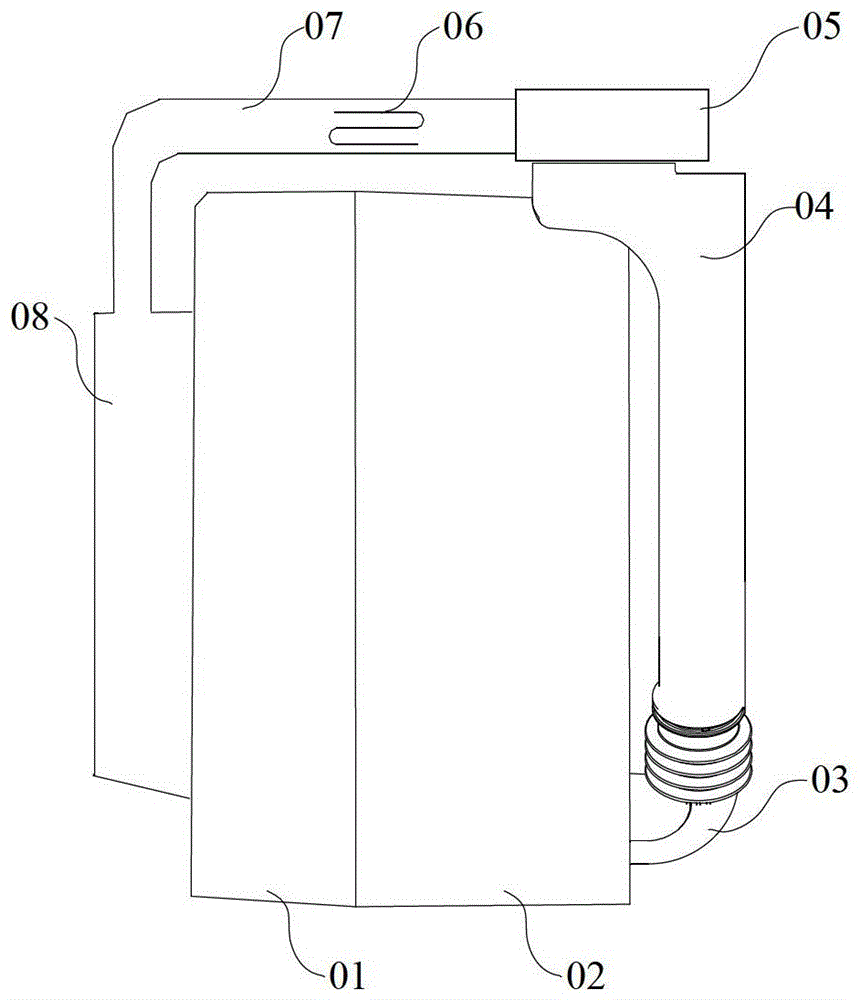

A washing and drying machine

A washing and drying machine and integrated technology, applied in the field of drying, can solve the problems of reducing the drying capacity of the cavity to be dried, reducing the drying efficiency of the condensation drying device, and occupying space for the condenser, so as to save raw materials, dry Increased dry capacity and good assemblability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

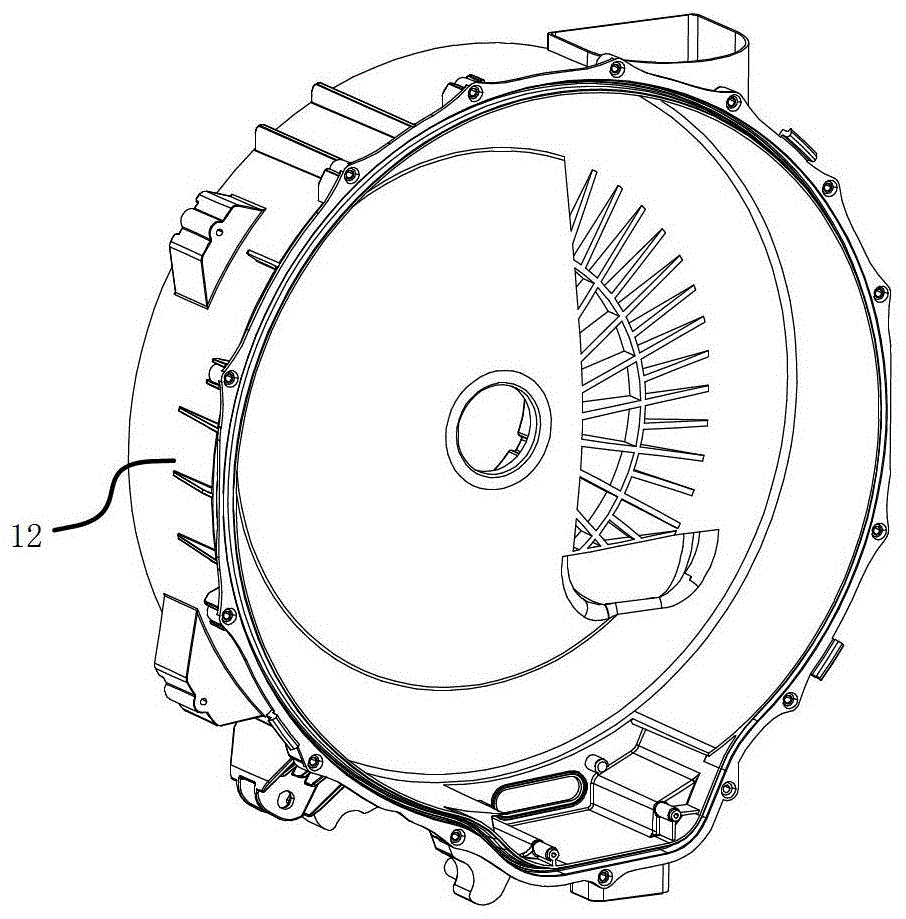

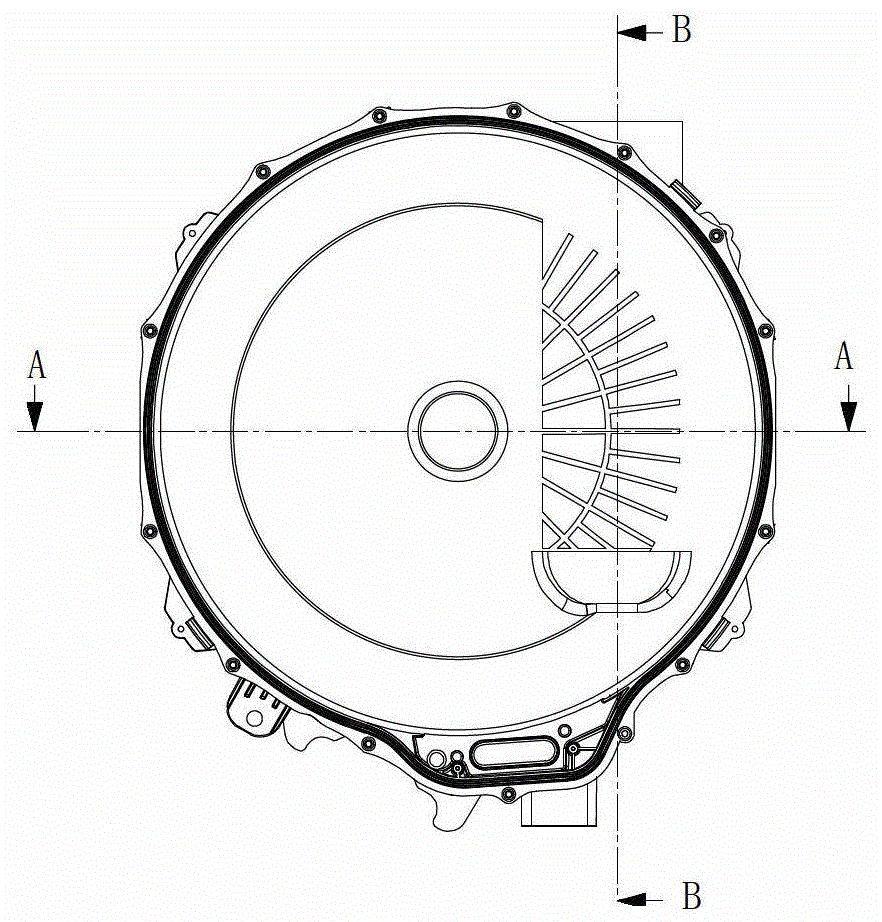

[0036] ginseng Figure 2 to Figure 8 As shown, the rear barrel 12 is the same part as the condenser 16 . The condenser 16 is a hollow cavity with an air inlet 16a and an air outlet 16b. The condenser 16 occupies the space of the rear rib of the rear barrel 12 .

[0037] During the forming process of the rear cylinder 12, the corresponding mold forms the condenser space. The rear barrel mold includes a first mold unit 18a, a second mold unit 18b and a condenser mold 18c. The first mold unit 18 a forms the space for accommodating the inner cylinder of the rear cylinder 12 , and the second mold unit 18 b forms the cylinder wall of the rear cylinder 12 . The first mould unit 18a further includes a condenser air inlet mould structure 18d for forming the air inlet of the condenser. The condenser mould 18c forms the condensation cavity of the condenser 16, the first mould unit 18a and the condenser mould 18c form the condenser wall of the condenser 16 close to the inner cylinder ...

Embodiment 2

[0040] A part of the cylinder wall of the rear cylinder and the condenser cover together form a condensation cavity, and the condensation cavity has an air inlet and an air outlet. The condenser occupies the space of the stiffener at the rear of the rear barrel. The condenser cover is a piece of space. The condenser cover is fastened to the rear cylinder. The rear barrel mold includes a first mold unit, a second mold unit, and a condenser mold. The first mold unit mainly forms the space of the rear barrel for accommodating the inner barrel, and the second mold unit forms the barrel wall of the rear barrel. The first mould unit and the second mould unit together form part of the cylindrical wall of the condenser, which together with the condenser cover forms the condenser. The first mould unit, the second mould unit and the condenser mould together form the air outlet and the condensation cavity of the condenser.

[0041] Compared with the traditional solution, this solutio...

Embodiment 3

[0043] The condenser is a pre-formed hollow tubular structure. The condenser is injection-molded into one body through an integral molding process with the rear barrel, and the condenser occupies the space of the reinforcing rib at the rear of the rear barrel. The condenser includes an air inlet and an air outlet. The rear barrel mold includes a first mold unit, a second mold unit and a condenser mold. A pre-formed condenser can be fitted to the outside of the condenser mould.

[0044] Before the injection of the rear barrel, the pre-molded condenser is first placed in the condenser mold, and then the injection is started. The first mold unit is filled in the accommodating space of the rear barrel, the second mold unit is surrounded by the outside of the first mold unit, and a certain injection molding space is reserved between the first mold unit and the second mold unit to form the barrel wall of the rear barrel by injection molding, The condenser mold is filled into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com