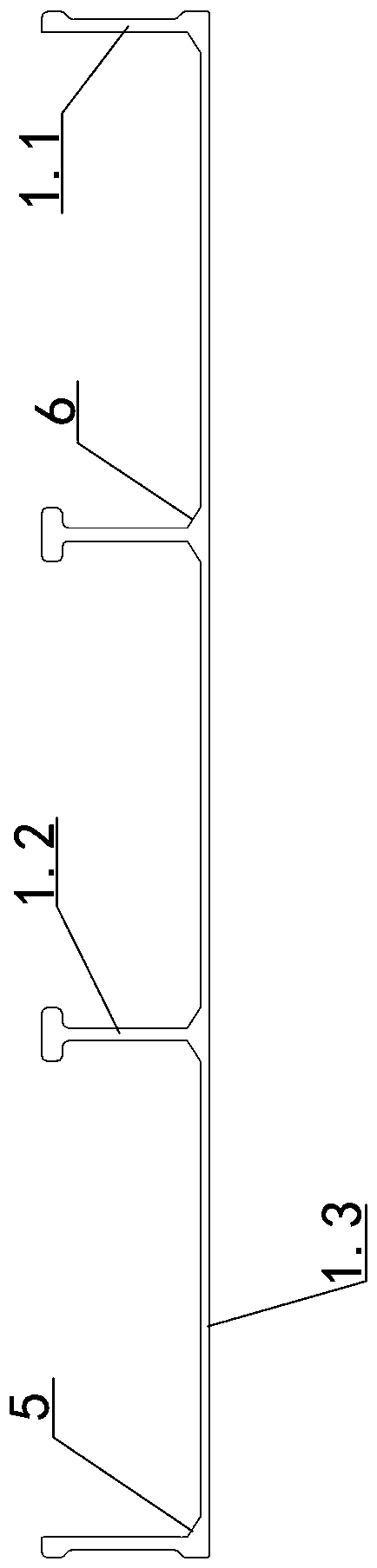

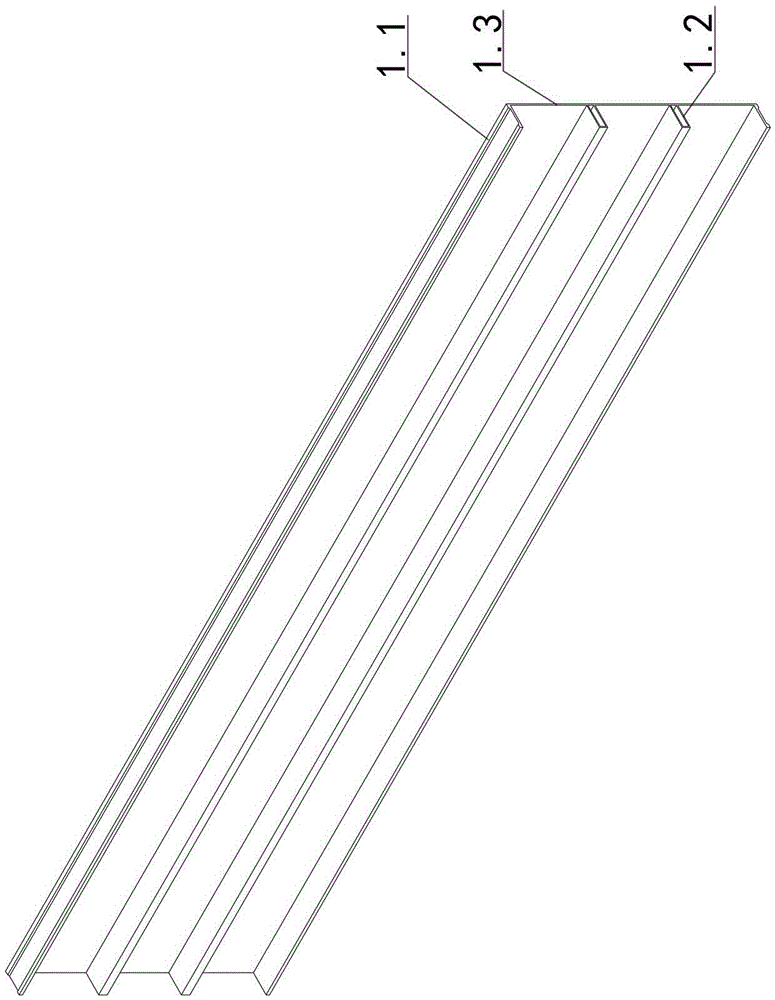

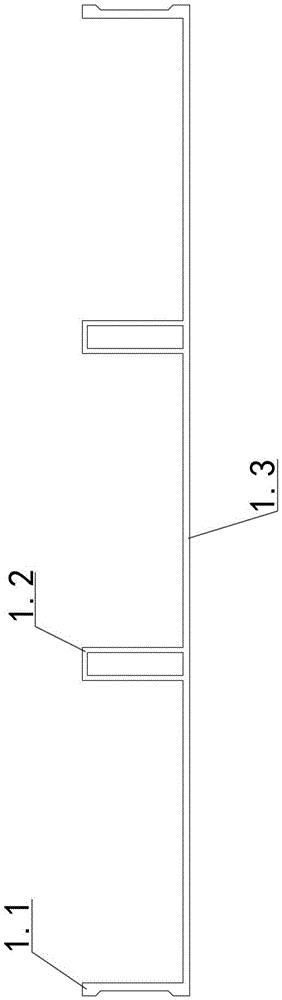

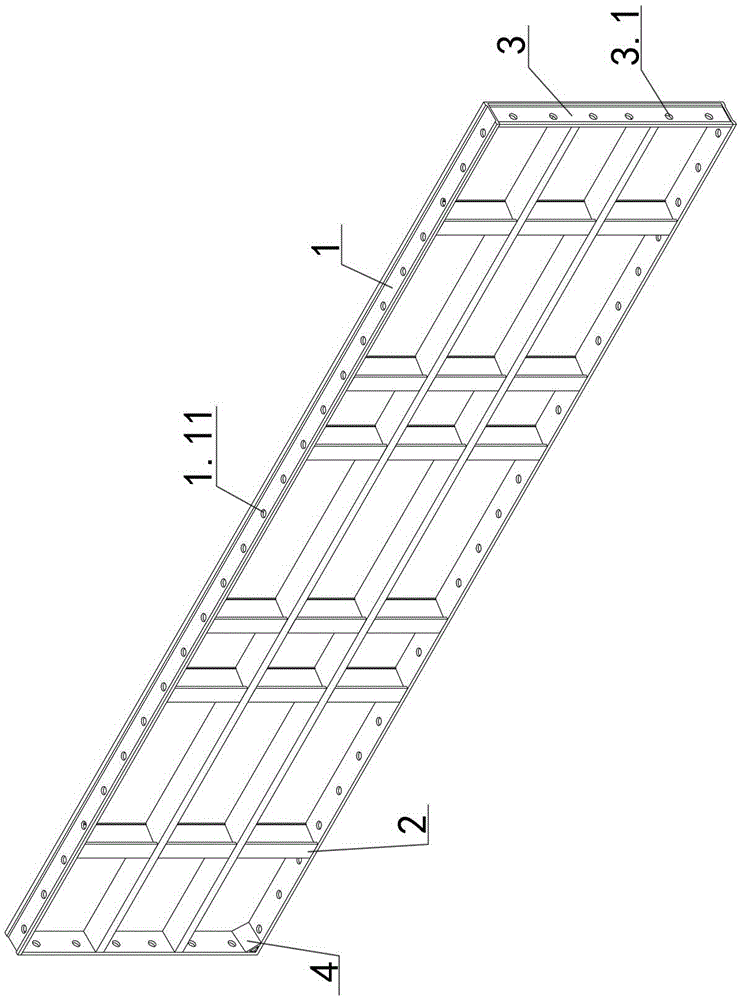

T-shaped section profile for aluminum alloy template and unit template structure of aluminum alloy template

InactiveCN105239771AReasonable section structureEasy to shapeForming/stuttering elementsStructural engineeringProcessing cost

The invention relates to a T-shaped section profile for an aluminum alloy template and a unit template structure of the aluminum alloy template. The T-shaped section profile is an integrally-molded aluminum alloy profiled plate and is composed of a groove body and a group of longitudinal reinforcing ribs, wherein the groove body is formed by a rectangular panel and two opposite longitudinal side frames on the back of the panel, and the longitudinal reinforcing ribs are uniformly distributed at the groove bottom of the groove body. The unit template structure comprises the T-shaped section profile of the aluminum alloy template, a transverse side frame, transverse reinforcing ribs and angle reinforcing blocks. The T-shaped section profile has the advantages of being definite in structure and simple in molding, little post processing of the template is required, the processing cost is reduced, and the light weight, safety in use and long service life of the template can be ensured; the construction efficiency is improved, and the standardized and systemized, industrialized production is easier; thus, the template has the advantages of being quick and convenient in disassembly and assembly, firm in mounting, high in construction efficiency and low in construction cost.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

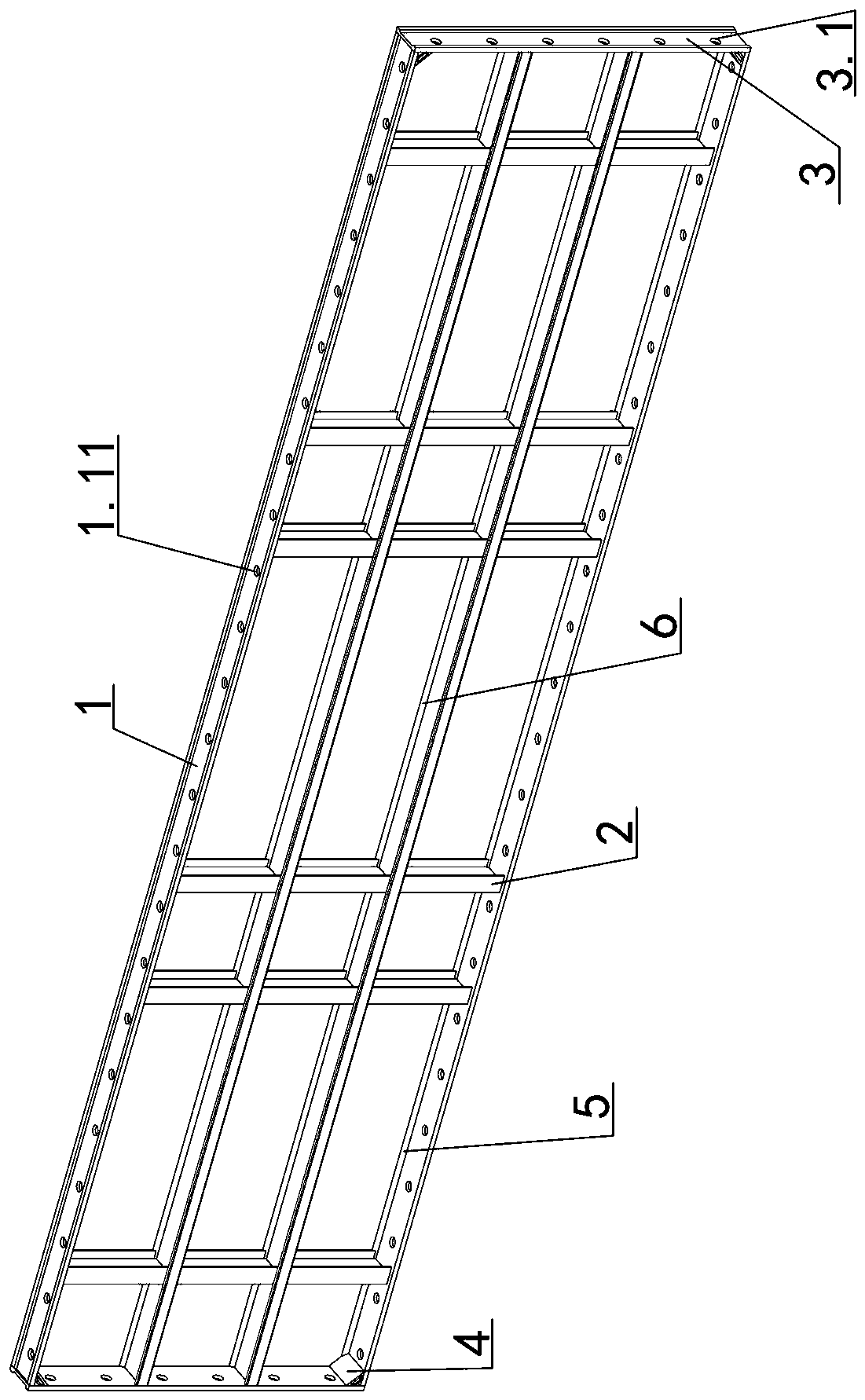

Aluminum alloy formwork rectangular-section profile and unit formwork structure of aluminum alloy formwork

InactiveCN105421762AReasonable section structureSectional structure is clearSheets/panelsForming/stuttering elementsMachiningAluminium alloy

The invention provides an aluminum alloy formwork rectangular-section profile and a unit formwork structure of an aluminum alloy formwork. The aluminum alloy formwork rectangular-section profile is an integrally-formed aluminum alloy special-shaped board and is composed of a groove and a set of longitudinal reinforcing ribs, wherein the groove is formed by a rectangular panel and two opposite longitudinal side frames arranged on the back face of the panel, and the longitudinal reinforcing ribs are evenly distributed at the bottom of the groove. The unit formwork structure of the aluminum alloy formwork comprises the aluminum alloy formwork rectangular-section profile, transverse side frames, transverse reinforcing ribs and corner reinforcing blocks. The aluminum alloy formwork rectangular-section profile and the unit formwork structure are clear in structure, easy to form and low in later formwork machining amount, machining cost is reduced, it can be guaranteed that the formwork is low in weight, safe in use and long in service life, construction efficiency is improved, standardized, systematic and industrial production is easier, formwork disassembly and assembly are rapid, easy and convenient, installation is firm, construction efficiency is high, and construction cost is low.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

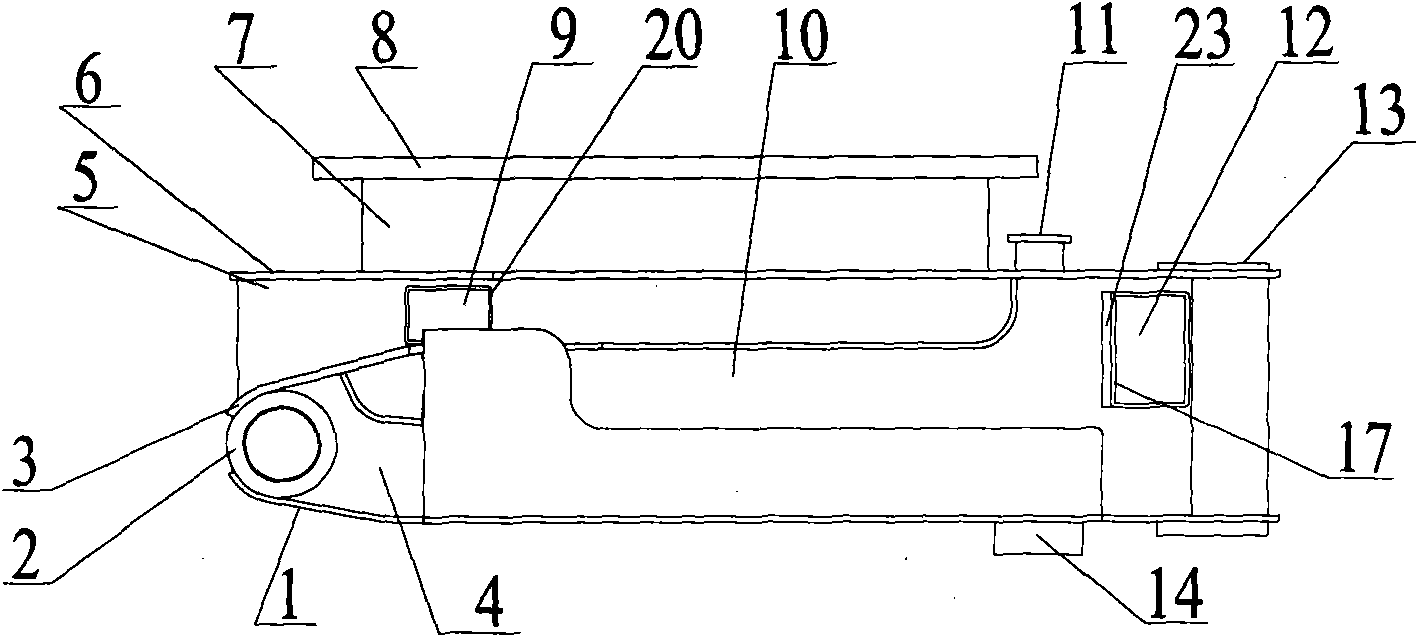

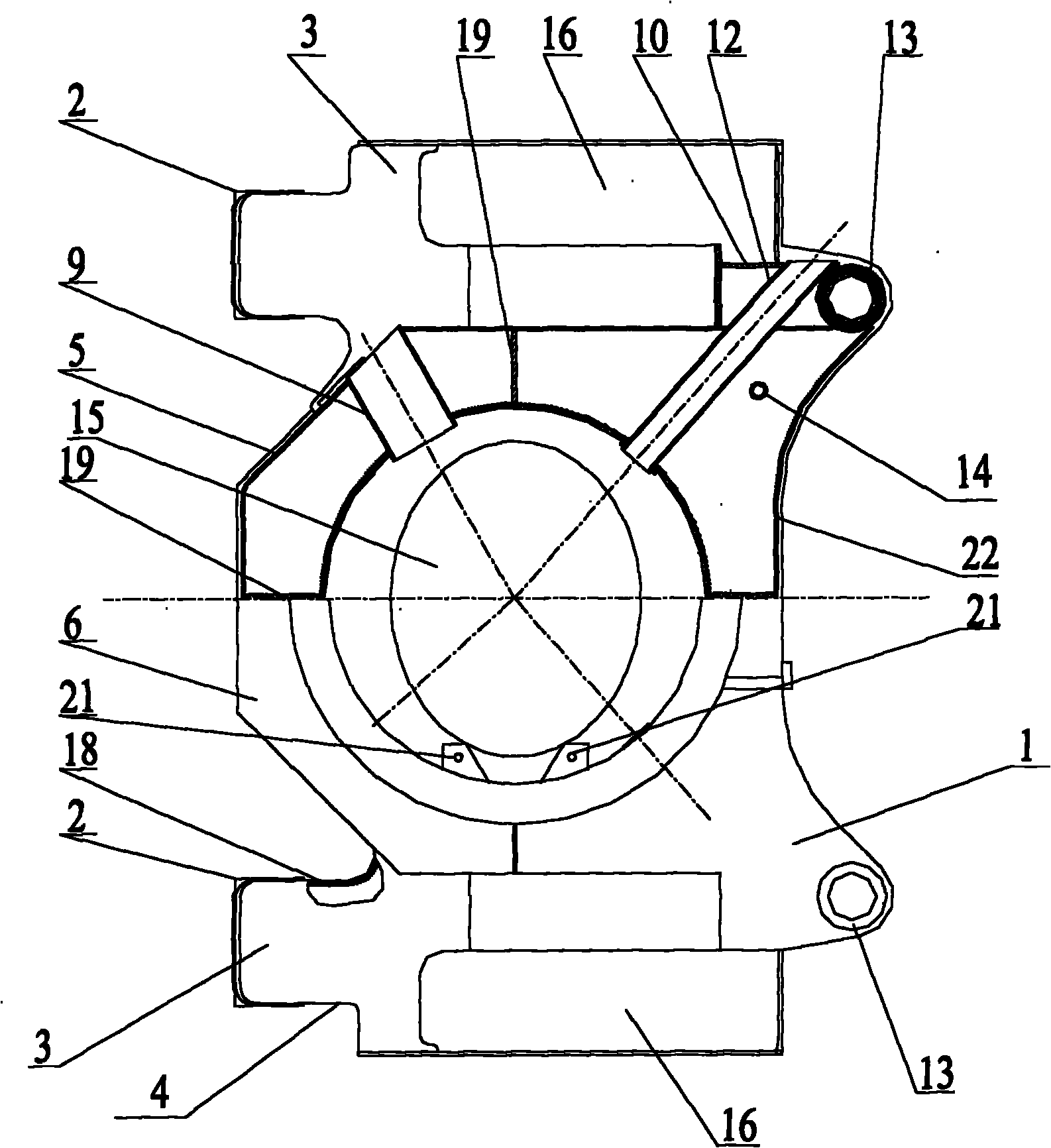

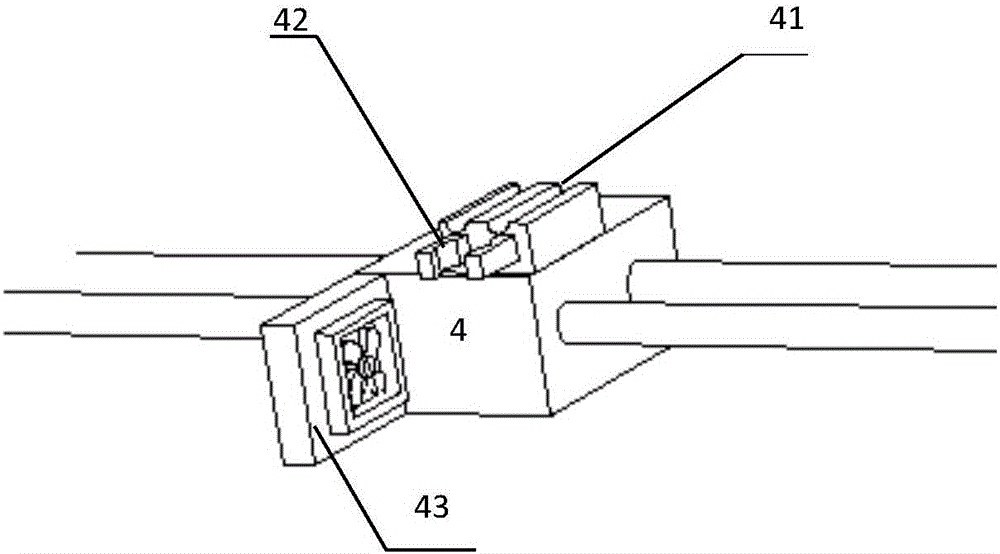

Method for processing titanium alloy sealing deep cavity threads

InactiveCN102990170ABreakthrough tremorBreakthrough processabilityThread cutting toolsThread cutting machinesKnife bladesBlade plate

The invention discloses a method for processing titanium alloy sealing deep cavity threads. The specific processing content is the sealing deep cavity threads of a titanium alloy fan shaft; a special lathing tool is used to process the titanium alloy sealing deep cavity threads and is formed by a toolbar and a blade (4), wherein the toolbar is specifically formed by a toolbar body (1), a processing cutting board (2) and a processing cutting board slideway (3); the specific requirements of the method for processing titanium alloy sealing deep cavity threads are that the tool only enters from a large end to process, a small diameter is firstly lathed, a hollow knife slot is then lathed, and the threads are lathed; and the processing parameter requirements are that the feed rate f is equal to 1.5mm / r, the rotating speed s is equal to 150-200 r, and the lathing depth ap is equal to 0.1-0.2mm. By the method, the cutting vibration can be effectively controlled, so that the technical bottleneck that a titanium alloy sealing deep cavity threaded cutter vibrates, cannot be observed and thus is difficult to process are broken through. The method has profound significance and inestimable economic benefit.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Excavator base with embedded auxiliary fuel tank

InactiveCN102700404AReduce the conditions of protectionLower center of gravityUnderstructuresSoil-shifting machines/dredgersTerrainCentral cylinder

The invention relates to an excavator base with an embedded auxiliary fuel tank. A central cylinder is arranged outside a central hole of the base; a closed cavity, namely the auxiliary fuel tank, is formed at the periphery of the central cylinder; the front part and the rear part of each side of a rear baffle plate of the fuel tank are respectively provided with a hole; the four holes are fuel pipe channels; each fuel pipe channel penetrates through the inner part and the outer part of the base and is communicated with a central hole in the central cylinder; and four fuel tank inner ribbed plates are distributed in the auxiliary fuel tank, so that the auxiliary fuel tank is divided into four small fuel tanks. The auxiliary fuel tank is added to the base, so that the independent and continuous working efficiency of an excavator is greatly improved; due to the design of the base, the gravity center of the excavator is lowered; the requirement of the excavator working under complicated terrain environment is met; and box-type structures are arranged on two sides of the base, so that the structural strength of the base is guaranteed, and the weight of the base is reduced.

Owner:张万军

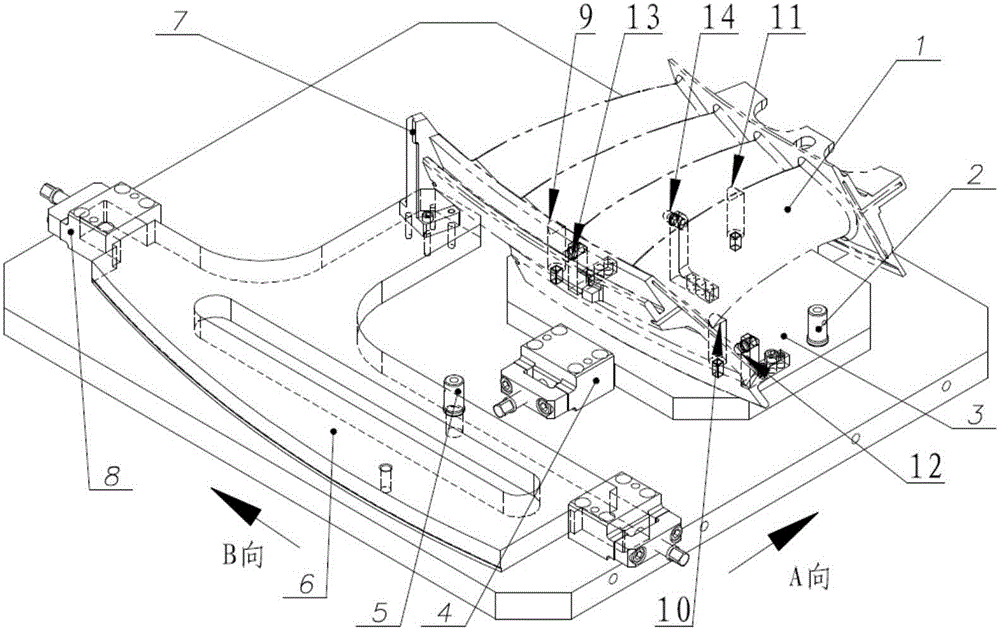

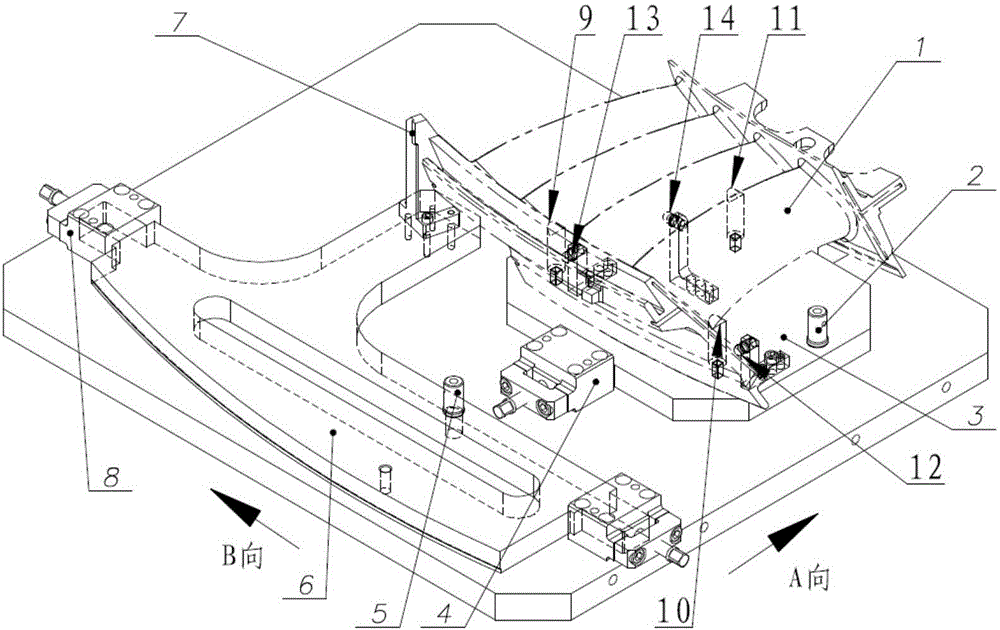

Device for detecting benchmark arc surface of quadruple guide vane

ActiveCN106610256AGuaranteed Design RequirementsImprove pass rateMechanical counters/curvatures measurementsSlide plateFlange

The invention discloses a device for detecting the arc benchmark of a quadruple guide vane. The device comprises a bottom plate (15), a sliding plate (3) arranged on the surface of the bottom plate and used for arranging a to-be-detected quadruple guide vane, a detecting plate (6) arranged on the surface of the bottom plate and used for providing a mobile guide rail surface for a detector, A-direction sliding guide adjusting components (4) arranged on the surface of the bottom plate and used for adjusting the position of the sliding plate through sliding in an direction A, B-direction sliding guide adjusting components (8) arranged on the surface of the bottom plate and used for adjusting the position of the detecting plate through sliding in an direction B, and a simulated zero meter aligning block (7) arranged on the detecting plate. By using the device to detect and adjust the benchmark arc surface of a large flange plate of a quadruple guide vane, detection can be completed with high quality, the detection operation can be simplified, and the detection efficiency can be improved.

Owner:AECC AERO SCI & TECH CO LTD

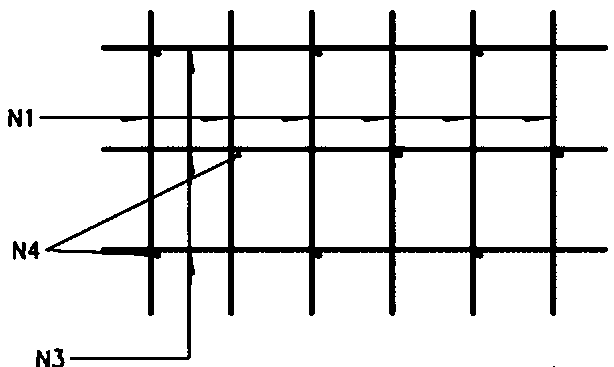

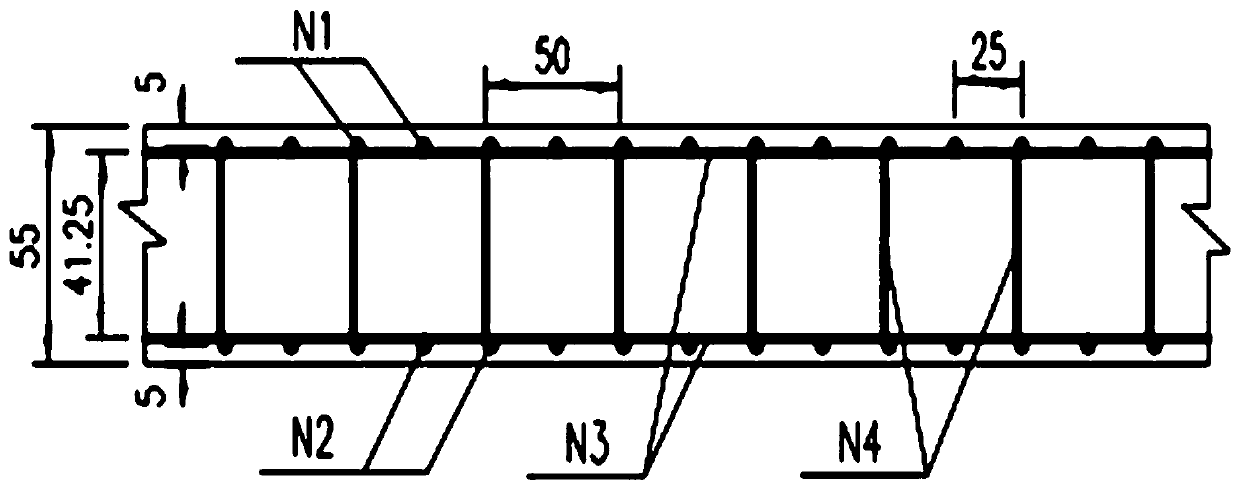

Tunnel second lining reinforcing steel bar protection layer control construction method

ActiveCN110700856AImprove installation qualityOvercoming control is technical problem of weak tunnel qualityUnderground chambersTunnel liningArchitectural engineeringRebar

The invention discloses a tunnel second lining reinforcing steel bar protection layer control construction method, and relates to the technical field of tunnel construction. The method comprises the specific steps of reinforcing steel bar positioning, wherein in the tunnel longitudinal and annular direction, positioning ribs are symmetrically mounted from the centre of an arch top to the two sides, connecting positions of longitudinal distribution ribs and / or annular main ribs are marked on the positioning ribs, inverted arch reinforcing steel bars of the first length are reserved in a construction joint of an inverted arch following wall, joints of adjacent longitudinal main ribs and / or the annular main ribs are staggered by the first width or above, and the thickness of a concrete net protection layer is the first thickness; and reinforcing steel bar mounting, wherein according to the reserved position, the longitudinal distribution ribs and / or annular main ribs are fixed to the connecting positions, the distribution ribs are laid and fixed, and finally, stirrups are laid. Through the implementation manner, the second lining reinforcing steel bar mounting quality is improved, andthe design needs are ensured.

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +1

A Proucting Approach for Oblique Oil Hole in Bearing Retainer

ActiveCN106334809AReduce processing costsGuaranteed Design RequirementsInterference fitProcessing cost

The invention discloses a proucting approach for oblique oil hole in bearing solid retainer, comprising the following steps: a: the making of special purpose device for drill guide: design a special purpose drill guide, which includes round platform, rectangular boss, draw-in groove, oblique location hole, guiding drill bushing; The processing of oblique location hole: determines the access site of oblique location hole on the special purpose drill, then conduct drilling processing after clamping tightly; The processing of guiding drill bushing: The guide bush is embedded in the oblique positioning hole in the guiding device , guide bushing and guide deviceInterference fit. b: The processing of the oblique oil hole: positioning the round platform diameter periphery of exclusive drill with pocket bore diameter arc surface, positioning groove bottom with retainer pocket bottom hole, and load each pocket hole of retainer one by one, processing inclined oil hole with manual and electric drills. The invention solves the problem of producing oblique oil hole of bearing retainer, reducing the processing cost and ensuring the design requirements of the product..

Owner:LUOYANG LYC BEARING

Method used for detecting four-joint guide blade reference arc surface

ActiveCN106643441AGuaranteed Design RequirementsImprove pass rateMechanical measuring arrangementsCheck pointMechanical engineering

The invention discloses a method used for detecting a four-joint guide blade reference arc surface; the method mainly comprises the following steps: using 6 positioning members to fix a four-joint guide blade on a slide board of a measuring device, and allowing the four-joint guide blade reference theory arc surface to match and be concentric with an arc guide rail surface arc on the measuring board; using an A-direction slide guide adjusting assembly to adjust the slide board in the A direction; using a meter check point of a meter check block fixed on the measuring board as the baseline, and using a dial gauge to measure the center of the arc guide rail surface and the center of the four-joint guide blade reference arc surface; using a B-direction slide guide adjusting assembly to adjust the slide board according to the reference arc surface center deviation direction, allowing the nonconcentricity between the reference arc surface center and the arc guide rail surface center to be in a set value scope, and recording the mobile distance of the slide board in the B direction; adjusting the mobile distance to be smaller than a design value, thus allowing the edge plate reference arc surface of the four-joint guide blade satisfies requirements, otherwise, the four-joint guide blade reference arc surface fails.

Owner:AECC AERO SCI & TECH CO LTD

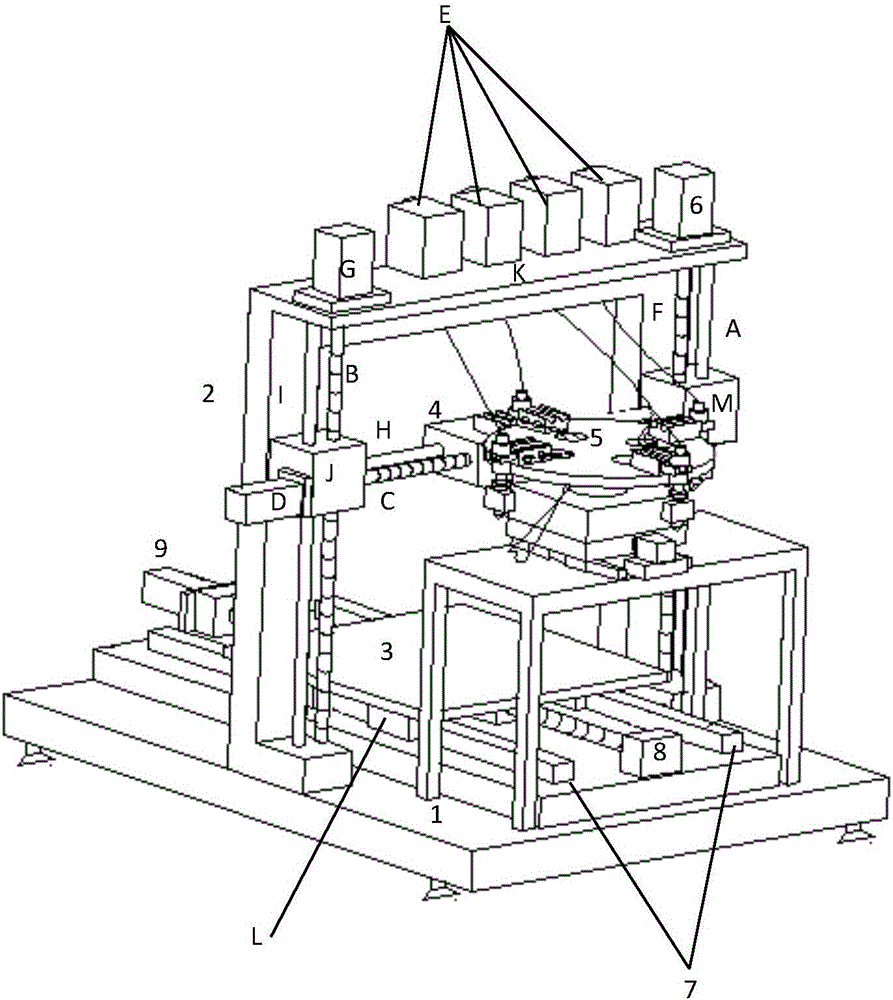

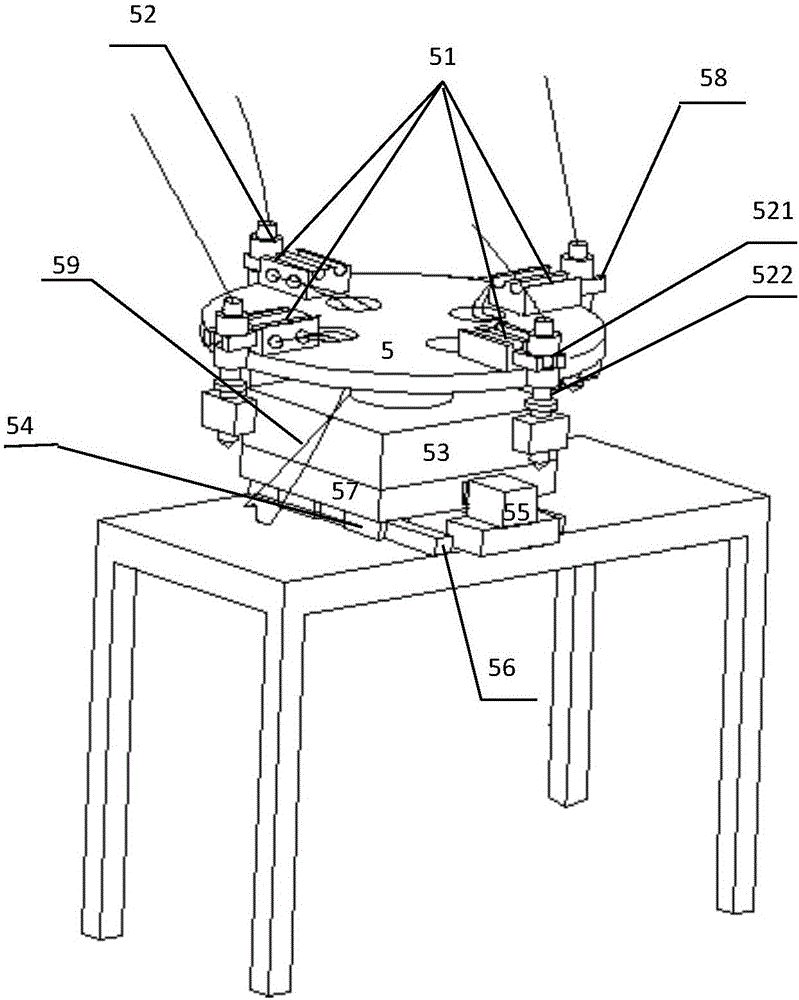

Multi-nozzle 3D printer

InactiveCN106827534AGuaranteed Design RequirementsAvoid installation errorsManufacturing platforms/substratesApplying layer meansCircular discFixed frame

The invention relates to a multi-nozzle 3D printer which comprises a rack, a portal frame, a printing platform, a nozzle fixing frame and a nozzle disc frame. The printing platform is arranged on the rack, a feeding mechanism for a printing material is fixed on a portal frame horizontal plate on the upper portion of the portal frame, the nozzle fixing frame is arranged below the portal frame horizontal plate, a first clamping jaw cylinder is fixed on the nozzle fixing frame, the nozzle disc frame is arranged on the right of the portal frame and arranged on the rack, multiple second clamping jaw cylinders are fixed on a nozzle disc, and each second clamping jaw cylinder is provided with a second clamping jaw cylinder clamping jaw. In a printing state, non-working nozzles are fixed on the nozzle disc, the second clamping jaw cylinder clamping jaws firmly grasp third steps of the nozzles, and each second clamping jaw cylinder is provided with a magnetic switch; working nozzles go onto the nozzle fixing frame through a rotating mechanism and a propelling mechanism, a first clamping jaw cylinder clamping jaw firmly grasps fifth steps on the nozzles, and the first clamping jaw cylinder is provided with a magnetic switch.

Owner:黄泽

Prefabricated steel tube bundle partially-prestressed concrete beam and construction method thereof

PendingCN111155714AImprove seismic performanceImprove deformation resistanceLoad-supporting elementsBuilding reinforcementsPrestressed concrete beamReinforced concrete

The invention discloses a prefabricated steel tube bundle partially-prestressed concrete beam and a construction method thereof. The beam comprises a hollow lattice type steel tube bundle, concrete, prestressed steel bars, baffles and anchoring steel bars, wherein the baffles are fixed to the two ends of the interior of the hollow lattice type steel tube bundle; a plurality of prestressed bar holes are formed in the lowermost layer of the baffle of a lowermost steel member, and a plurality of preformed holes are formed in other layers; the other baffles are provided with a plurality of layers,wherein a plurality of preformed holes are formed in each layer; the prestressed steel bars are arranged in the prestressed bar holes in a sliding manner and penetrate through the whole beam; the prestressed steel bars are loaded with control stress and anchored; the anchoring steel bars are inserted into the preformed holes and fixed; and concrete is poured between the baffles, and after strength requirements are met, prestress is released, and therefore the steel tube bundle partially-prestressed concrete beam is formed. The beam combines advantages of a steel reinforced concrete structureand a prestressed concrete structure, so that the anti-vibration property and the anti-deformation capacity of the beam are improved, the bearing capacity is high, the later-period bearing capacity isstable, and the structural rigidity is greatly improved.

Owner:HEBEI UNIV OF TECH +1

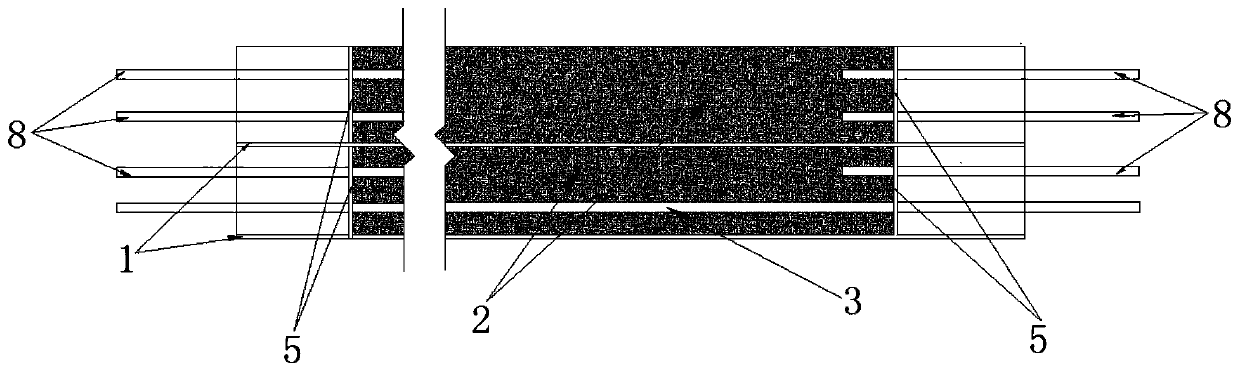

Multi-path parallel optical assembly packaging structure and multi-path parallel optical assembly

ActiveCN107703589AImprove air tightnessImprove reliabilityCoupling light guidesEngineeringMulti path

The present invention discloses a multi-path parallel optical assembly packaging structure and a multi-path parallel optical assembly having the packaging structure. The packaging structure comprisesa top plate, an intermediate shell and a bottom plate, the intermediate shell comprises an annular frame and a tail tube, the annular frame is used to form an airtight cavity with the top plate and the bottom plate, and the tail tube and the annular frame are molded integrally and are communicated with the airtight cavity. The bottom plate comprises a substrate and a metal plate, the substrate isequipped with an internal wiring terminal located inside the airtight cavity, a chip loading hole and an external wiring terminal located outside the airtight cavity, and the metal plate is soldered on the bottom surface of the substrate and seals the chip loading hole, wherein after an optical joint at one end of a multi-path parallel optical fiber ribbon penetrates the tail tube and enters the annular frame, the tail tube and the multi-path parallel optical fiber ribbon are sealed via the solders. According to the present invention, via the airtight cavity, the key components are sealed effectively, by a mode that the tail tube is sealed by the solders, the large scale of a product is avoided while the optical signals are transmitted reliably, and the market demands are conducive to being satisfied.

Owner:HISENSE & JONHON OPTICAL ELECTRICAL TECH CO LTD

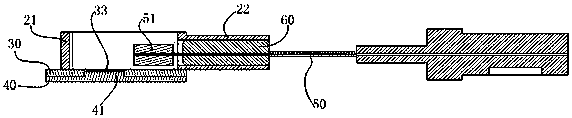

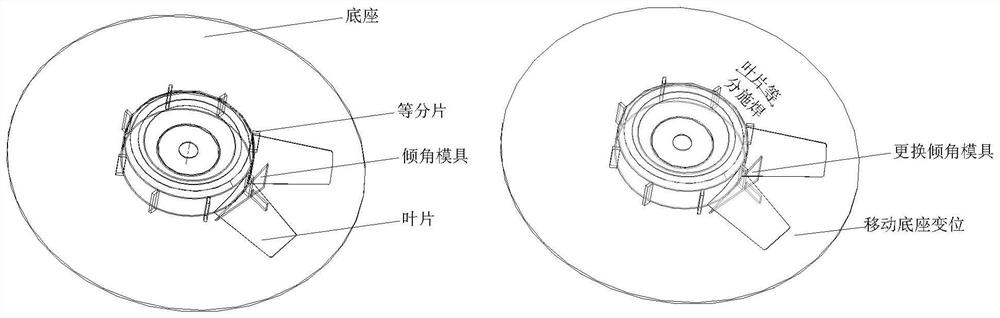

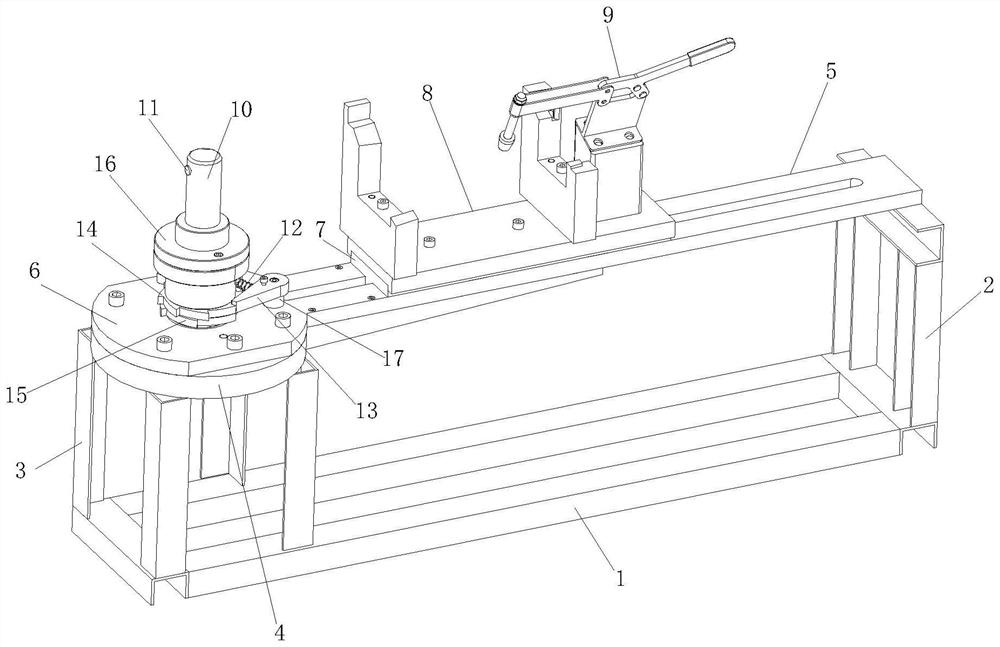

Tool device used for high-precision welding of high-end axial flow fan impeller

InactiveCN113399918AControlling UncertaintyGuaranteed Design RequirementsWelding/cutting auxillary devicesAuxillary welding devicesImpellerPhysics

The invention relates to the field of fan impeller tool equipment, in particular to a tool device used for high-precision welding of a high-end axial flow fan impeller. The tool device comprises a base, a support and a supporting table are respectively fixedly arranged at two ends of the base, a fixed plate is fixedly arranged on the supporting table, a universal fixed seat is detachably and fixedly connected onto the fixed plate, the universal fixed seat is integrally and fixedly connected with a sliding rail, an equal division mechanism for equally dividing the rotation angles of a hub is arranged on the universal fixed seat, the equal division mechanism is detachably and fixedly connected with the hub, a special blade mold matched with blades is arranged on the sliding rail, a quick clamping assembly is arranged on the special blade mold, the blades are fixed to the special blade mold through the quick clamping assembly, the special blade mold pushes the blades to abut against the equal division positions of the hub and is connected with the hub in a welded mode. According to the tool device used for high-precision welding of the high-end axial flow fan impeller, the welding standardization operation is improved, the precision of a welding part is improved, the design and use requirements are met, the labor intensity is reduced, and the working efficiency is improved.

Owner:湖南金诺动力设备制造有限公司

Drainage method of underground water pipe in dam concrete warehouse area

ActiveCN102287003ALittle construction disturbanceCivilization ConstructionDamsClimate change adaptationEngineeringDraining tube

The invention relates to a dam concrete cabin surface water accumulation hidden pipe discharge method. A water discharge main pipe is arranged in a preset region and is communicated with the upstream and the downstream of a dam, water discharge branch pipes are introduced to the left side and the right side of the dam body of the dam from the water discharge main pipe and are communicated with each dam block in a region, and a vertical water discharge branch pipe is connected onto the water discharge branch pipes of each dam block and is communicated with each concrete cabin position in each dam block. The dam concrete cabin surface water accumulation hidden pipe discharge method is characterized in that in the dam concrete casting construction process, the pre-buried water discharge pipenetwork continuously extends and expands to all concrete casting dam blocks along with the dam body concrete casting progress, each newly cast concrete cabin position in the dam region is fully covered, the water discharge problem of large-area accumulated water of the dam concrete cabin surface is solved, a dry ground construction environment condition is created for the concrete casting, the concrete casting quality is ensured, the construction interference is reduced, and the engineering civilization construction is realized.

Owner:CHINA GEZHOUBA GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com