Shield tunnel grouting layer performance detection method

A detection method and technology of shield tunneling, applied in the field of construction science, can solve problems such as the inability to detect the quality of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

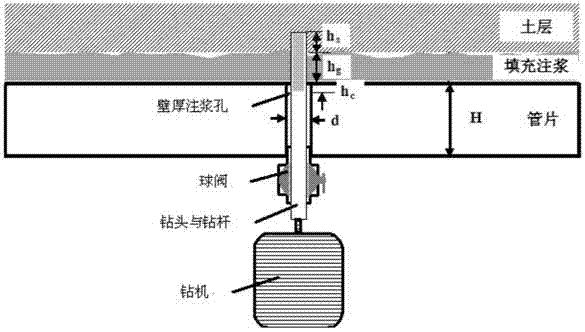

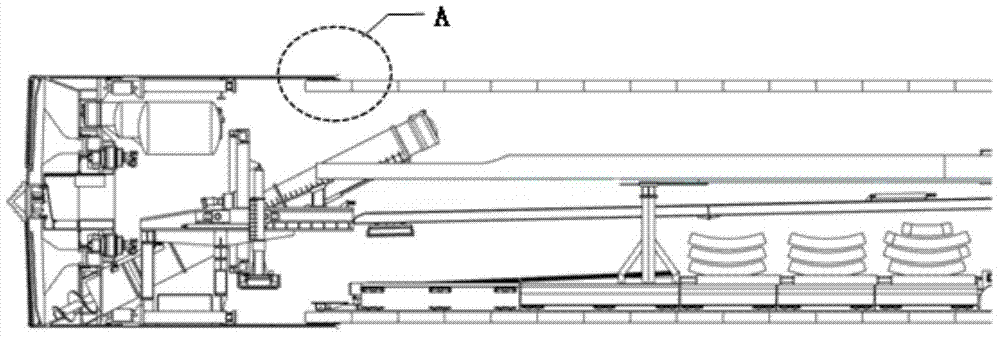

[0026] as attached Figure 1~4 As shown, a shield tunnel grouting layer performance testing method is characterized in that it includes the following steps:

[0027] First, unscrew the bulkhead of the reserved grouting hole in the tunnel segment;

[0028] Next, install the ball valve at the reserved grouting hole of the segment, the inner diameter of the ball valve is 40mm

[0029] Then, position the drilling rig, and install the drill bit and drill pipe on the drilling rig;

[0030] The fourth step is to pass the drill bit and drill pipe through the ball valve, drill through the grouting hole into the grouting layer, and then extend into the soil layer around the tunnel. The drill bit extends into the soil layer 100mm;

[0031] The fifth step is to pull out the drill bit from the drill hole, take out the core sample, and put it into the sample cylinder;

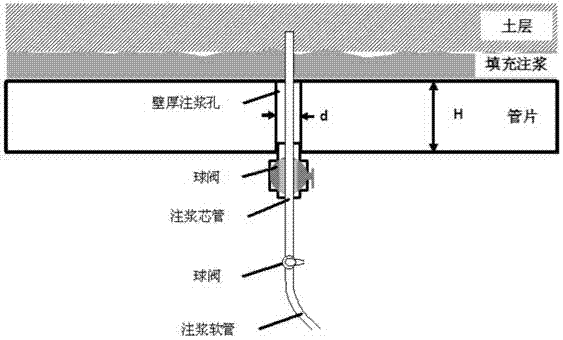

[0032] as attached Figure 5 As shown, finally, the grouting core pipe is passed through the ball valve and inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com