Patents

Literature

64results about How to "Improve drying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

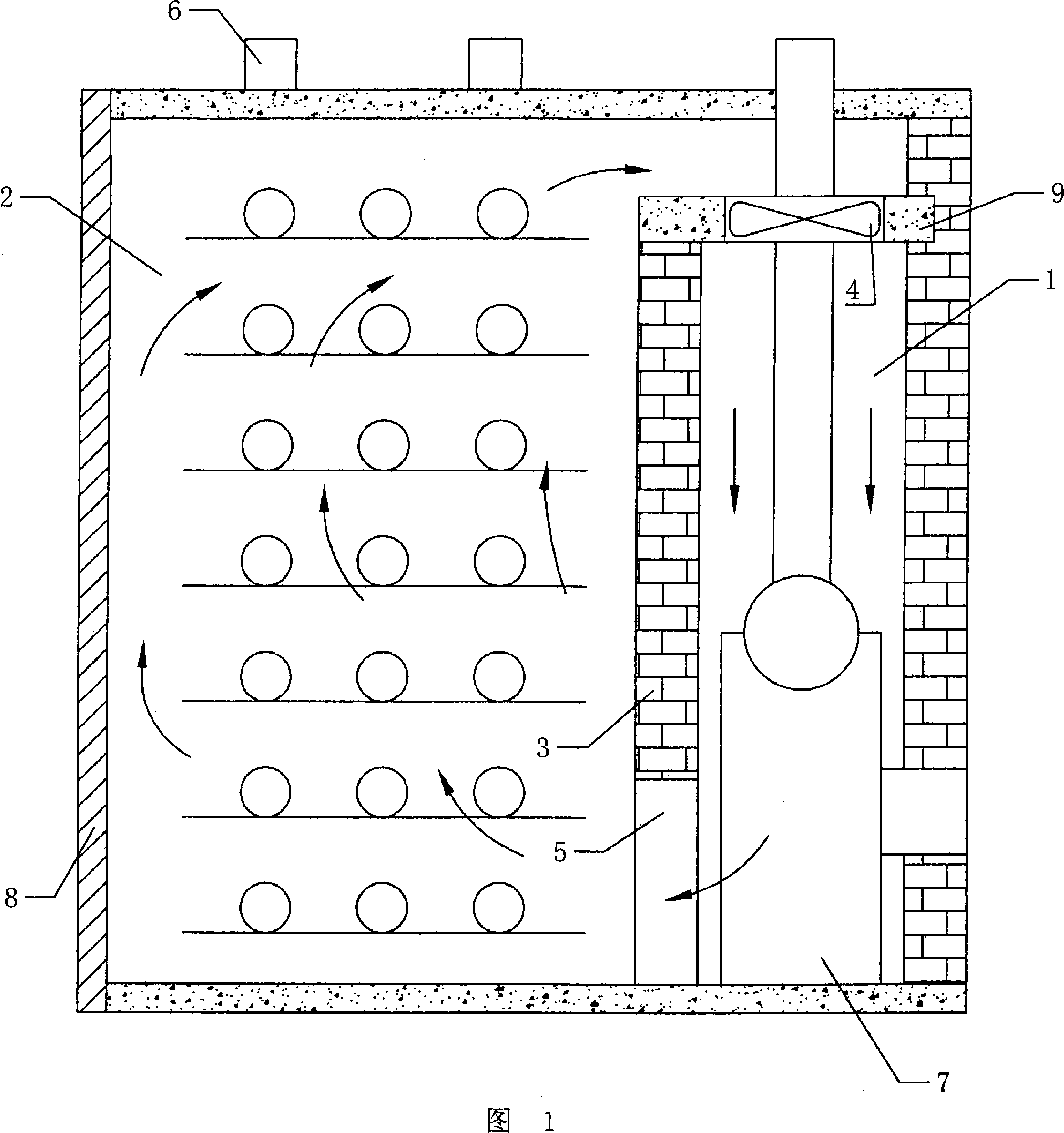

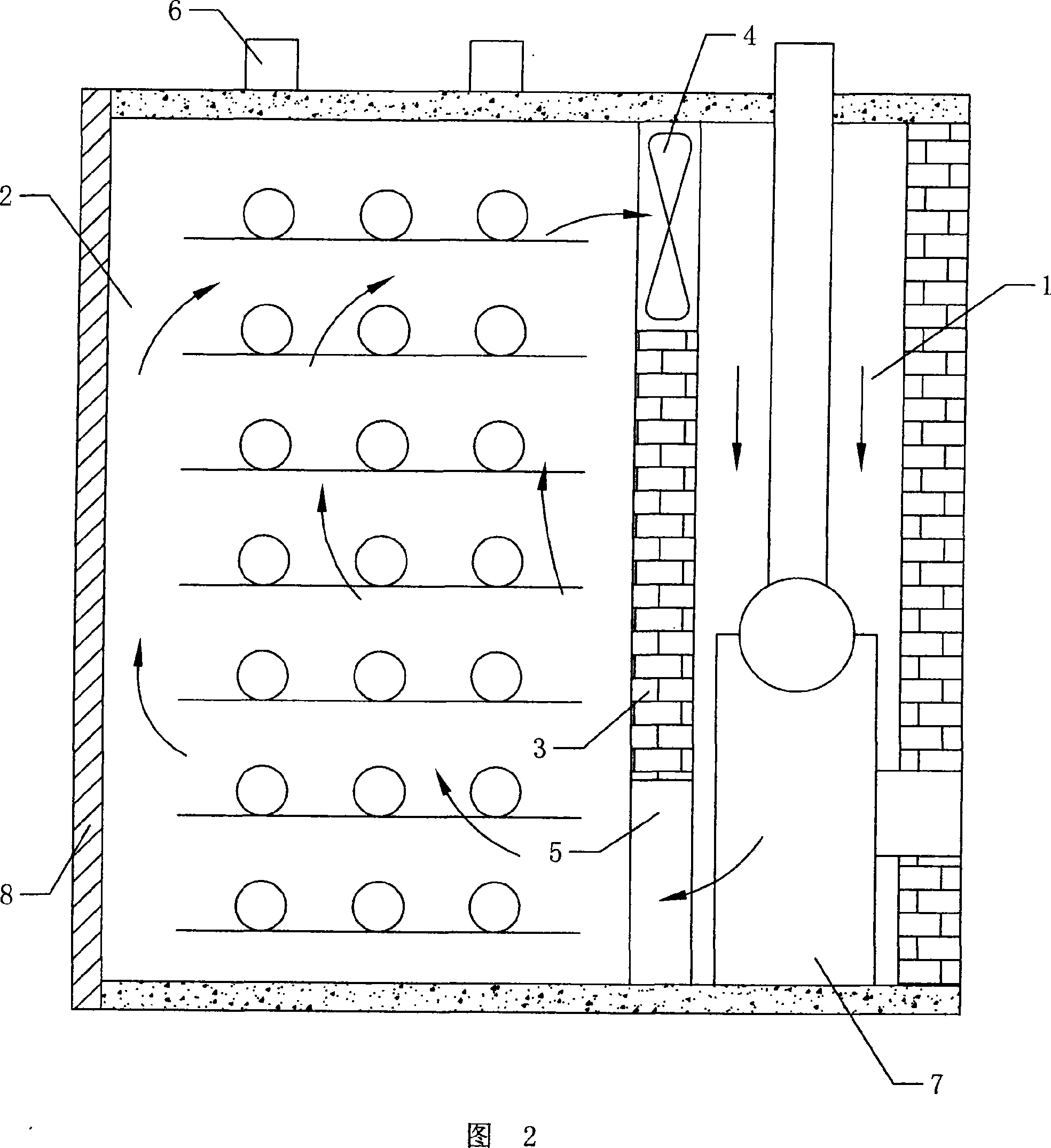

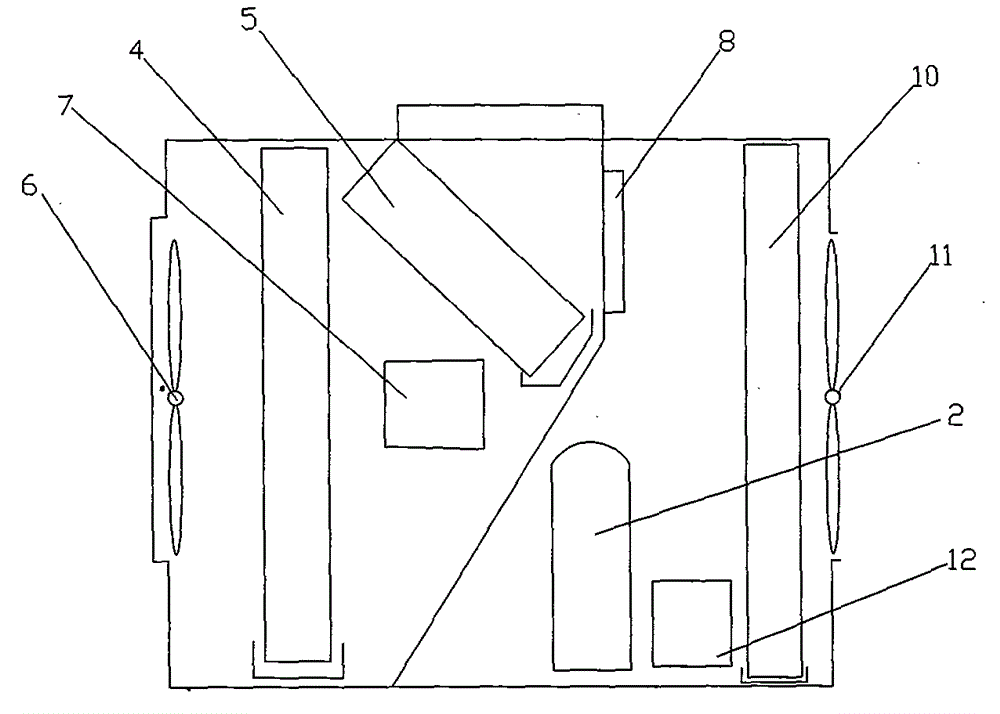

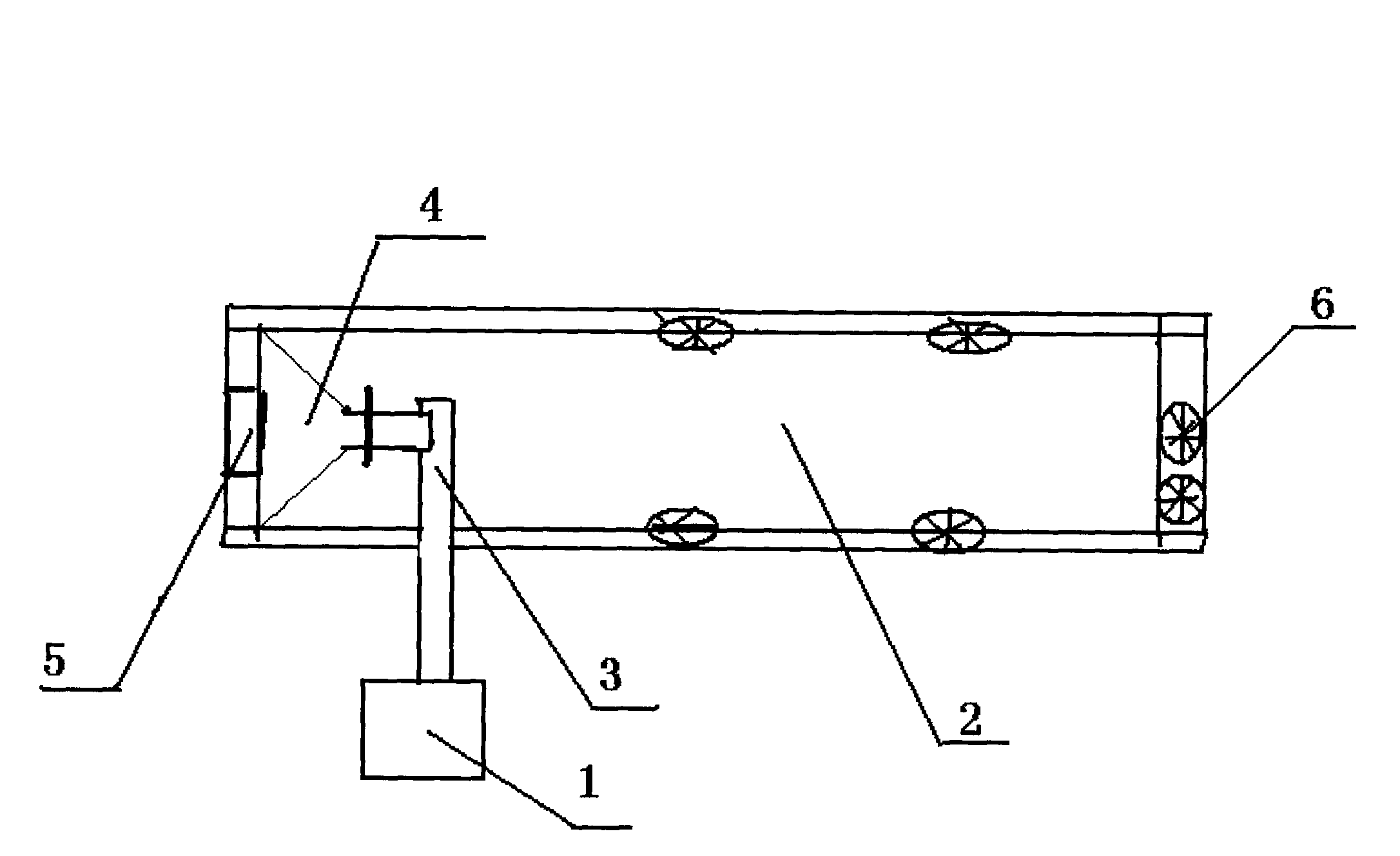

Lumber drying kiln

InactiveCN101144681AHigh thermal efficiencySmooth and even circulationDrying solid materials with heatDrying gas arrangementsEngineeringCombustion

The invention discloses a lumber drying kiln. An isolation wall is arranged between the bottom part and the top part in the drying kiln, the isolation wall divides the space in the kiln into an air heating room used for installing a drying furnace, and a lumber drying room; wherein, an upper ventilation opening is arranged at the upper part of the isolation wall, a lower ventilation opening is arranged at the lower part of the isolation wall, a fan used for blowing air to the air heating room from the lumber drying room is arranged between the air heating room and the lumber drying room; an air exhaust passage is arranged at the top part corresponding to the lumber drying room; because the fan is arranged at the position of the upper ventilation opening, the fan sucks the hot air from the lumber drying room to blow into a lumber heating room, the back flow does not happen, thereby leading the heated air circulation to be smoother, therefore the drying quality to be improved. Because the isolation wall is arranged between the air heating room and the lumber drying room, the charring of the lumber close to a combustion furnace because of over high temperature is avoided, the lumber far away the combustion furnace does not have the drying phenomenon, to lead the drying to be evener.

Owner:李祥文

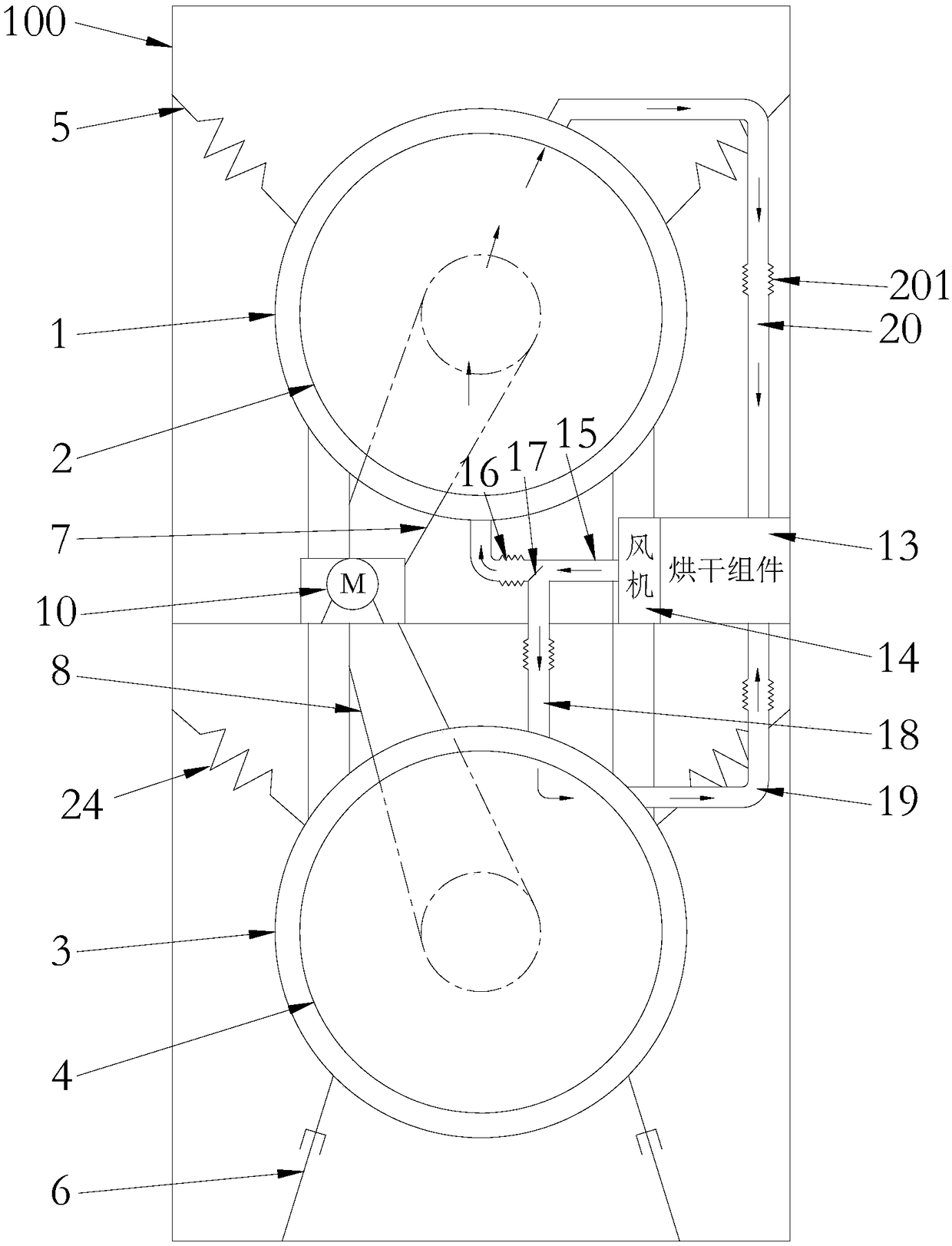

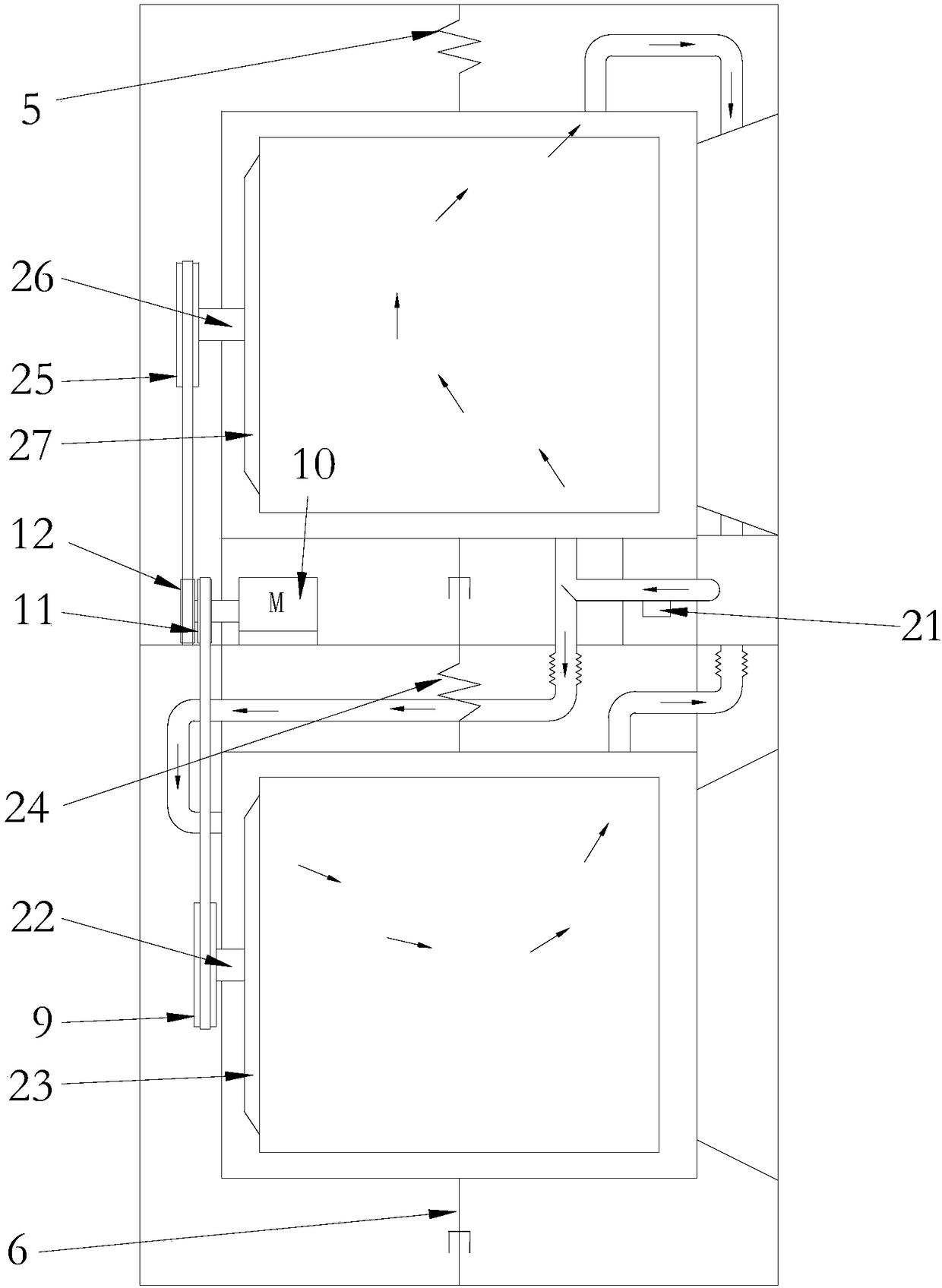

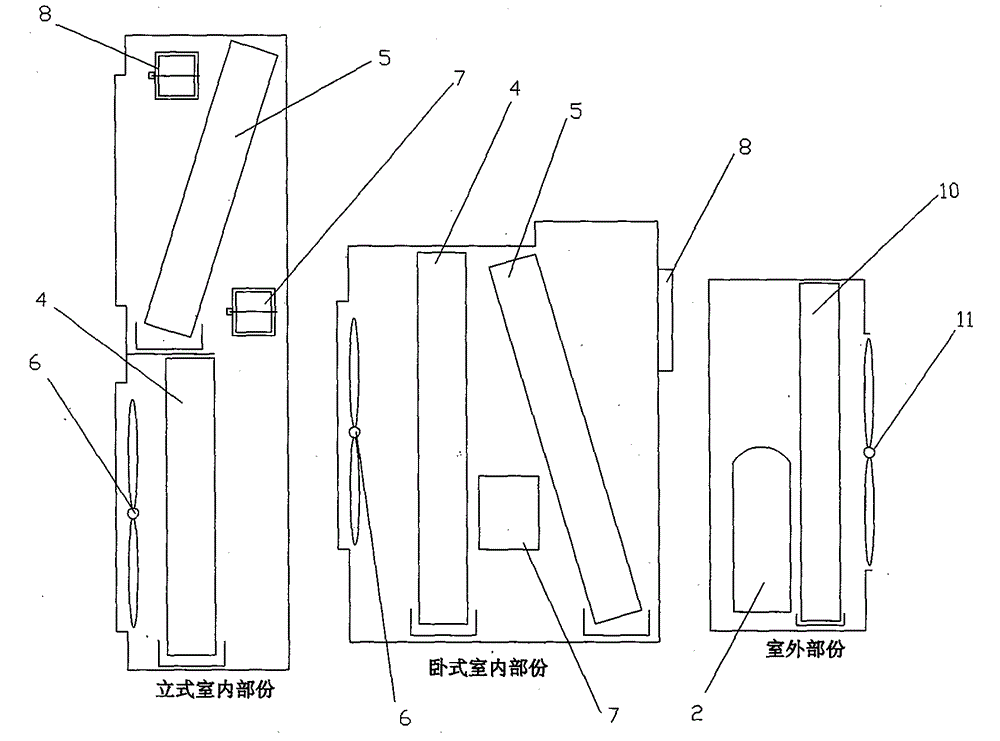

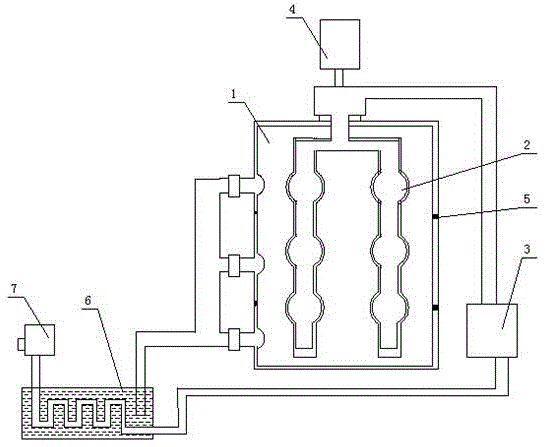

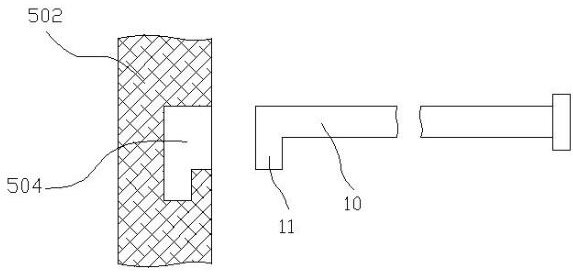

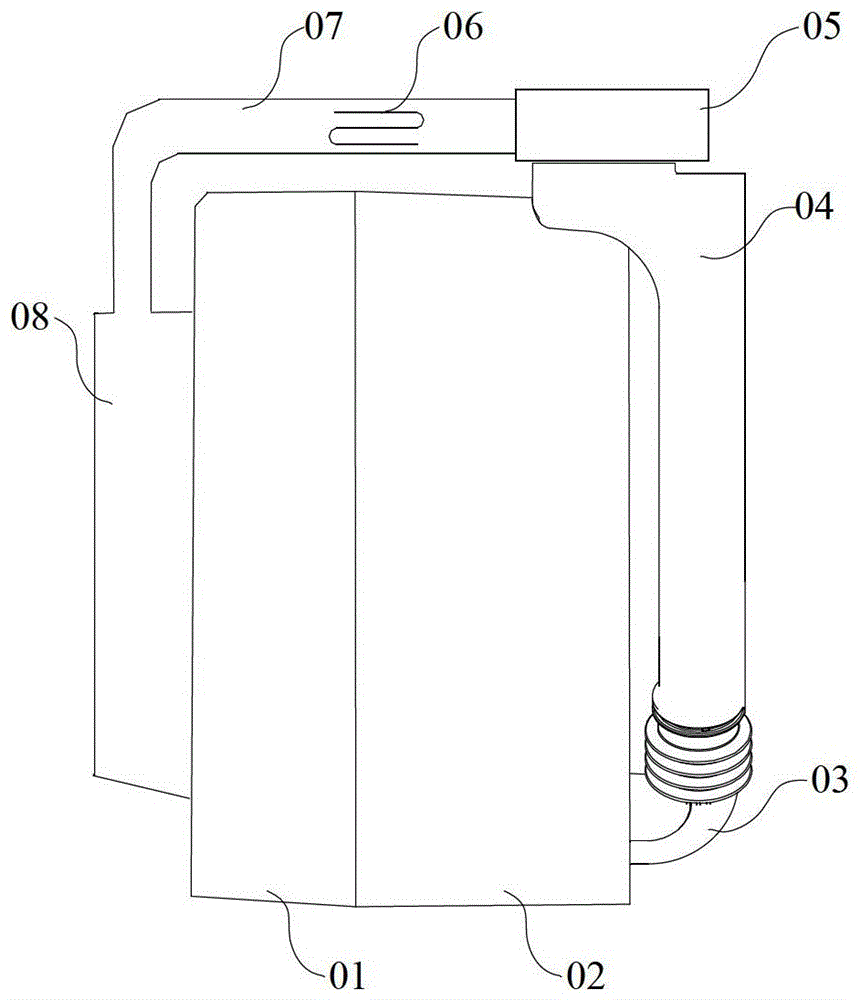

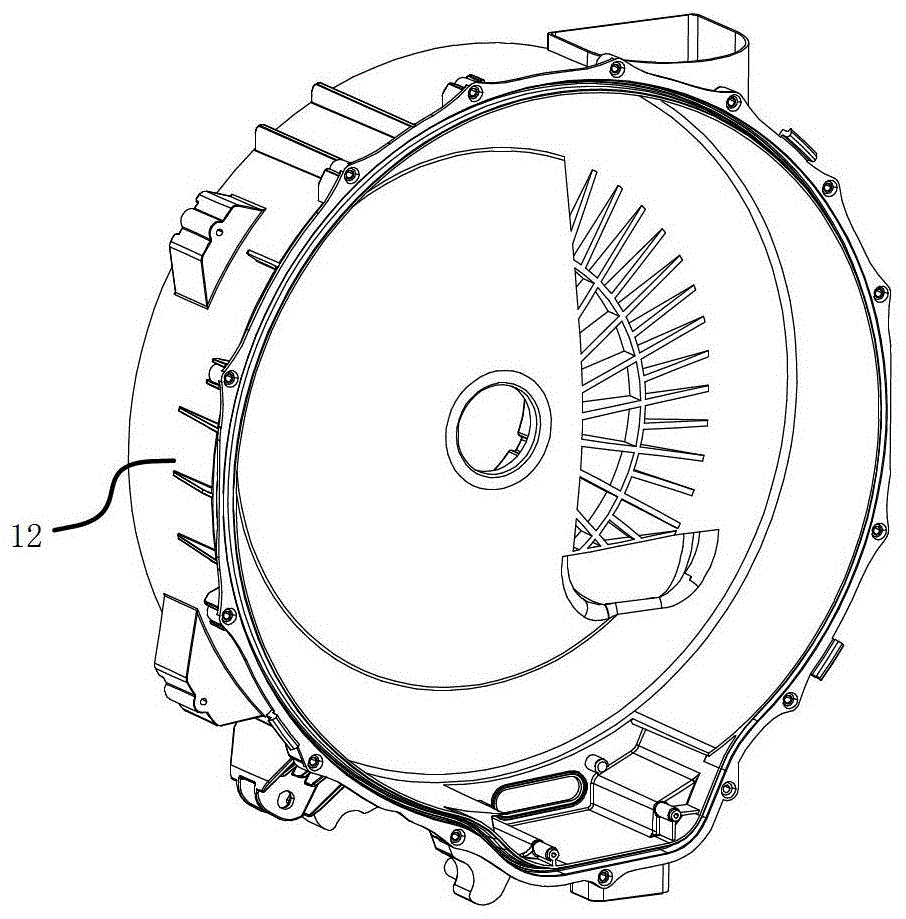

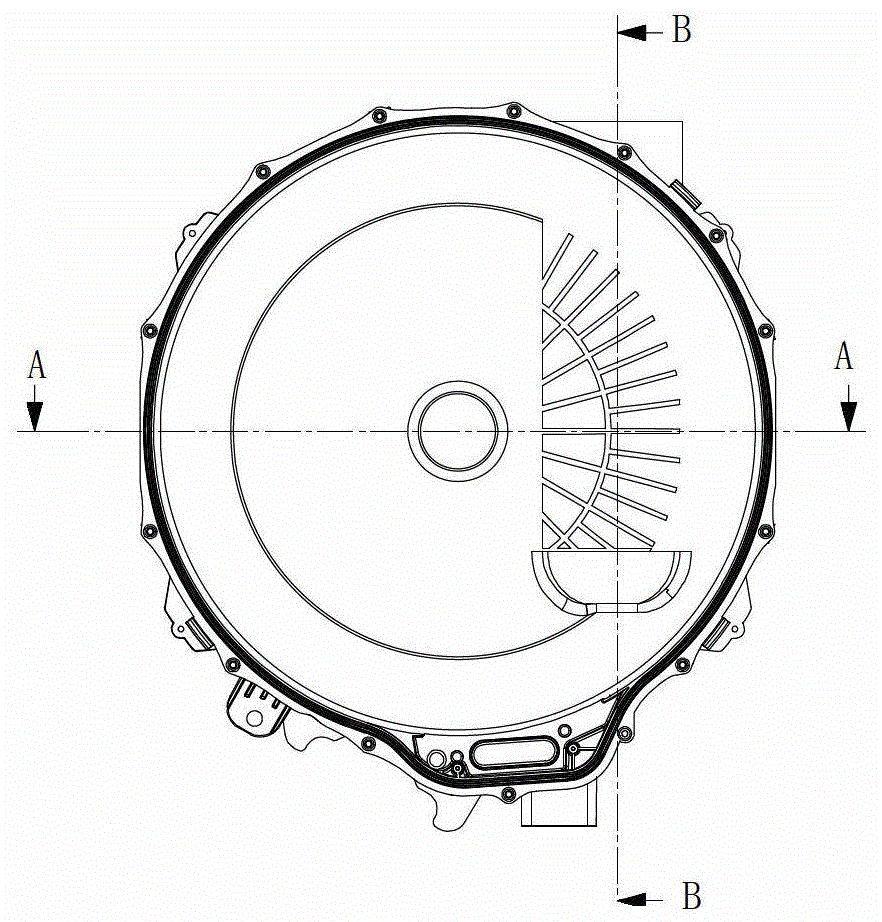

Drying system, washing-drying machine and control method of washing-drying machine

InactiveCN108085941AImprove drying capacityReduce manufacturing costOther washing machinesControl devices for washing apparatusPulp and paper industryAirflow

The invention discloses a drying system, a washing-drying machine and a control method of the washing-drying machine. The drying system is applied to the washing-drying machine. The washing-drying machine comprises a first drum and a second drum arranged in parallel; the drying system comprises an air duct component; an air duct control device is arranged in the air duct component and is used forconnecting or disconnecting the air duct component and the first drum and / or the second drum so that drying flow can be independently delivered into the first drum or the second drum or delivered intoboth the first drum and the second drum. The drying system herein can be shared by the two drums in a two-drum washing-drying machine, so that the manufacture cost of the washing-drying machine can be reduced and space used thereby can be decreased at the premise of improving drying capacity of the single washing-drying machine.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method of extra high molecular cation polyacrylamide

The present invention relates to an extra-high molecular cation polyacrylamide preparation method. Said preparation method includes the steps of copolymerization of acrylamide and ammonium (methyl) acryloyloxyethyltrimethyl chloride aqueous solution, monomer refinery, purification, adding multicomponent initiator and additive, polymerization, heat-insulating, granulating, drying, pulverizing and sieving so as to obtain the invented extra-high molecular cation polyacrylamide whose molecular weight is 23000000 and dissolving speed is less than or equal to 30min. The invented product can be used as water-purifying agent for treating waste water and sewage in the several extensive fields.

Owner:JIANGDU CITY CHEM PLANT

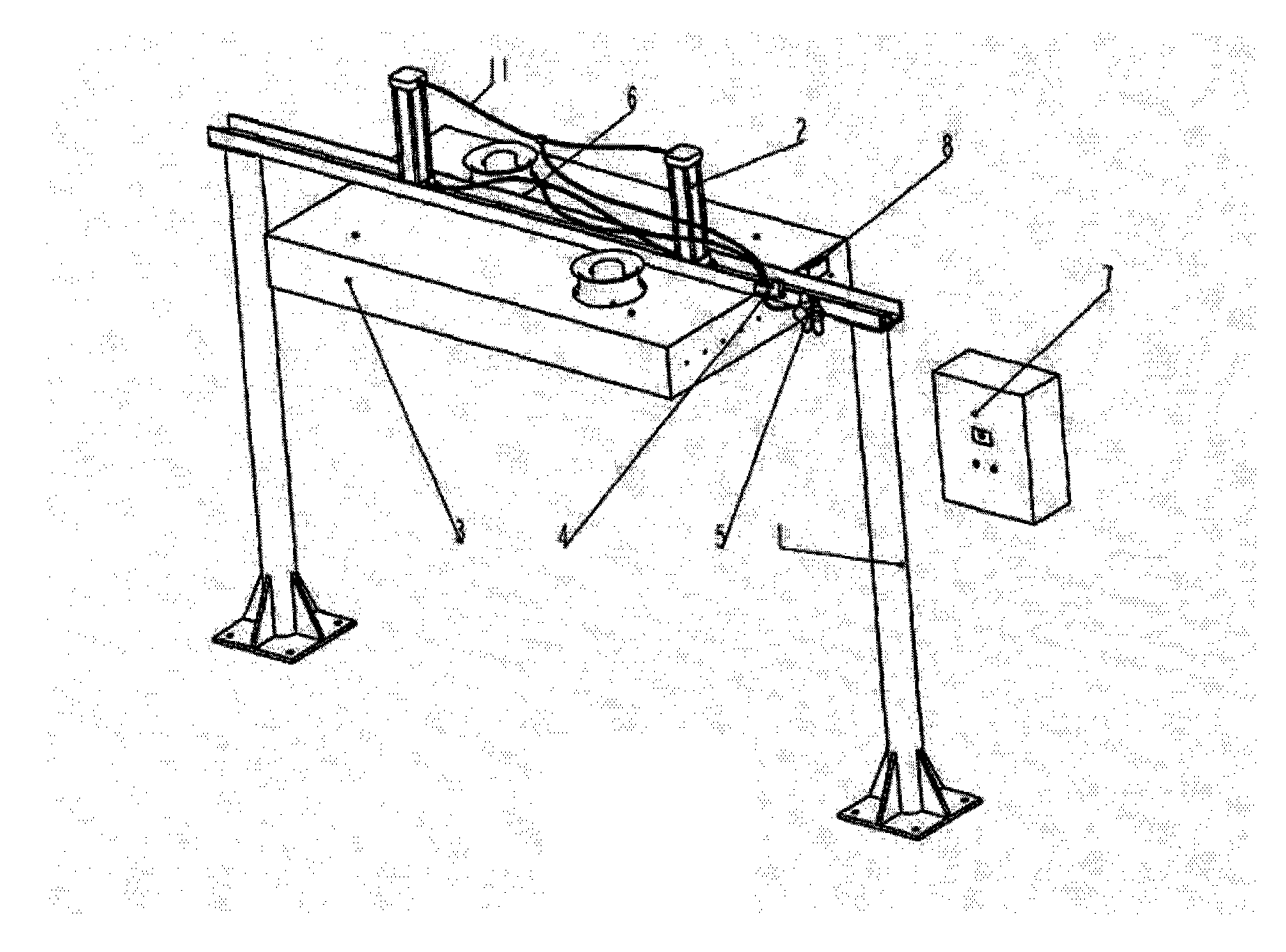

Equipment for drying synthetic leather production line

InactiveCN101598491AStrong drying capacityIncrease line speedDrying solid materials with heatDrying machines with progressive movementsMedium waveElectric control

The invention provides equipment for drying a synthetic leather production line. The equipment comprises a supporting device, a medium-wave infrared radiation device, an electric control device and an emergency separation device; the medium-wave infrared radiation device comprises a medium-wave infrared tube; the emergency separation device comprises a cylinder which is fixed on the supporting device; a piston of the cylinder is connected with the medium-wave infrared tube; the electric control device comprises a control circuit which is electrically connected with the emergency separation device; and when the production line has power outage or failure, the control circuit outputs a control signal to the emergency separation device so as to control the motion of the piston of the cylinder to ensure that the medium-wave infrared tube and the production line are separated to a safe distance. The equipment can be used for preheating and drying the synthetic leather production line using water-based resin as a raw material and can improve a line speed of the production line. The equipment has emergency processing capacity, can control the separation of the drying equipment and the production line through temperature, thus greatly reducing the occurring probability of fire.

Owner:丽水市优耐克水性树脂科技有限公司

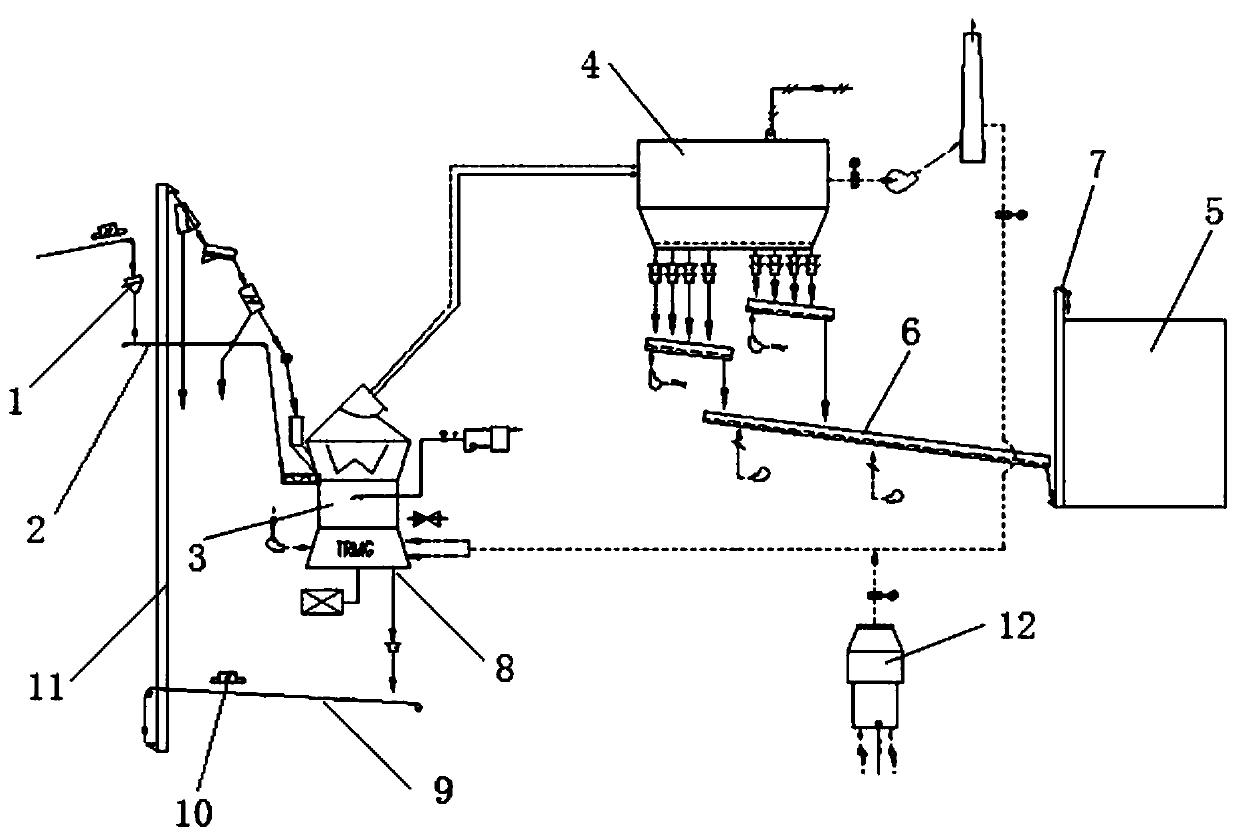

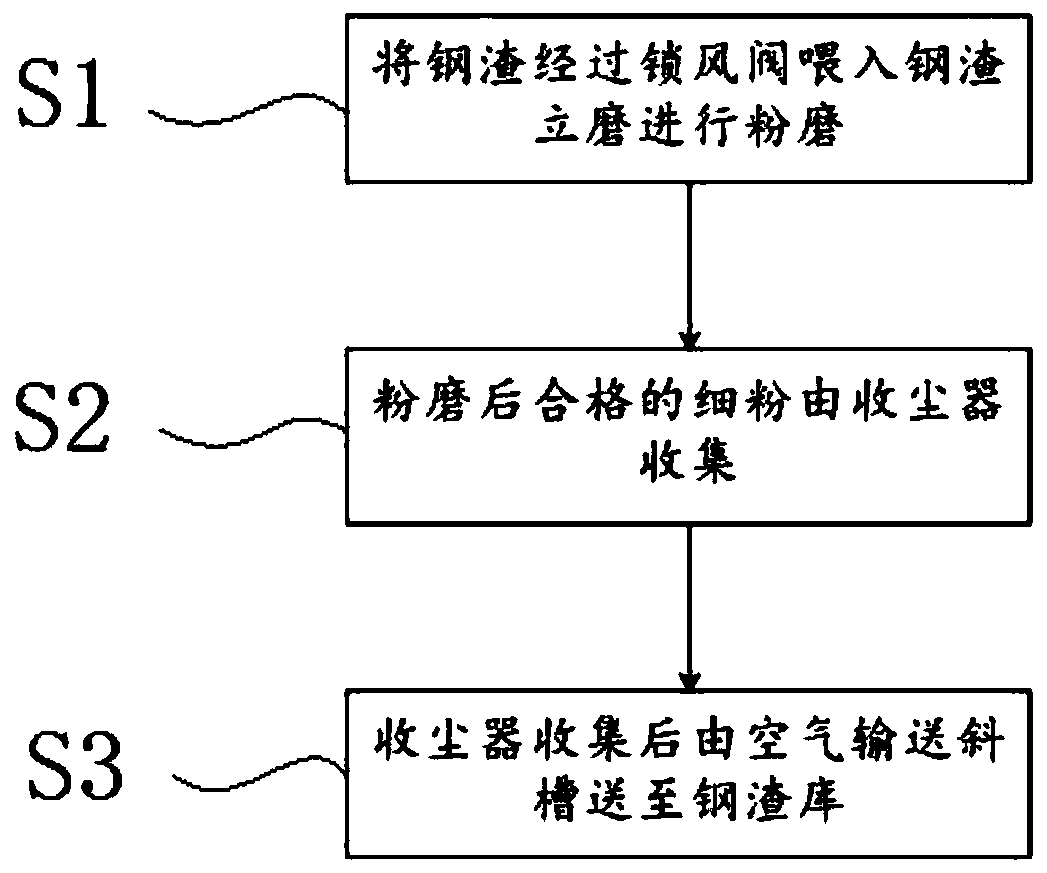

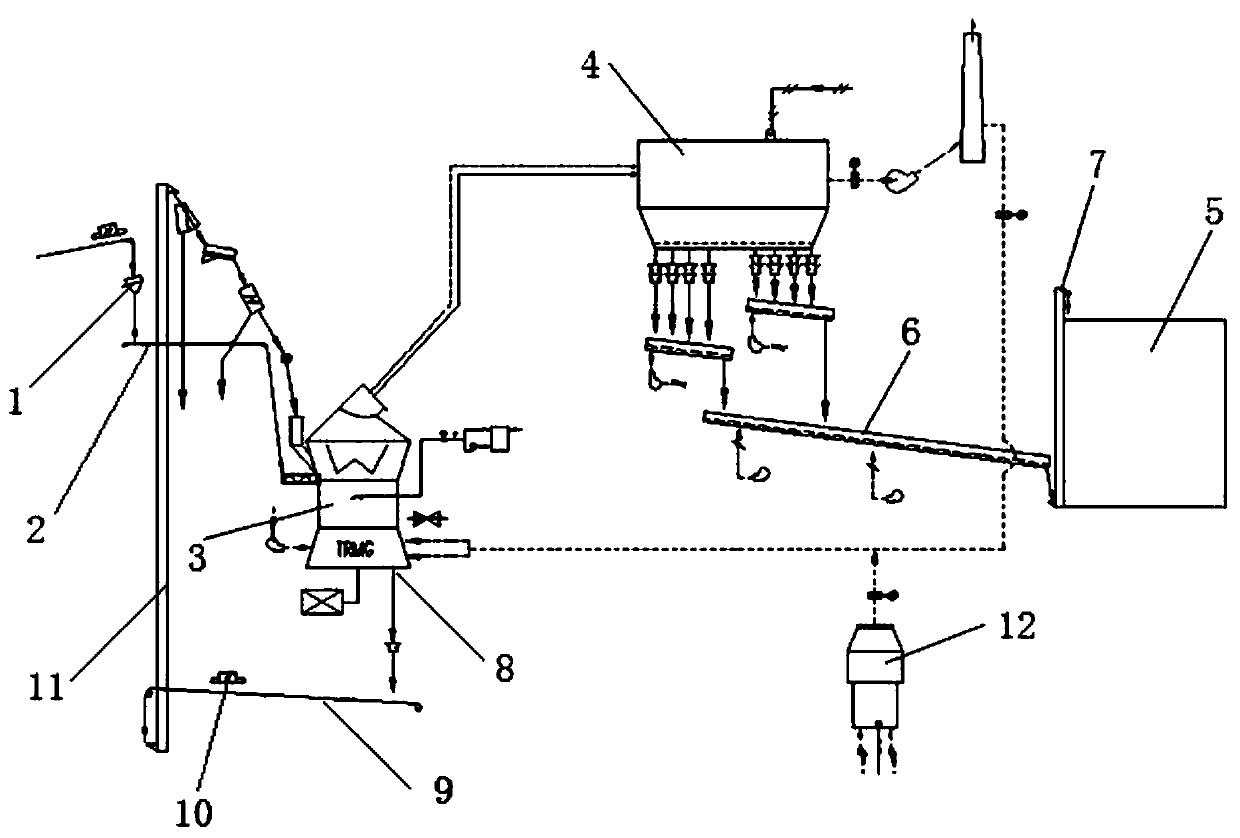

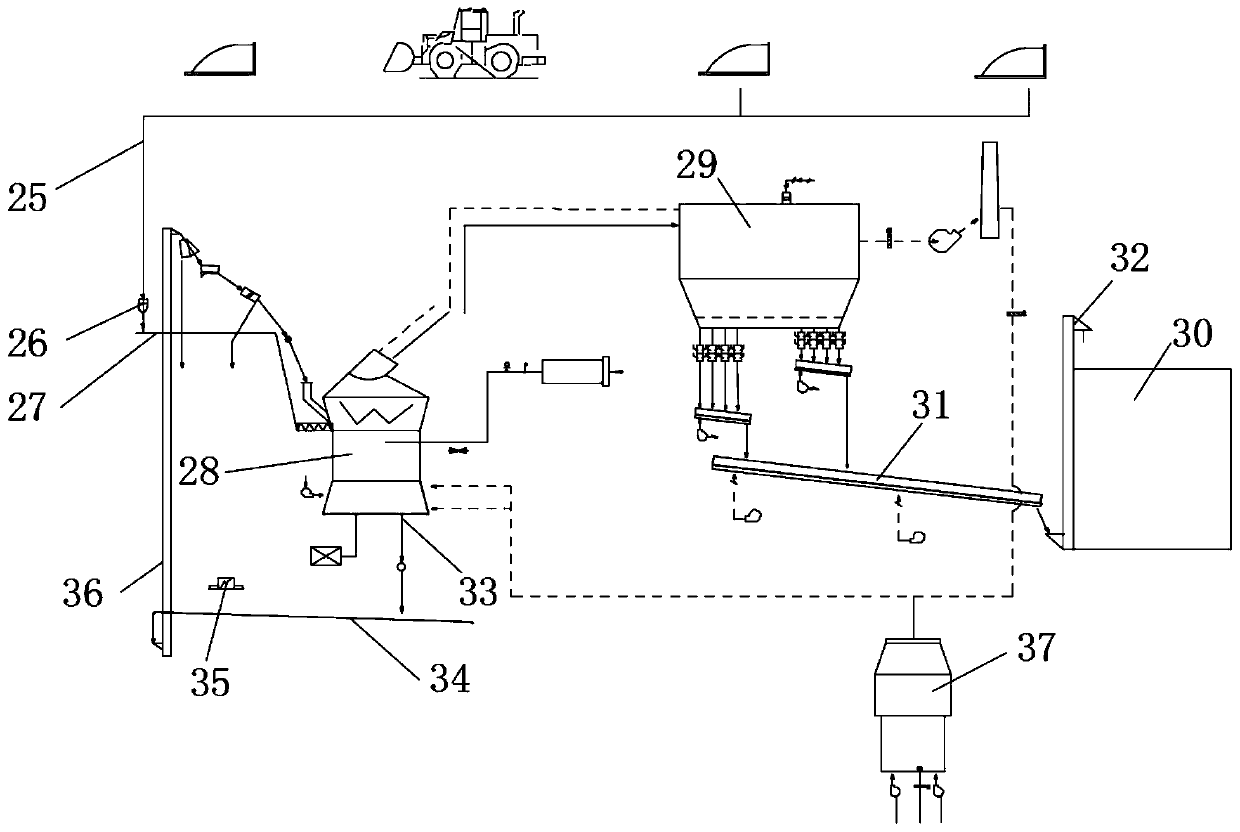

Superfine steel slag treatment system and method

The invention provides a superfine steel slag treatment system and method. The superfine steel slag treatment system comprises a metering device, a feeding belt conveyor, a steel slag vertical mill, adust collector and a steel slag warehouse, the metering device is connected with the steel slag vertical mill through the feeding belt conveyor, the steel slag vertical mill is provided with an air lock valve and an air ring, steel slag enters the steel slag vertical mill through the air lock valve to be ground, the ground steel slag is brought into the dust collector by gas of the air ring to becollected, and the dust collector is connected with the steel slag warehouse through an air conveying chute. The superfine steel slag treatment method comprises the steps that S1, the steel slag is fed into the steel slag vertical mill through the air lock valve to be ground; S2, qualified ground fine powder is collected by the dust collector; and S3, the fine powder is collected by the dust collector and then is conveyed to the steel slag warehouse by the air conveying chute. According to the superfine steel slag treatment system and method, free-state calcium in the steel slag is reduced through multiple grinding of the steel slag vertical mill, the steel slag can be efficiently ground, activity of finished products is improved, product competitiveness is enhanced, and through a formedhot air channel, the steel slag is dried while being ground in the steel slag vertical mill.

Owner:天津亿诚集团有限公司

Process for preparing superfine high-activity metakaolin by utilizing vertical high-pressure mill

InactiveCN102060302ALow investment costReduce production investment costsAluminium silicatesChemical industryGranularityKaolin clay

The invention relates to a process for preparing superfine high-activity metakaolin by utilizing a vertical high-pressure mill, which is characterized by comprising the following steps of: firstly, crushing crude ore of metakaolin into 325+ / -30 meshes, grinding the crushed crude ore by the vertical high-pressure mill to obtain a superfine high-activity metakaolin powdery material with a particle size of 2-2.5mum, then conveying the superfine metakaolin to a rotary kiln feeding system by a fan, adding the superfine metakaolin into a rotary kiln by an automatic feeding machine, then carrying out high-temperature calcining on the superfine metakaolin in the rotary kiln with the temperature of 600-900 DEG C and the calcining time of 1-4 h, and preparing a superfine metakaolin product. The process has the advantages that the production cost is greatly reduced, the occupied area is only 50% of that of a ball mill system, the production efficiency is high, the energy is saved, the environment is protected, the granularity of a product is fine and uniform, the particle size of the product is 2.1-3.0mum, the minimum particle size can be controlled to be 2mum, and the uniformity is over 90%.

Owner:INNER MONGOLIA TIANZHIJIAO KAOLIN CO LTD

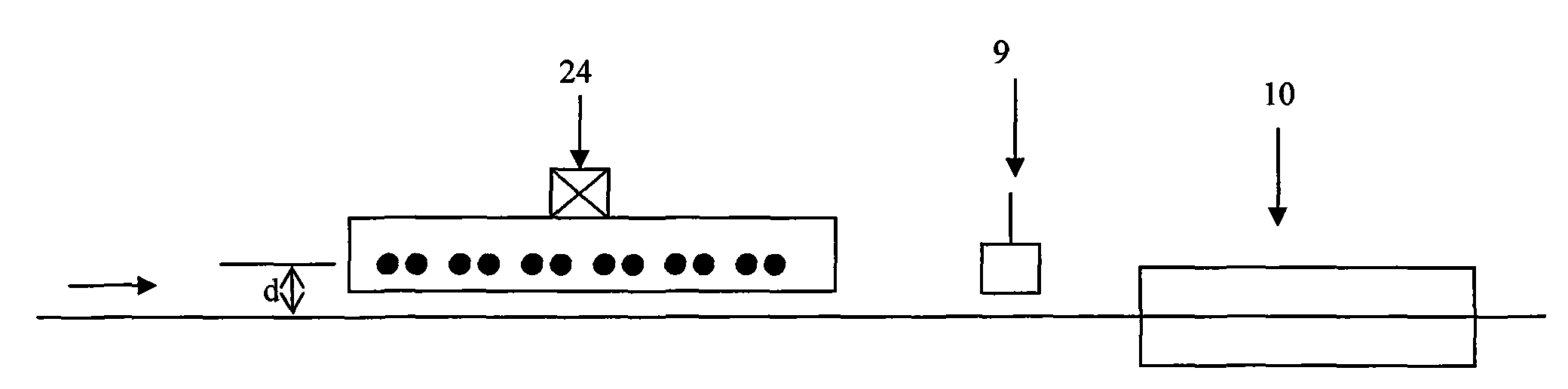

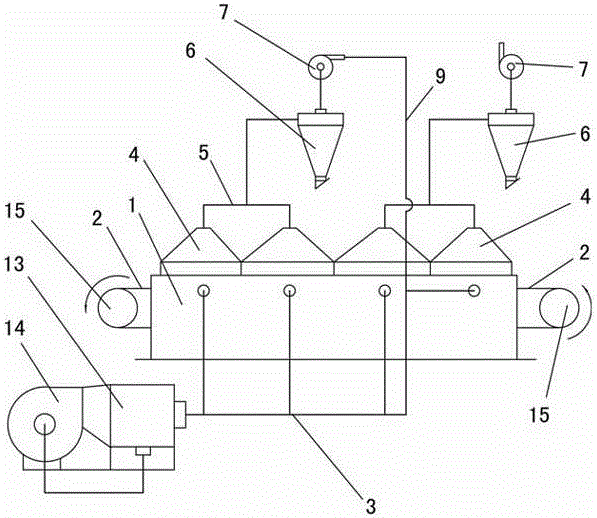

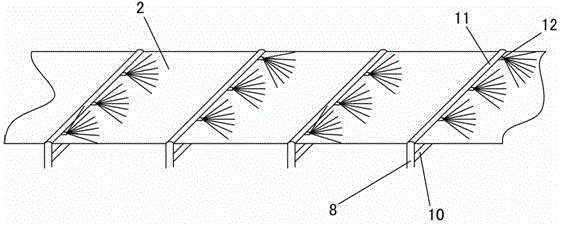

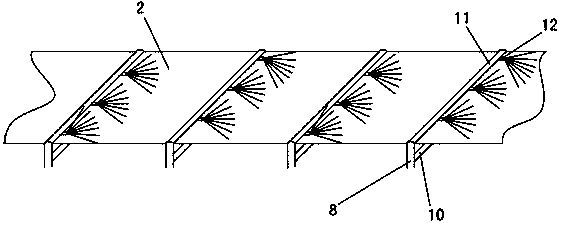

Electromagnetic heating tunnel type steel belt fluid bed dryer

InactiveCN105783471AEmission reductionImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsCycloneEngineering

The invention discloses an electromagnetic heating tunnel type steel belt fluid bed dryer which comprises an electromagnetic high-frequency heating part and a drying part. The drying part comprises a tunnel dryer main body, a steel belt, air feeding hoses, a plurality of air gathering covers, a plurality of air gathering pipes, cyclone separators and air exhausting fans arranged above the cyclone separators. Vertical air inlet pipes are arranged at one side of the steel belt; an above-belt air inlet pipe and an under-belt air inlet pipe are connected to each vertical air inlet pipe; air blowing nozzles are distributed on a pipe body of each above-belt air inlet pipe and a pipe body of each under-belt air inlet pipe. The electromagnetic high-frequency heating part comprises an electromagnetic high-frequency air heater and a high pressure fan. According to the electromagnetic heating tunnel type steel belt fluid bed dryer, the electromagnetic high-frequency heating technology is adopted, and the electromagnetic heating tunnel type steel belt fluid bed dryer has the characteristics of being wide in applicability, adjustable in temperature and fast in warming up; during the drying process, conductive drying is conducted by means of heating the steel belt, materials are subjected to direct drying through gas, and the materials are also subjected to fluidized stirring through the gas; the drying capability is high; and drying tail gas of the last stage is reclaimed, energy consumption is thus lowered, and dust discharge during the drying process is reduced.

Owner:江西省鑫纬业环保设备制造有限公司

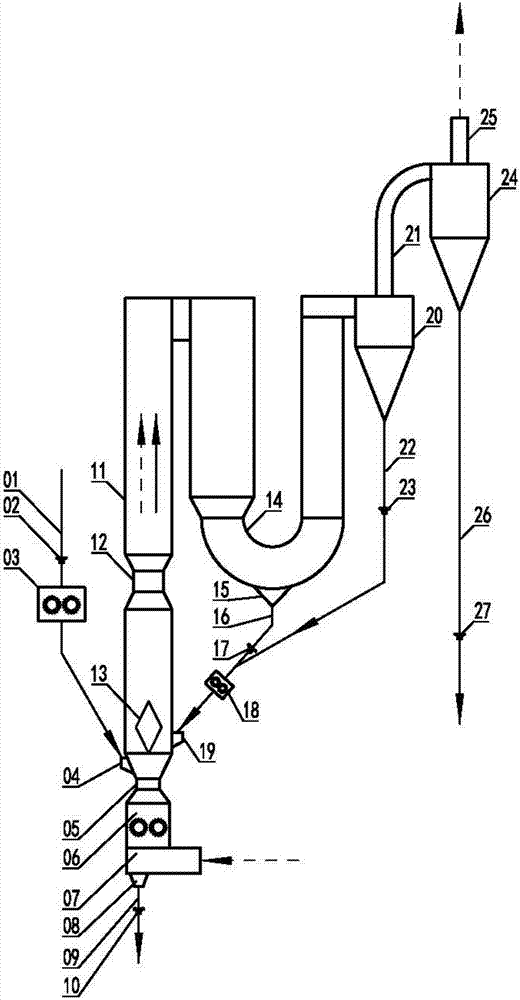

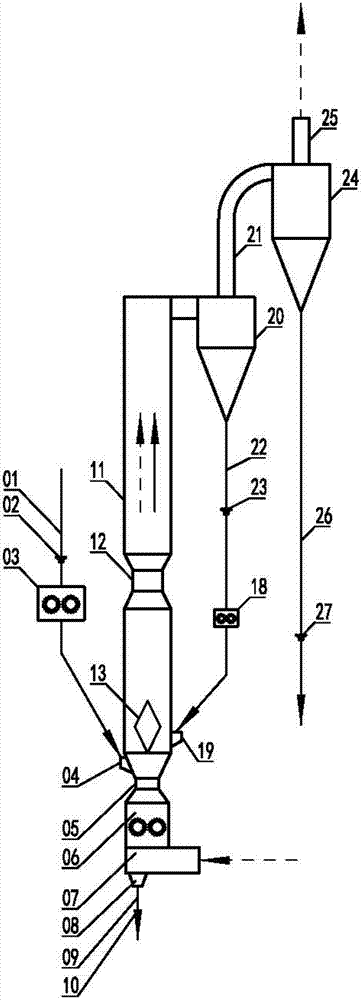

Suspended-state outer-circulation drying system

ActiveCN107473554AIncrease drying capacityIncrease surface areaSludge treatment by de-watering/drying/thickeningWater treatment parameter controlUnit volumeHeating efficiency

Disclosed is a suspended-state outer-circulation drying system. The system comprises a drying device, a recycling separator and a cyclone separator; a first air locking valve and a first-stage scattering device are arranged on a first feeding pipe at a material feeding end of the drying device; a first material disperser is arranged at a material feeding opening; a second-stage scattering device is arranged at the lower part of the drying device; an air inlet pipe and an ash collecting chamber are arranged under the second scattering device; a material discharging pipe which is equipped with a second air locking valve is arranged at the bottom of the ash collecting chamber; the recycling separator is connected with a top outlet of the drying device, and ash-containing gas which flows out of the drying device enters the recycling separator tangentially; a first air outlet is arranged at the top of the recycling separator; a second feeding pipe which is equipped with a fourth air locking valve is connected with a bottom outlet of the recycling separator; the cyclone separator is connected with the first air outlet, and the ash-containing gas enters the cyclone separator tangentially; a second air outlet is arranged at the top of the cyclone separator; and a third feeding pipe which is equipped with a fifth air locking valve is connected with a bottom outlet of the cyclone separator. In the drying system provided by the invention, an outer-circulation system is used to separate, scatter and continue to dry large particles, so that the drying capacity per unit volume of a dryer is increased, material are dried completely, and heat efficiency of the system is increased.

Owner:北京中科领向环保研究院有限公司

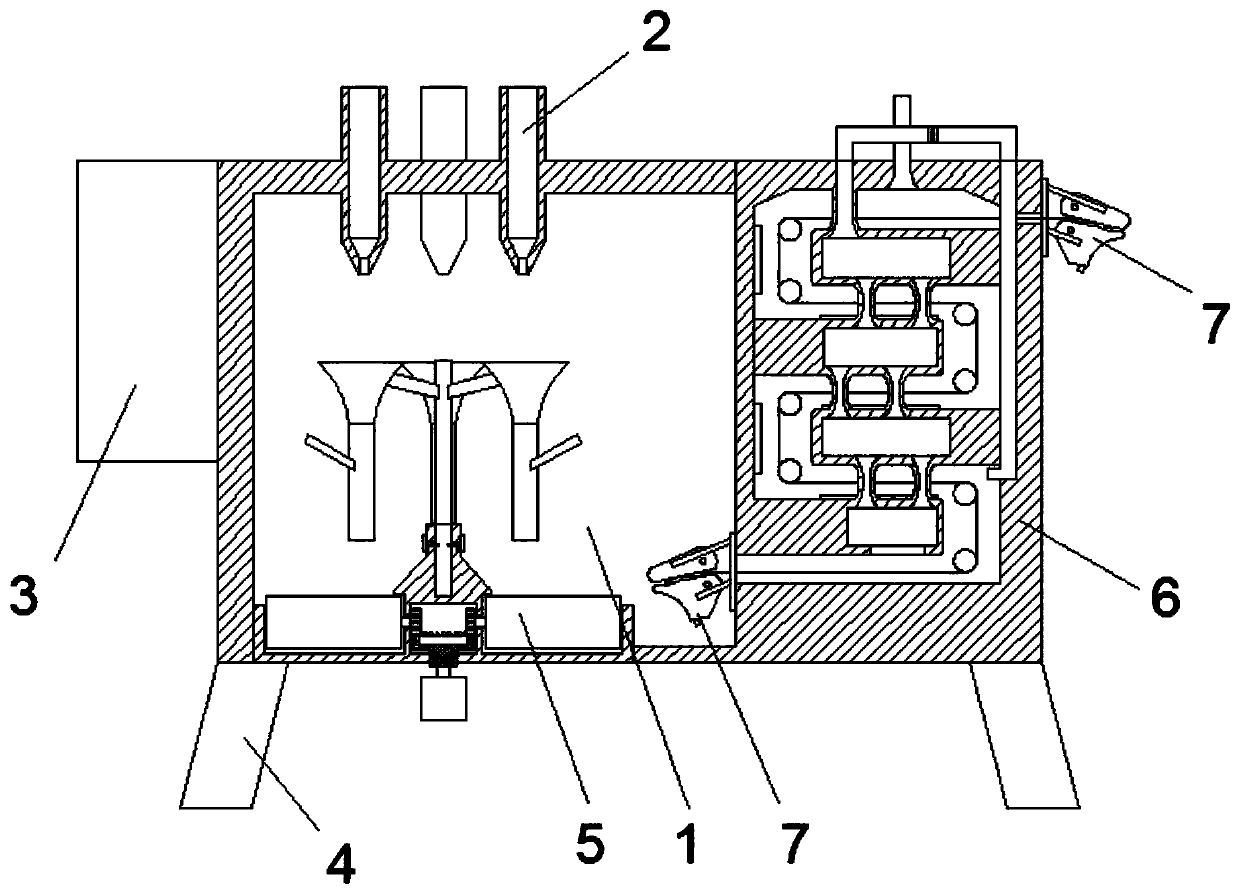

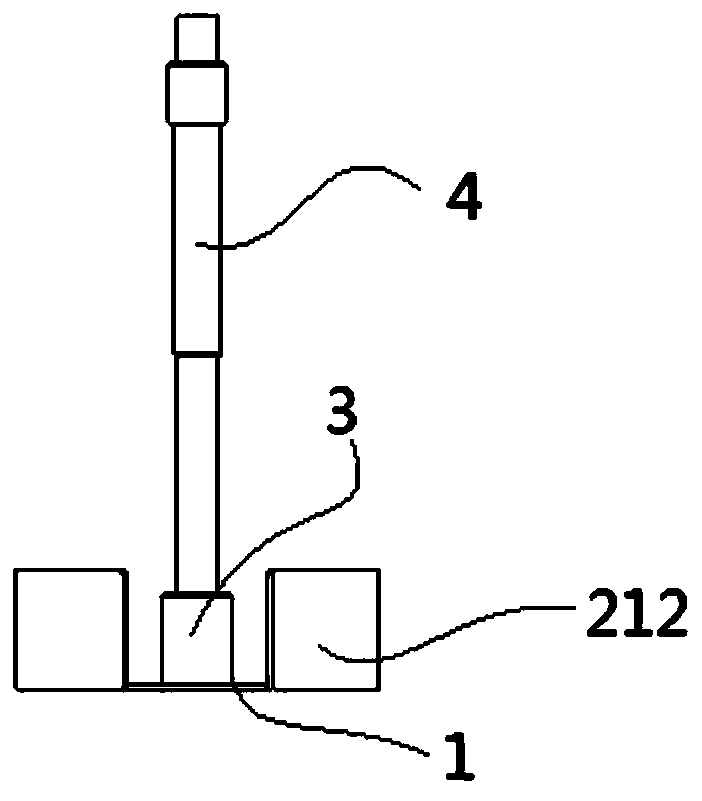

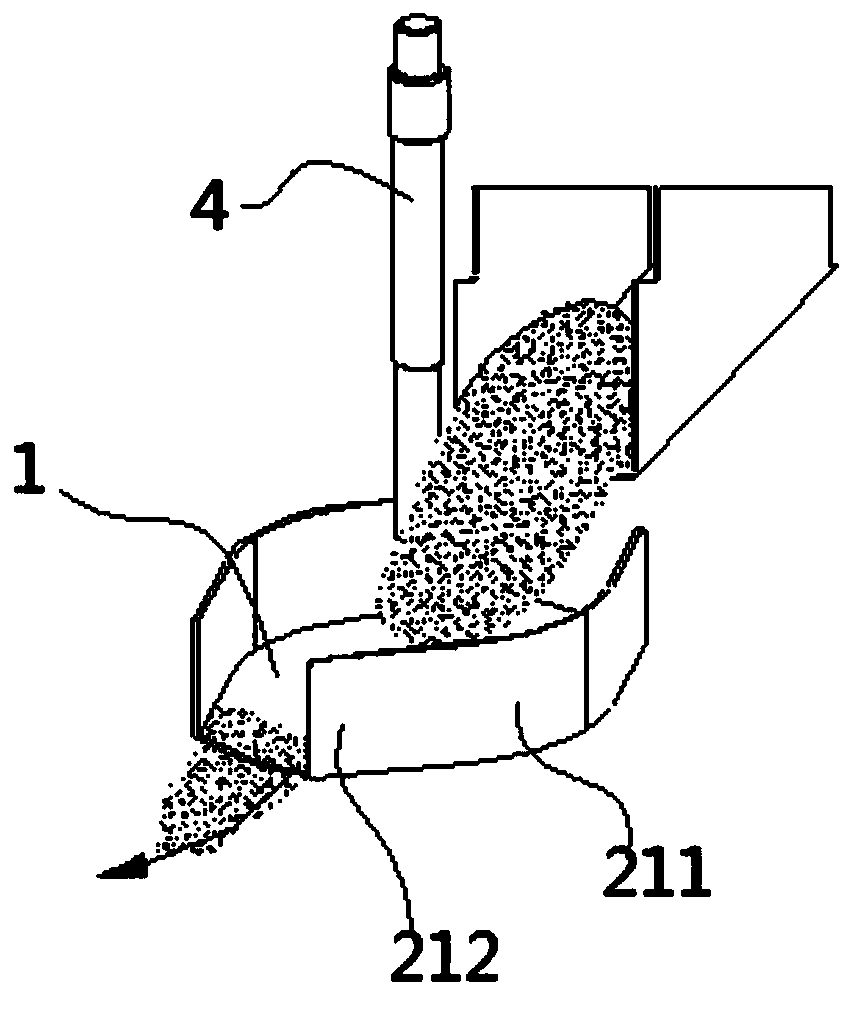

Nanofiber electrostatic spinning equipment

ActiveCN110106562AEasy dischargeAvoid mixingArtificial thread manufacturing machinesFilament manufactureEngineeringNanofiber

Nanofiber electrostatic spinning equipment comprises a spinning shell, a spinning head, a power supply box, shell bottom feet, a collecting device, a drying device and a conveying roller, wherein thespinning head is arranged at the top end of the spinning shell; the power supply box is arranged on the outer wall of the spinning shell, and the power supply box is electrically connected with the spinning head through a wire; the shell bottom feet are arranged on the bottom surface of the shell; the collecting device is arranged on one side of the bottom end of the spinning shell, and the dryingdevice is arranged on one side of the spinning shell; the conveying roller is arranged at an inlet of a drying box and an outlet of the drying box. According to the equipment, the collecting device and the conveying roller are designed, so that the preparation smoothness and stability of a system are improved; meanwhile, the drying device is designed, so that products have better performance.

Owner:HIDETAKA NANO TECH CO LTD

High-purity flaky vanadium pentoxide and preparation method thereof

ActiveCN109319839AImprove drying efficiencyImprove drying capacityVanadium oxidesAir atmosphereVanadium(V) oxide

The invention discloses high-purity flaky vanadium pentoxide and a preparation method thereof. The method comprises the following steps that a vanadium source is rapidly dried in a spray drying mode so as to prepare a powder vanadium source, meanwhile, a part of the vanadium source is decomposed into vanadium pentoxide, then calcining is carried out in vacuum heating furnace, smelting is carried out in an oxygen-enriched air atmosphere, and then molten vanadium pentoxide flows into water-cooling rotating disc centrifugal flaking equipment through a flow guide pipe for flaking. The method has the advantages that the productivity is large, and the production efficiency is high, the applicability on the raw materials is high, the purity of the flaky vanadium pentoxide is high, the size is easy to control, in addition, the pollution is small, and even the powder vanadium pentoxide can be produced.

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

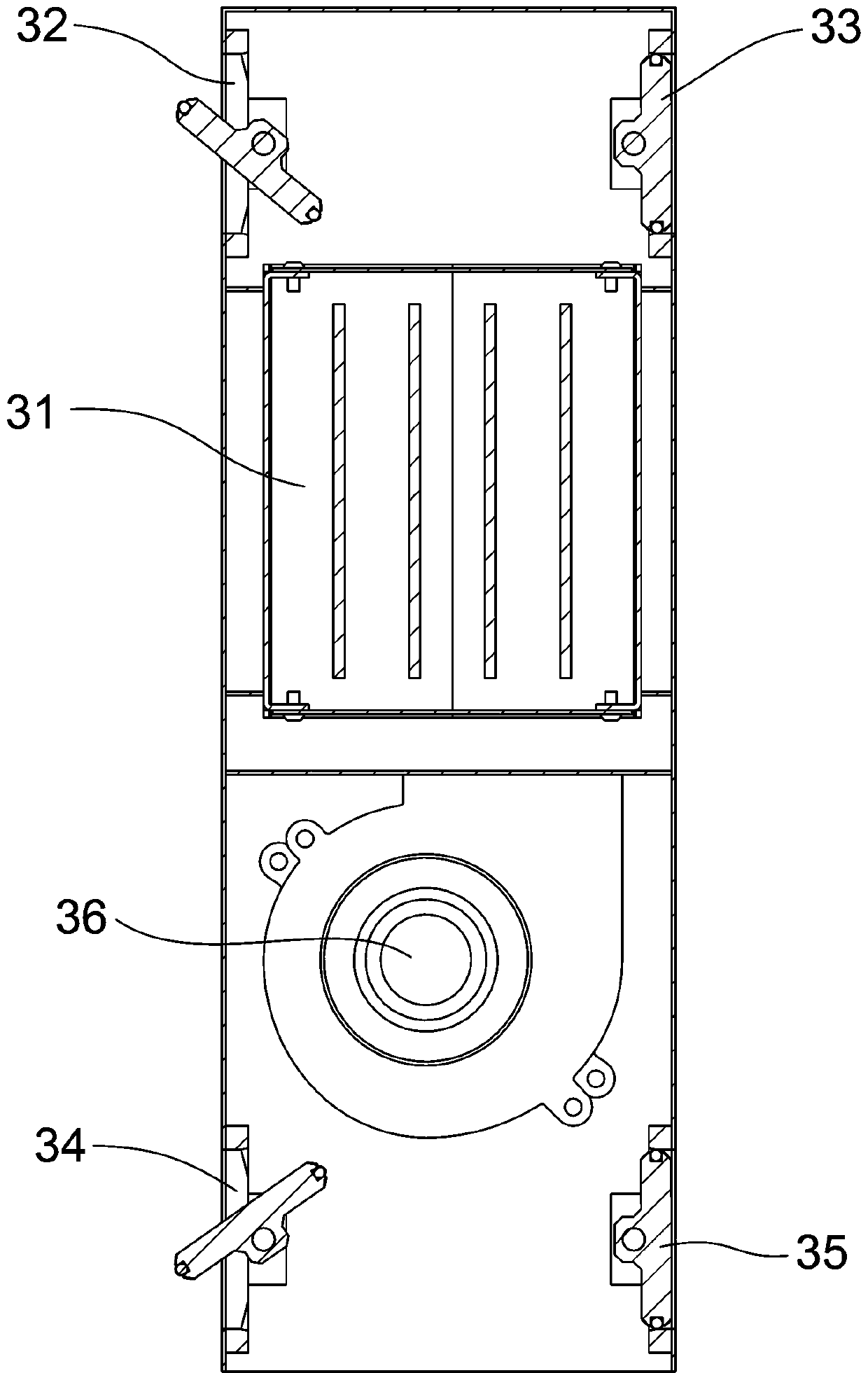

Equipment for drying materials by using air energy

ActiveCN110388802AGood containmentPrevent leakageDrying gas arrangementsDrying chambers/containersSlide platePulp and paper industry

The invention provides equipment for drying materials by using air energy. The equipment comprises a housing, heat pump drying machines, a driving door body and sill pillars, wherein the heat pump drying machines are respectively embedded into the left and right sides of the top end of the housing, air guide pipes are fixedly connected to the bottom ends of the heat pump drying machines, filter screens are embedded into the bottom ends of the inner walls of the air guide pipes, an observation window is embedded into the middle of the front end of the housing, the sill pillars are integrally arranged on four corners of the bottom end of the housing, chutes are respectively embedded into the middle of the upper and lower ends of the housing, the driving door body is movably connected to themiddle of the chutes, sliding plates are respectively arranged in the middle of the front and back ends of the driving door body, a comoving rope is fixedly connected to the middle of the left end ofthe inner side of the driving door body, low-speed motors are respectively embedded into the middle of the left and right sides of the inner wall of the housing, rotating posts are fixedly connected to the low-speed motors respectively, and arc plates are fixedly connected to the front and back ends of the outer walls of the rotating posts respectively by virtue of support rods. The whole device has the advantages of structural stability, simple material drying step, convenience in use and operation, good drying effect, energy conservation and environmental friendliness.

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

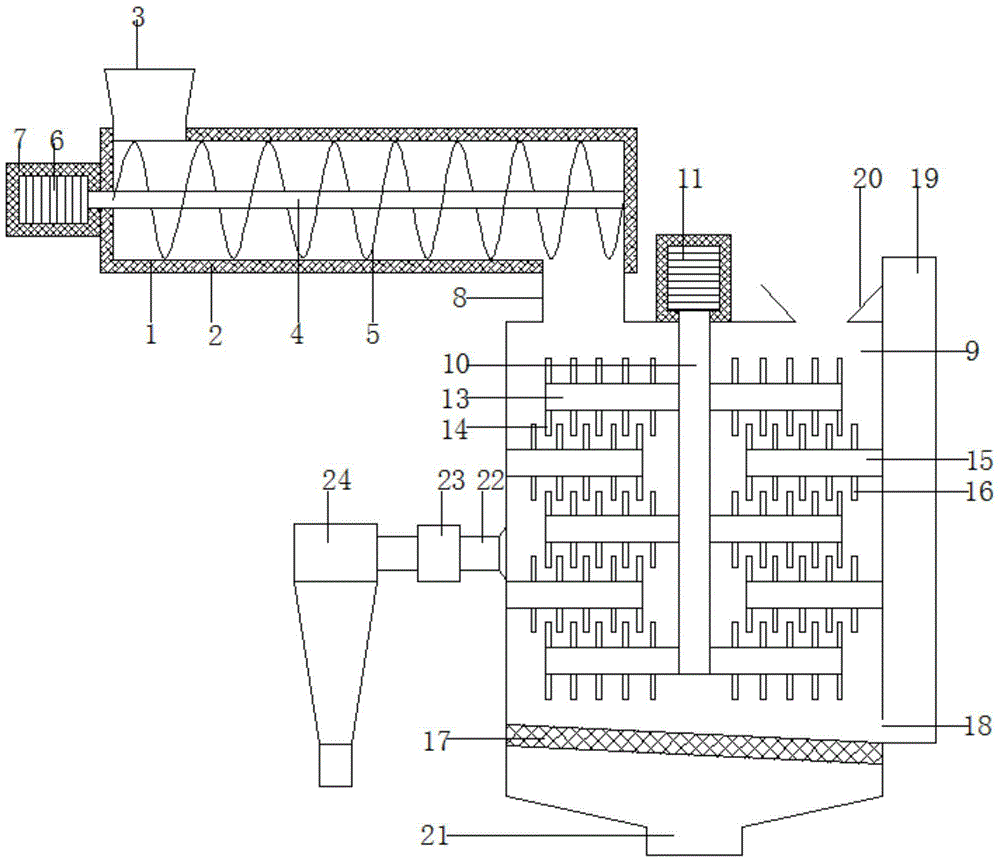

Automatic material conveying pulverizer for ceramic production

The invention discloses an automatic material conveying pulverizer for ceramic production, which comprises a material conveying barrel, a pulverizer body and a bag-type duct collector, wherein the outer wall of the material conveying barrel is coated with an electric heating layer; a material inlet hopper is arranged on the upper side of the left end of the material conveying barrel; a first rotating shaft is horizontally arranged in at the axis inside the material conveying barrel; and a plurality of screw blades are uniformly arranged on the first rotating shaft from left to right. According to the automatic material conveying pulverizer for ceramic production, automatic material conveyance is realized by the material conveying barrel; materials are pre-crushed and dried in the conveying process; the materials are beaten and crushed under the joint effect of rotation crushing rods, rotation beating short rods, fixed crushing rods and fixed beating short rods; the beating force is strong; the crushing intensity is high; the work efficiency of the pulverizer is improved; the materials the magnitudes of which do not conform to requirements are circularly crushed; the crushing effect of the pulverizer is ensured; dust produced in the crushing process can be collected by the bag-type dust collector; environment is protected; and the waste of raw materials is reduced.

Owner:苏晓玲

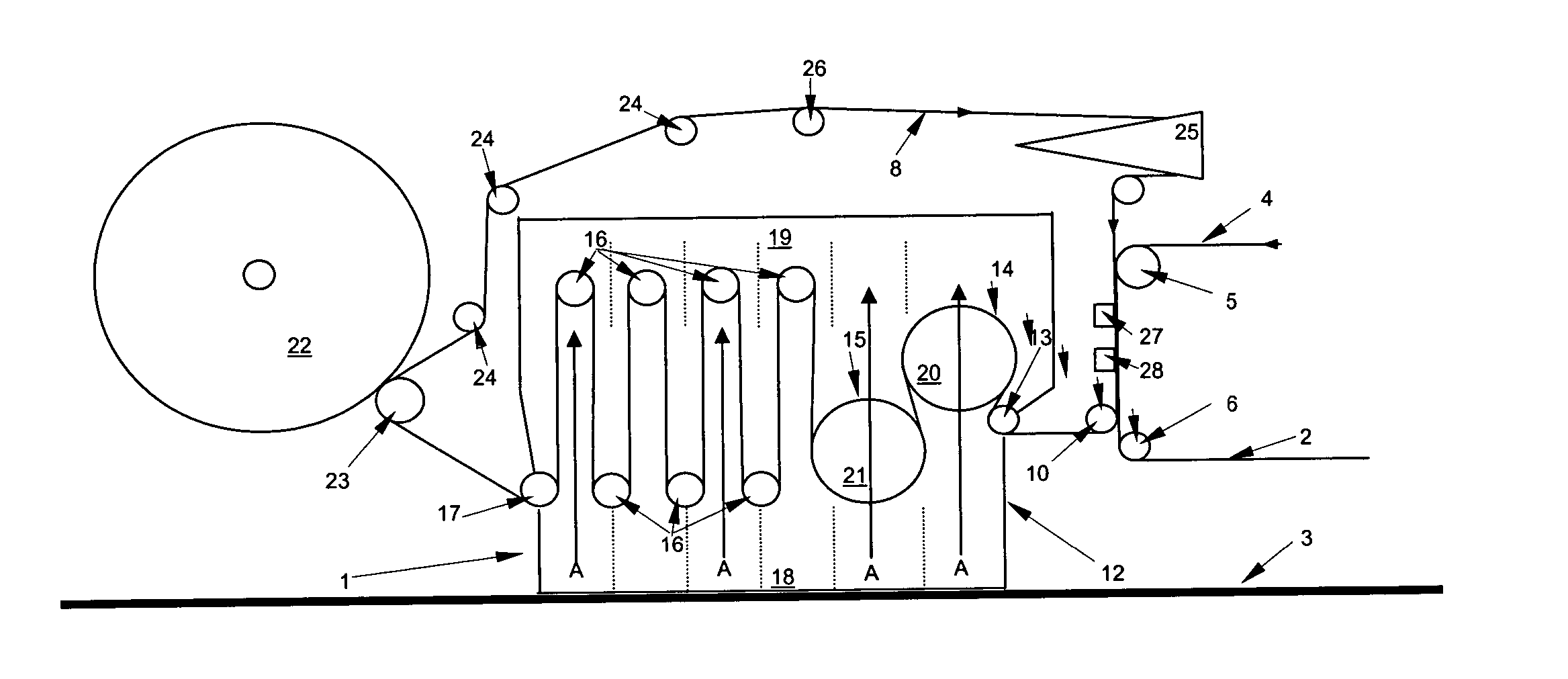

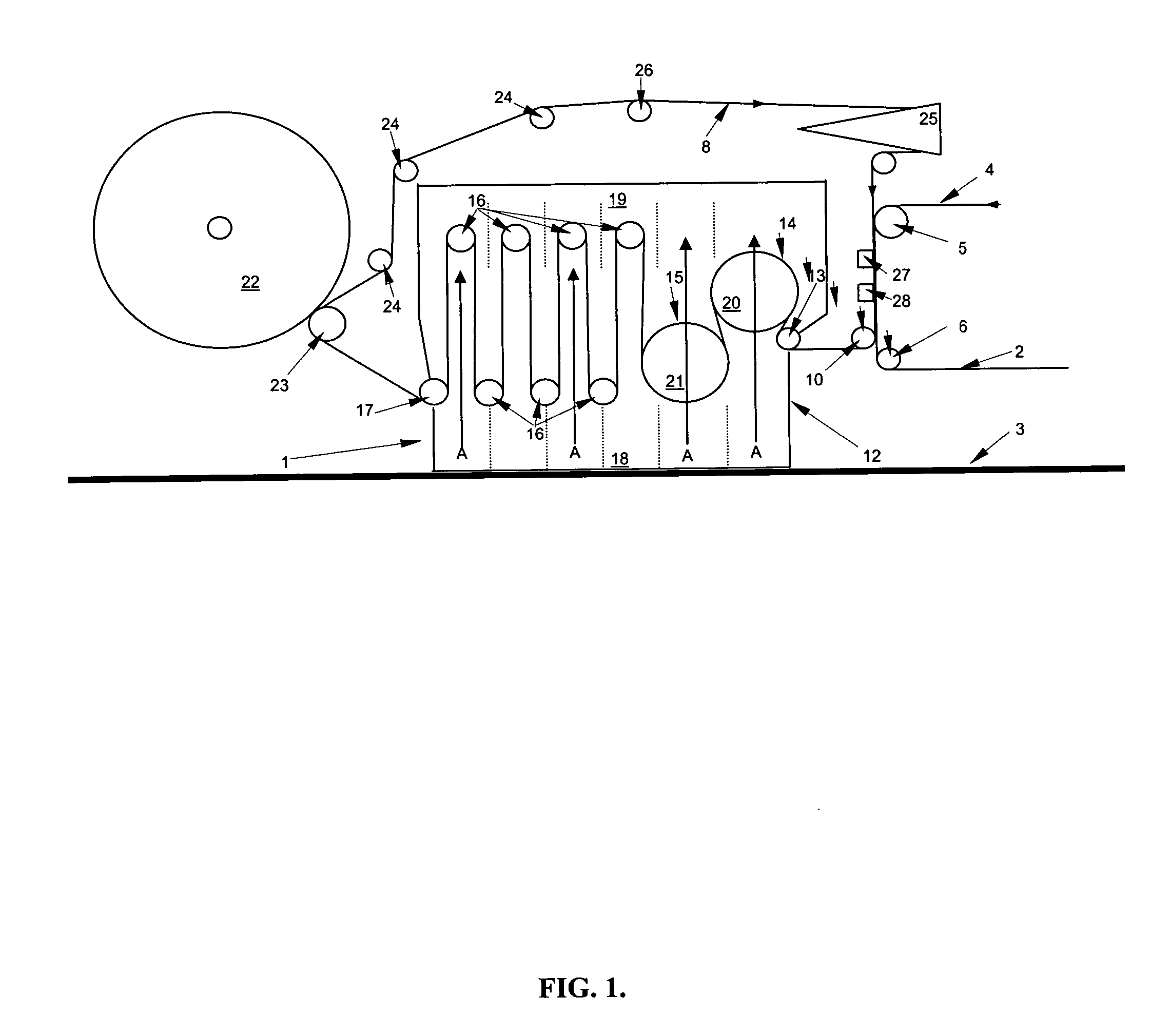

Serpentine paper drying machine

Owner:REISINGER LEE W

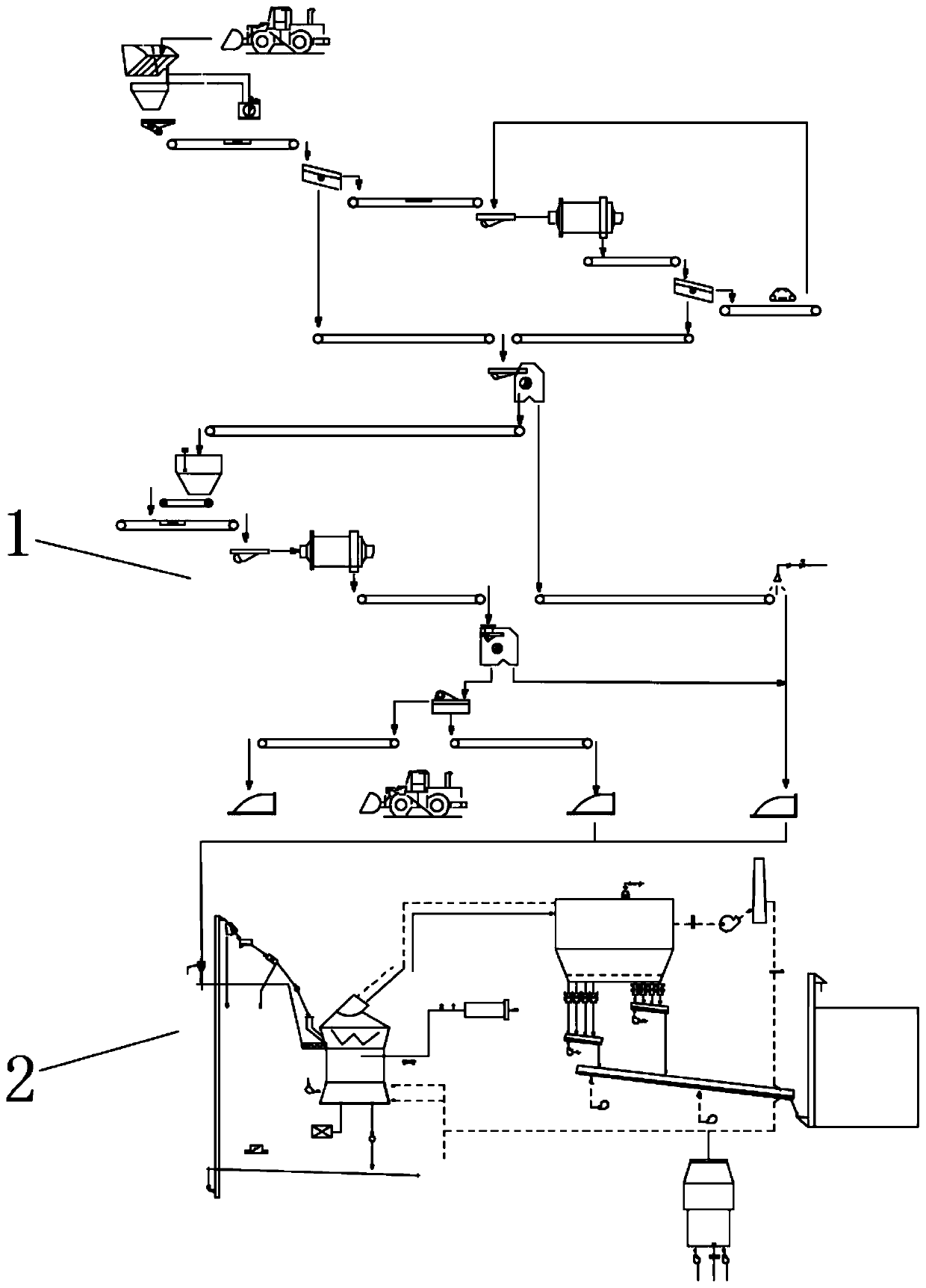

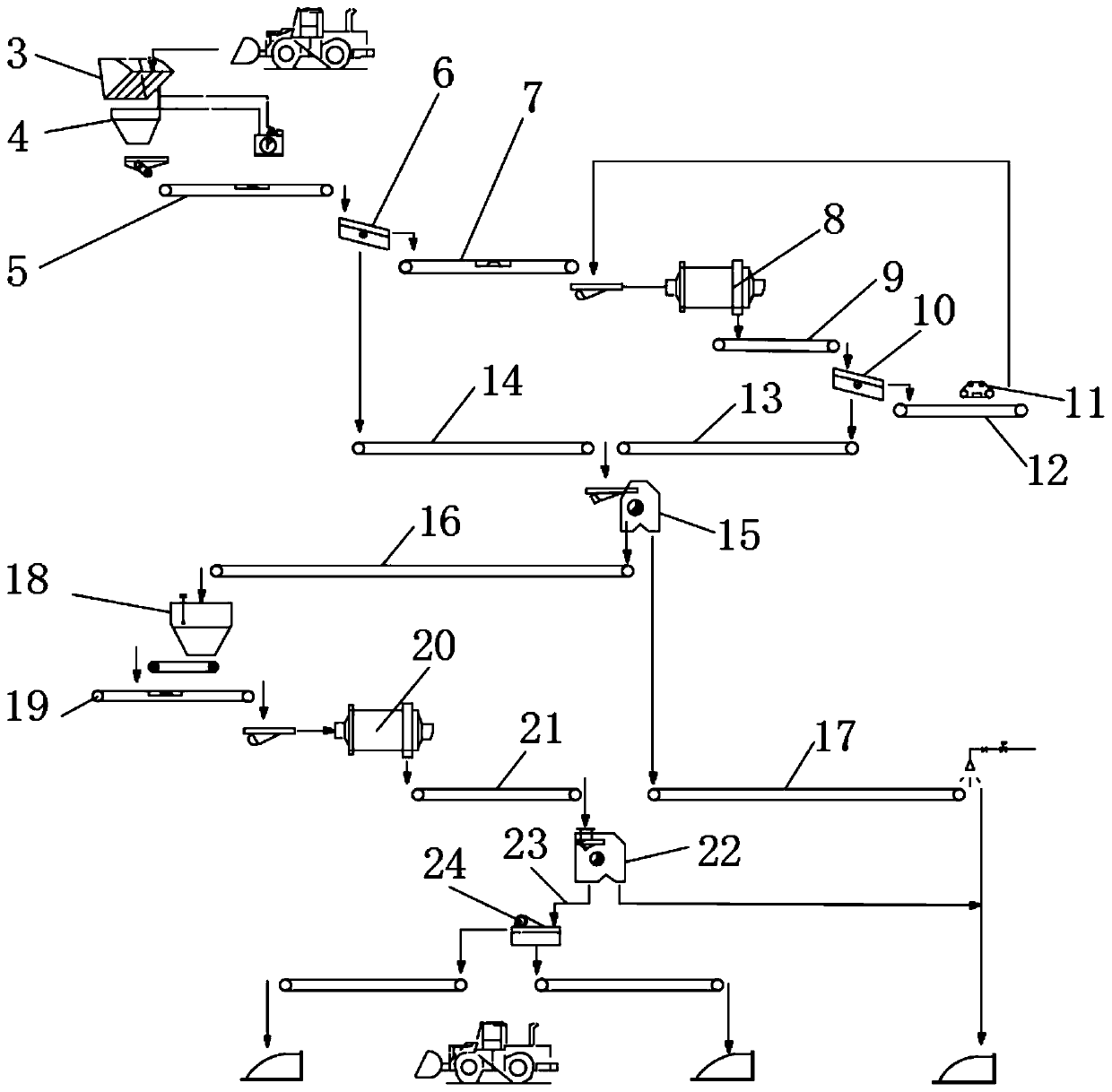

Steel slag combined grinding system and method

The invention provides a steel slag combined grinding system and method. The steel slag combined grinding system comprises a fine grinding device and a superfine grinding device; the fine grinding device comprises a receptacle trough, a first vibration screen, a steel slag magnetic drum classificator, a buffer bin, a second rod mill, a magnetic separator and a third vibration screen; and the superfine grinding device comprises a metering device, a feeding belt conveyor, a steel slag vertical mill, a dust collector and a steel slag warehouse. Fine treatment of steel slag is achieved, space waste and environment pollution are reduced, the steel slag is subjected to multiple crushing, magnetic separation and screening, energy consumption can be reduced, slag and iron are separated, the iron and the slag can be secondarily utilized, and economic benefits are increased; multiple products can be formed through technologies such as multiple screening, magnetic separation and rod milling, anddifferent demands of markets can be met; and free-state calcium in the steel slag is reduced through multiple grinding of the steel slag vertical mill, the steel slag can be efficiently ground, activity of finished products is improved, and product competitiveness is enhanced.

Owner:天津亿诚集团有限公司

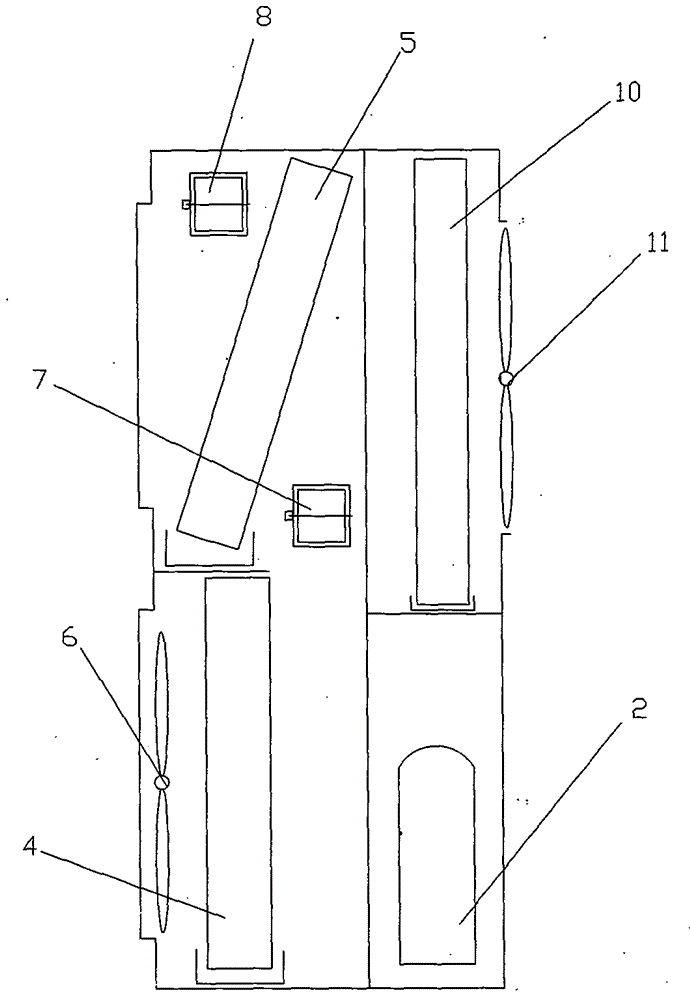

Constant-temperature dehumidifying air-energy heat-pump drying fresh air conditioner

InactiveCN105890078AFully efficient and energy-saving special effectsReasonable and efficient useLighting and heating apparatusSpace heating and ventilation detailsFresh airProcess engineering

The invention discloses a constant-temperature dehumidifying air-energy heat-pump drying fresh air conditioner which comprises a main case, an intelligent temperature and humidity controller, a heat pump compressor, a multi-path circulating control device, a multi-path throttling device, an indoor ventilating fan, an outdoor ventilating fan, an indoor primary heat exchanger, an indoor secondary heat exchanger and an outdoor heat exchanger, wherein the intelligent temperature and humidity controller is used for detecting the temperature, the humidity and the cleanliness of indoor air, the temperature, the humidity and the cleanliness of outdoor air, and the parameters of the running statuses of facilities; the main case together with the indoor ventilating fan, the indoor primary heat exchanger and the indoor secondary heat exchanger forms an indoor ventilating and air supplying loop; and the main case together with the outdoor ventilating fan and the outdoor heat exchanger forms an outdoor heat exchanging and ventilating loop. The constant-temperature dehumidifying air-energy heat-pump drying fresh-air air conditioner has the advantages that multiple different working modes are realized; the adaptability is strong; further, an energy source can be sufficiently utilized; the energy consumption is decreased; and the waste of a resource is reduced.

Owner:陈意军

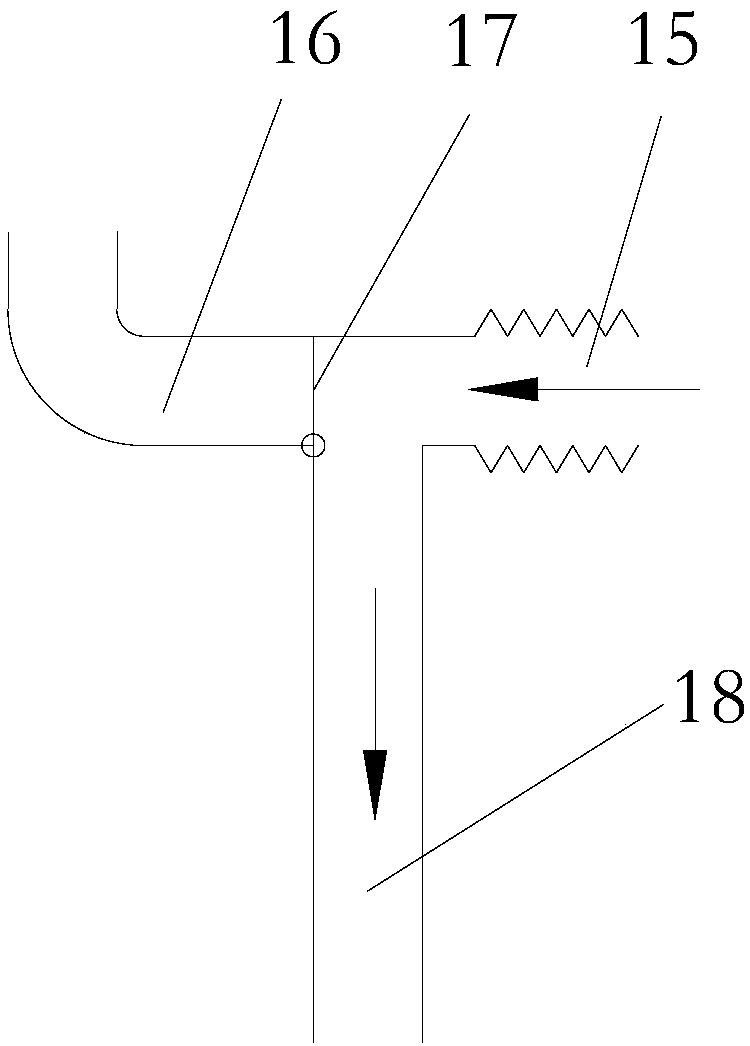

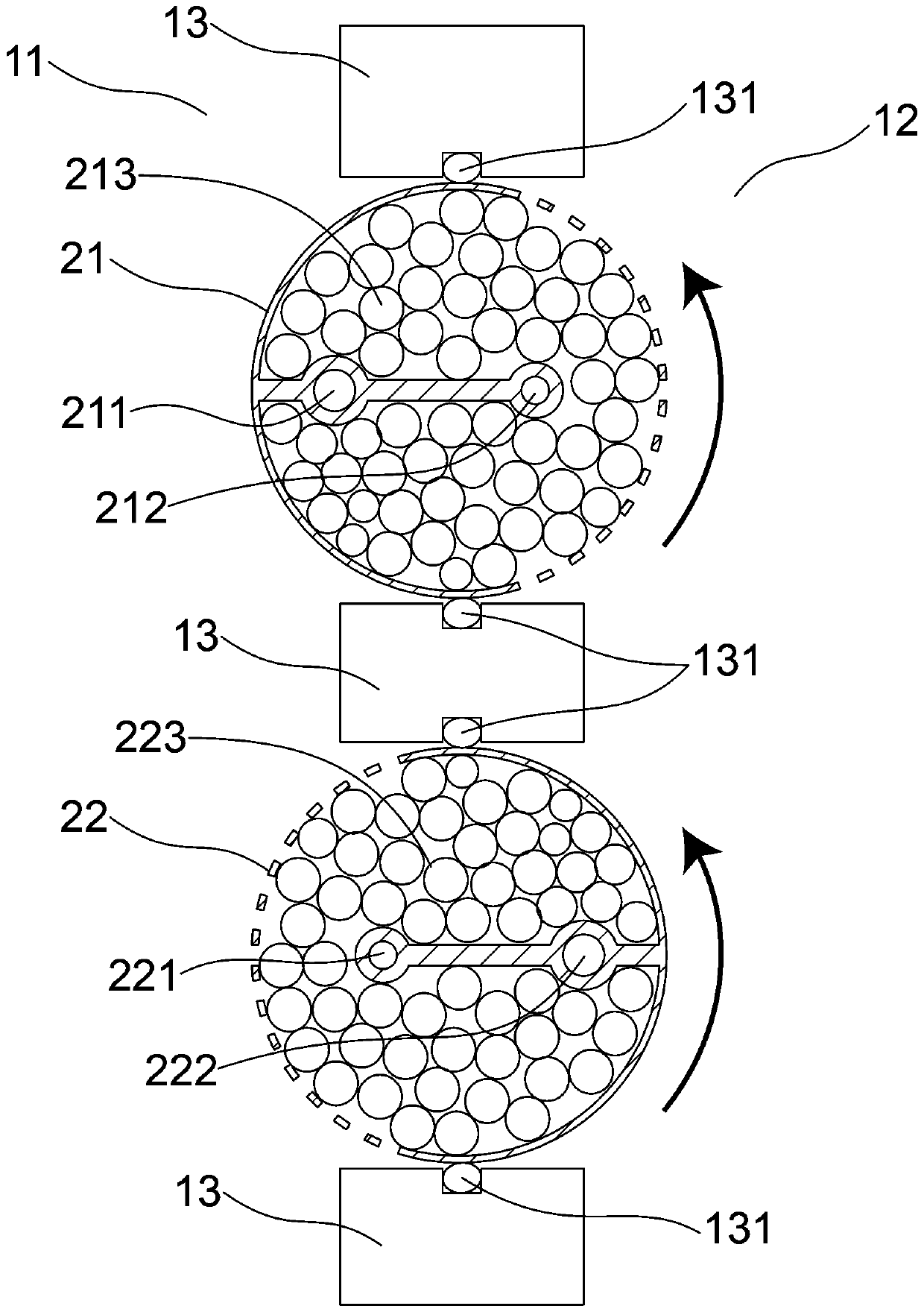

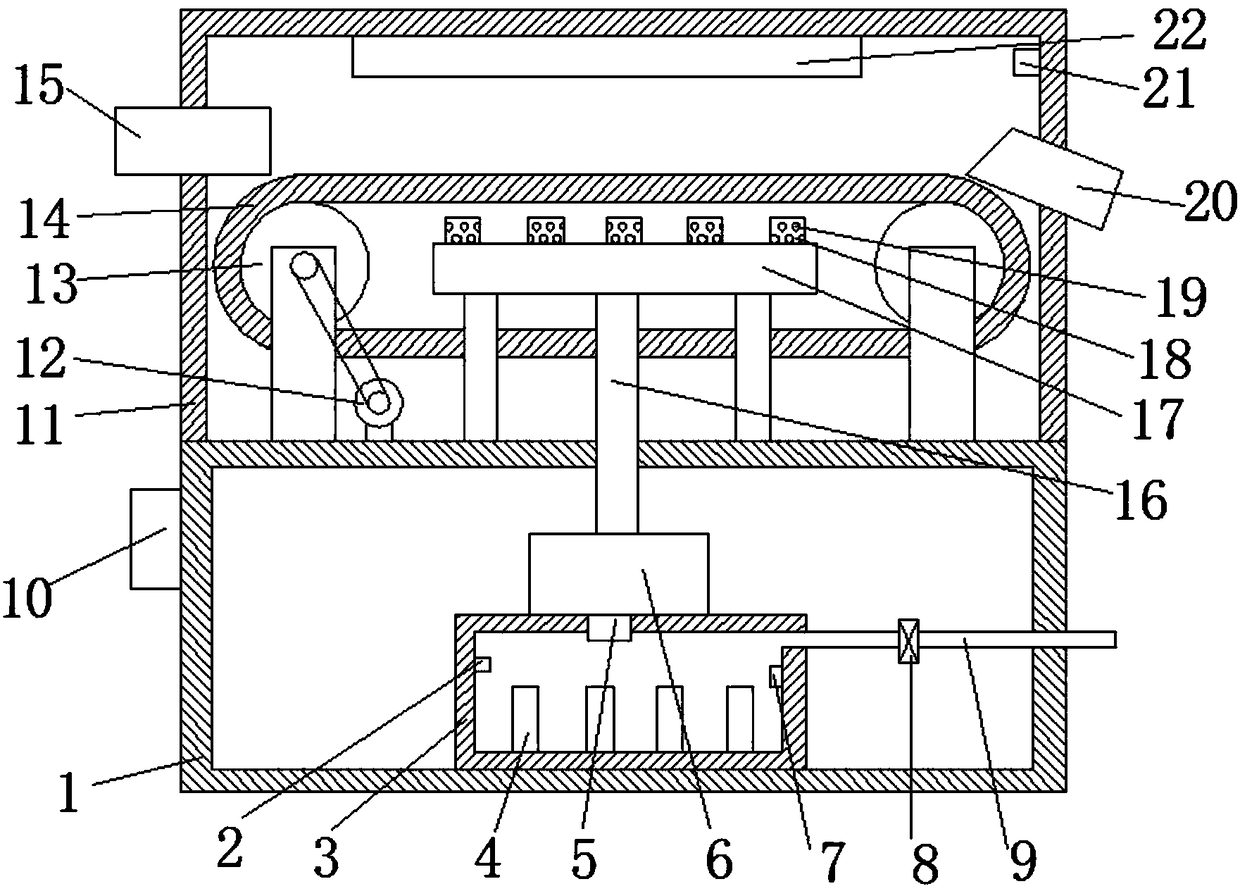

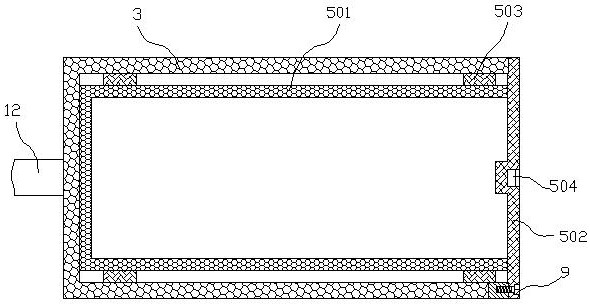

Air drying device used for closed cavity and control method of device

PendingCN110743331AImprove drying capacityRealize switchingGas treatmentDispersed particle separationPhysicsElectric machinery

The invention discloses an air drying device used for a closed cavity and a control method of the device, and belongs to the technical field of moisture-proof equipment. The confined space is continuously dried by using two or more groups of drying components in a circulation manner, and an active switching mechanism driven by a motor and an electromagnet is adopted, so that switching of the connection state of a drying box can be quickly realized, and moisture diffused into the cavity during the switching can be almost negligible to realize the purpose of controlling the moisture in the closed cavity to an extremely low level. The solution improves the drying capacity of a current moisture-proof box by one or more orders of magnitude, and meets the application needs for strict moisture control in 3D printing supplies storage and the like.

Owner:严铜

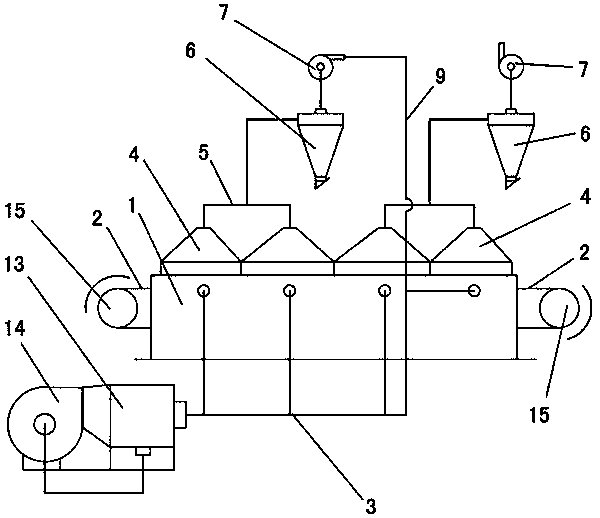

Dust-removing dryer for grain

InactiveCN106804699AFast and efficient dryingImprove qualityUsing liquid separation agentSeed preservation by dryingPulp and paper industryAir blower

The invention relates to a dust-removing dryer for grain and belongs to the field of agricultural drying machinery. The dryer comprises a box, an air heater and a purification tank, wherein water is contained in the purification tank, an air blower is arranged at the top of the box, an air outlet of the air blower is connected with an air inlet of the box, and an air inlet of the air blower is connected with the air heater through a pipeline; drying pipes are arranged in the box, a plurality of through holes are formed in the side wall of each drying pipe, and exhaust ports are formed in one side wall of the box and extend into the liquid level of the purification tank. The dust-removing dryer for the grain dries the grain in an up-ventilation and down-exhaust manner, the grain is ensured to be dried quickly and effectively, and the workload of farmers can be reduced; moisture in the grain is fully diffused, the quality of the dried grain is higher, the exhaust ports are placed in water, impurities and dust in exhaust air are adsorbed by water, pollution can be prevented, the exhaust air is purified, and the dryer is simple in structure and has very high practicability.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

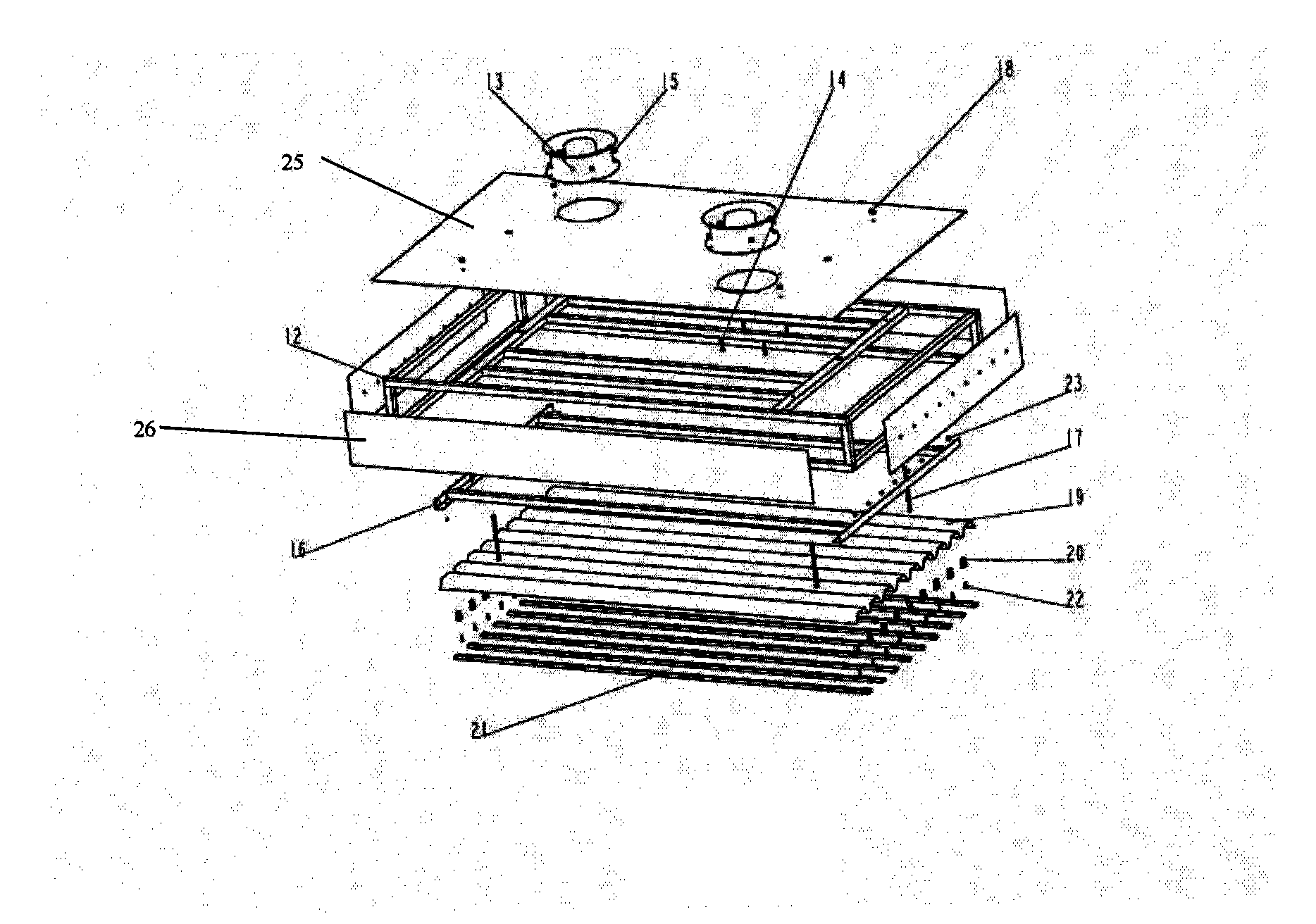

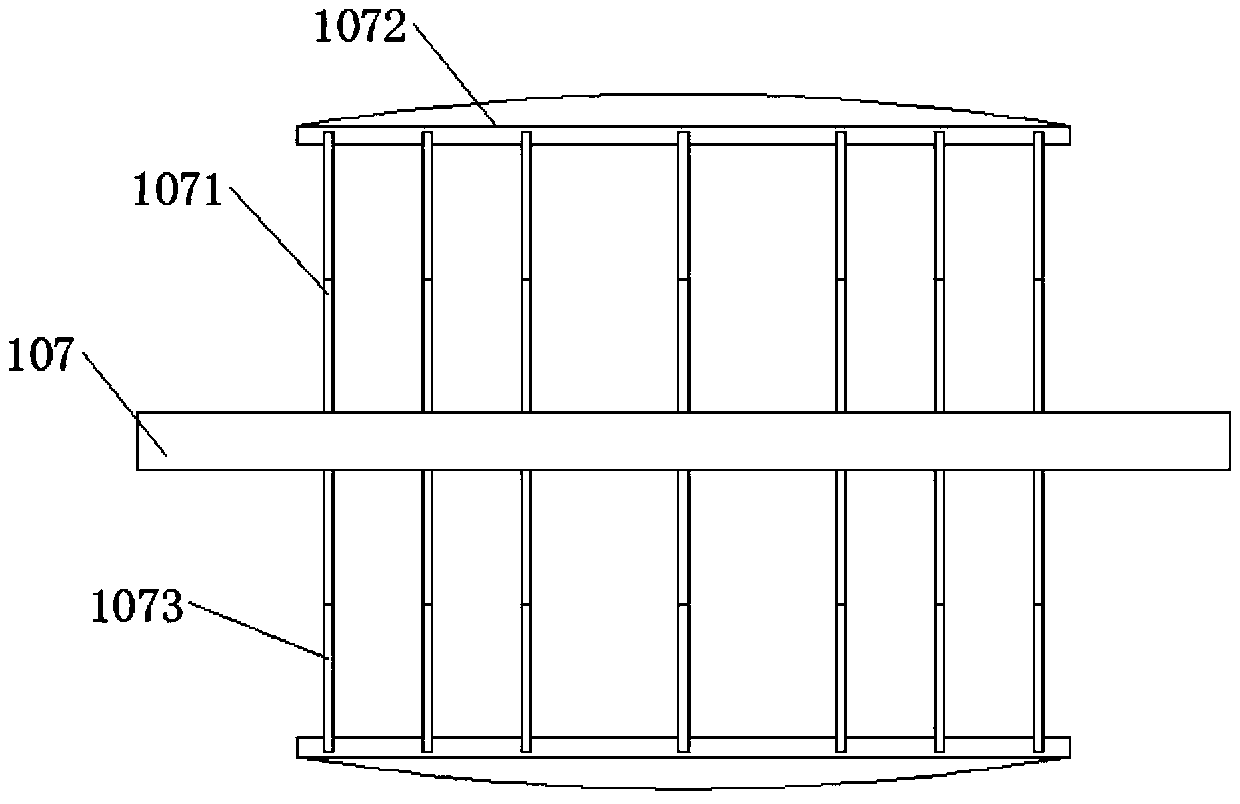

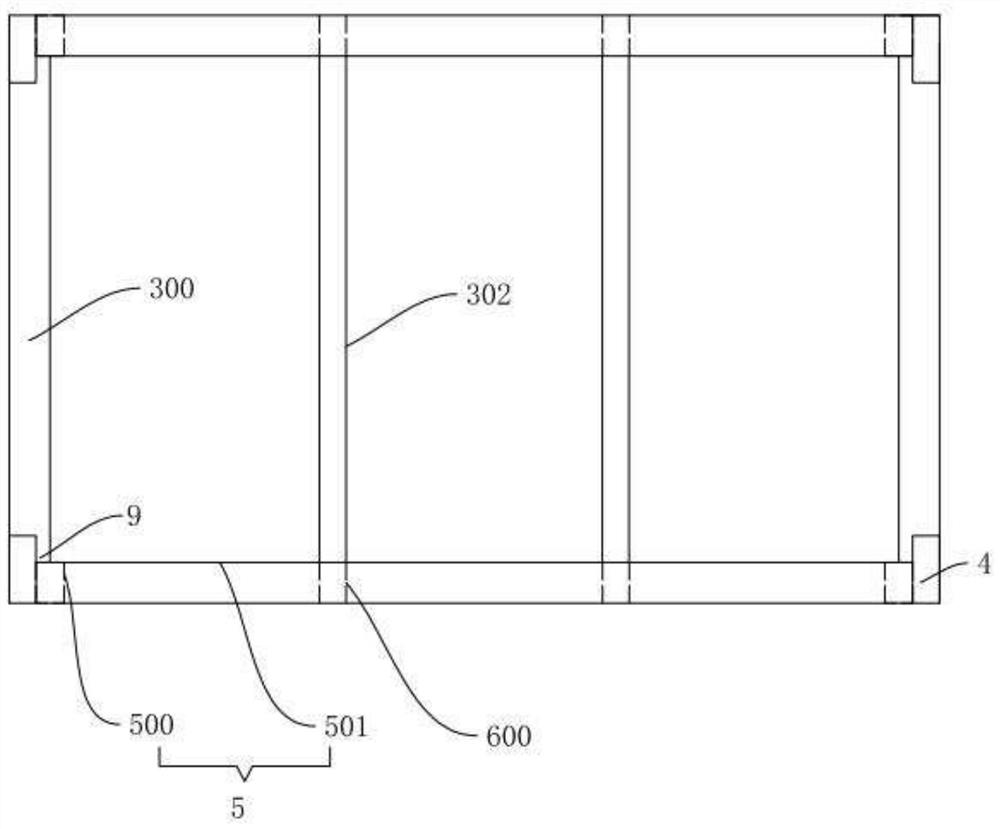

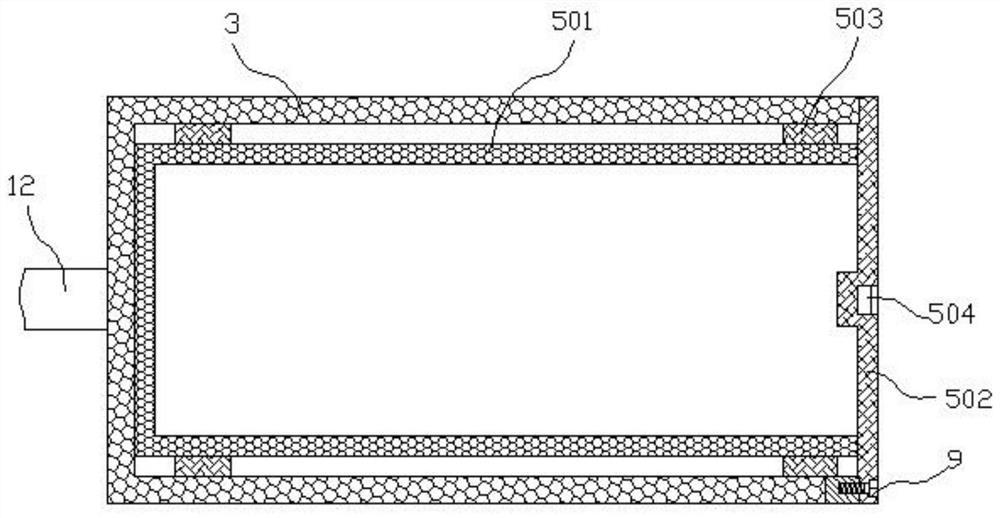

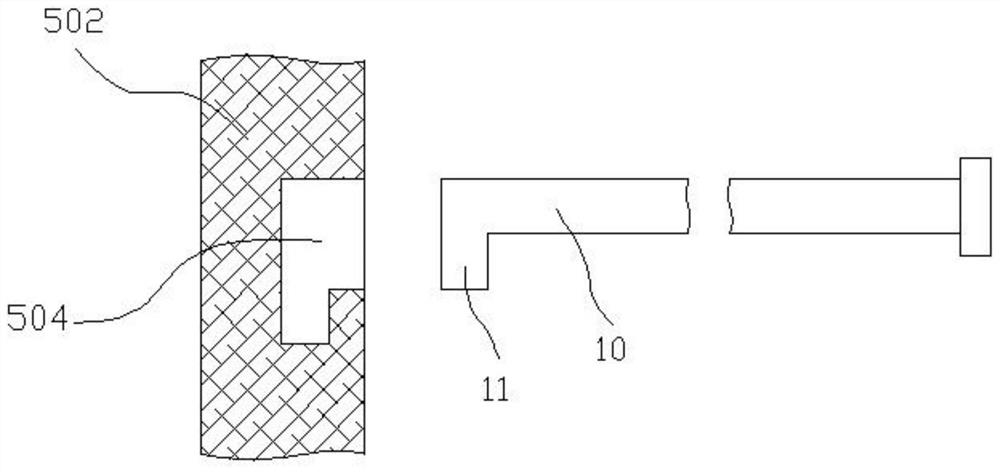

Drying structure, drying device and drying method

PendingCN114315089AImprove dehydration rateImprove drying capacitySludge treatment by de-watering/drying/thickeningSludgeDry structure

The invention relates to a drying structure, a drying device and a drying method, the drying structure comprises at least two mesh plates and a drying layer arranged between the mesh plates, and at least one layer of gap is arranged between the adjacent mesh plates. Correspondingly, the invention further provides a drying device, and the drying device comprises a frame structure used for storing the drying structure and ventilation equipment capable of storing the frame structure. The drying device is arranged, the gaps are formed between the adjacent mesh plates, it can be guaranteed that air can penetrate through the gaps to enter the fiber structures covering the mud raw materials, then the air drying speed is increased, the fiber structures and the mesh plates are arranged in the drying device in a layer-by-layer stacking mode, and the drying efficiency is improved. And the drying device with the drying structure is moved to the ventilation equipment, so that the sludge raw material can reach an extremely high dehydration rate in unit time, the sludge drying amount is increased, the power consumption per kilogram is reduced, and the advantages of low energy consumption cost and high dehydration efficiency are achieved.

Owner:WUXI DELINHAI ENVIRONMENTAL PROTECTION TECH CO LTD

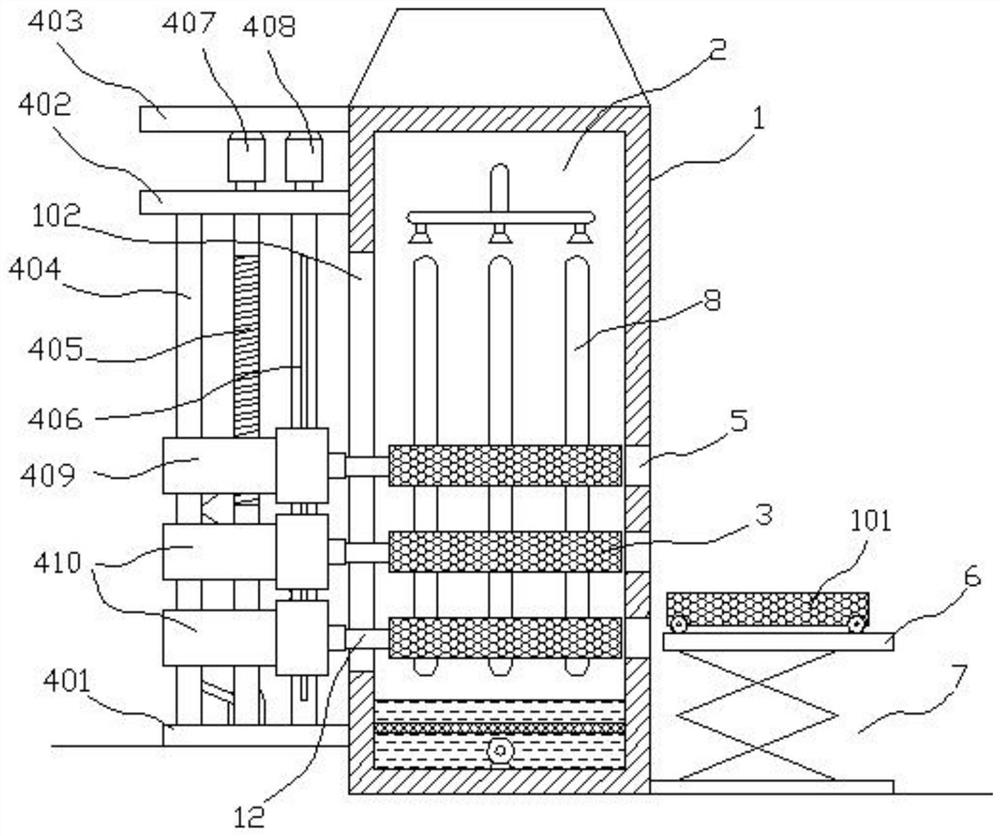

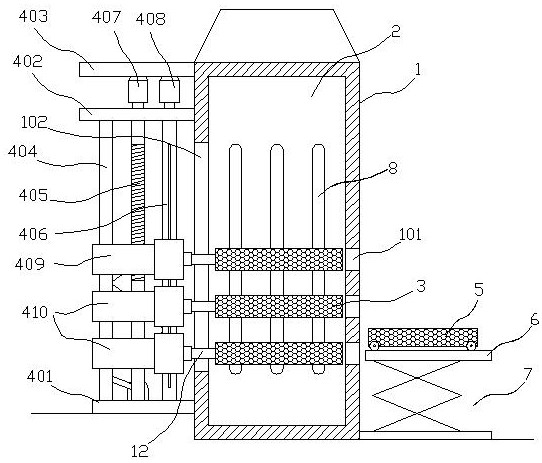

Tea seed cleaning and drying integrated equipment for camellia oil processing

ActiveCN113317528AImprove drying efficiencyImprove qualityFatty-oils/fats productionFood treatmentAgricultural engineeringWater pipe

The invention discloses tea seed cleaning and drying integrated equipment for camellia oil processing, and relates to the technical field of tea seed processing. The equipment comprises a drying tower, drying frames, frame vehicles, a driving mechanism for driving the drying frames to do up-and-down synchronous same-distance linear motion and to overturn and a lifting platform for feeding the frame vehicles into the frames. The multiple drying frames are driven by the driving mechanism which is uniquely designed, tea seed materials can be statically and dynamically dried, the drying efficiency and quality are improved, the automation degree is high, time and labor are saved, operation is convenient, the labor cost is greatly reduced, the dried tea seed materials are evenly heated, and the risk of reworking and secondary processing production is reduced. A water accumulating tank, a water suction pump, a water pipe and spraying heads are additionally arranged on a tower body, so that the equipment has the function of cleaning the tea seed materials in the frames, and then cleaning and drying operation on the tea seed materials can be sequentially completed by one set of equipment.

Owner:安徽东旭大别山农业科技有限公司

Tunnel type heat drying chamber

InactiveCN103134296AStrong drying capacitySatisfy dry processingDrying solid materials with heatDrying machines with progressive movementsProcess engineeringEngineering

A tunnel type heat drying chamber comprises a fan and a tunnel type heat drying chamber body, wherein a warm air pipe of the fan is connected with the tunnel type heat drying chamber body and enters into the tunnel type heat drying chamber body, an air equaling device is arranged on an air outlet of the warm air pipe, and a plurality of moisture removal fans are arranged on the peripheral walls inside the tunnel type heat drying chamber body. The tunnel type heat drying chamber has strong drying processing capacity, can meet requirements for drying of agricultural and sideline products, and is high in working efficiency.

Owner:NANTONG JINXU METAL PROD

An electromagnetic heating tunnel steel belt fluidized dryer

InactiveCN105783471BEmission reductionImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsCycloneEngineering

The invention discloses an electromagnetic heating tunnel type steel belt fluid bed dryer which comprises an electromagnetic high-frequency heating part and a drying part. The drying part comprises a tunnel dryer main body, a steel belt, air feeding hoses, a plurality of air gathering covers, a plurality of air gathering pipes, cyclone separators and air exhausting fans arranged above the cyclone separators. Vertical air inlet pipes are arranged at one side of the steel belt; an above-belt air inlet pipe and an under-belt air inlet pipe are connected to each vertical air inlet pipe; air blowing nozzles are distributed on a pipe body of each above-belt air inlet pipe and a pipe body of each under-belt air inlet pipe. The electromagnetic high-frequency heating part comprises an electromagnetic high-frequency air heater and a high pressure fan. According to the electromagnetic heating tunnel type steel belt fluid bed dryer, the electromagnetic high-frequency heating technology is adopted, and the electromagnetic heating tunnel type steel belt fluid bed dryer has the characteristics of being wide in applicability, adjustable in temperature and fast in warming up; during the drying process, conductive drying is conducted by means of heating the steel belt, materials are subjected to direct drying through gas, and the materials are also subjected to fluidized stirring through the gas; the drying capability is high; and drying tail gas of the last stage is reclaimed, energy consumption is thus lowered, and dust discharge during the drying process is reduced.

Owner:江西省鑫纬业环保设备制造有限公司

A honeysuckle drying processing method

InactiveCN104896879AImprove drying capacityIncrease productionDrying machines with local agitationDrying machines with materials at restEngineeringHoneysuckle

The invention provides a honeysuckle drying processing method. The method comprises the steps of building an electric drying room, building honeysuckle shed frames in the electric drying room, using an enzyme deactivating and water removing machine to perform enzyme deactivating and water removing on fresh flowers before drying, and putting the flowers in the drying room for drying. The drying method increases the drying efficiency, saves cost, increases the honeysuckle drying quantity by more than 10 times, and guarantees high quality of dried finished products. The first-grade flower finished products are of high yield.

Owner:杨文成

Drying device with uniform heating function for carpet gluing machine

InactiveCN108620295AEasy to operateImprove drying capacityPretreated surfacesCoatingsEngineeringLiquid level sensor

The invention discloses a drying device with a uniform heating function for a carpet gluing machine, and belongs to the technical field of carpet manufacturing equipment. The drying device comprises abox body, a heating water tank is arranged at the bottom of the inner cavity of the box body, a heating plate is vertically arranged at the bottom of the inner cavity of the heating water tank, and atemperature sensor is arranged on the left side of the inner cavity of the heating water tank; and a liquid level sensor is arranged on the right side of the inner cavity of the heating water tank, and the top on the right side of the inner cavity of the heating water tank is provided with a water inlet pipe. According to the drying device, the structure is simple, the use is convenient, the design is ingenious, and the practicability and the novelty are very high; a carpet on a conveyor belt can be heated by utilizing steam, the carpet can be heated by utilizing a first heating plate as well, moreover, the carpet is uniformly heated, so that the drying effect is good, and the time consumption is short; and the peculiar smell of the carpet can be reduced by utilizing the steam to heat thecarpet, a controller is further used to control the whole device, so that the labor intensity of a worker is reduced, and the operation of the worker is facilitated.

Owner:TIANJIN JUYUE CARPET

Combination mode of mesh belt type dryers

ActiveCN108224996ATake advantage ofImprove drying capacityDrying machine combinationsDrying gas arrangementsPulp and paper industryMoisture absorption

The invention discloses a combination mode of mesh belt type dryers. A plurality of mesh belt type dryers are jointly distributed nearby, most dryers are set as main dryers, a small number of dryers are set as auxiliary dryers, a dry hot-blast air medium is fed in from the upper middle portions of the main dryers, water is brought away after hot-blast air passes through materials, upper moist hotair is exhausted from the tops of the dryers, damp and hot air containing little water at the middle and lower portions is forcibly exhausted through a fan from the lower portion to be fed to the auxiliary dryers to be recycled. The utilized hot-blast air medium is recycled and fed into the auxiliary dryers, the air is exhausted from the tops after moisture absorption, and the purposes of sufficiently utilizing heat energy, increasing the drying amount and lowering energy consumption are achieved.

Owner:SICHUAN NANCHONG SHOUCHUANG TECH

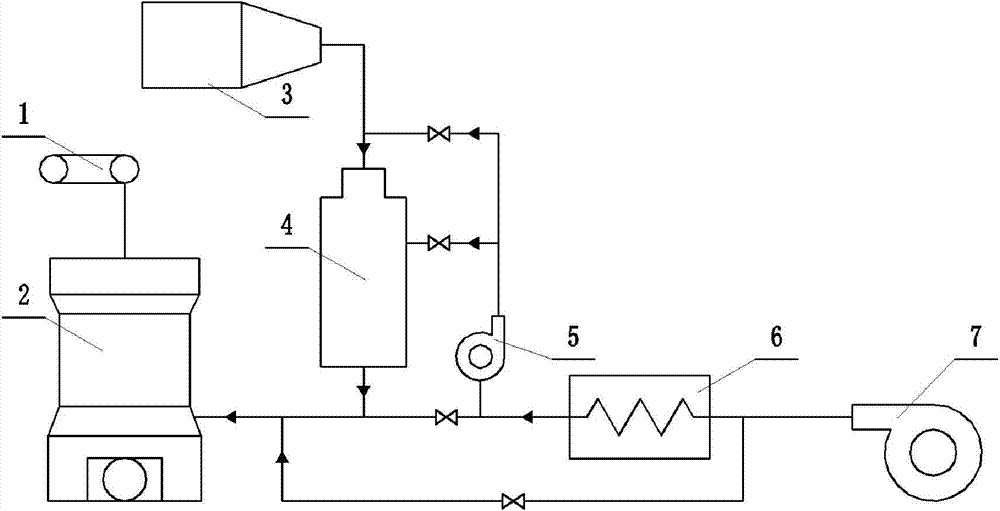

High-moisture lignite medium-speed coal mill pulverizing system heating primary air through coal gas burning

InactiveCN103925606AImprove drying capacityKeep dryLump/pulverulent fuel preparationBrown coalProcess engineering

The invention discloses a high-moisture lignite medium-speed coal mill pulverizing system heating primary air through coal gas burning. The system comprises a medium-speed coal mill, a coal gas generator, a fan, a high-temperature flue gas generator, a primary air fan, a coal feeder and an air preheater, can complete drying of high-moisture lignite and is composed of the medium-speed coal mill, the coal gas generator, the fan and the high-temperature flue gas generator. The system leads part of boiler heat primary air and coal gas generated by the coal gas generator into the high-temperature flue gas generator for burning, and hot flue gas generated by burning and rest heat primary air are mixed to serve as a drying agent to enter the coal mill, so that temperature of the drying agent is increased, and drying capability of the lignite boiler pulverizing system is improved. By the system, the problem that an existing high-moisture lignite medium-speed coal mill pulverizing system heating primary air through pulverized coal burning is insufficient in drying capability is solved well.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

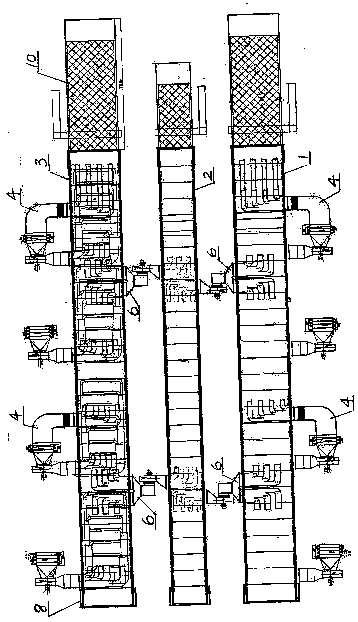

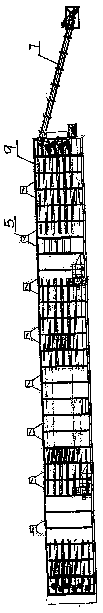

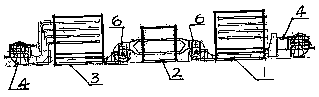

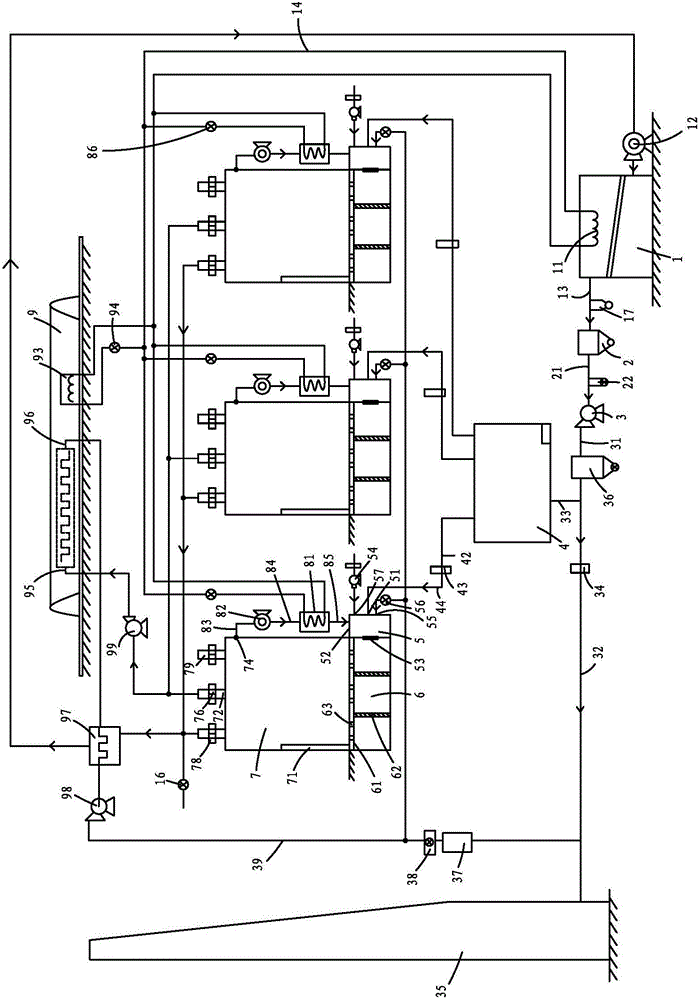

A drying kiln system for mixed application of radiator and furnace gas

ActiveCN104501547BReduce lossesEasy dischargeDrying gas arrangementsDrying machines with local agitationAtmospheric airDry heat

A radiator and furnace gas hybrid application drying kiln system comprises an organic heat transfer material heater, a furnace gas exhausting chimney, a multi-tube dust cleaner, a boiler induced-draft fan, a furnace gas buffer chamber, a plurality of drying room units and a tunnel drying kiln. The organic heat transfer material heater is provided with a steam generator and a boiler blower; the steam generator is connected with a heat supply pipeline which is connected to each drying room unit; the boiler blower is connected to a heat recoverer; the multi-tube dust cleaner is connected to the boiler induced-draft fan; an air duct of the boiler induced-draft fan form two branches which are respectively connected to the furnace gas buffer chamber and the furnace gas exhausting chimney; the furnace gas buffer chamber is connected to each drying room unit. Humidity of a dry-heat air medium is regulated by cooling of internal air of the drying kiln and tail gas of the tunnel drying kiln, heat loss caused by convection interference of external atmospheric air is reduced, and tail gas, waste gas and harmful substance recovery is realized.

Owner:FUJIAN YONGAN FORESTRY GRP CO LTD

An efficient and environmentally friendly tea seed drying equipment for camellia oleifera processing

ActiveCN113324385BImprove drying efficiencyImprove qualityDrying solid materialsFatty-oils/fats productionAgricultural scienceCamellia oleifera

The invention discloses a high-efficiency and environment-friendly tea seed drying equipment for camellia oleifera processing, which relates to the technical field of camellia oleifera seed processing. The overturned drive mechanism and the above-mentioned frame car are sent into the frame to lift the platform, and the multiple drying frames are driven by the uniquely designed drive mechanism, which can achieve static and dynamic drying of tea seed materials. The two modes and switching can be Significantly speed up the drying efficiency of the material. During the drying period, the water and impurities in the tea seed material can be discharged, which significantly improves the quality of the dried material. The machine is used to arrange the space of the frame and the materials in it, and the degree of automation is improved. High, time-saving and labor-saving, convenient operation, greatly reduced labor costs, and the dried tea seed materials are heated evenly, and the drying degree can be kept consistent, which solves the common problems of uneven, incomplete and poor consistency of tea seed materials.

Owner:安徽东旭大别山农业科技有限公司

A washing and drying machine

ActiveCN103911824BImprove heat transfer efficiencyReduce depthWashing machine with receptaclesTextiles and paperCylinder moldPulp and paper industry

The invention discloses a clothes washing and drying machine. The clothes washing and drying machine comprises an inner cylinder, an outer cylinder, and a drying assembly communicated with the inner cylinder and the outer cylinder; the drying assembly comprises a condenser and a dryer; the dryer comprises a circulating fan and a heater both arranged in the dryer, the condenser comprises an air inlet and an air outlet, and a condensation cavity formed by the inner walls of the condenser, the outer cylinder comprises a front cylinder and a rear cylinder, the two of which are fixedly connected with each other, and the rear cylinder and the condenser are formed into an integrated structure by using a rear cylinder mold and a condenser module and an integrated processing manner. The clothes washing and drying machine is characterized in that apart from heat exchange happening inside the condenser, the temperature of one side, close to a drying material receiving assembly, of the condenser is higher than the temperature in the drying material receiving assembly, so that heat exchange also happens on the surface of the condenser and water drops are formed on the surface, and therefore, high heat exchange efficiency of the condenser is guaranteed. Meanwhile, when the clothes washing and drying machine is arranged in a case of the same size, the drying capacity of the clothes washing and drying machine with such a structure can be improved to a certain extent.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

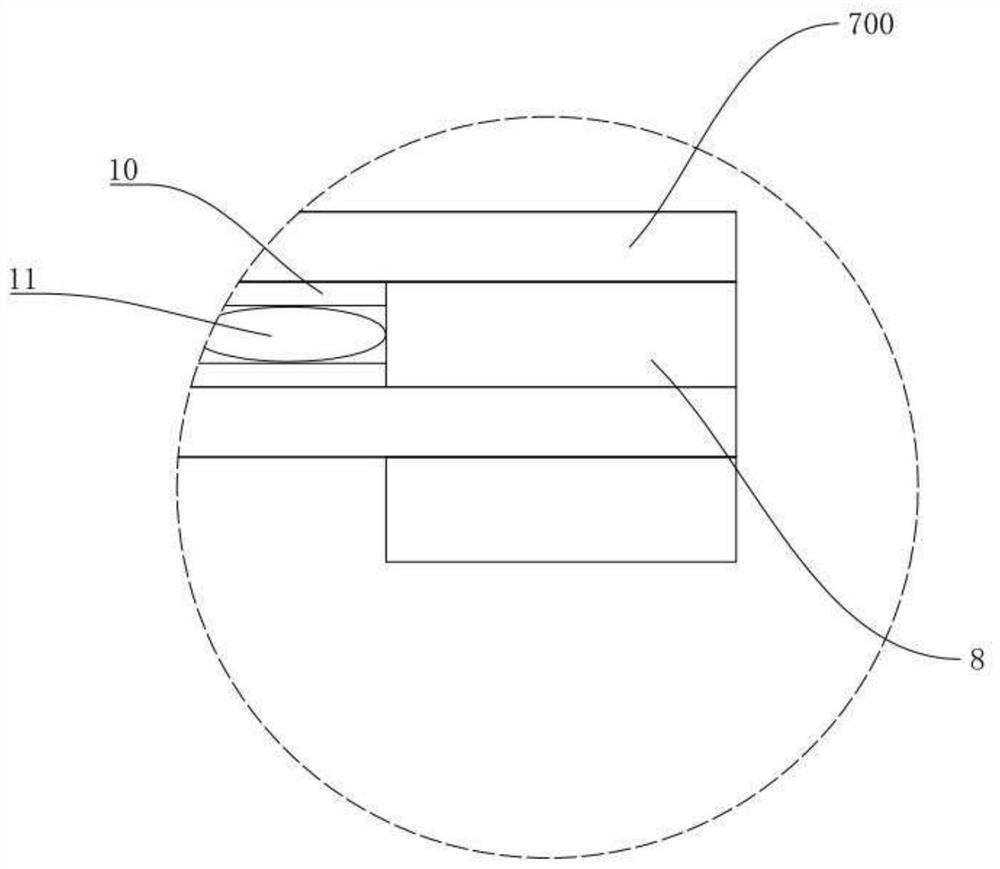

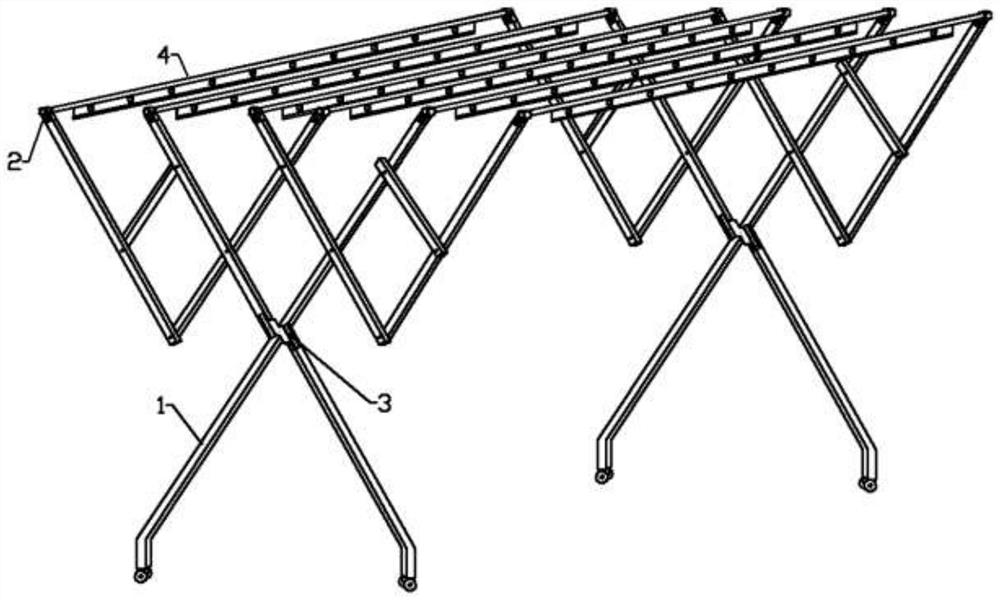

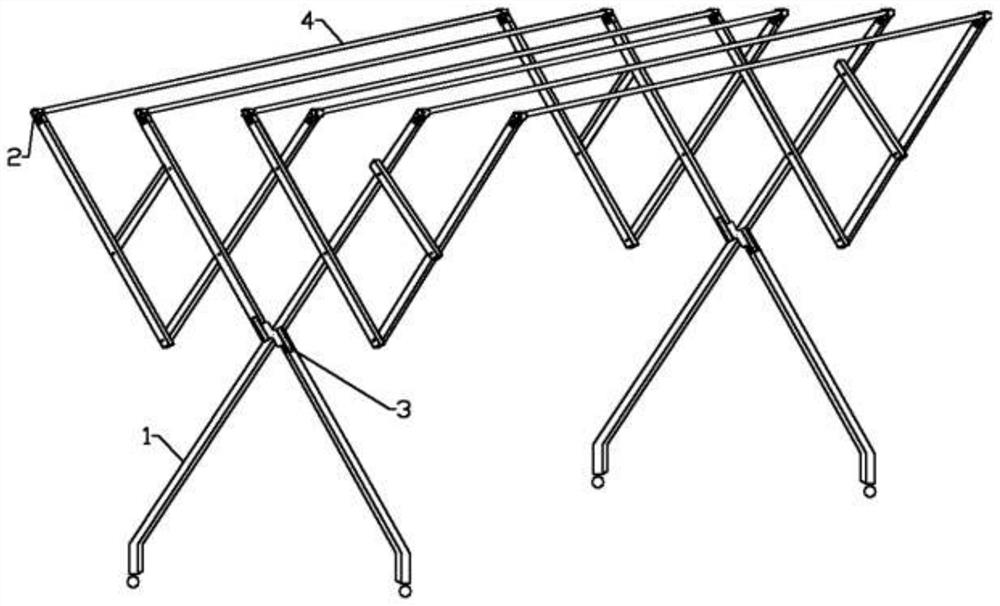

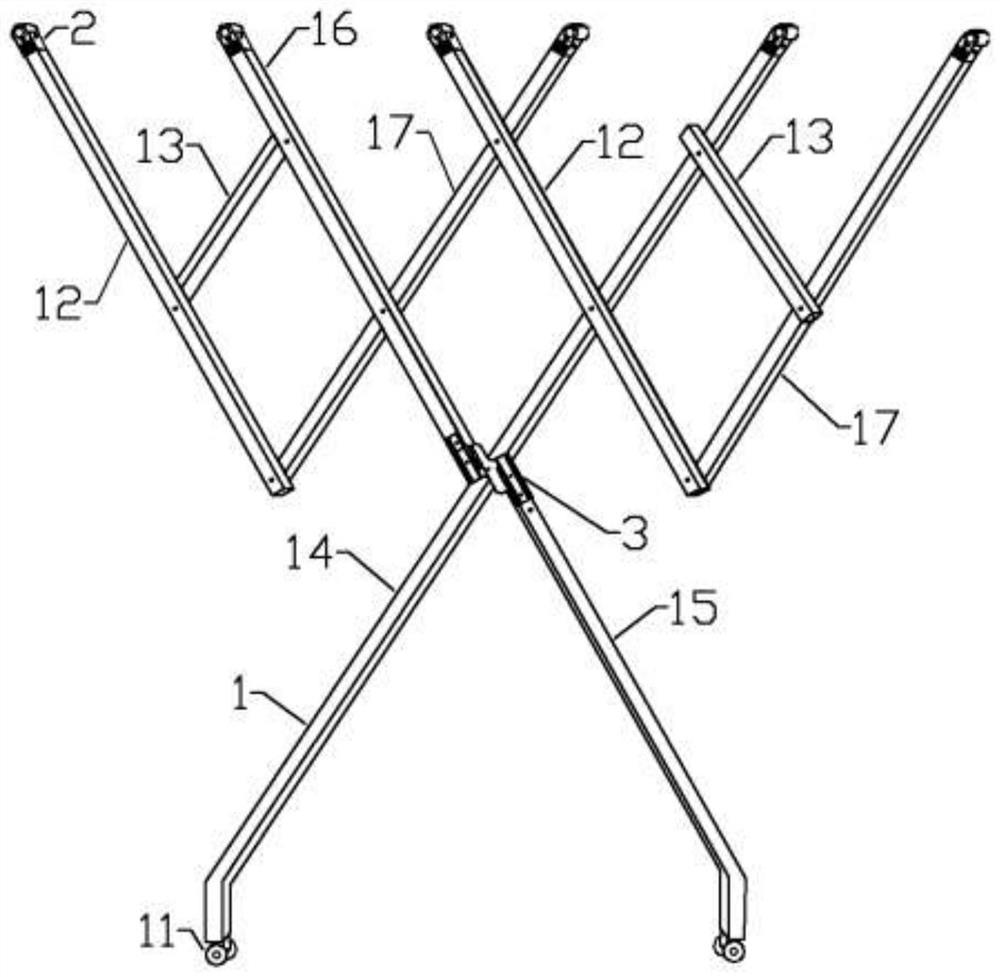

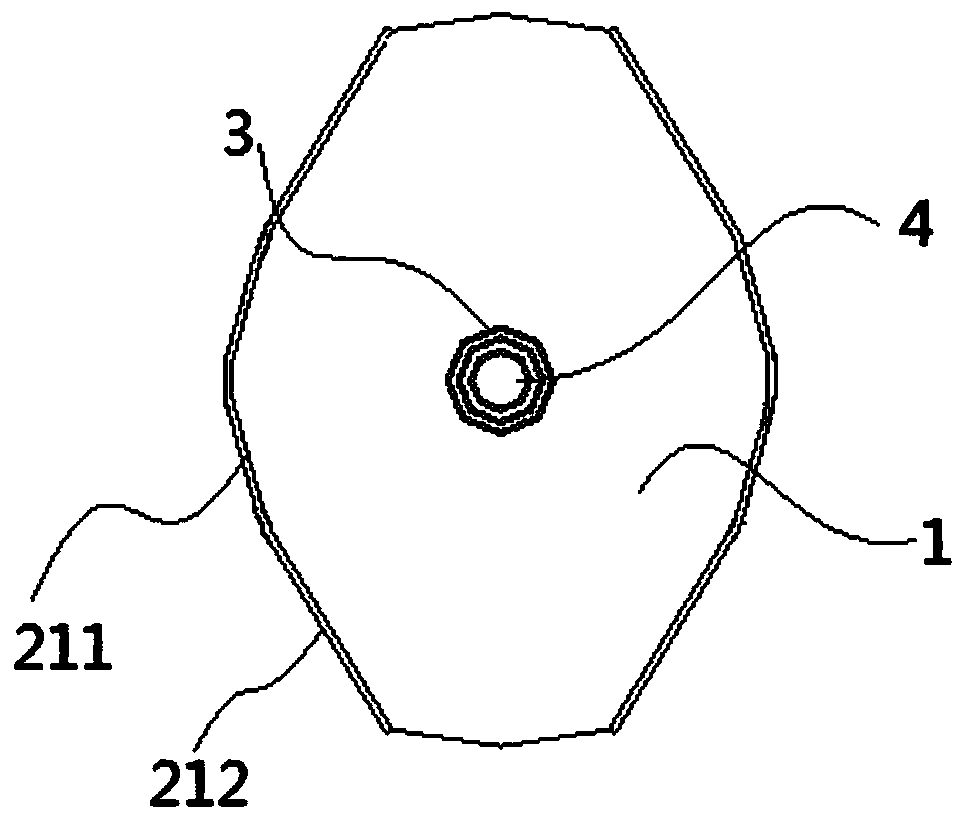

Installation-free W-shaped floor type clothes hanger

PendingCN113152042AAchieve horizontal foldAchieving Vertical FoldingOther drying apparatusTextiles and paperClothes hangerIndustrial engineering

The invention discloses an installation-free W-shaped floor type clothes hanger. The installation-free W-shaped floor type clothes hanger comprises supporting frames, installation connectors, folding clamping blocks and cross rods; the number of the supporting frames is two; the installation connectors are installed at the tops of the supporting frames; the two ends of the cross rods are fixed between the two supporting frames through the installation connectors, and the installation connectors are foldable connectors; and the folding clamping blocks are arranged on the supporting frames, and multiple supporting rods are fixed through the folding clamping blocks so that the supporting frames can be folded. The folding clamping blocks are installed on the supporting frames, the whole supporting frame body can be folded, and transverse folding of the clothes hanger can be achieved when the clothes hanger is not used; and in addition, longitudinal folding of the clothes hanger can be achieved through the foldable installation connectors, the supporting frames and the cross rods are folded together, the storage space is greatly saved, and the problem that a clothes hanger used by small-sized families or rental people occupies too large space is effectively solved.

Owner:广东蔓莎蒂科技有限公司

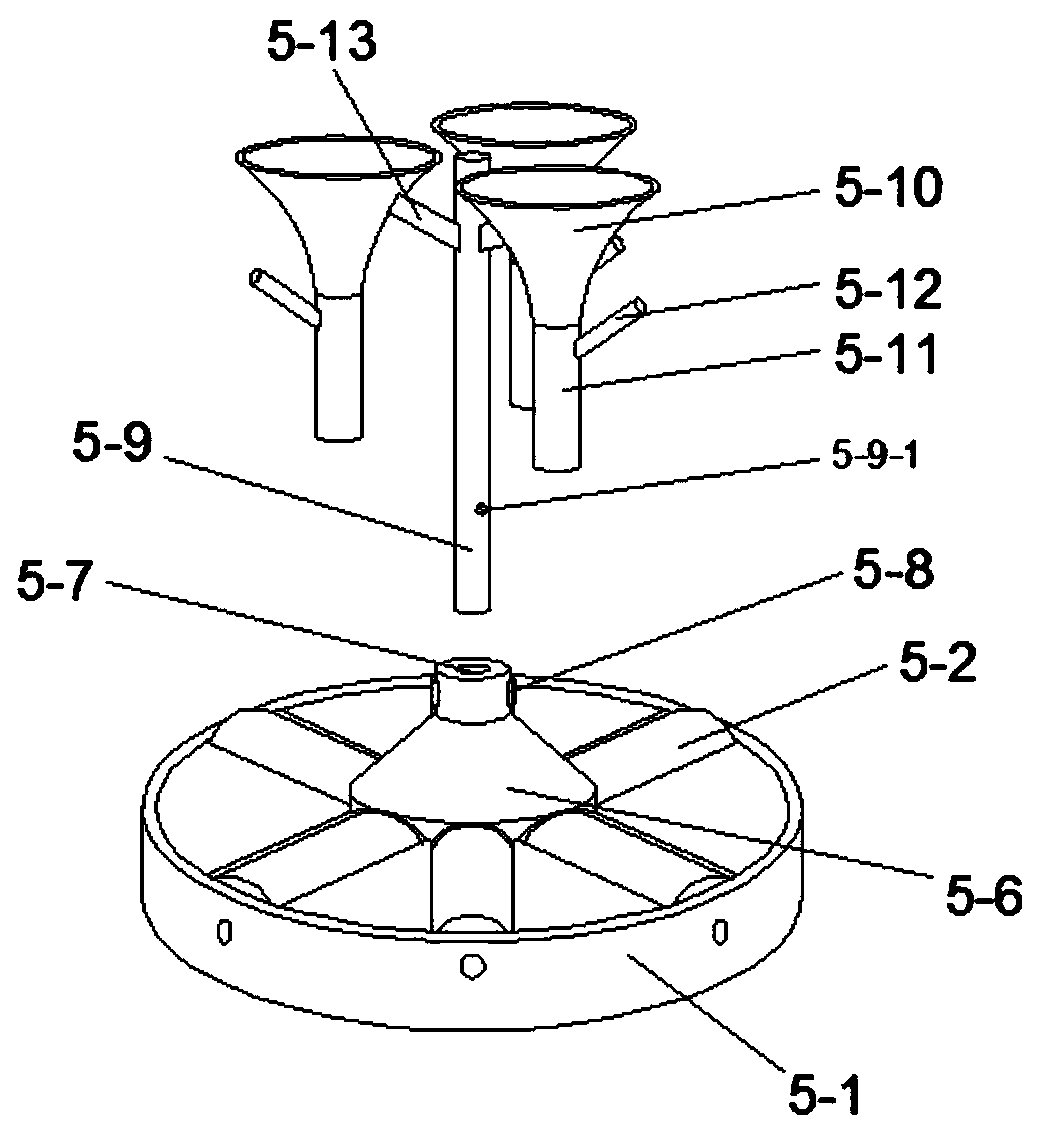

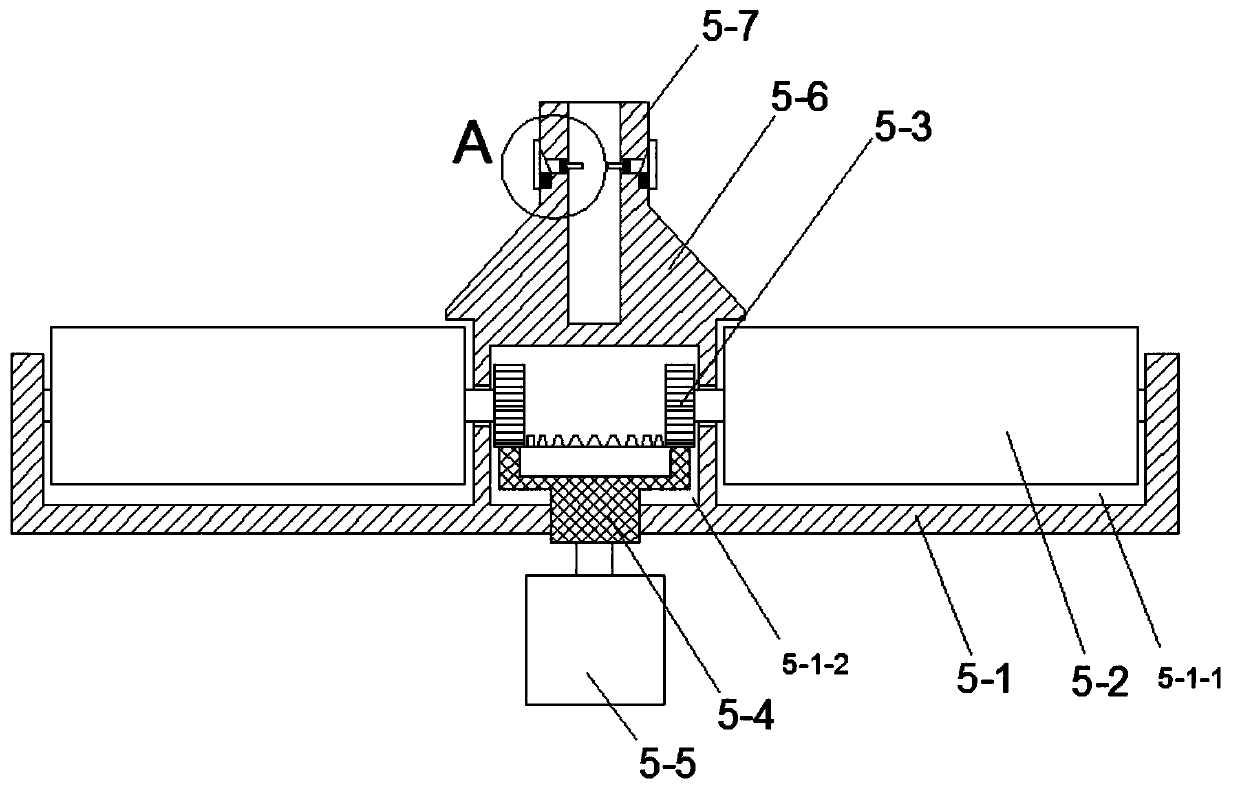

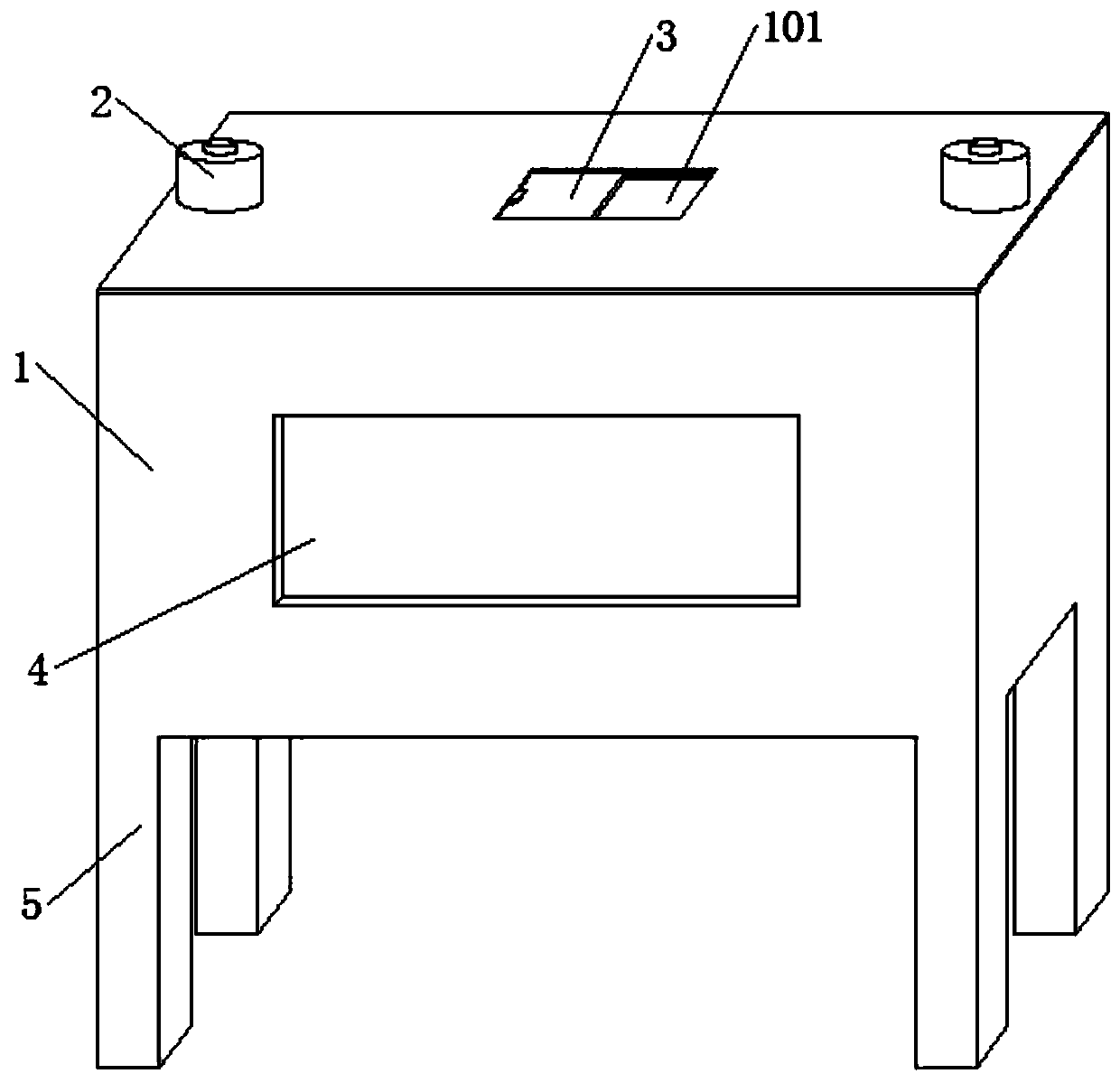

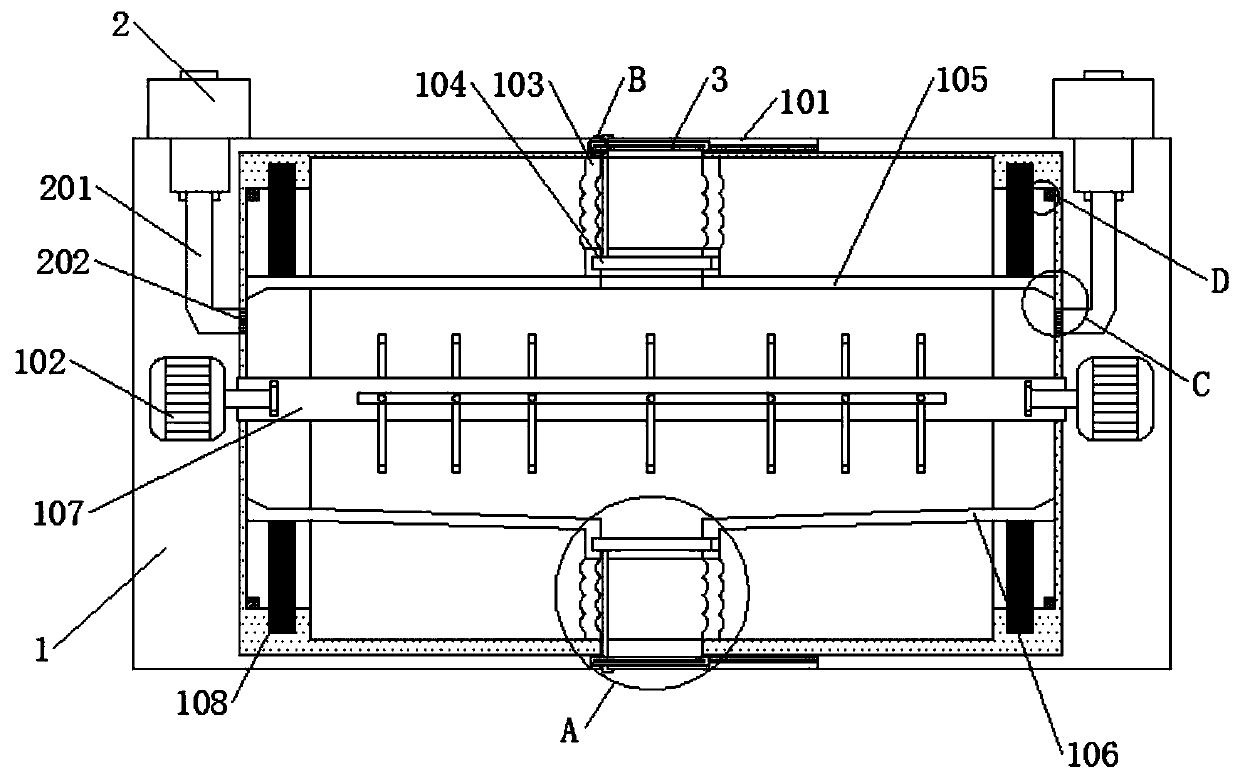

Grain throwing device and grain drying machine

ActiveCN110906706AThe spreading process is smoothSolve the problem of uneven accumulationDrying solid materials without heatDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention provides a grain throwing device. The grain throwing device comprises a bottom plate and a guide component arranged on the bottom plate and used for guiding grains, wherein the guide component comprises a guide plate; the guide plate comprises an arc-shaped section and a straight section; an extension direction of the straight section is a tangential direction of the tail end of thearc-shaped section. The device is capable of uniformly throwing the grains and uniformly scattering the grains into a drying chamber, so that the problem that the grains are unevenly piled in the drying chamber can be effectively solved; the effective utilization rate of the space of the drying chamber and the grain drying efficiency are improved; the grains can be uniformly heated and are uniformin water content in the drying process; in addition, the invention also provides a grain drying machine comprising the grain throwing device; the grain drying machine is capable of uniformly drying the grains; the space utilization rate of the drying chamber is high; the drying quantity in unit time is high; the grains can be uniformly heated in the drying process; the water content of the grainstreated by the drying machine is uniform.

Owner:HUNAN NONGYOU MACHINERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com