Suspended-state outer-circulation drying system

A drying system and external circulation technology, which is applied in dehydration/drying/thickened sludge treatment, water treatment parameter control, water/sludge/sewage treatment, etc., can solve problems such as large structure, large heat loss, and low thermal efficiency , to achieve the effect of avoiding multiple cycles, adjusting the particle size of the finished product, and improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

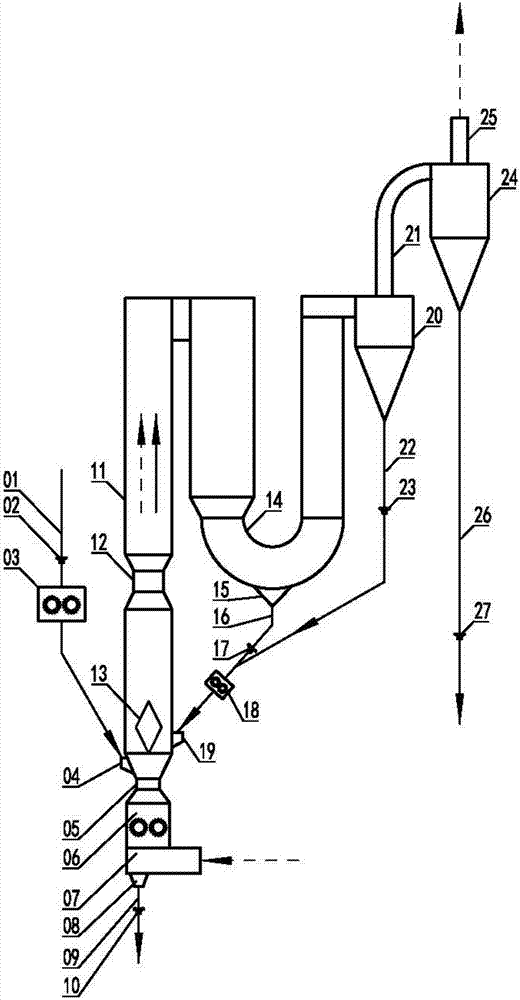

[0030] Such as figure 1 , The suspension external circulation drying system of the present invention mainly includes a dryer 11 , a circulation separator 20 and a cyclone separator 24 .

[0031] A first-level dispersing device 03 is arranged on the feeding pipe 01 at the feed end of the dryer 11 , and an air lock valve 02 is arranged in front of the first-level dispersing device 03 . The feed inlet is provided with a material disperser 104, and the dryer 11 is multi-sectioned up and down, and a jetting shrinkage 12 is arranged between adjacent sections. The bottom of the last section is provided with a bottom spout shrinkage 05, and a material disperser 104 is connected to the side of the bottom spout shrinkage 05. The bottom of the dryer 11 is equipped with a material second-level dispersing device 06, the lower part of the second-level dispersing device 06 is connected to the air duct 07, and the bottom is the ash collection bin 08, and the bottom of the ash collection bin ...

Embodiment 2

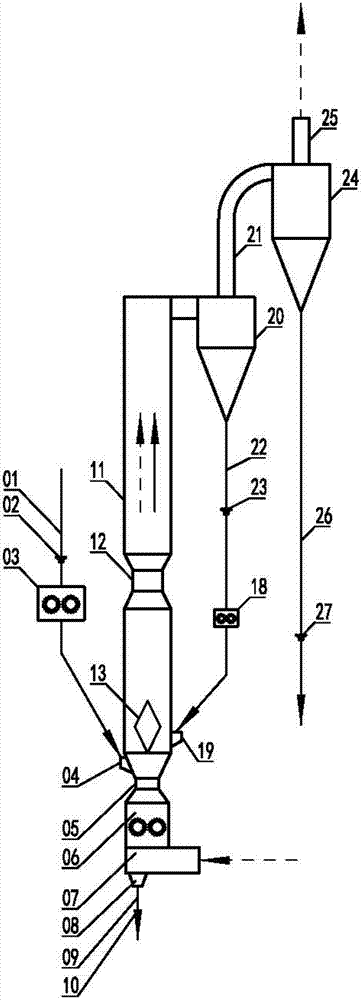

[0037] Such as figure 2 , the gooseneck elbow 14 and the return system of the gooseneck elbow 14 are canceled at the outlet of the dryer 11, and the gooseneck elbow 14 may not be installed in some low-moisture sludge treatment processes to reduce system resistance and reduce system pressure. Energy consumption, the structure of all the other parts is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com