Insulation structure of ground power supply sliding contact wire of electric flat car and construction technology thereof

A technology of ground power supply and electric flat car, which is applied to vehicle components, devices along the running track, laying tracks, etc., can solve the problems of complex construction process, and achieve the effects of increasing economic benefits, reducing construction costs, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

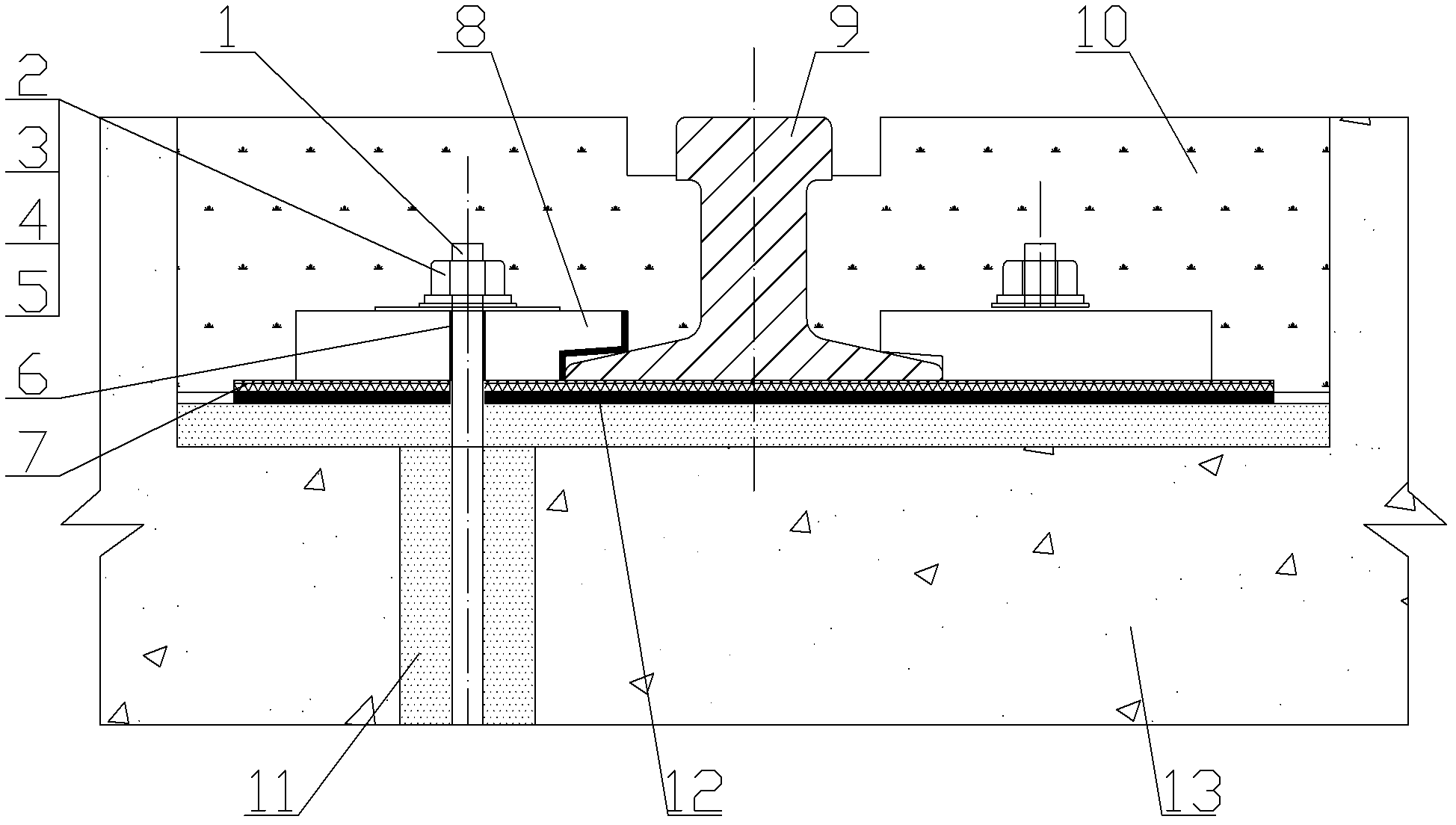

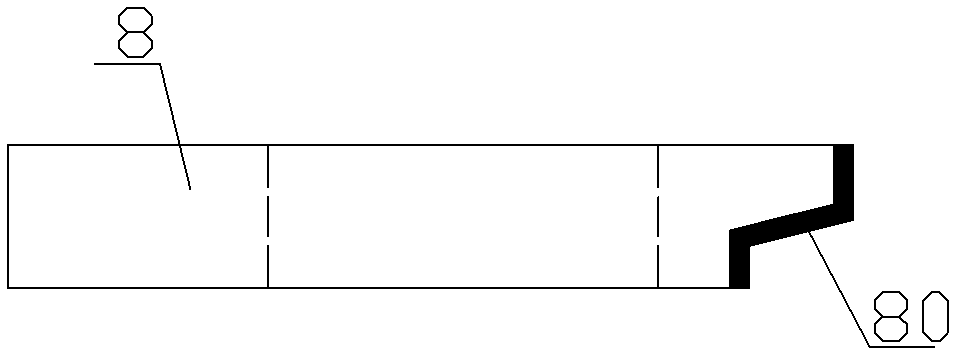

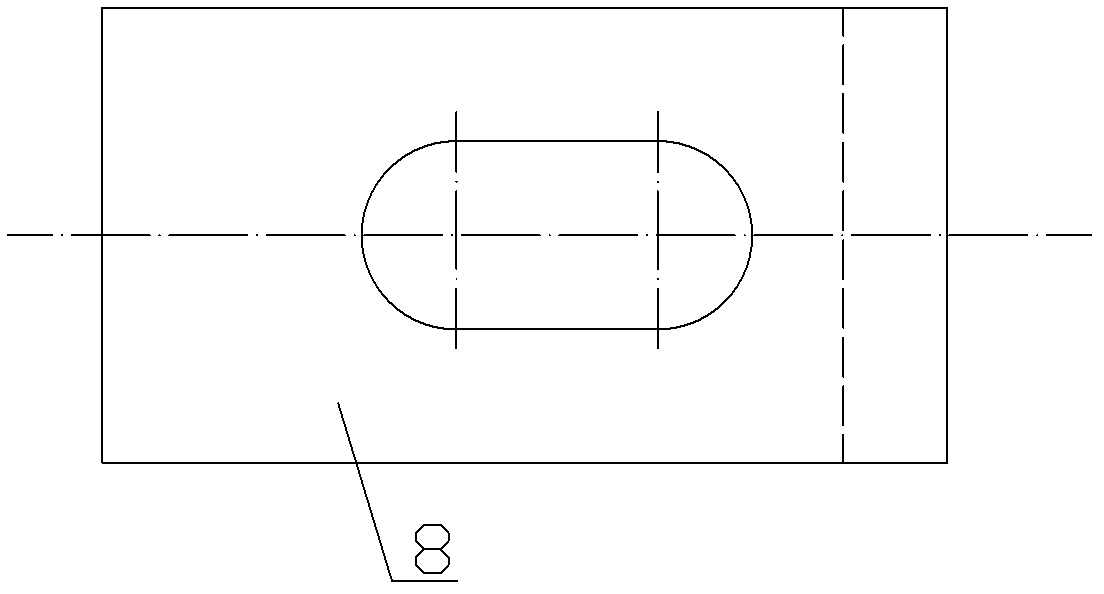

[0029] Such as figure 1 As shown, this embodiment discloses an insulation structure for ground power supply trolley lines of an electric flat car. The track 9 of the electric flat car is arranged in the groove of the foundation 14 of the flat car, and the two sides of the track 9 are respectively installed on the anchor bolts 1 The upper pressing plate 8 is fixed. An elastic insulating backing plate 7 and a steel backing plate 12 are successively laid under the track 9 and the pressure plate 8 , and high-strength grouting material 11 is filled between the steel backing plate 12 and the flat car foundation 14 . A nut 2 for fixing the pressure plate 8 is arranged on the top of the anchor bolt 1 , and a spring washer 3 and a steel washer 4 are arranged in sequence between the nut 2 and the pressure plate 8 .

[0030] According to the requirements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com