Flexible welding production line for side wall plate of automobile

A welding production line, automobile side technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment and other directions, can solve the problems of easily damaged parts surface, shunt and operation difficulties, low degree of flexibility, etc., to reduce equipment capital investment , The effect of improving flexible production capacity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

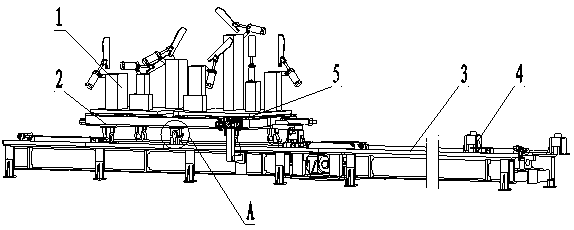

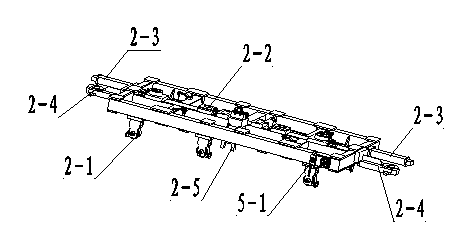

[0021] Referring to Fig. 1, the present invention comprises clamp body 1, trolley 2, frame 3, drive mechanism 4 and PLC control system 5, and described clamp body 1 is installed on the trolley 2, and described trolley 2 is connected with drive mechanism 4, Under the control of the PLC control system 5, it is pulled by the driving mechanism 4 and reciprocates on the track of the frame 3 to realize the delivery of the fixtures and workpieces of the welding production line. The driving mechanism 4 is arranged on the frame 3, and the frame 3 Fixed on level ground.

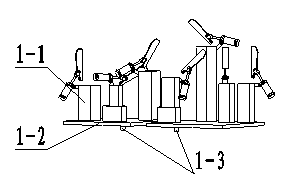

[0022] See Figure 1, figure 2 , the clamp body 1 of the present invention includes a set of clamp units 1-1 and a clamp fixing plate 1-2, the number and layout of the clamp units 1-1 match the structure of the welded workpiece, and the clamp unit 1-1 is installed on the clamp On the fixing plate 1-2, the bottom surface of the fixture fixing plate 1-2 is provided with a main fixture positioning pin 1-3, and the main f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com