A Proucting Approach for Oblique Oil Hole in Bearing Retainer

A technology of a solid cage and a processing method, applied in the field of bearing cage processing, can solve the problems of high cost, large drilling force, low efficiency, etc., and achieve the effect of reducing processing cost and ensuring design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention are described with reference to the accompanying drawings.

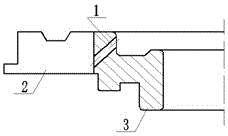

[0018] Such as figure 1 The shown cage 3 has a cage pocket 2 on it, and an oblique oil hole 1 is provided at the bottom of the cage pocket 2. The method for processing the oblique oil hole of a bearing entity cage according to the present invention mainly includes processed as figure 1 The shown oblique oil hole 1 comprises the following steps:

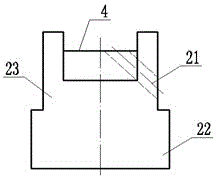

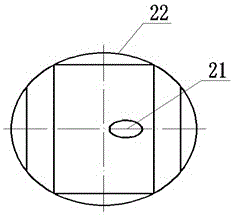

[0019] a: Manufacture of special drill guiding device (tooling): such as figure 2 , image 3 , Figure 5 The shown guiding device is composed of a circular platform 22, a rectangular boss 23, a draw-in groove 4, an oblique positioning hole 21, and a guiding drill sleeve 13. The round table 22 and the rectangular boss 23 are integrally formed. In the embodiment, the round table 22 is made of a copper rod of suitable size, and the rectangular boss 23 and the slot 4 are milled on a vertical machining center. The rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com