Flexible device for punching forming of egg-box-shaped structures

A stamping forming and egg box technology, applied in the field of mechanical engineering, can solve the problems of single type and unadjustable punch spacing, and achieve the effect of improving efficiency and flexible production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

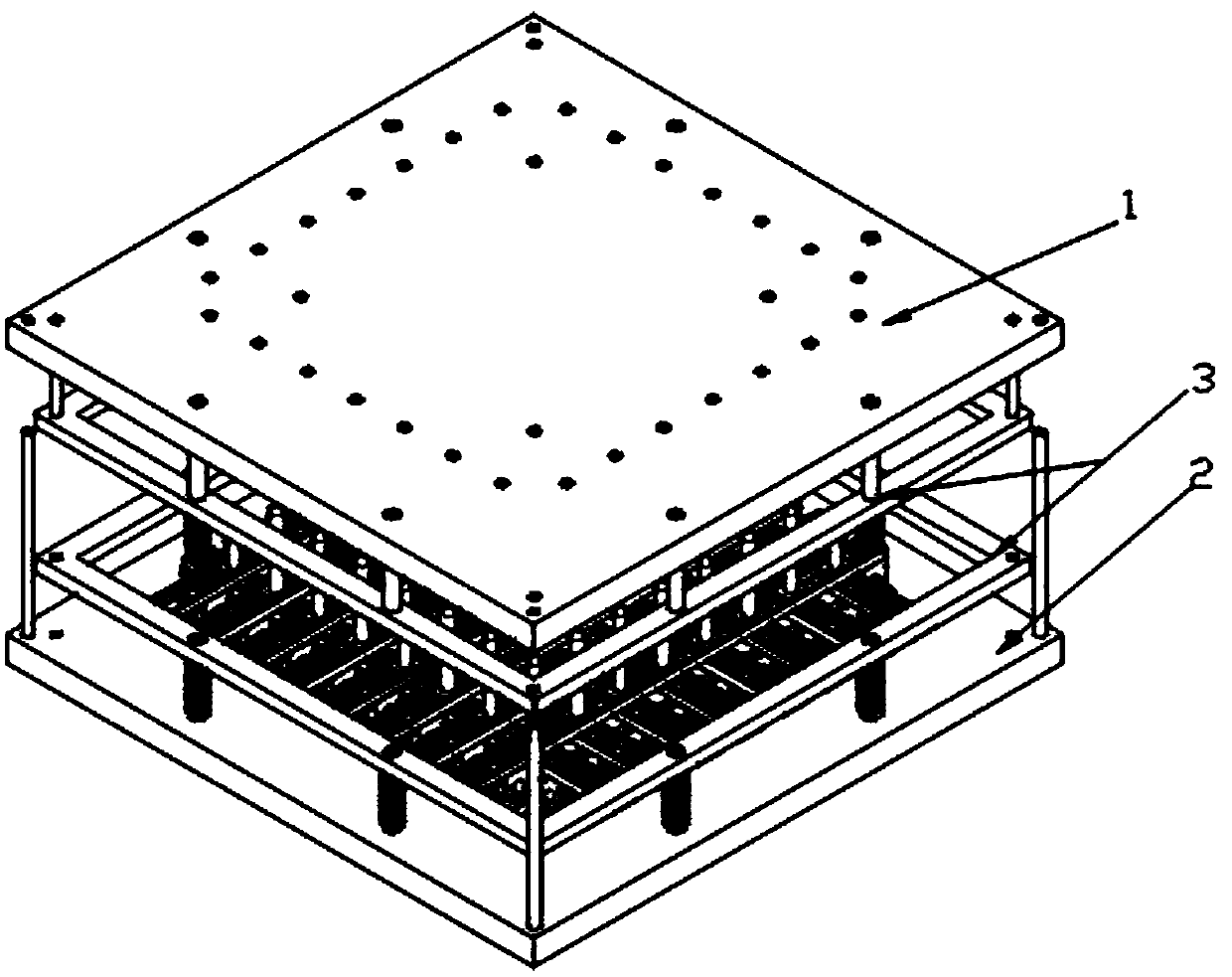

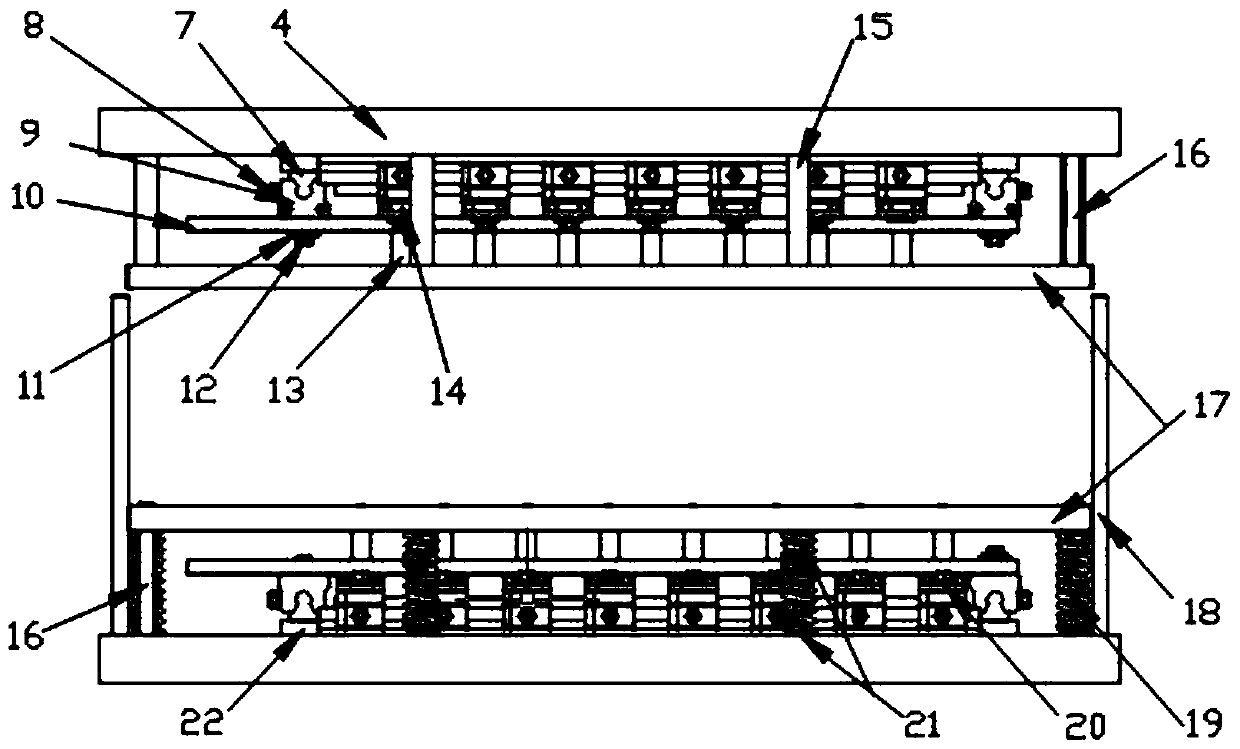

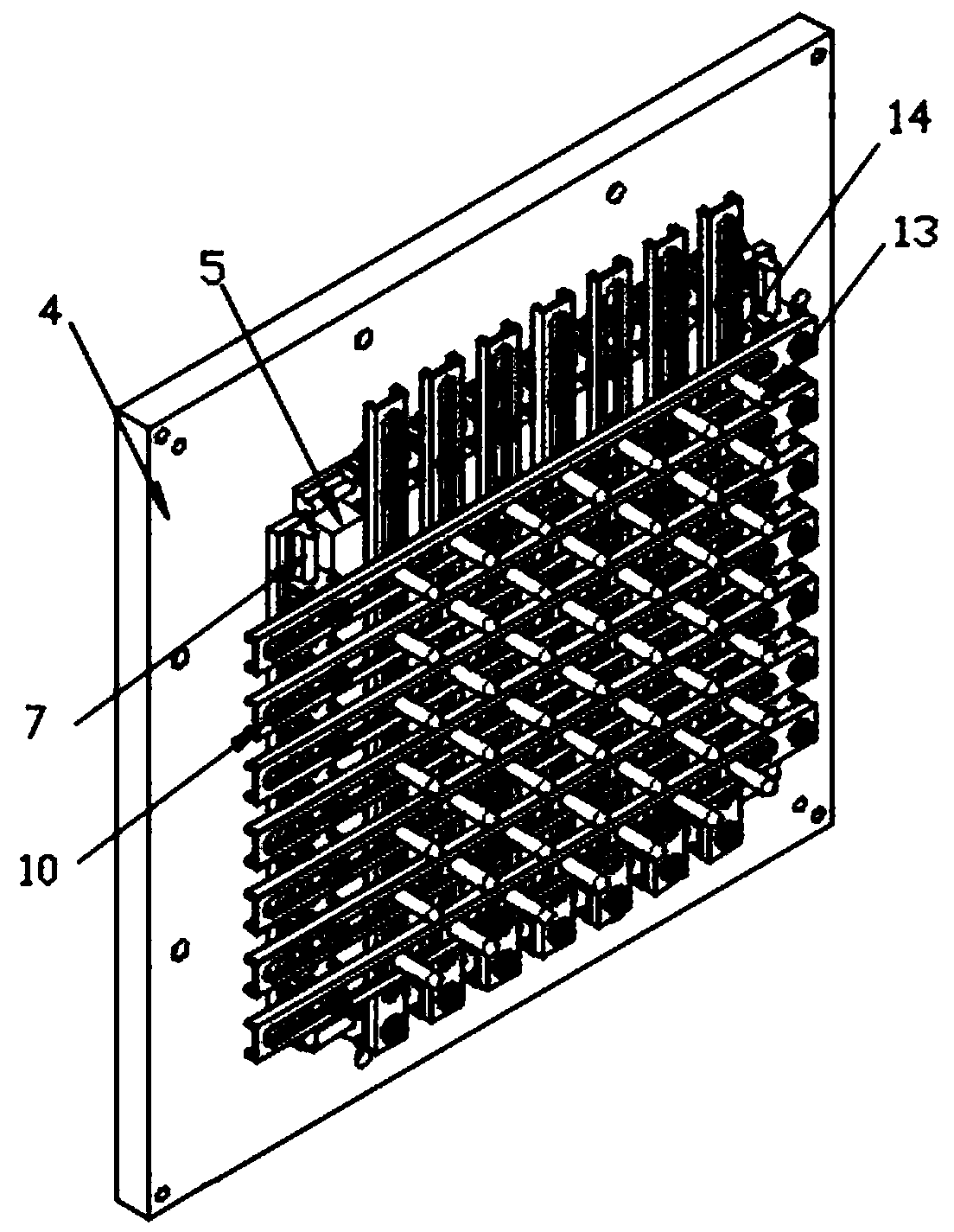

[0022] Figure 1 is a schematic diagram of a flexible mold for stamping an egg-box-shaped structure. The upper part of the figure is a pressing unit 1 equipped with an adjustable punch, the lower part is a fixed unit 2 equipped with an adjustable punch, and an edge-holding mechanism 3 for clamping the stamped sheet is installed between the two units. According to the shape of the egg box to be processed, first adjust the distance and position of the punches of the pressing unit 1 through the guide rail slider adjustment mechanism, so that the punches on the pressing unit 1 are arranged according to the egg box-shaped structure to be punched, and then according to The punch position of the pressing unit 1 is also adjusted by the guide rail slider adjustment mechanism to adjust the punch position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com