Double-bed sludge drying incineration system and incineration method

A sludge drying and sludge technology, applied in combustion methods, dehydration/drying/thickened sludge treatment, incinerators, etc., can solve the problems of limited drying production capacity, low heat transfer coefficient of rotary kiln and moving bed, etc. Achieve the effect of high drying strength, improved drying production capacity, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

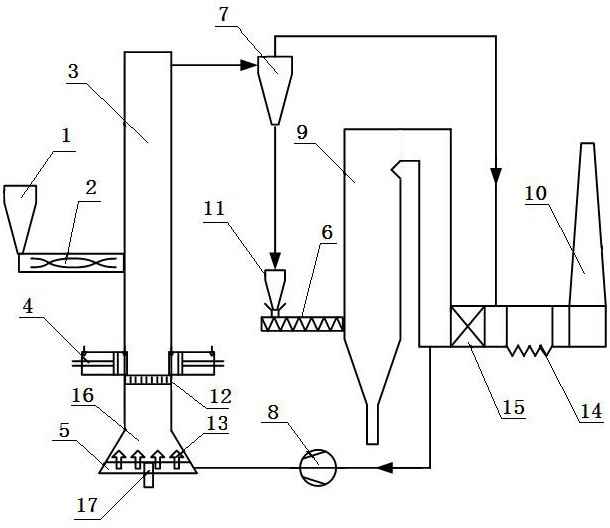

[0018] A double-bed sludge drying and incineration system, which consists of: a wet sludge bin 1, the bottom of the wet sludge bin is connected to a plunger pump 2, and the plunger pump is connected to an air flow bed 3, the The top of the entrained entrained bed is connected with the separator 7, the lower part of the plunger pump in the entrained entrained bed is equipped with a grate 12, the two sides above the grate are respectively equipped with a crusher 4, and the bottom of the entrained entrained bed is equipped with a fluidized bed 16. There is an air chamber 5 below the fluidized bed, an air cap 13 is installed on the upper part of the air chamber, and a slag discharge port 17 is installed at the bottom of the air chamber. The air chamber is connected to the boiler 9 through the induced draft fan 8, The top of the separator is connected to the front end of the dust collector 14, the bottom of the separator is connected to the dry sludge bin 11, the dry sludge bin is c...

Embodiment 2

[0020] According to the double-bed sludge drying and incineration system described in Embodiment 1, the air preheater 15 and the dust collector are installed in sequence at the tail of the boiler, and the dust collector is connected to the chimney 10, and the dust collector is connected to the chimney 10. The induced draft fan is arranged between the front end of the air preheater and the air chamber.

Embodiment 3

[0022] According to the double-bed sludge drying and incineration system described in Example 1, the grate is installed in the lower part of the air-flow bed as a grid structure with a grid distance of 15mm, and extrusion crushers are arranged on both sides of the upper plane of the grate , the structure of the hood is a bell type, the hood has an inner hole of the core tube and an outer hole of the outer cover, and the fluidization wind speed at the bottom of the entrained flow bed is 2~4m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com