Machining device used for split-type ball bearing and machining method thereof

A technology for processing devices and ball bearings, which is applied in positioning devices, metal processing equipment, metal processing machine parts, etc., can solve the problems of inability to realize two hemispheres into one body, reduced utilization rate of parts materials, and low utilization rate of parts materials. Achieve the effects of convenient and reliable use, increased processing efficiency, and increased utilization of product materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

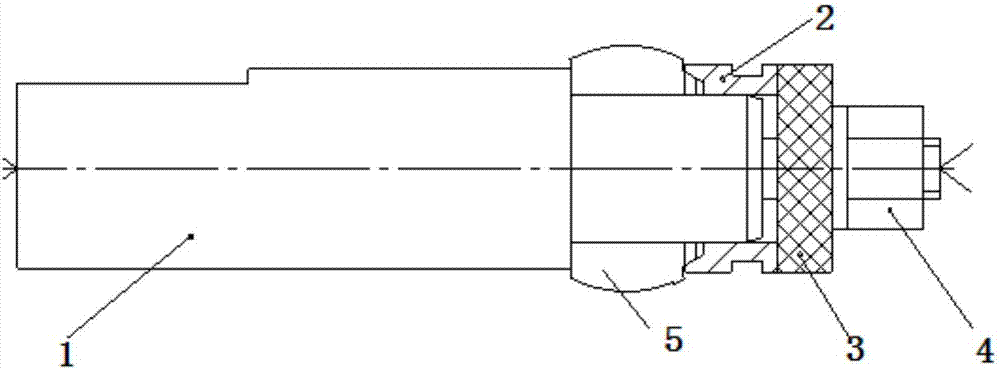

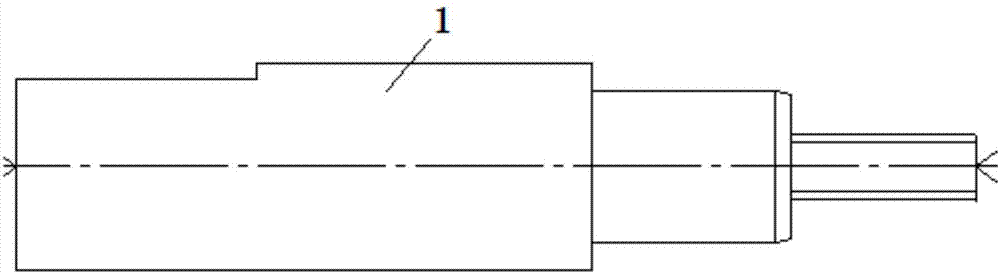

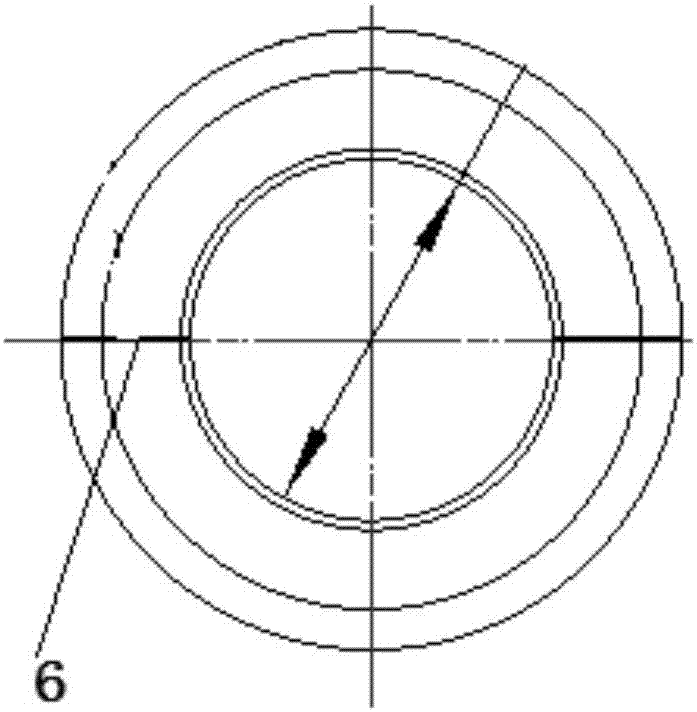

[0028] Such as figure 1 , figure 2 , image 3 As shown, a split ball bearing processing device includes a mandrel 1 for clamping parts 5 to be processed, one end of the mandrel 1 is a stepped shaft, and the stepped shafts of the mandrel 1 are installed in order from large to small The part 5 to be processed, the limit ring 4, the washer 2 and the nut 3, one end of the part 5 to be processed is in contact with the shoulder end face of the mandrel 1, the other end of the part 5 to be processed is in contact with one end of the limit ring 4, and the other end of the limit ring 4 It is in contact with one end of washer 2, and the other end of washer 2 is in contact with one end of nut 3;

[0029] Among them, the parts to be processed are two hemispherical bearings to be processed, that is, split ball bearings to be processed;

[0030] The stepped shaft of mandrel 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com