Preliminary bracing construction method for tunnel with surrounding rocks containing collapsible loess and soft rocks

A technology of collapsible loess and initial support, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of increased tunnel support, increased construction difficulty, poor self-stabilizing ability, etc., and avoid long-term suffering. Excessive force, low construction cost, and the effect of releasing surrounding rock stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

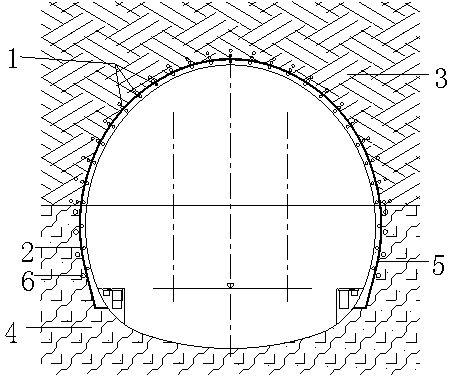

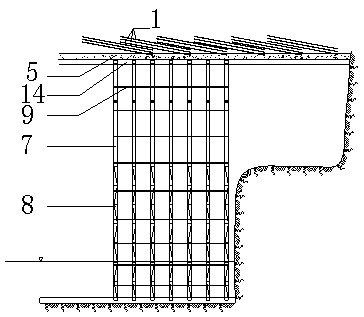

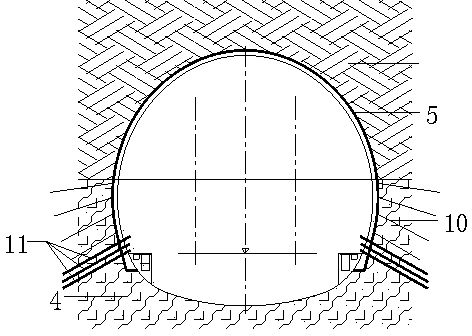

[0030] A construction method for primary support of a tunnel with collapsible loess and soft rock in the surrounding rock of the present invention, there are two types of rock-soil layers on the cross-section of the tunnel surrounding rock, that is, the tunnel surrounding rock contains collapsible loess and soft rock at the same time. The loess layer 3 and the soft rock layer 4, and the collapsible loess layer 3 is located above the soft rock layer 4, the construction method of the present embodiment specifically includes the following steps:

[0031] (1) Construction advanced pipe shed

[0032] Such as figure 1 As shown, the concrete arch is constructed outside the outline of the open cave as a guide wall, the I-beam is pre-embedded in the arch, and the guide steel pipe is accurately placed according to the designed hole position. The I-beam and the guide steel pipe are welded as a whole. Use the theodolite to determine the plane position of the orifice pipe on the I-beam wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com