Composite connection type hydraulic knife handle

A composite connection and tool holder technology, applied in the field of composite connection hydraulic tool holders, can solve the problems of restricting the use of the tool holder, affecting the sealing performance of the hydraulic passage, replacing and maintaining the main body of the tool holder and the inner tank separately, and improving the overall performance. Strength, avoidance of extravasation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

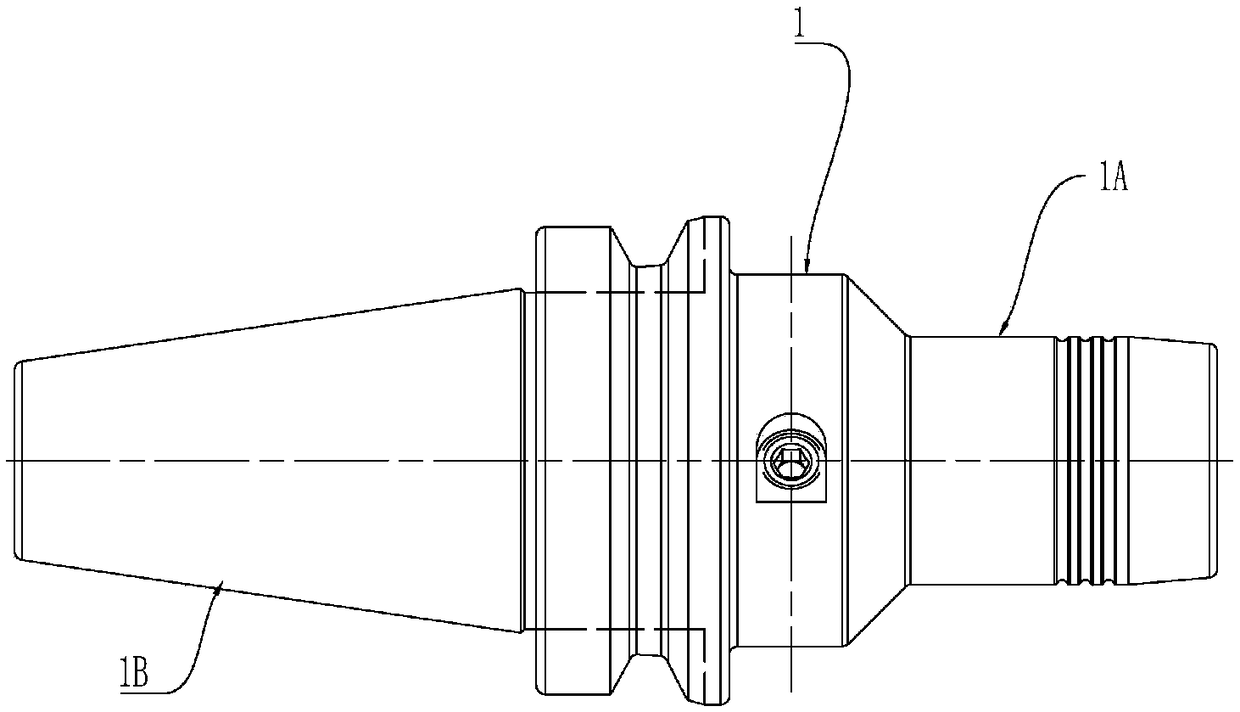

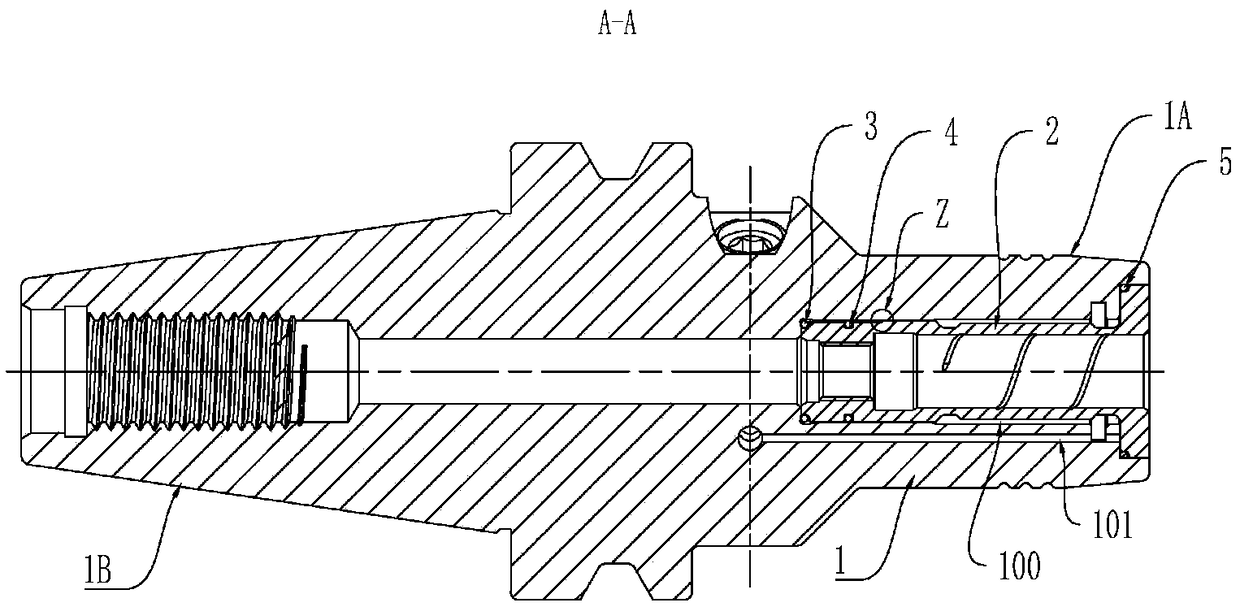

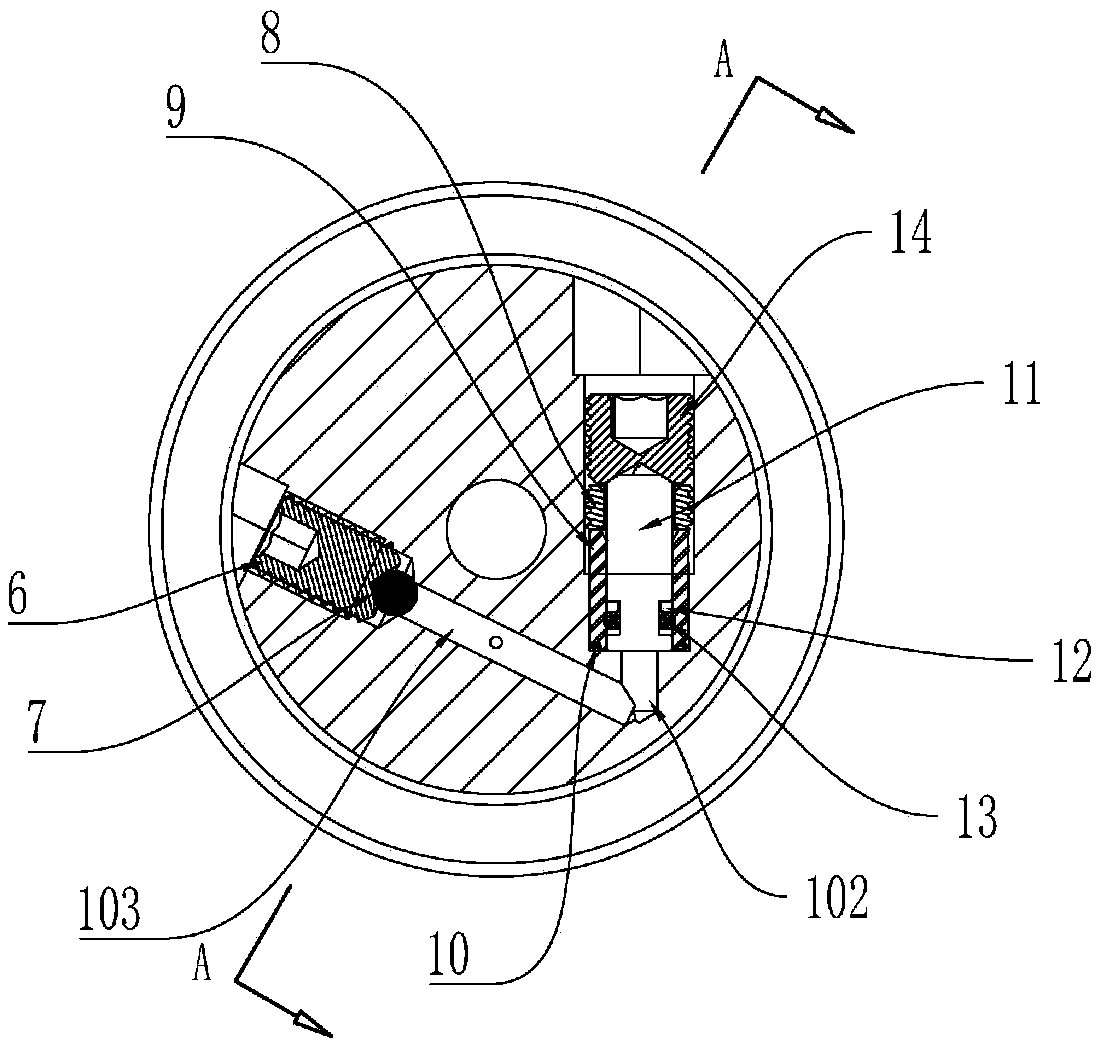

[0043] See attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 The present invention is further described.

[0044] The invention relates to a composite connection hydraulic knife handle, which comprises a knife handle main body (1) and an elastic thin-walled inner ring (2) arranged inside the knife handle main body (1), the knife handle main body (1) and the elastic thin-walled inner ring (2). A hydraulic oil chamber (100) is arranged between the inner rings (2); the tool handle main body (1) is also provided with a hydraulic oil injection and discharge hole (103), a pressure hole (102), and a The hydraulic oil diversion hole (101) connected to the oil filling hole (103) and the pressure hole (102) is connected with the hydraulic oil chamber (100); a hydraulic passage is set on the top of the pressure hole (102); the hydraulic pressure The channel is assembled with a piston rod (11), a piston sleeve (9), and a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com