Self-triggering voltage setting method of spark gap of 500kV series compensation system

A spark gap and self-triggering technology, applied in spark gap adjustment and other directions, can solve the problems of large dispersion of self-triggering voltage, self-triggering of main gap, bypass of series compensation, etc., and achieve the effect of reducing false self-triggering of spark gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

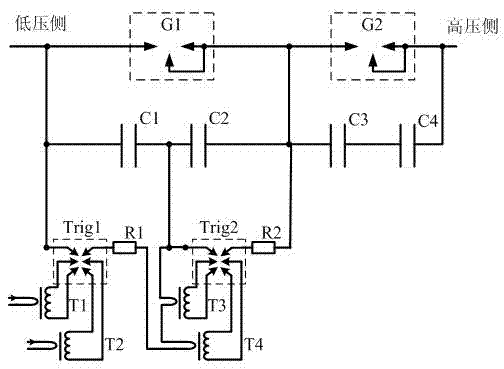

Method used

Image

Examples

Embodiment 1

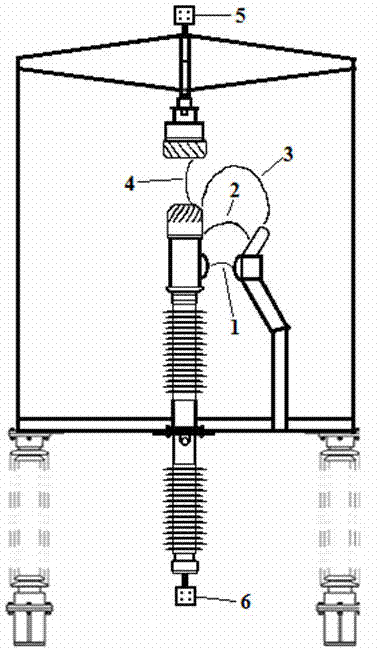

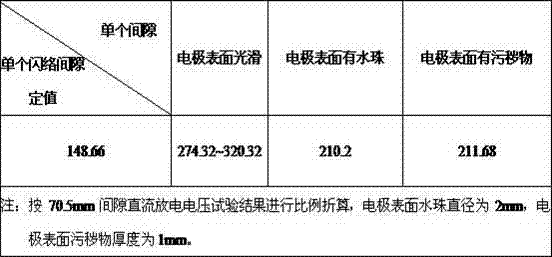

[0037] Balance I circuit and II circuit series compensation are located in Pingguo series compensation station, the series compensation protection level is 190kVp (2.3p.u.), and the self-trigger voltage setting value is 209kVp. The spark gap model is XLSK-30PL, which is composed of two spark gap chambers. The flashover gap self-triggering voltage of each gap chamber is 104.5kVp. Each gap chamber has two trigger gaps, and each trigger gap has a self-triggering voltage setting value It is 52.3kVp. According to the experimental research results, when the electrode surface is smooth and clean, the self-triggering voltage range of the flashover gap is 93~116kVp; ~74.4kVp, that is to say, the normal range of the self-triggering voltage of the entire flashover gap is 186~232kVp. Under abnormal conditions, the self-triggering voltage is 136~148.8kVp; in extreme cases, the self-triggering voltage is 99kVp. Because of this, when the second line of the sky fails, the series compensation...

Embodiment 2

[0048] According to the adjustment strategy proposed by the present invention, the self-triggering value of each flashover gap of the PCS-GAP-160 spark gap produced by Nanjing Nanrui Jibao Electric Co., Ltd. was adjusted to 1.8p.u., and its working reliability was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com