Bio-based degradable flame-retardant polylactic acid engineering material and preparation method thereof

An engineering material, polylactic acid technology, applied in the field of bio-based degradable flame-retardant polylactic acid engineering materials and their preparation, can solve the problems of damaged mechanical properties of materials, increased costs, etc., and achieves improved compatibility, improved dispersibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 700g of polylactic acid pellets, 300g of surface-treated white wine distillers grains, mix the above pellets in a high-speed mixer, and add them to a torque rheometer under the conditions of conventional temperature and screw speed to melt together. Mix to obtain the polylactic acid engineering material of the present invention. The limiting oxygen index is 18.5%, and there is no droplet phenomenon, but it cannot pass the UL-94 test. The carbon residue rate at 600°C is 10.94%, and the tensile strength is 53.5MPa.

Embodiment 2

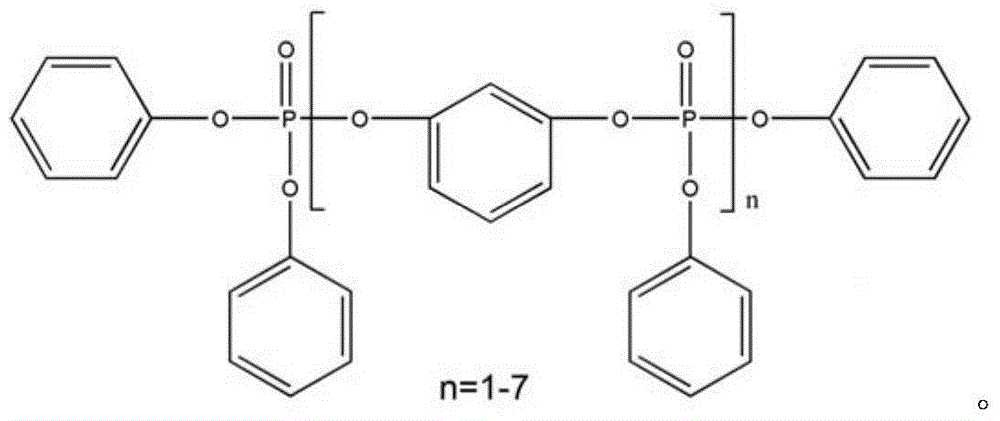

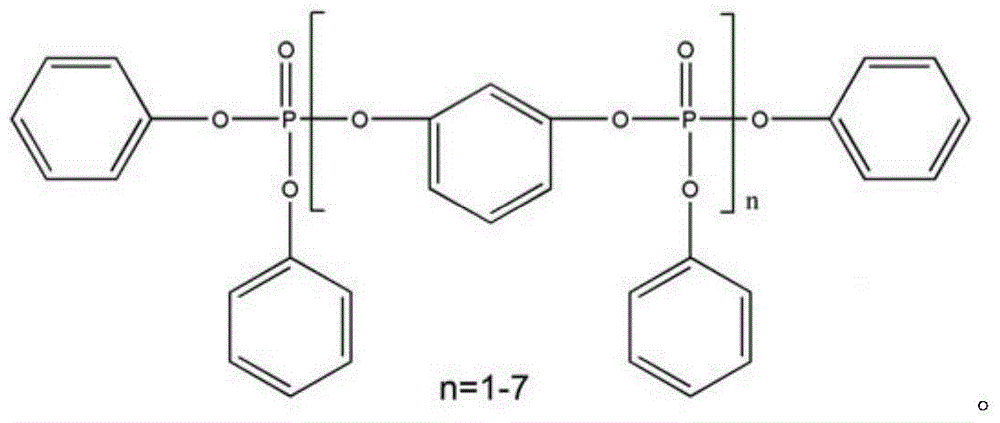

[0026] Weigh 700g of polylactic acid pellets, 250g of surface-treated liquor distillers grains, RDP50g, mix the above pellets in a high-speed mixer, and add them to the torque rheometer under the conditions of conventional temperature and screw speed Melt blending to obtain the polylactic acid engineering material of the present invention. The limiting oxygen index is 21.0%, no droplet phenomenon, UL-94 test V-0 level, the carbon residue rate at 600°C is 9.33%, and the tensile strength is 59.4MPa.

Embodiment 3

[0028] Weigh 700g of polylactic acid pellets, 200g of surface-treated liquor distillers grains, and 100g of RDP, mix the above pellets in a high-speed mixer, and add them to the torque rheometer under the conditions of conventional temperature and screw speed Melt blending to obtain the polylactic acid engineering material of the present invention. The limiting oxygen index is 24.5%, no droplet phenomenon, UL-94 test V-0 level, the carbon residue rate at 600°C is 8.32%, and the tensile strength is 56.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com