Drum Type Gas Jet Impact Dryer

A gas jet and drum type technology, applied in the direction of non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of operation, small heat capacity coefficient, unfavorable feeding and discharging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

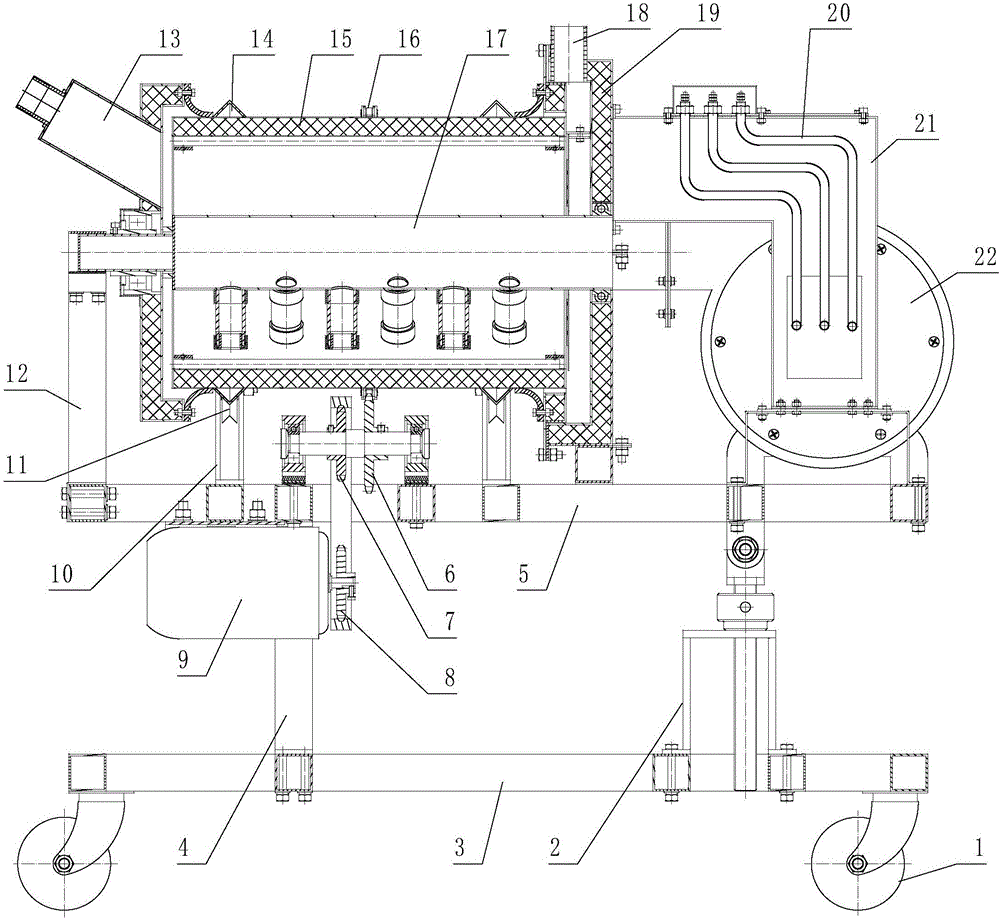

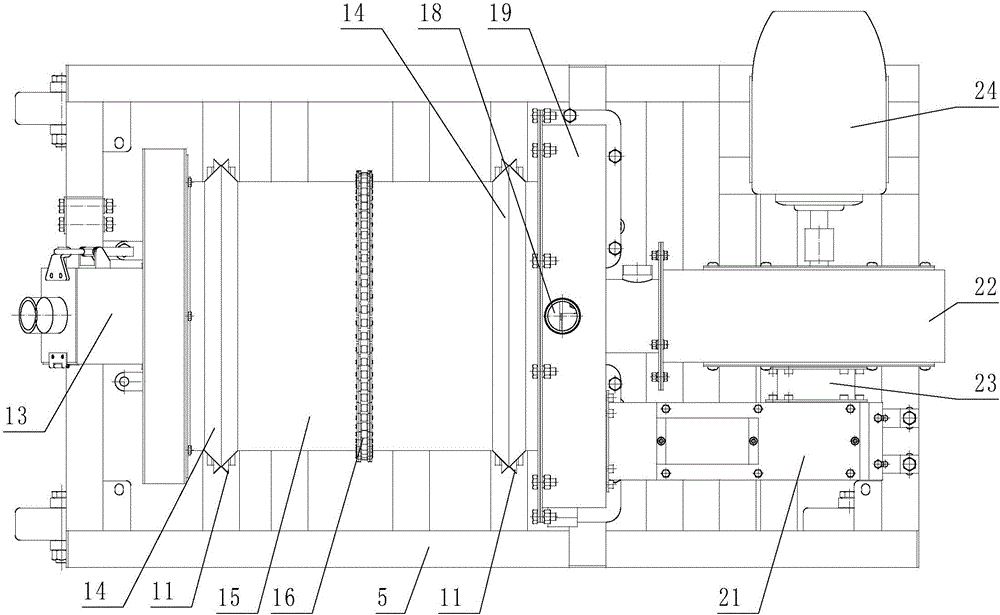

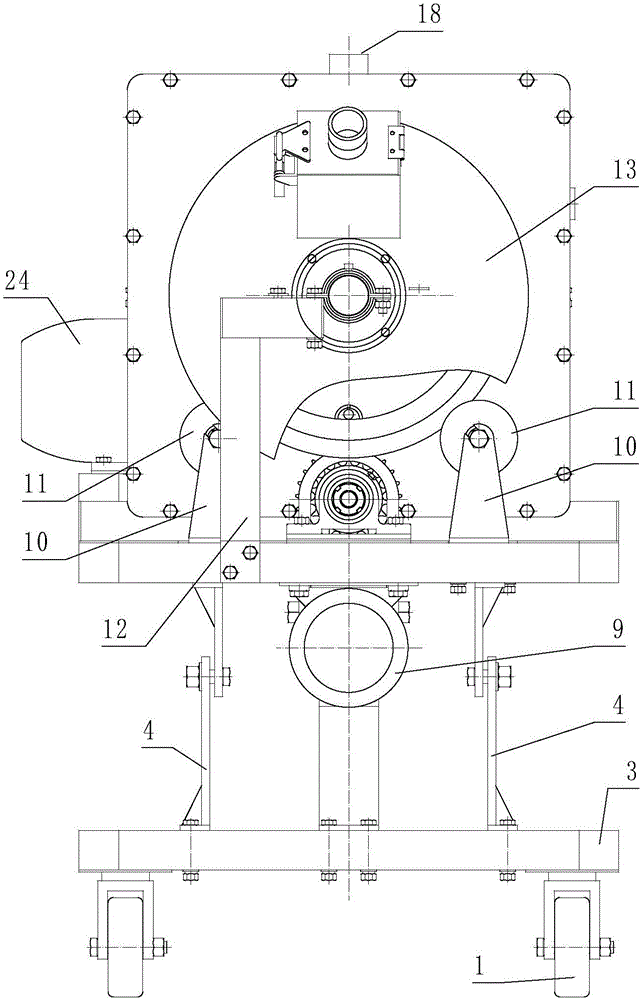

[0070] Referring to the accompanying drawings: a drum type gas jet impact dryer mainly includes a main frame 3 and a walking wheel 1, a vehicle frame 5 is provided above the general frame 3, and a centrifugal fan 22 is provided above the vehicle frame 5 , heater 21, material drum 15, transmission group;

[0071] The structure of the heater 21 mainly includes a heater housing 21-1, the heater housing 21-1 is provided with an air inlet 21-3 and an air outlet 21-2, and the heater housing 21-1 There is an electric heating tube 20 inside;

[0072]The structure of the material drum 15 mainly includes a cylinder body 15-1, one side of the cylinder body 15-1 is provided with a return air end box 19, and the other side is provided with a feeding and discharging mechanism 13, and the cylinder body 15-1 There is an airflow impact mechanism 17 inside;

[0073] The cylinder 15-1 is a hollow shell with a central rotating shaft 15-3, one end of the cylinder 15-1 is provided with a sieve pl...

Embodiment 2

[0081] Compared with Embodiment 1, the difference of this embodiment is that the overall frame 3 and the vehicle frame 5 are connected with the lifting mechanism 2 through the overall frame bracket 4, and the overall frame bracket 4 is close to the material drum 15 Its structure includes the upper part 4-2 of the bracket group and the lower part 4-1 of the bracket group, and the upper part 4-2 of the bracket group and the lower part 4-1 of the bracket group are hinged to each other; the structure of the lifting mechanism 2 includes lifting Seat 2-4, lifting screw rod 2-1, lifting nut 2-3, described lifting seat 2-4 is fixedly connected with main frame 3, and lifting nut 2-3 is arranged on the top of described lifting seat 2-4, and lifting nut 2-3 is provided with a lifting torsion bar 2-5, the lifting screw 2-1 passes through the lifting nut 2-3 and the lifting seat 2-4, and the lifting screw 2-1 and the lifting nut 2-3 are threaded Connected, the upper part 2-2 of the lifting...

Embodiment 3

[0083] Compared with Embodiment 2, the difference of this embodiment is that the structure of the transmission group includes a driving gear 8, a driven pinion 7, a driven large gear 6, the driving gear 8 is connected with the motor II 9, and the driving gear 8 is driven by a chain with the driven pinion 7, the driven pinion 7 and the driven large gear 6 are coaxially connected, and the driven large gear 6 is meshed with the chain 16 on the material drum 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com