Electromagnetic heating tunnel type steel belt fluid bed dryer

A dryer and tunnel-type technology, which is applied in the field of electromagnetic heating tunnel-type steel belt fluidized dryer, can solve the problems of large heat loss, low drying efficiency, and resistance wire burnout, so as to reduce dust emission , High drying efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

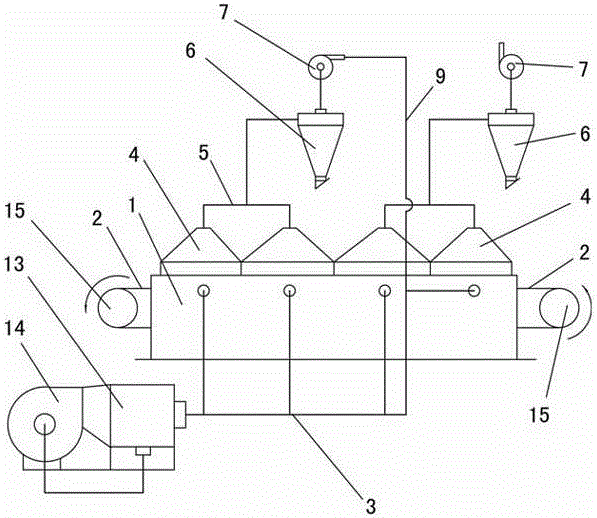

[0014] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

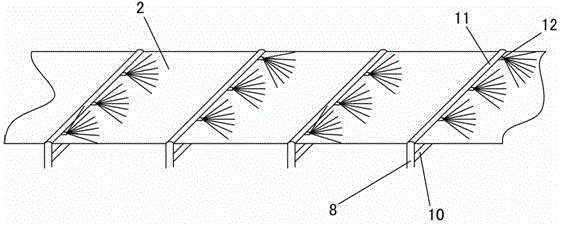

[0015] Such as figure 1 with 2 As shown, the electromagnetic heating tunnel type steel strip fluidized dryer proposed by the present invention includes an electromagnetic high-frequency heating part and a drying part; The steel belt 2 used to transport materials, the air supply pipe group 3 arranged in parallel on the side of the tunnel dryer main body 1 and supplying air to the tunnel dryer main body 1, and the multiple air supply pipes arranged on the upper part of the tunnel dryer main body 1 Gathering hood 4, a plurality of gas collecting pipes 5 connected to each gas collecting hood, the cyclone separator 6 connected to the gas collecting hood 4 through the gas collecting pipe 5 and the exhaust blower 7 arranged on the top of the cyclone separator 6, said One side of the steel belt 2 is provided with a row of vertical air intake pipes 8, and each air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com