Process for producing moderate temperature modified bitumen by continuously pressurizing and hot-polymerizing at two stages connected in series

A modified asphalt, medium temperature technology, applied in the direction of chemical processing of tar pitch/petroleum pitch/natural pitch, etc., can solve the problems of limited production capacity, high equipment requirements, low reaction pressure, etc., and achieve the improvement of equipment operating rate and equipment The effect of low requirements and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

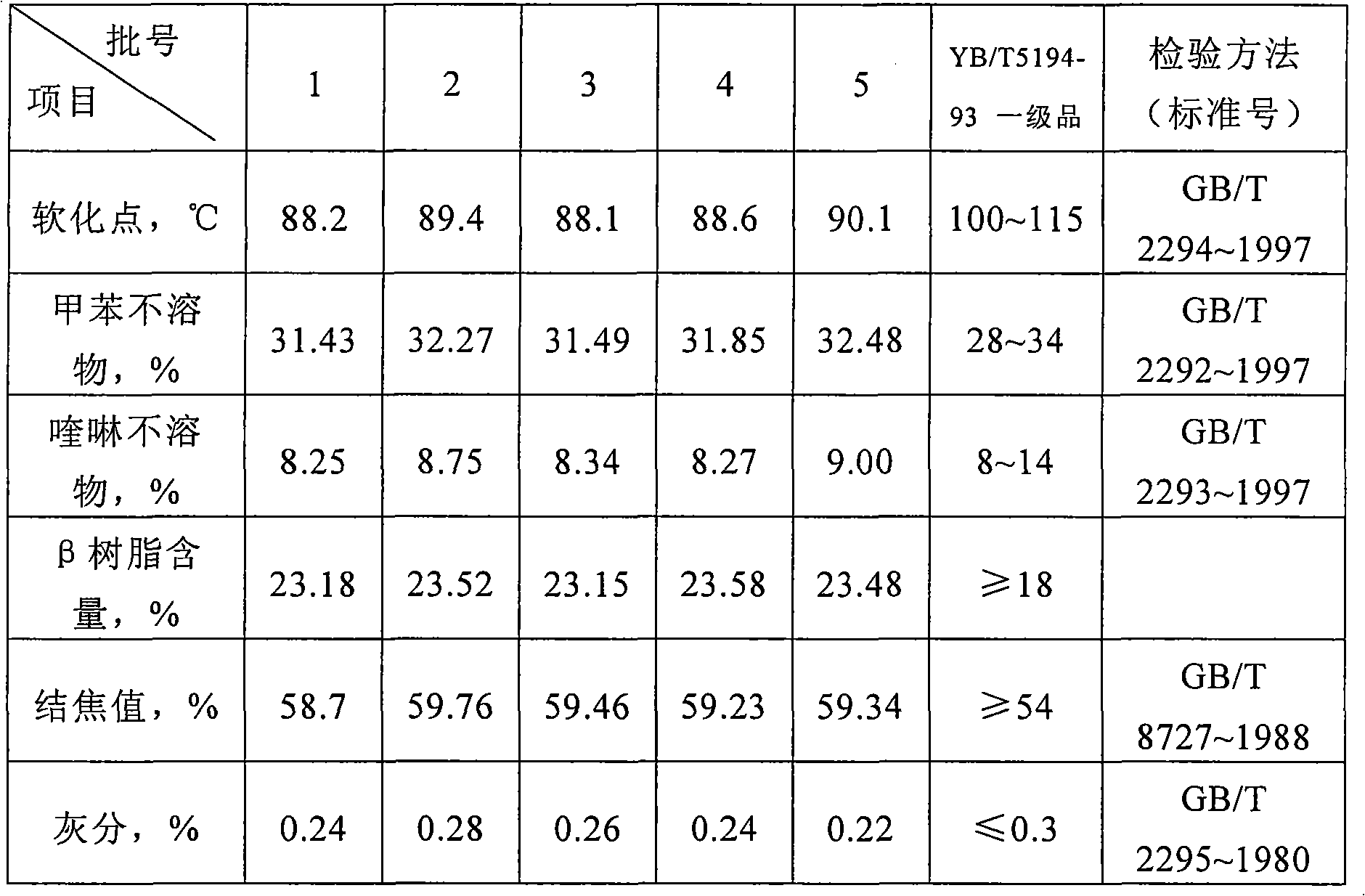

[0084] In this embodiment, the medium-temperature asphalt discharged from the tar secondary evaporator is used as the raw material, and the production device can process 100,000 tons of medium-temperature asphalt annually. Among them, "medium-temperature asphalt discharged from the tar secondary evaporator" refers to a medium-temperature asphalt with a softening point of 75-90°C, 15-25% of toluene insolubles, <6% of quinoline insolubles, and <0.3% of ash.

[0085] In this example, two stages and two reactors connected in series are used for asphalt upgrading.

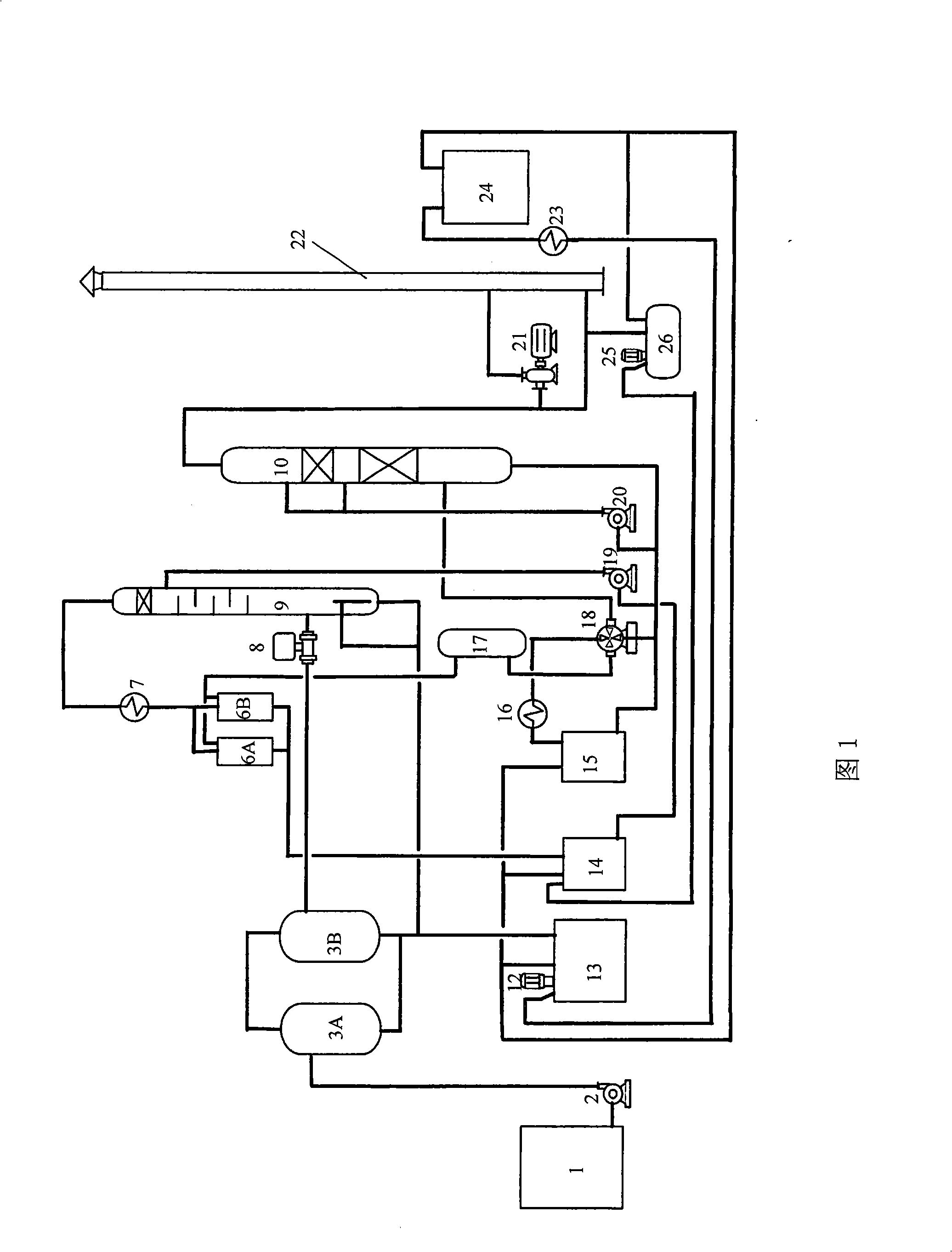

[0086] Referring to Figure 1, the medium-temperature asphalt enters the medium-temperature asphalt raw material tank 1, and the temperature of the asphalt in the raw material tank 1 is 340-360 ° C. After the asphalt raw material pump 2 is pressurized to 0.8-1.0 Mpa, it enters the first-stage thermal polymerization reactor 3A, and the reactor The volume is 20m 3 , In this reactor, the medium-temperature asphalt is heate...

Embodiment 2

[0099] In this embodiment, medium-temperature modified asphalt is produced from medium-temperature asphalt from the tar tank farm. Among them, "medium-temperature asphalt from the tar tank farm" refers to the medium-temperature asphalt produced during the start-up and shutdown of tar distillation and production adjustment, with a low content of toluene insolubles and low temperature, with a softening point of 80-90°C and a toluene-insoluble content of 25 ~28%, quinoline insoluble matter 6~10%.

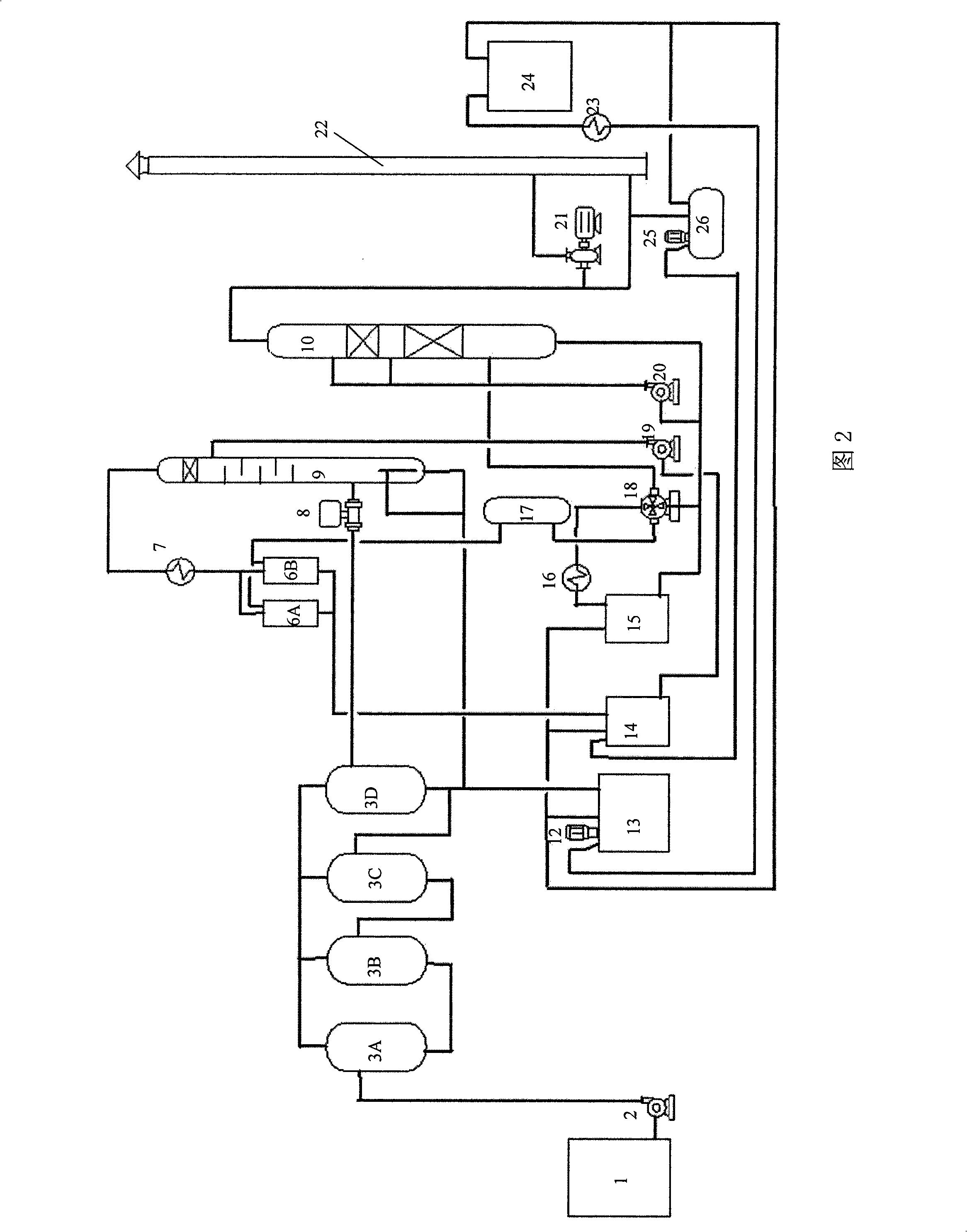

[0100] As shown in Figure 2, in this embodiment, four reactors in series are used for production. The medium-temperature asphalt in the tank area is sent to the medium-temperature asphalt raw material tank, pressurized by the asphalt booster pump, and then sent to the upper part of the reactor 3A for the first stage of reaction, and the materials for the reactor 3B, reactor 3C, and reactor 3D for the second stage of the reaction are all Feed from the bottom of the reactor and discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com