Strengthening pulp house decorative material mixed with saw powder and method for producing the same

A technology for interior decoration and manufacturing methods, which is applied in the directions of papermaking, textiles, papermaking, fiberboard, etc., and can solve the problems of poor moisture resistance, reduced wet strength, and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 》

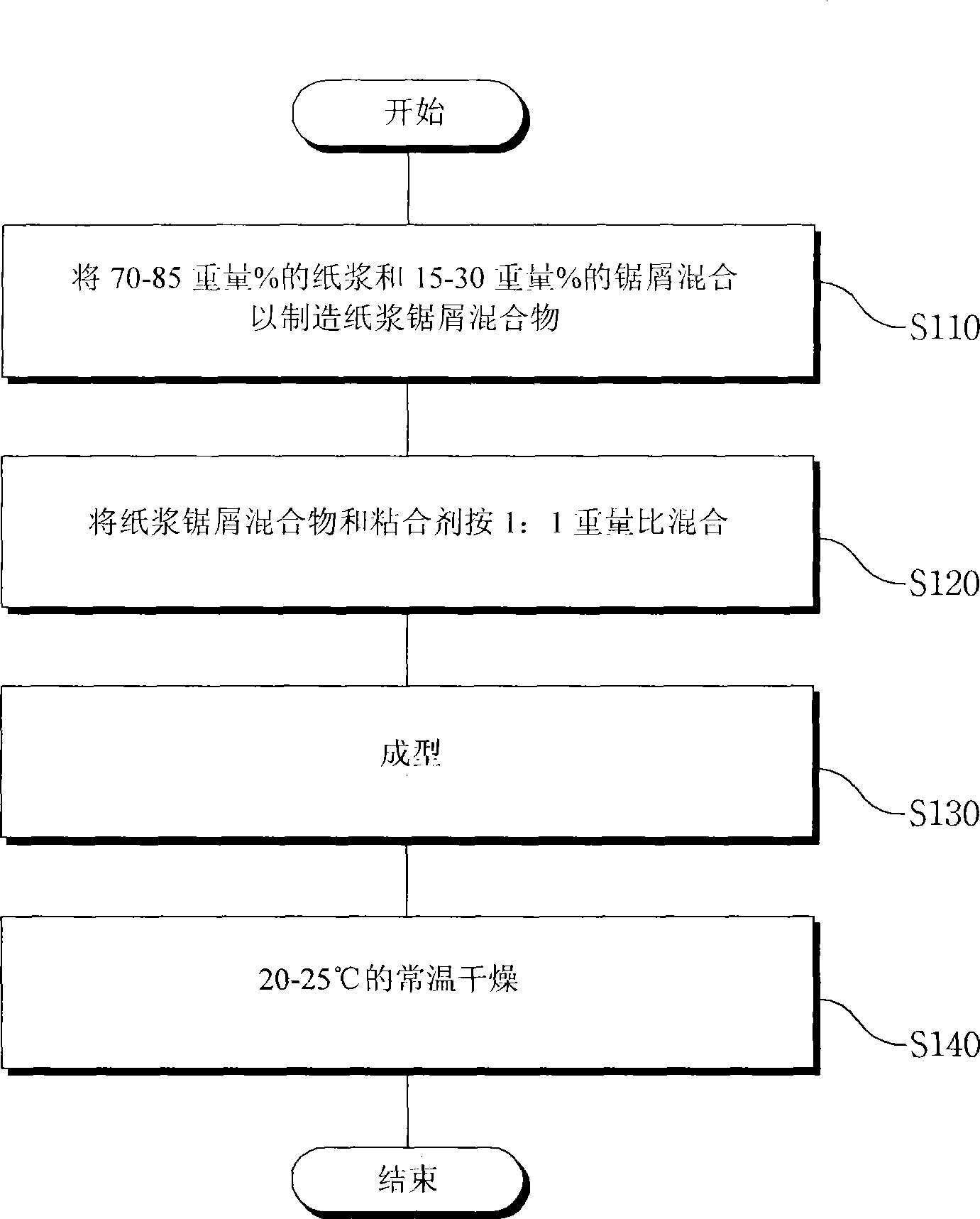

[0022] figure 1 It is a process explanatory drawing of the manufacturing method of the sawdust-mixed reinforced pulp indoor device material related to the first example of the present invention.

[0023] refer to figure 1 , The method for producing a reinforced pulp interior decoration material mixed with sawdust according to the first example of the present invention includes mixing 70-85% by weight of pulp made from recycled waste paper and 15-30% by weight of sawdust to form The pulp sawdust mixture forming stage (S110) of the pulp sawdust mixture; the binder mixing stage (S120) in which the binder and the above pulp sawdust mixture are mixed in a weight ratio of 1:1; Put the pulp sawdust mixture of the agent into the mold and shape it, and the forming stage (S130) of manufacturing the reinforced pulp interior decoration material; and dry the formed reinforced pulp interior decoration material at a normal temperature of 20-25° C. Drying stage (S140). Here, the adhesive c...

no. 2 example 》

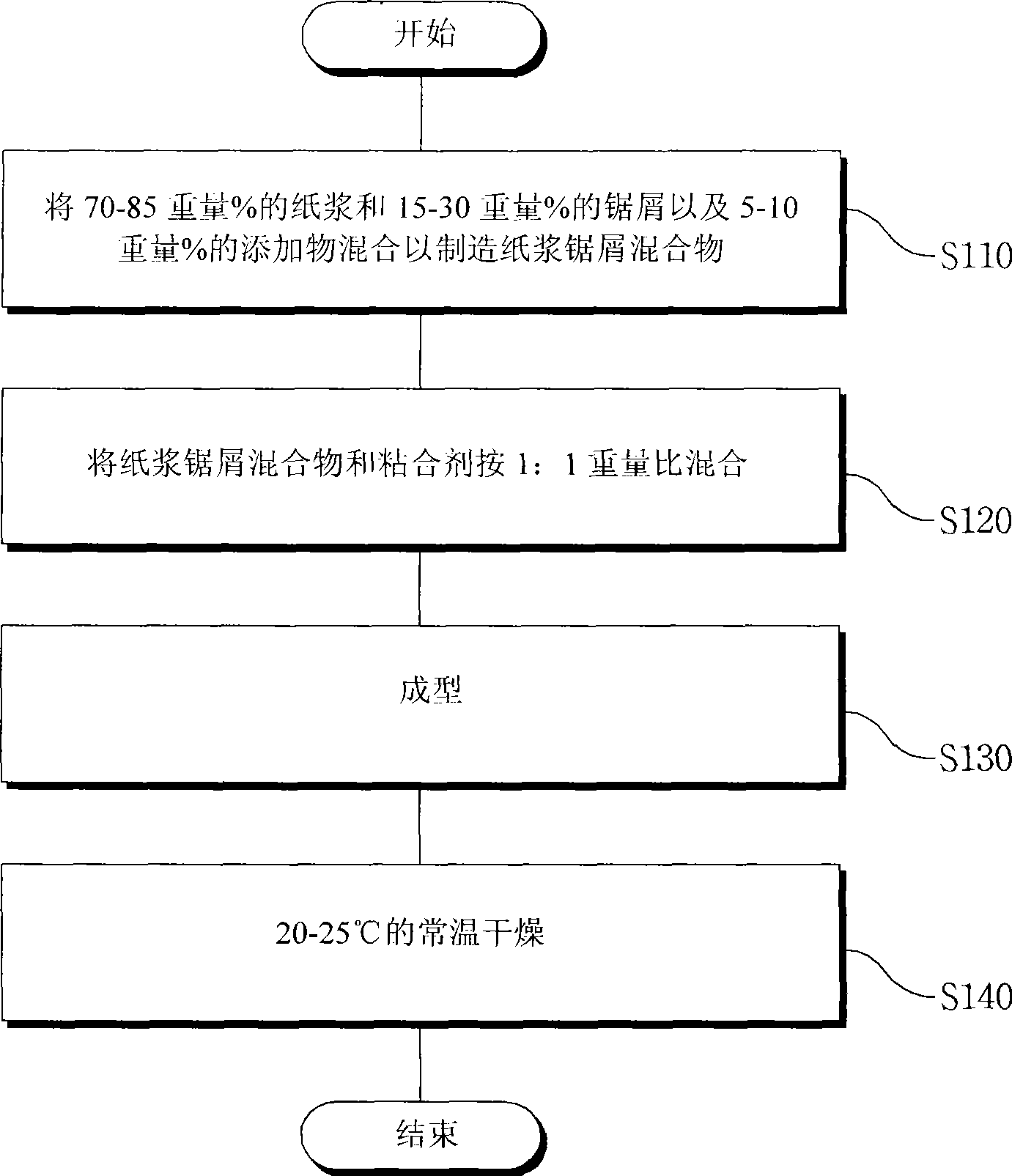

[0031] figure 2 It is a process explanatory drawing of the manufacturing method of the sawdust-mixed reinforced pulp interior material related to the second example of the present invention.

[0032] refer to figure 2 , The second example of the present invention relates to a method for producing a reinforced pulp interior decoration material mixed with sawdust, comprising mixing 60-70% by weight of pulp made from recycled waste paper, 15-20% by weight of sawdust and 5-10% by weight % by weight of the additives are mixed to form a pulp sawdust mixture forming stage (S210); the binder and the above-mentioned pulp sawdust mixture are mixed in a weight ratio of 1:1. S220); put the above-mentioned pulp sawdust mixture mixed with binder into a mold and shape it to form a molding stage (S230) of making reinforced pulp interior decoration materials; and dry the molded pulp at a normal temperature of 20-25°C The drying stage (S240) consists of strengthening the pulp interior decor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com