Heavy automobile two-segment drive bridge set collar processing method

A heavy-duty vehicle and processing method technology, applied in the field of auto parts, can solve problems such as endangering safe driving, aggravating parts, and early damage to wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

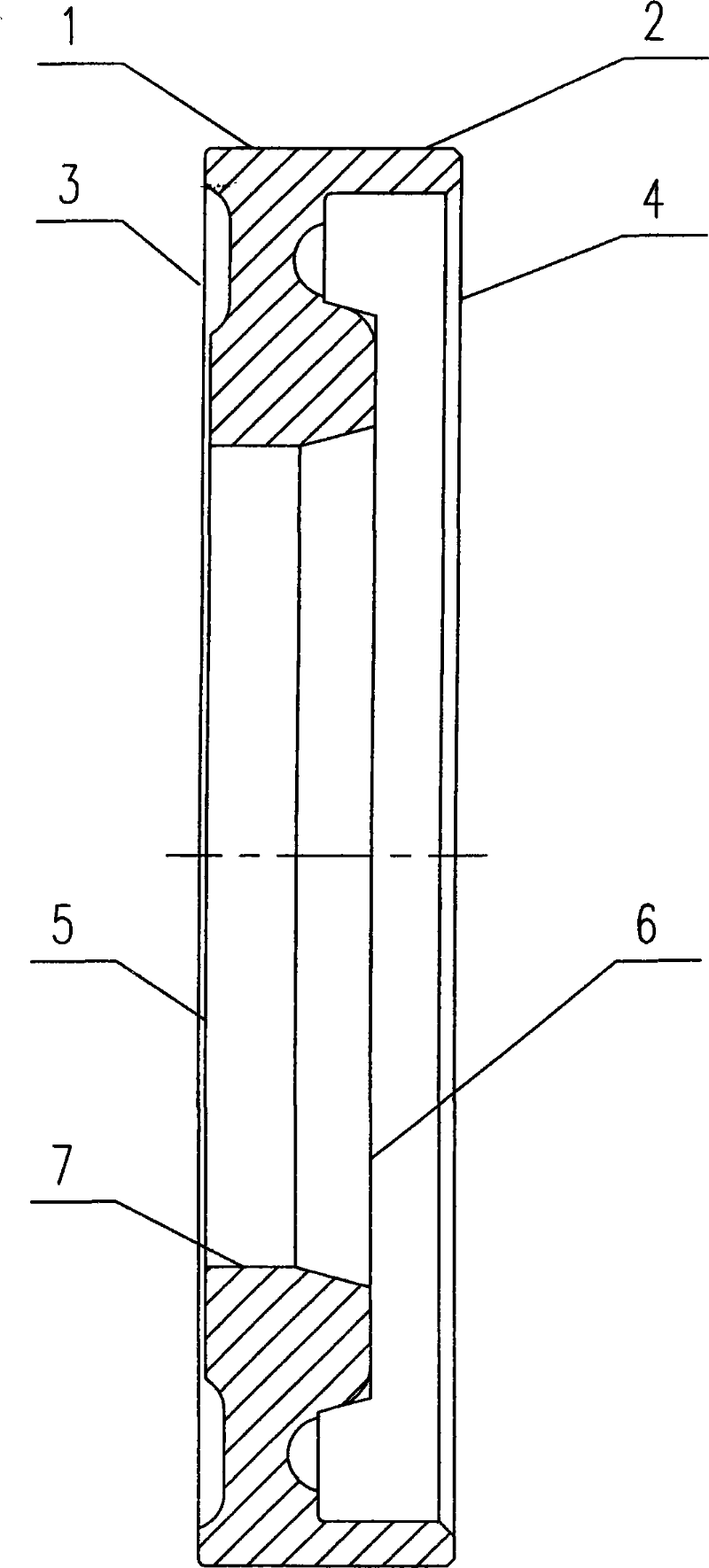

[0018] Embodiment: As shown in the accompanying drawings, the specific process steps of processing the driving axle spacer are as follows:

[0019] 1. According to the size and precision of the workpiece, the selected equipment for the production of the drive axle spacer is determined to be: ordinary lathe, CNC lathe, and grinding machine. Co-sign the blank drawing with the forging factory to determine the blank forging requirements and rough machining benchmarks;

[0020] 2. According to the processing equipment and workpiece requirements, design the processing plan and tooling fixture for each process, and determine the specifications and models of the tools used according to the hardness of the processed workpiece;

[0021] 3. Take the rear end face 3 and half of the outer circle A1 of the workpiece as the reference, and clamp them with jaws, and turn the front end face 4 and the other half of the outer circle B2 on the CK50 CNC lathe. At this time, the processing size must ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com