Horizontal rotary dryer

A rotary and dryer technology, applied in dryers, drying, lighting and heating equipment, etc., can solve the problems of poor thermal efficiency compared with indirect heating, large exhaust treatment equipment, etc., to increase contact time and contact area The effect of large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

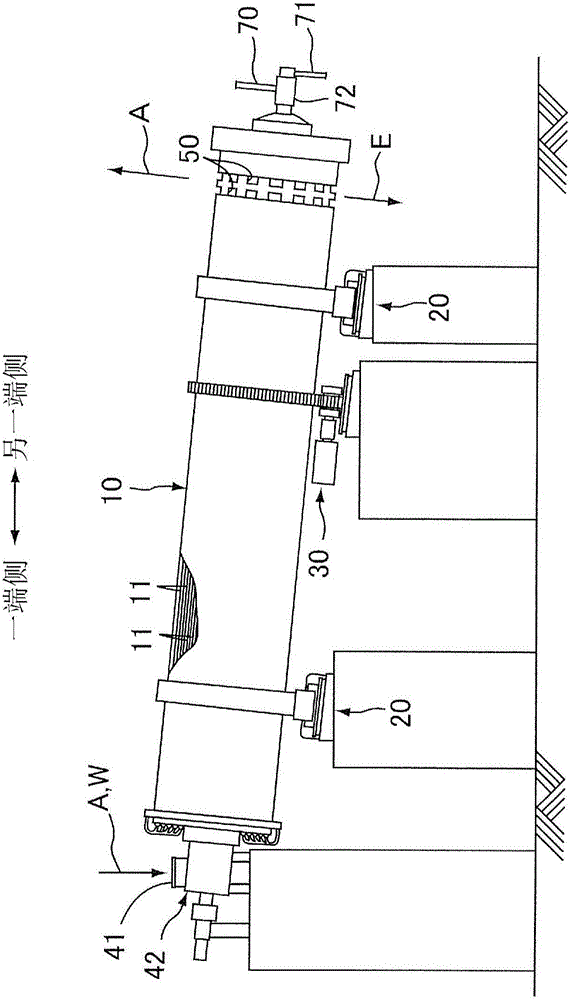

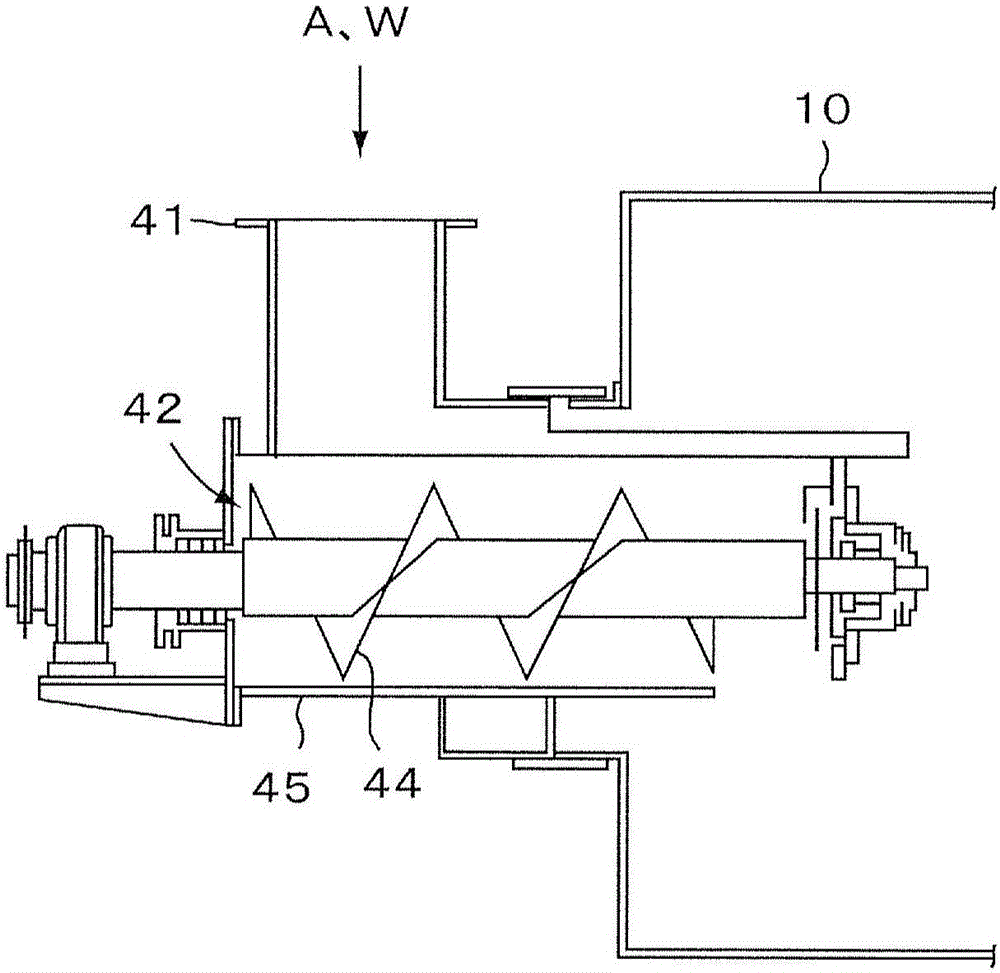

[0054] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. In addition, the following description and drawings are merely descriptions and drawings showing an example of an embodiment of the present invention, and should not be interpreted to limit the content of the present invention to this embodiment.

[0055] (processed object W)

[0056] First, there is no limitation on the object W to be dried, but specific examples thereof include ores such as coal, copper ore, iron powder, and zinc powder, metal-based substances, and terephthalic acid. , Resin-based substances such as polyethylene, polyoxymethylene, and polyvinyl chloride, processed food-based substances such as methionine, gluten flour, processed soybean powder, corn fiber, and corn germ, inorganic-based substances such as gypsum, aluminum oxide, and soda ash, and dehydrated sludge Wait.

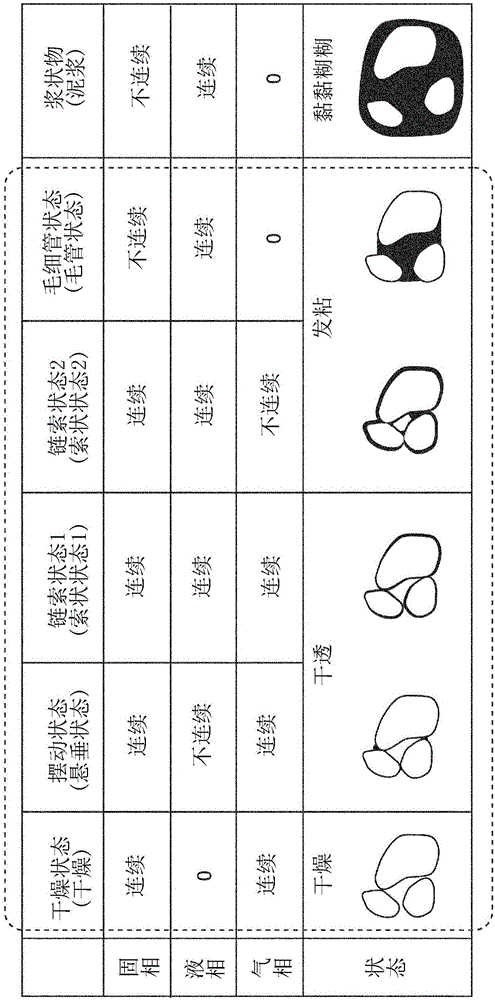

[0057] Regarding the object W to be processed, it is preferable that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com