Excavator base with embedded auxiliary fuel tank

A technology for excavators and auxiliary fuel tanks, which is applied in the direction of earth movers/shovels, substructures, and buildings, can solve problems such as single base function, achieve compact structure, prolong continuous working time, and reduce security conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

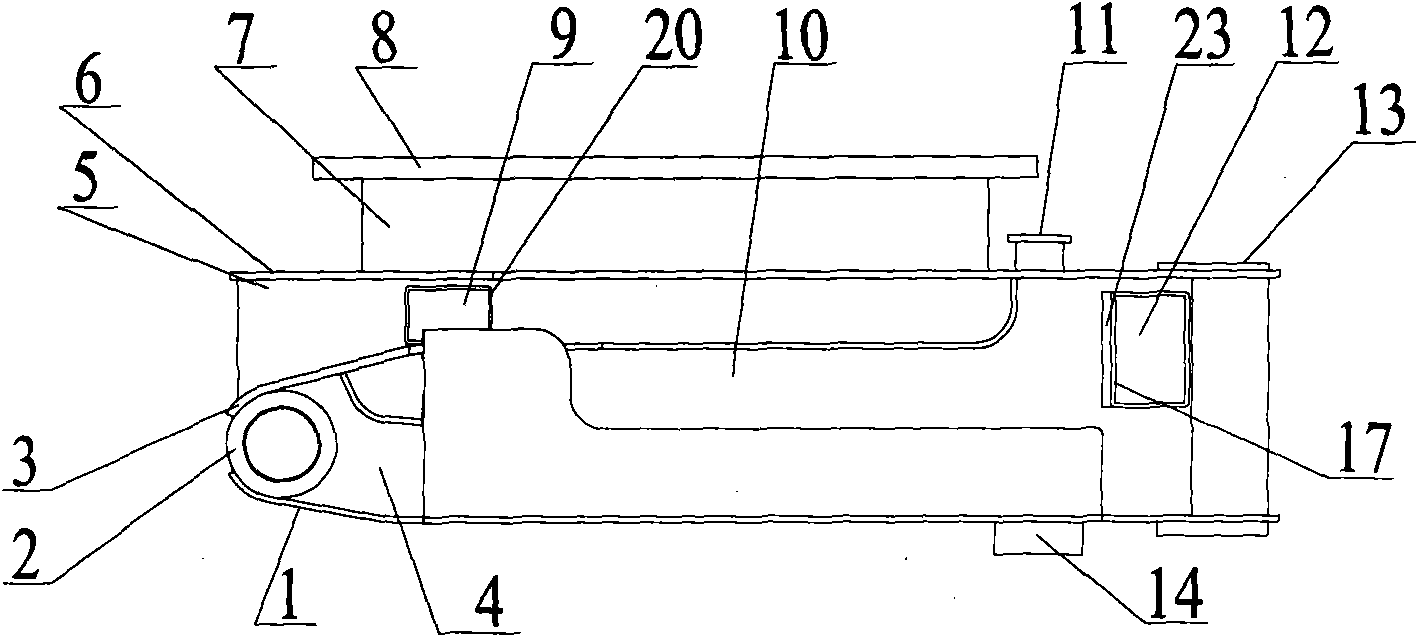

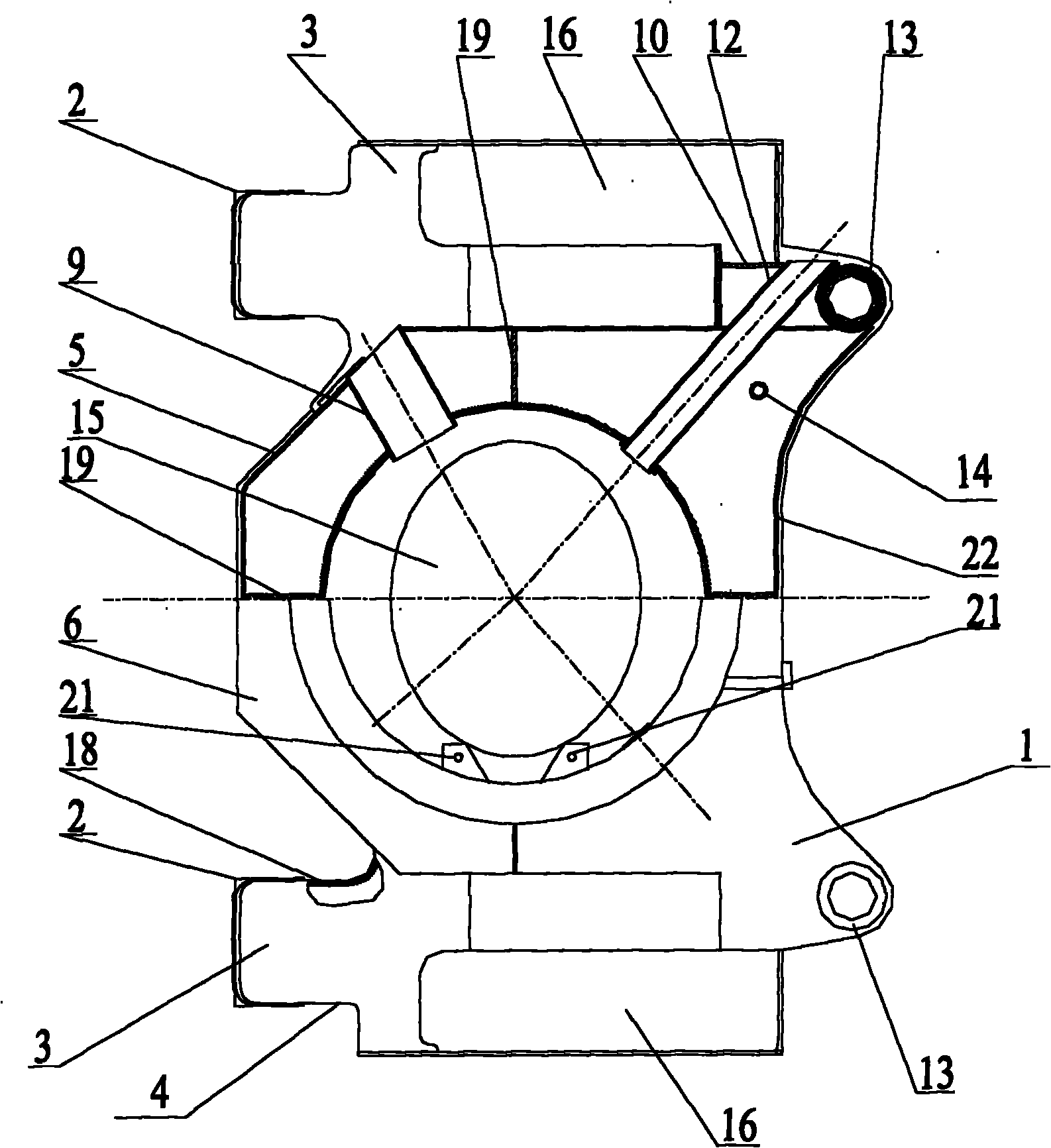

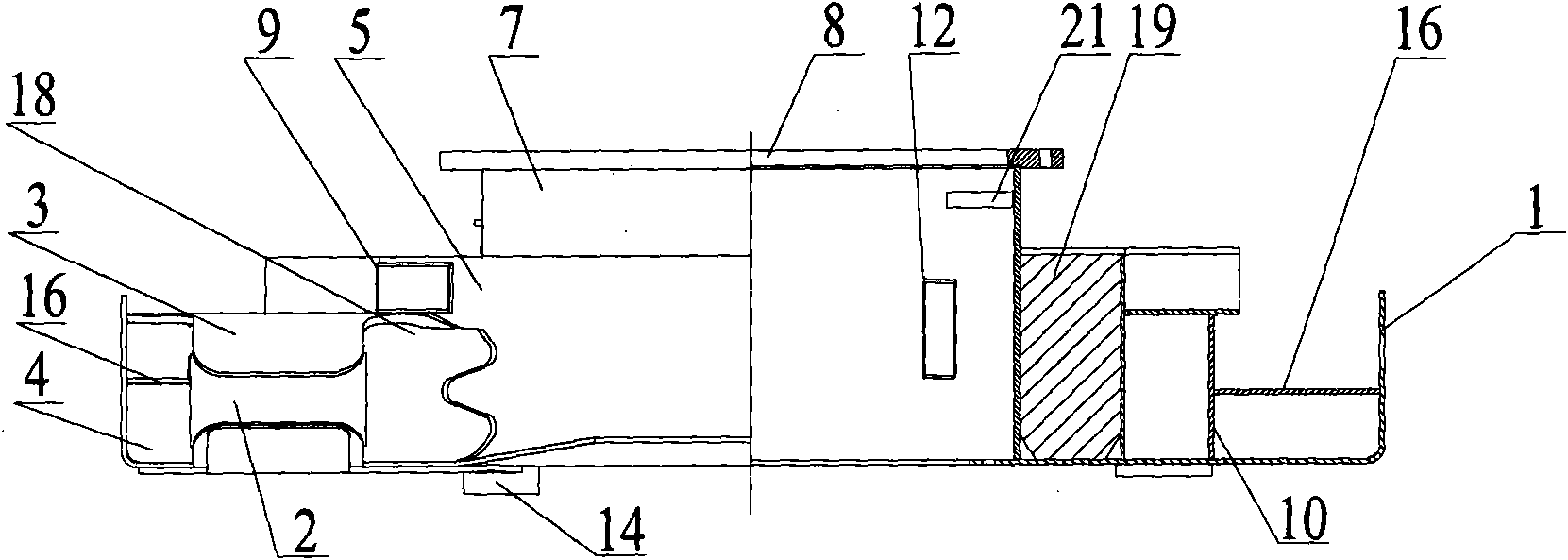

[0017] see Figure 1-Figure 3 , the bottom plate 1 of the excavator base of the present invention is a U-shaped structure with left and right upward warping edges, a central hole 15 is opened in the middle of the bottom plate 1, and a central cylinder 7 enclosing the central hole 15 is arranged outside the central hole 15. . A front leg bushing 13 is installed vertically on both sides of the front end of the base plate 1, and a rear leg bushing 2 is horizontally installed on both sides of the rear end of the bottom plate 1; Cylindrical structure with through holes. The periphery of the central cylinder 7 is enclosed by the rear baffle 5 of the fuel tank and the front baffle 22 of the fuel tank, and together with the bottom plate 1 forms a closed cavity—that is, the auxiliary fuel tank. The fuel tank rear baffle 5 is in a convex shape symmetrical to the axis, and the fuel tank front baffle 22 is in a concave shape symmetrical to the axis. . In the auxiliary fuel tank, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com