Automatic conveying apparatus for parts

An automatic conveying device and parts technology, which is applied in conveyor control devices, vibrating conveyors, conveyors, etc., can solve the problems of high parts rejection rate, prone to accidents, low parts conveying efficiency, etc. The effect of high conveying efficiency and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

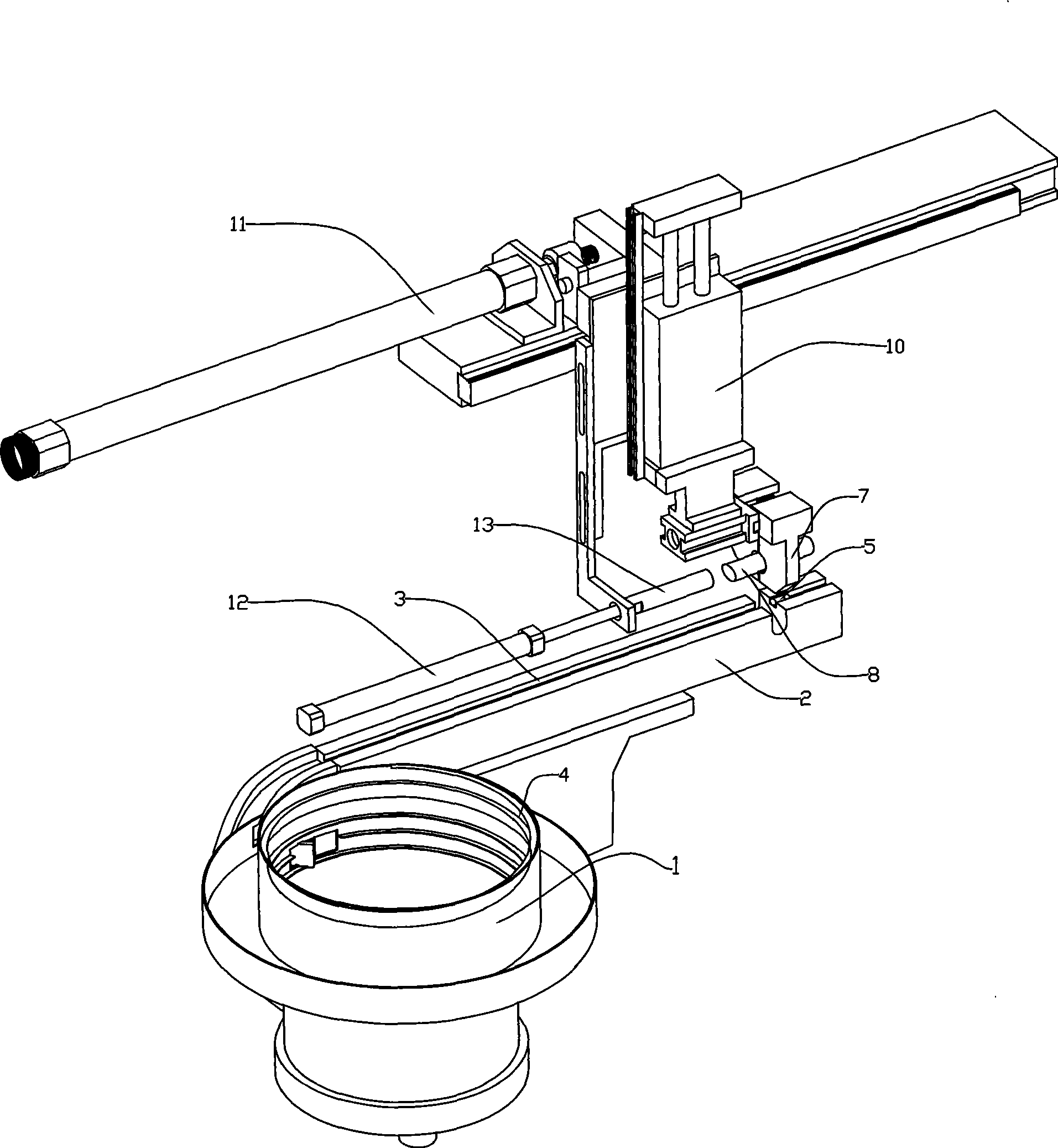

[0007] A parts automatic conveying device, such as figure 1 , including a vibrating plate 1 and a vibrating groove 2, a groove 3 for conveying parts on the vibrating groove is connected to the outlet end of the conveying groove 4 spirally arranged on the vibrating plate, and the end of the vibrating groove is equipped with a manipulator 7 capable of clamping workpieces, The manipulator is installed on the No. 1 cylinder 10, and the No. 1 cylinder is installed on the No. 2 cylinder 11. The manipulator can be driven to move up and down in the vertical direction and move back and forth in the horizontal direction through the No. 1 cylinder and the No. 2 cylinder. The automatic parts delivery device also includes three No. 12 cylinder, No. 3 cylinder front end is installed with a push block 13 that moves back and forth. The position of the push block is opposite to the feed port of the processing equipment. in place. The manipulator can be a device capable of clamping parts from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com