Production line process simulation optimization method and system

A technology of process simulation and optimization method, applied in the direction of design optimization/simulation, special data processing application, etc., can solve the waste of resources, production cost, prolonged manufacturing cycle, small batch, multi-variety characteristic manufacturing resource allocation, process capability and load balance Synchronous manufacturing takt control, complete set of node planning, manufacturing cost control and optimization difficulties, etc., to achieve the effect of efficient utilization, balanced manufacturing capacity, and reduction of uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings.

[0046] In order to meet the needs of the new model of intelligent manufacturing in the military industry, and closely focus on the outstanding problems in the "variable batch, multi-variety production" model and the manufacturing guarantee requirements for new product development, a digital production line modeling and simulation system suitable for the military industry is proposed. Optimize technical solutions.

[0047] An embodiment of the present application provides a production line process simulation optimization method, and the main process of the method is described as follows.

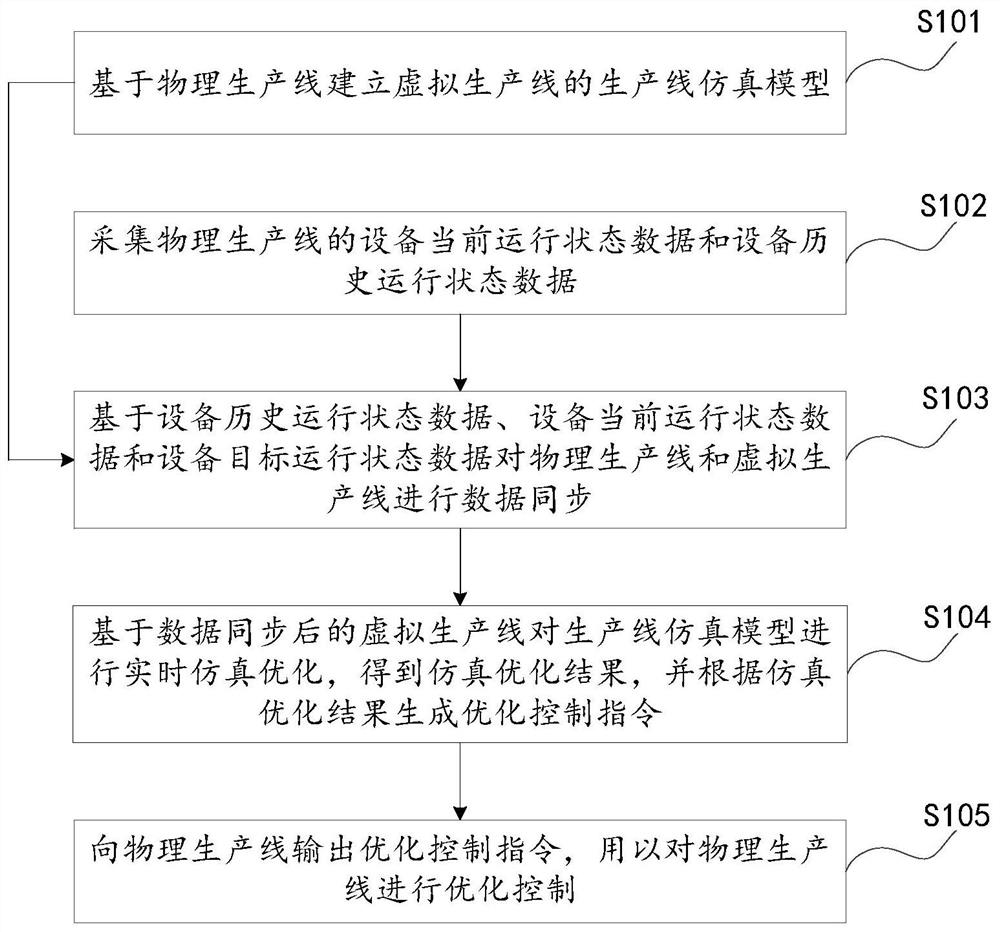

[0048] refer to figure 1 , the production line process simulation optimization method includes (steps S101~S105):

[0049] Step S101, establishing a production line simulation model of a virtual production line based on a physical production line;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com