Positioning tool for gear pitch circle clamp

A technology for positioning tooling and gear joints, which is applied in the field of gear processing, can solve the problems of low processing efficiency, high labor cost, difficulty in passing the gear index circle and radial runout of the inner hole, etc., and achieve the effect of convenient and simple assembly and disassembly, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

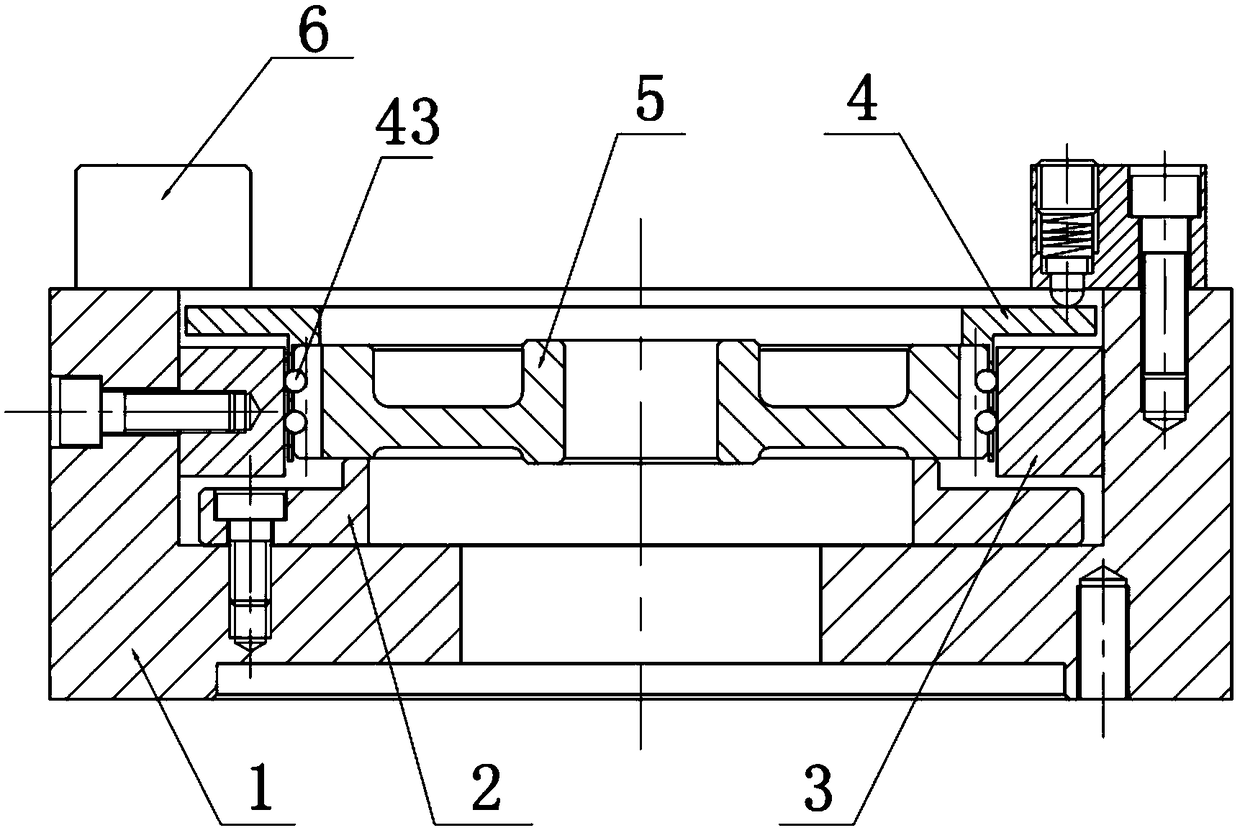

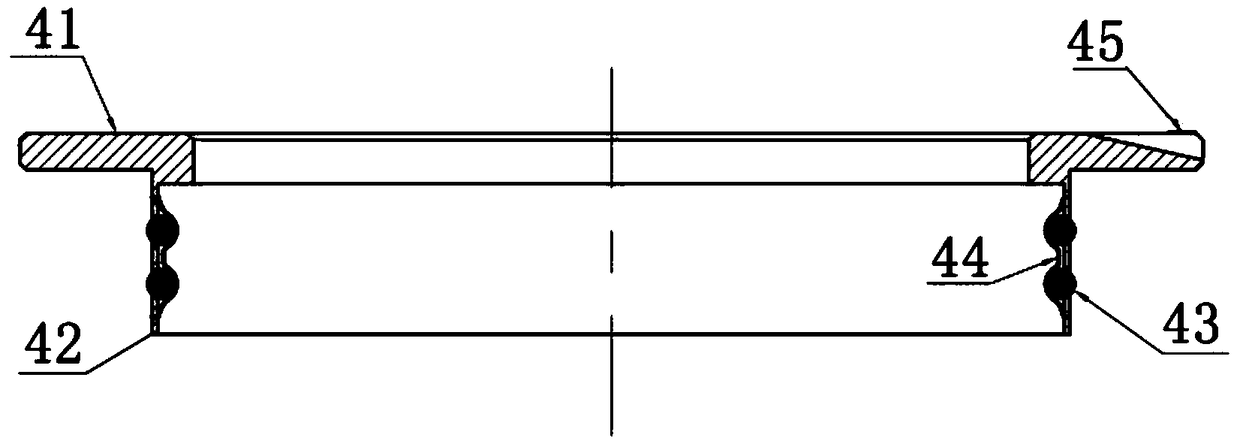

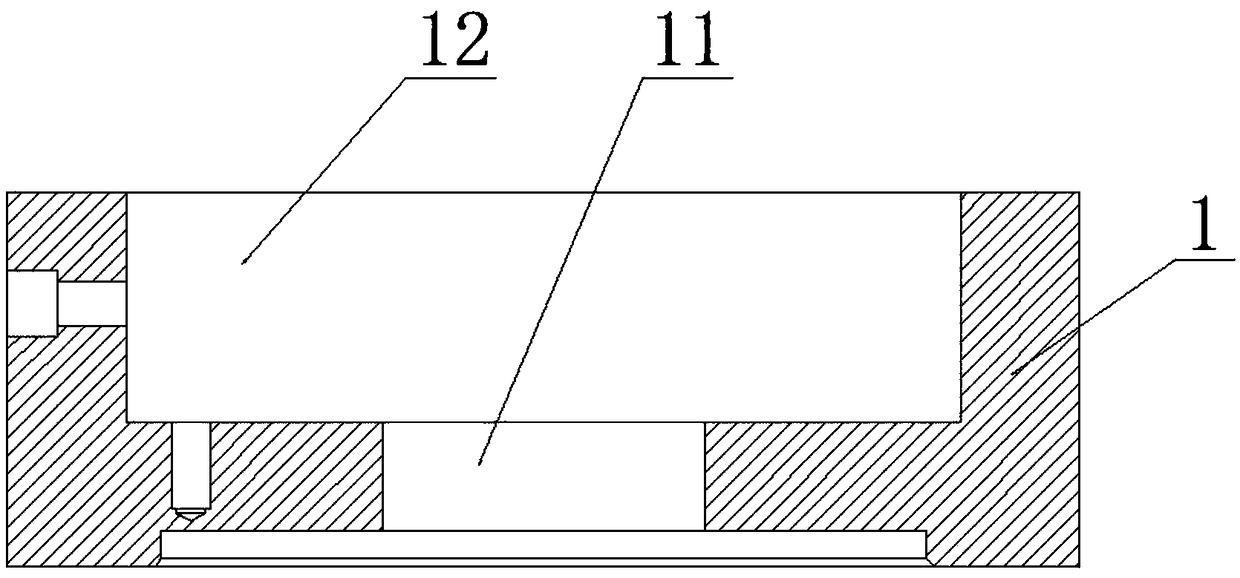

[0032] Such as Figure 1-8 As shown, the present invention provides a gear pitch circle fixture positioning tool, including a clamp body 1; the upper end of the clamp body 1 is provided with a gear workpiece installation groove 12; The positioning plate 2 on the end face of the workpiece 5; the clamp body 1 is provided with a plurality of wedges 3 around the gear workpiece installation groove 12; Including the pressure plate 41 pressed on the gear workpiece 5, the lower end of the pressure plate 41 is provided with a ball structure at the corresponding position of the wedge 3, and the ball structure includes both the tooth surfaces of the pitch circle of the gear workpiece 5 and the end surface of the wedge 3. The ball 43; the upper end of the cage 4 is provided with a plurality of elastic compression structures 6 fixed on the clamp body 1.

[0033] According to the gear pitch circle fixture positioning tool of the present invention, the gear workpiece installation groove 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com