Method used for detecting four-joint guide blade reference arc surface

A technology of guide vanes and arc surfaces, applied in the field of quadruple guide vane processing, can solve problems such as inaccurate measurement data evaluation, achieve the effects of improving product qualification rate, ensuring design requirements, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

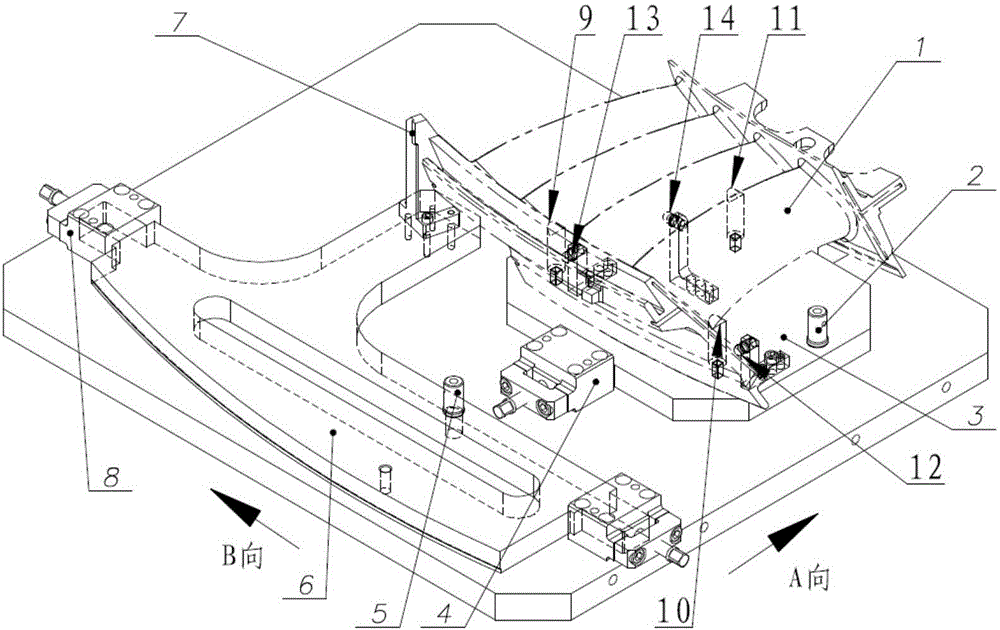

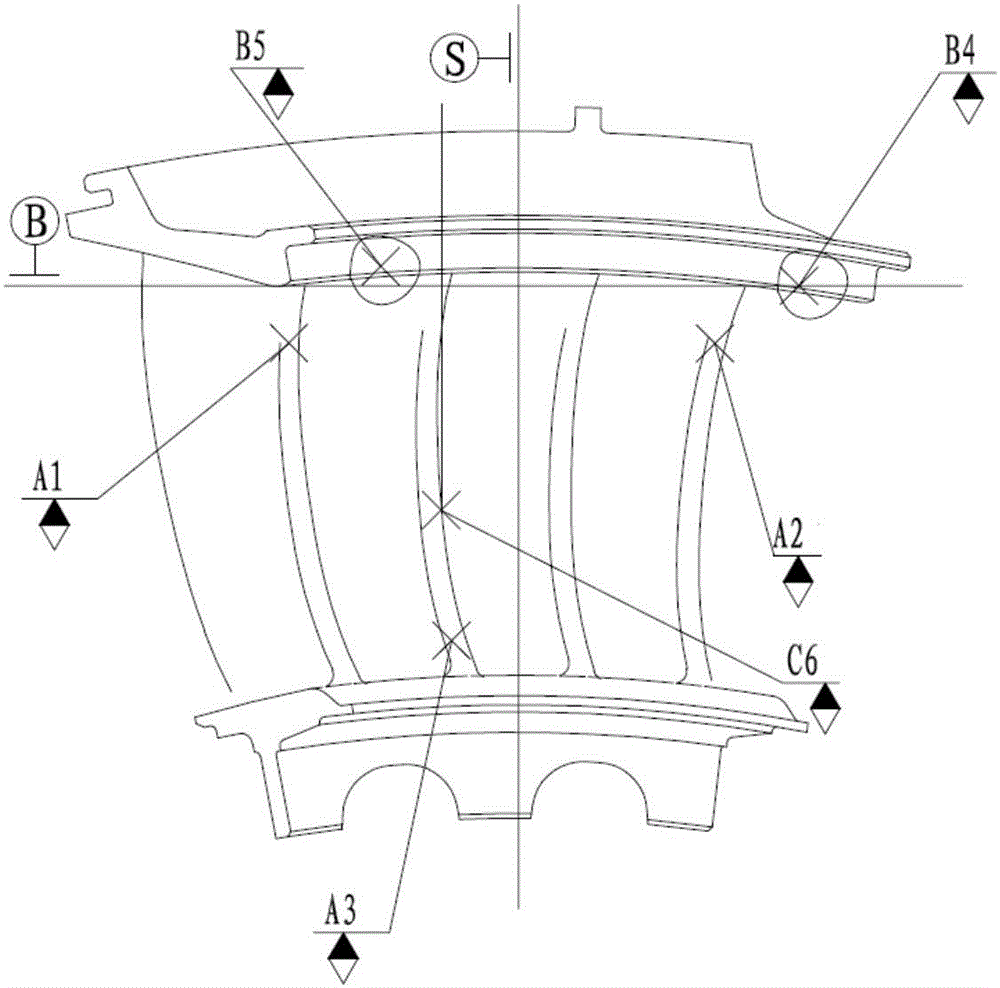

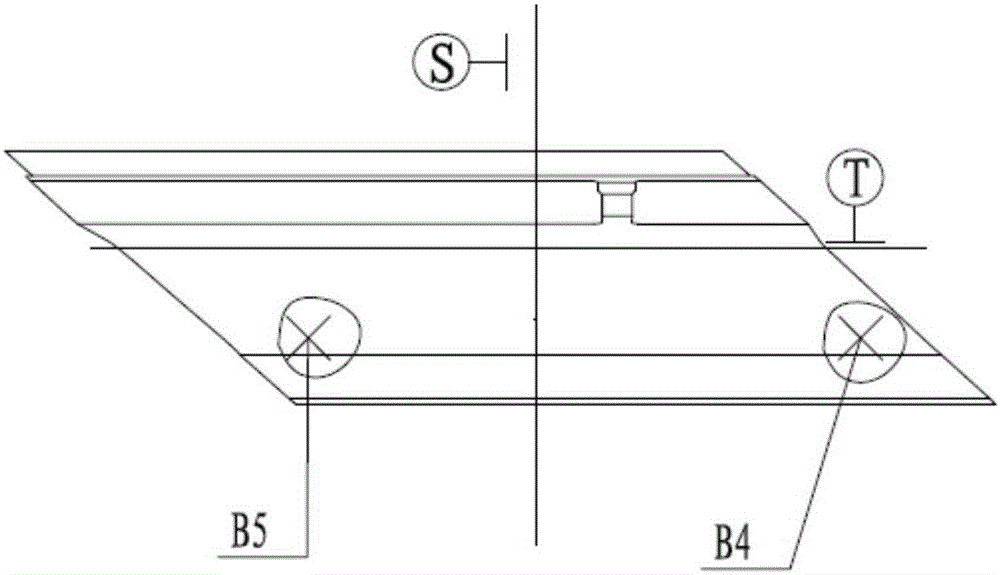

[0026] In the method for detecting the reference arc surface of the quadruple guide vanes in this embodiment, the detection device used has a structure such as figure 1 , Figure 3-1 , Figure 3-2 , Figure 3-3 , Pic 4-1 Figure 4-2 As shown, the structure of the detected quadruple guide vanes is as follows diagram 2-1 , Figure 2-2 and Figure 2-3shown. In this embodiment, the A1 point positioning member 9, the A2 point positioning member 10 and the A3 point positioning member 11 used to locate the leading edge of the quadruple guide blades are positioning pins fixed on the bottom plate 15, and the positioning pins are connected to the quadruple joints through the positioning pin cylinder. Functional positioning of the leading edge of the guide vane; the B4 point positioning member 12 and the B5 point positioning member 13 used to locate the back of the reference arc surface of the quadruple guide vane, and the C6 point positioning member 14 used to locate the back o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com