Equipment for drying synthetic leather production line

A technology for drying equipment and production lines, applied in drying, drying machines, lighting and heating equipment, etc., can solve problems such as hidden safety hazards, low degree of automation, easy to cause fire, etc., and achieve improved line speed and strong drying capacity. , the effect of reducing the probability of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

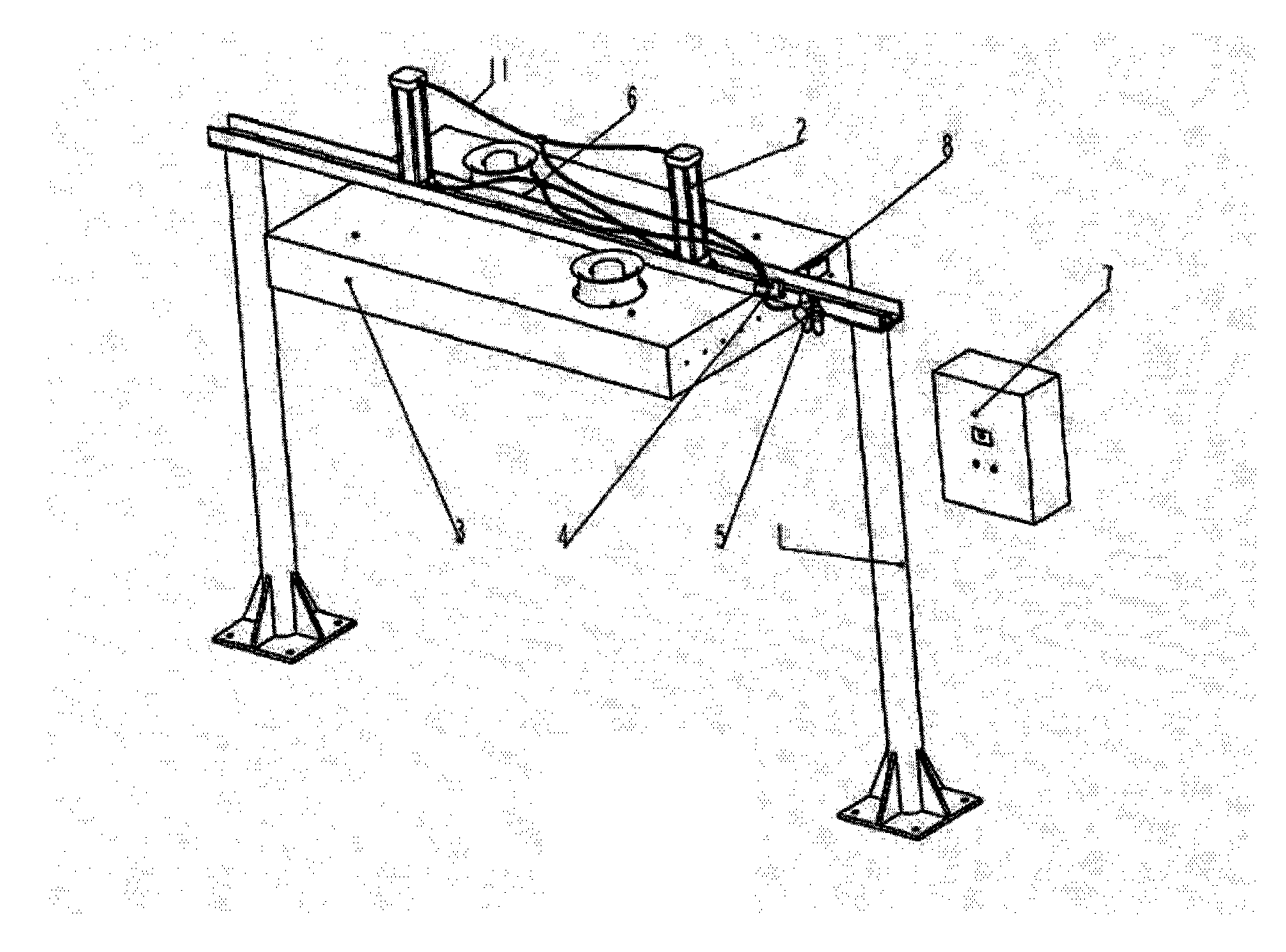

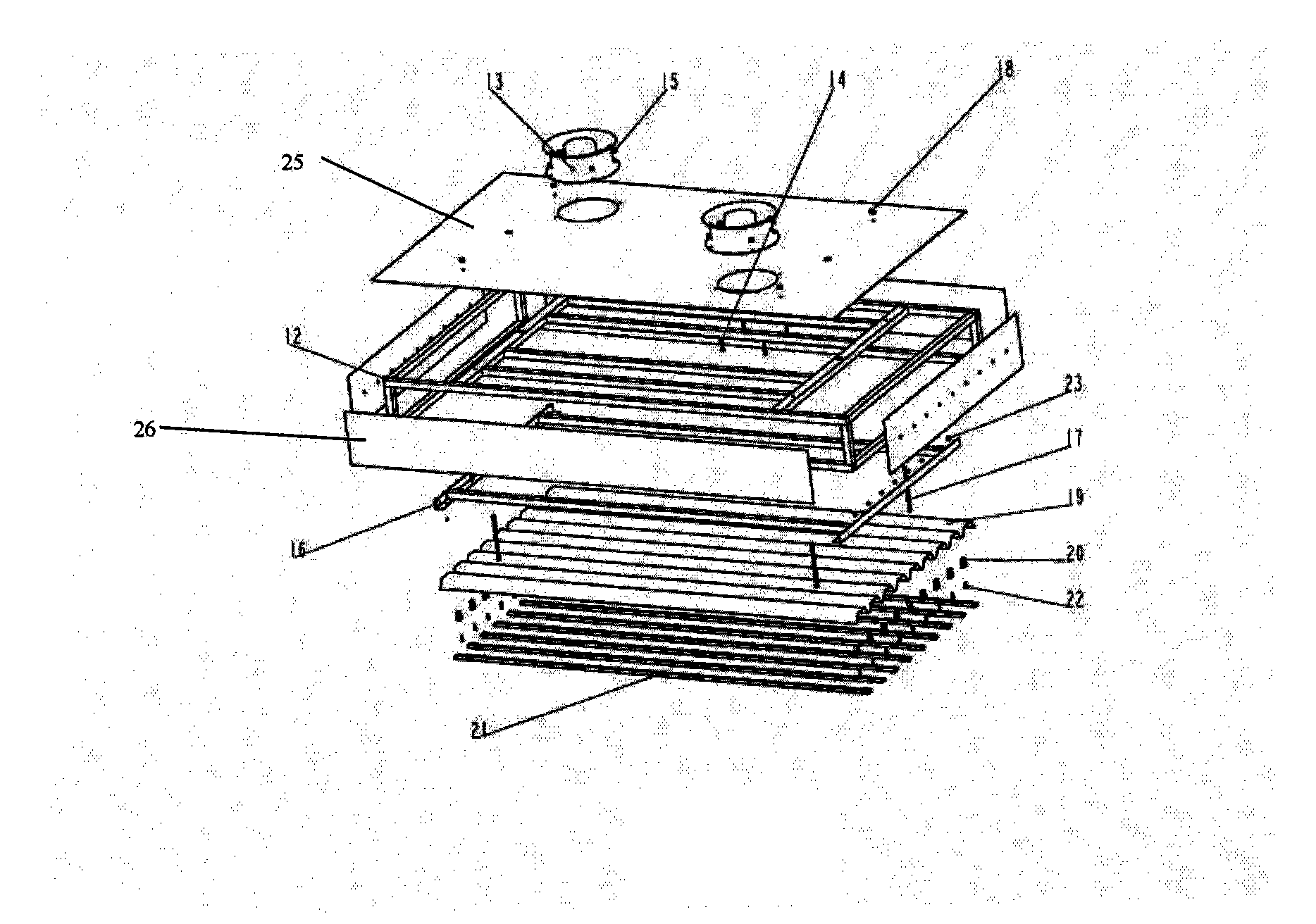

[0021] Below, describe the present invention in detail in conjunction with accompanying drawing and embodiment, wherein:

[0022] In the present invention, a mid-wave infrared radiation device is particularly used as a heat source. Infrared heating is a type of radiant heating. The infrared light emitted by the infrared radiator (light source) is absorbed by the material in the form of molecular (atom) resonance, so as to achieve the purpose of heating the object. This radiant heating method directly and directionally heats the surface of the object and a certain depth with matching wavelengths and selective penetration capabilities. It is a very efficient method of heating, drying and curing, so infrared heating is particularly suitable for use Synthetic leather production line for water-based resin coatings.

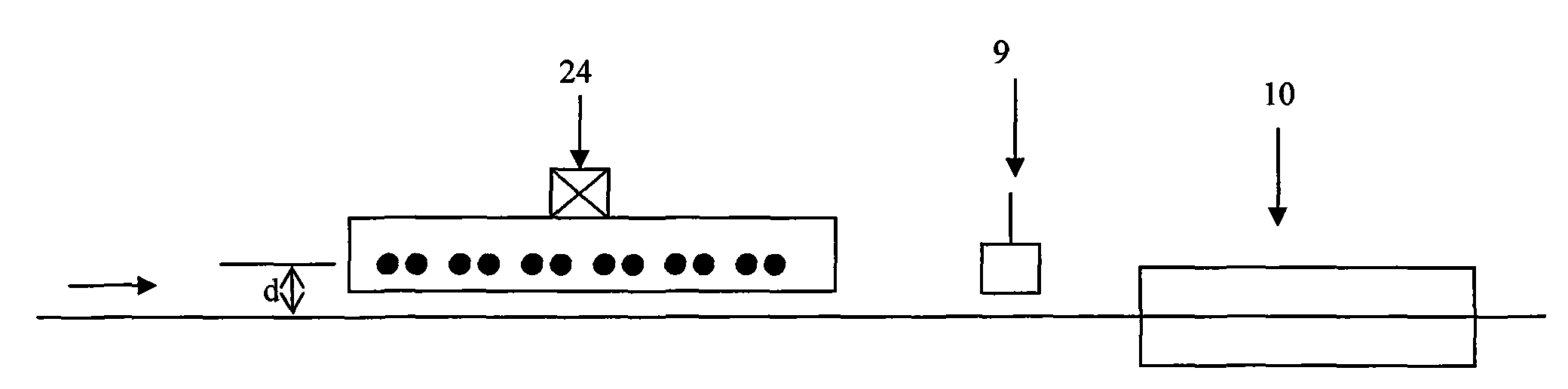

[0023] figure 1 The overall process of coating and drying of the synthetic leather production line according to one embodiment of the present invention is shown. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com