Ultrahigh-temperature thermal current simulation system used for spacecraft vacuum thermal test

A vacuum thermal test and simulation system technology, which is applied in the field of heating simulation systems under ultra-high temperature and extremely high heat flow conditions, can solve problems such as inability to simulate thermal environments, and achieve the effect of ensuring smooth development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following introduction is the specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

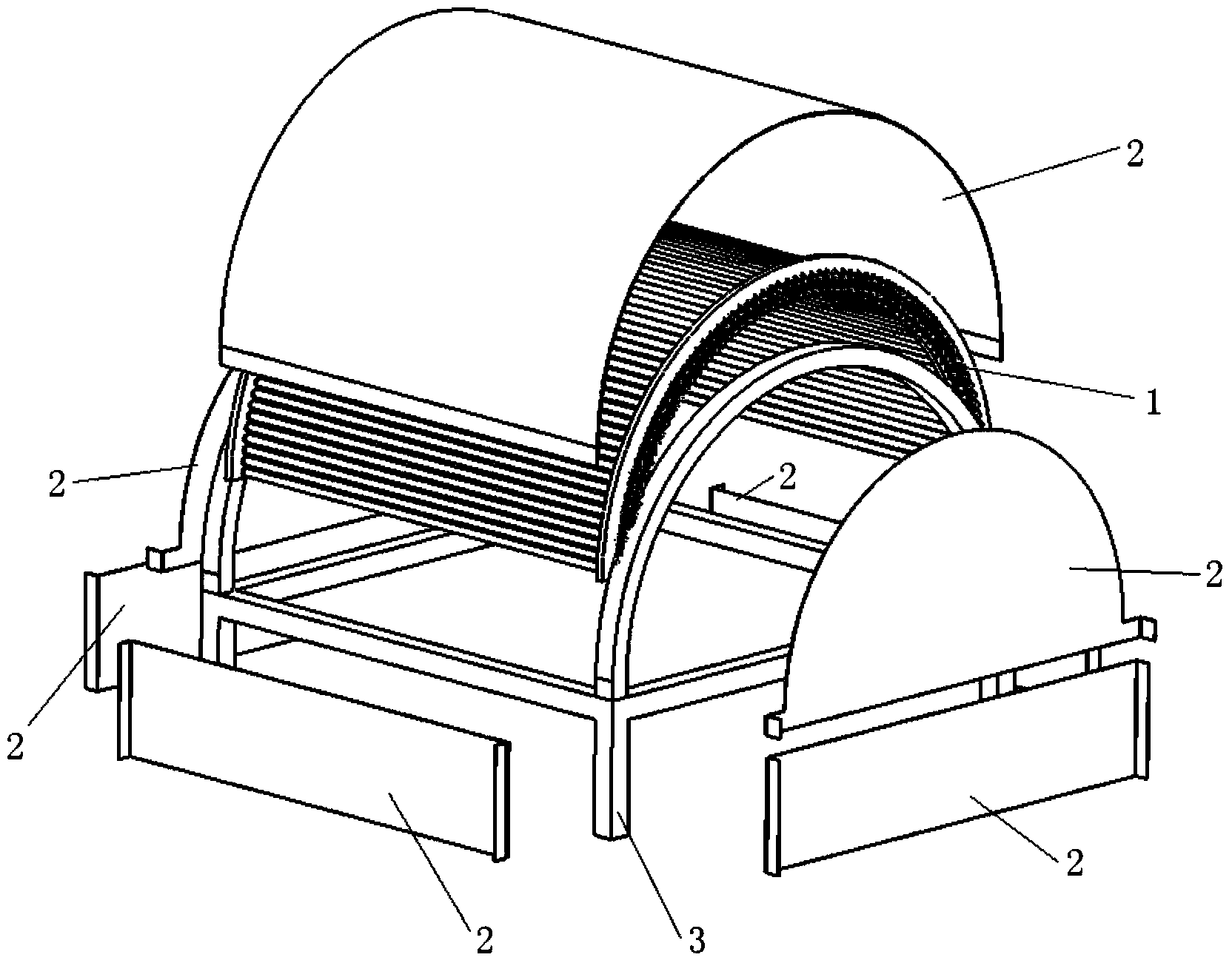

[0019] The present invention is an ultra-high temperature and extremely high heat flow simulation system for spacecraft vacuum heat test in a vacuum low-temperature environment simulation container. The structure diagram is as follows figure 1 as shown,

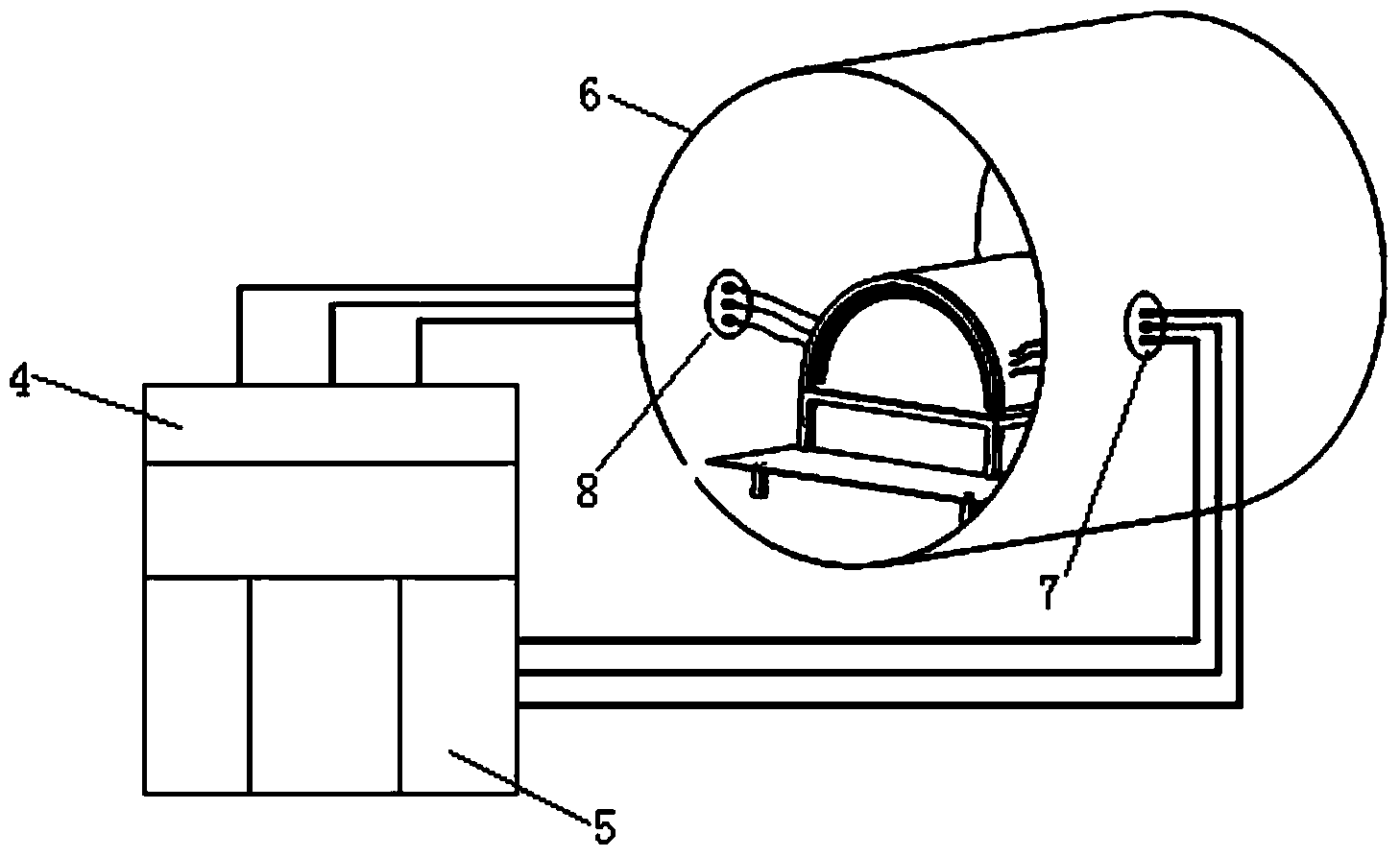

[0020] The ultra-high temperature and extremely high heat flow simulation system of the present invention mainly includes a semi-cylindrical graphite heating array 1, a high-reflectivity high-temperature heat insulation component unit 2, a graphite heating array mounting bracket 3, an ultra-high temperature mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com