Patents

Literature

70results about How to "Reduce the chance of fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

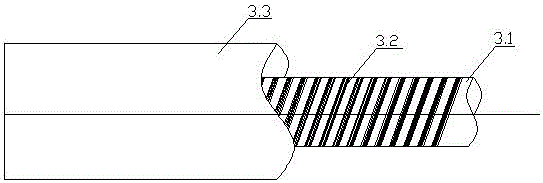

Antistatic type composite flame retardant fiber and preparation method thereof

ActiveCN102108566AImprove antistatic performanceImprove flame retardant performanceElectroconductive/antistatic filament manufactureFilament/thread formingFiberPolyester

The invention provides antistatic flame retardant fiber and preparation method thereof. The cross section of the fiber is a sheath-core structure; a sheath layer contains conductive powder and halogen-free flame-retardant polyamide 6; a core layer is polyester, the polyamide 6 or a polyamide 66, wherein the weight ratio of the sheath layer to the core layer is (15:85) to (25:75), and the conductive powder accounts for 5-7% of the total mass of the sheath layer. Since conductive power is added in the halogen-free flame-retardant polyamide 6, so that the fiber is endowed with the antistatic function and the flame-retardant function, particularly the electrostatic absorption of dust, caused by fiber, can be reduced because of anti-static function, and then the cleanness and favorable cleanable performance of a fiber product can be kept; and meanwhile the fiber with the sheath-core structure can still keep favorable mechanical properties and spinning property. While keeping better antistatic and flame-retardant properties and mechanical properties, the fiber reduces the production cost and improves the processing properties, thereby being more user-friendly for downstream users.

Owner:CHINESE TEXTILE ACAD

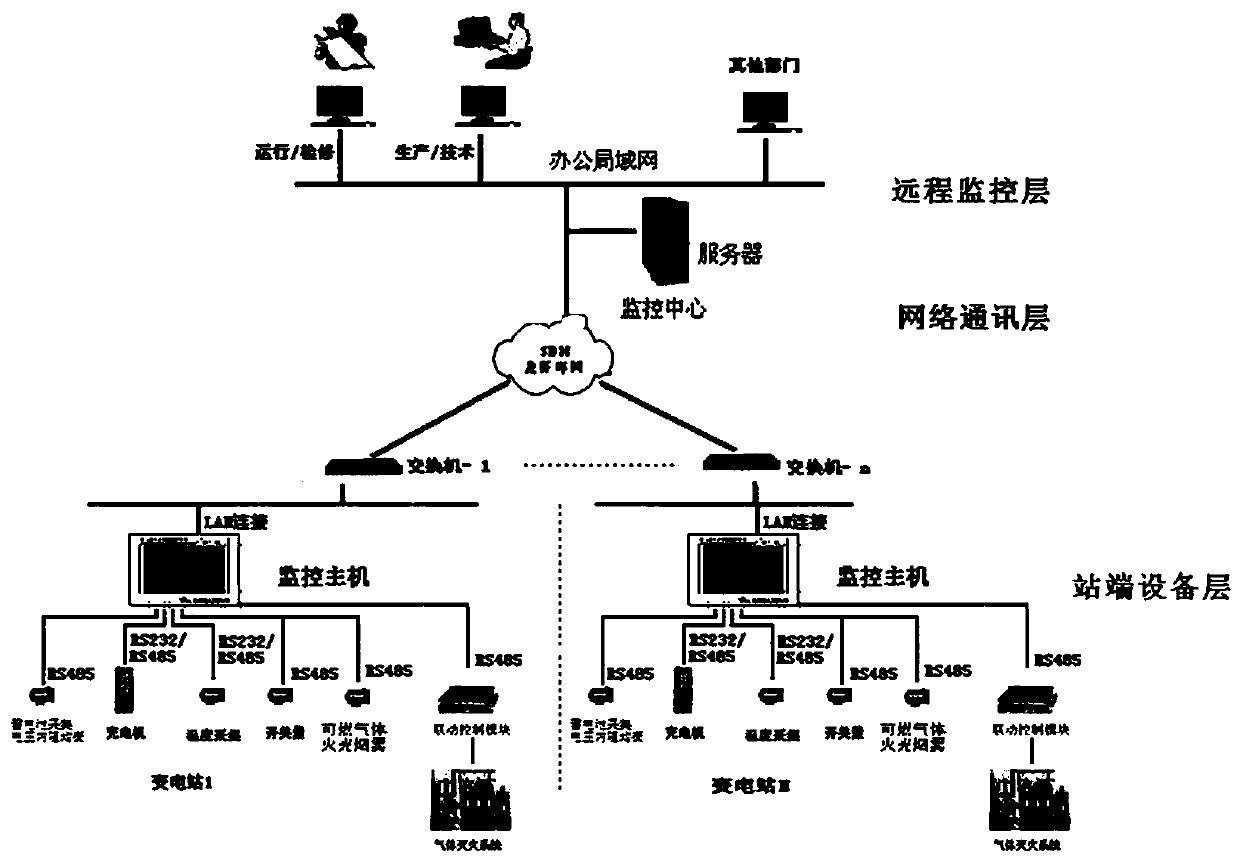

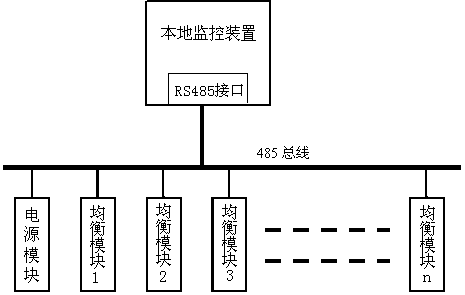

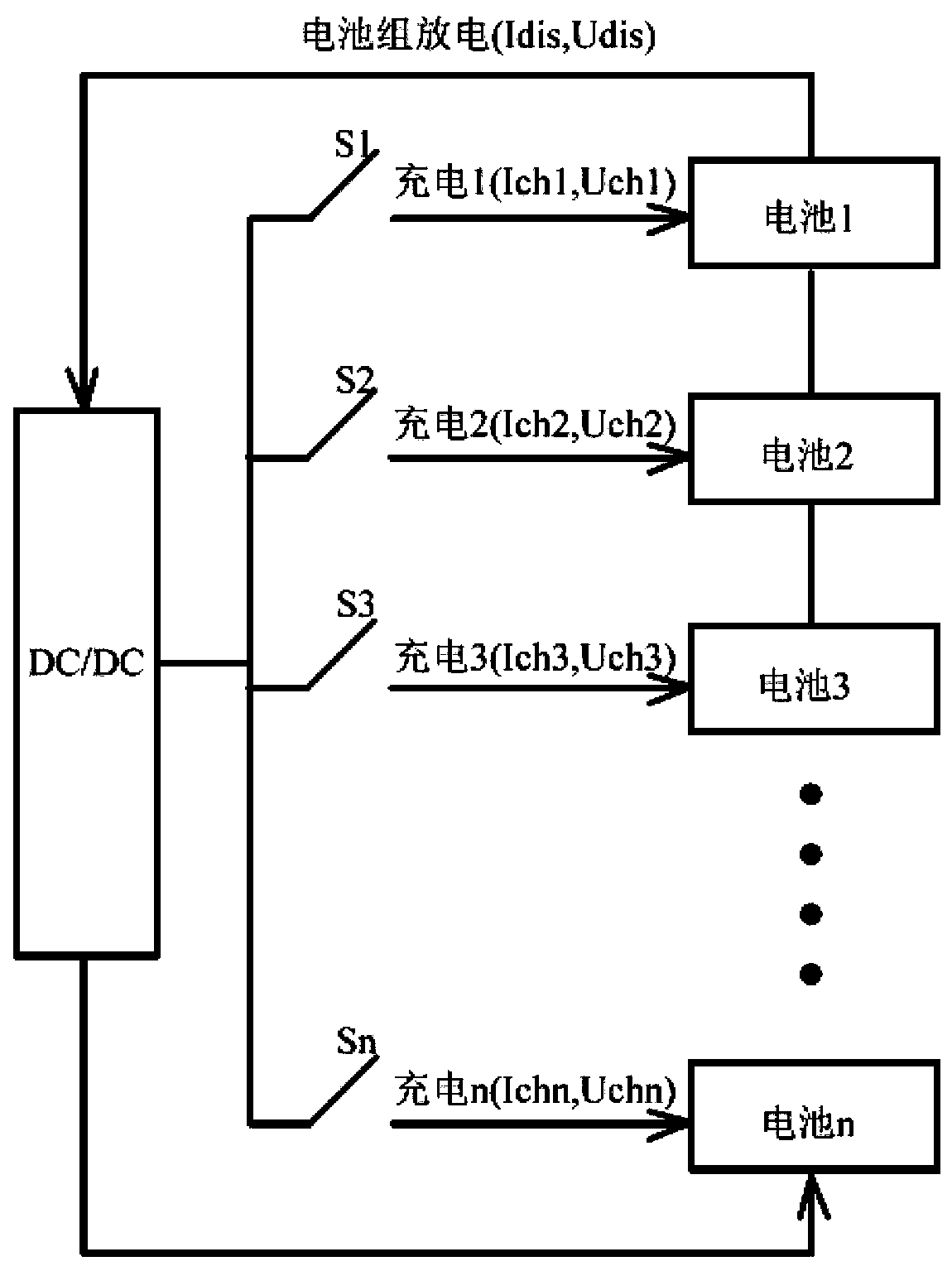

Fire pre-judging and extinguishing system and method for storage battery pack of direct current power system

InactiveCN110882504ASolve technical problems that affect other equipment and even the entire substation will be destroyedGuaranteed uptimeFire rescueFire alarm smoke/gas actuationInternal resistanceCircuit breaker

The invention provides a fire pre-judging and extinguishing system for a storage battery pack of a direct current power system. The system comprises a remote monitoring layer, a network communicatinglayer and a station end equipment layer. The invention provides a fire pre-judging and extinguishing method for the storage battery pack of the direct current power system at the same time. The station end equipment layer collects operation state information of the storage battery pack. By means of the network communicating layer, the information is transferred to a data center server, and then distributed to all remote monitoring terminals of the remote monitoring layer. According to the system, by collecting the operation state information of storage battery pack voltage, single-body voltage, inner resistance, temperature, charging and discharging current and the like of the storage battery pack, working state information of an outlet fuse or breaker of the storage battery pack, workingstate information of a charger, combustible gas smoke alarm information and the like are monitored online, the integrated comprehensive fire pre-judging and extinguishing system is put up, by the adoption of multiple monitoring measures, monitoring is accurate and in time, the loss caused by fires can be reduced to the largest extent, and safe and stable operation of the direct current power system is guaranteed.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +1

New-type inflaming retarding material and preparation method thereof

The invention relates to a new-type inflaming retarding material and a preparation method thereof. The inflaming retarding material comprises the following raw materials in parts by weight: 100 parts of polypropylene, 5-16 parts of modifier, 5-10 parts of compound flame retardant. The new-type inflaming retarding material has better fire resistance, can effectively lower the probability of occurrence of fire disasters, reduce the damages caused by fire disaster compared with other polypropylene plastic foam materials, and can prepare the inflaming retarding materials with different inflaming retarding performances through controlling the content of the compound flame retardant at the same foaming multiplying power.

Owner:北京东方绿达科技发展有限责任公司

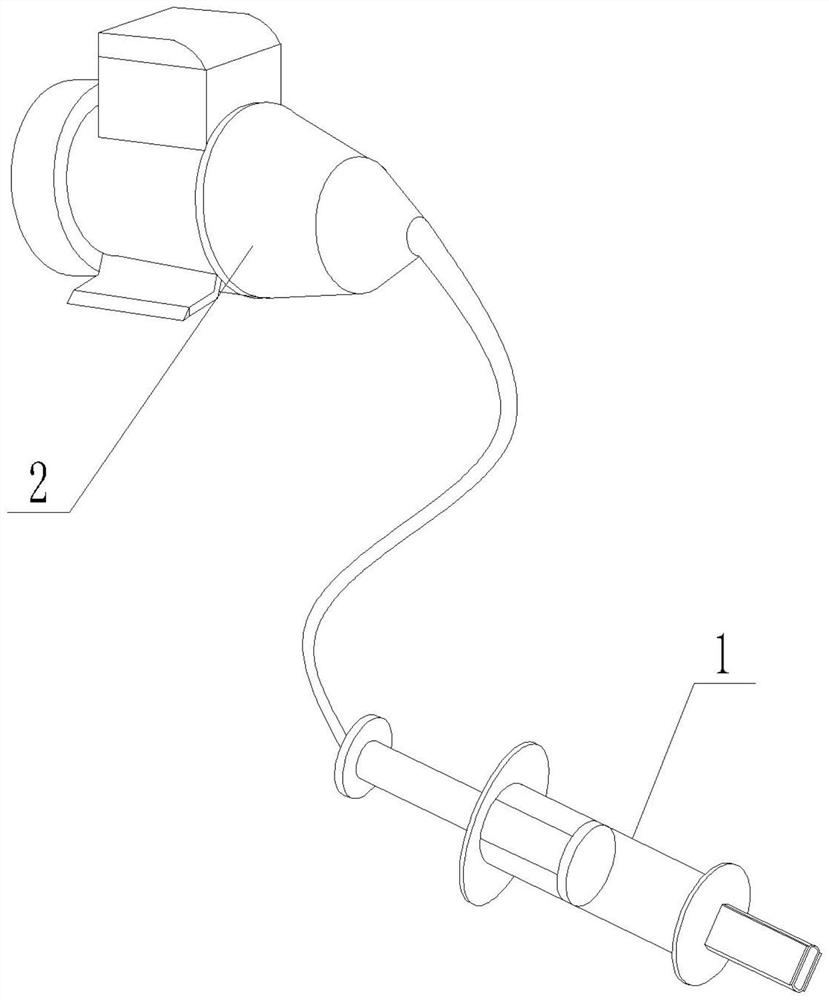

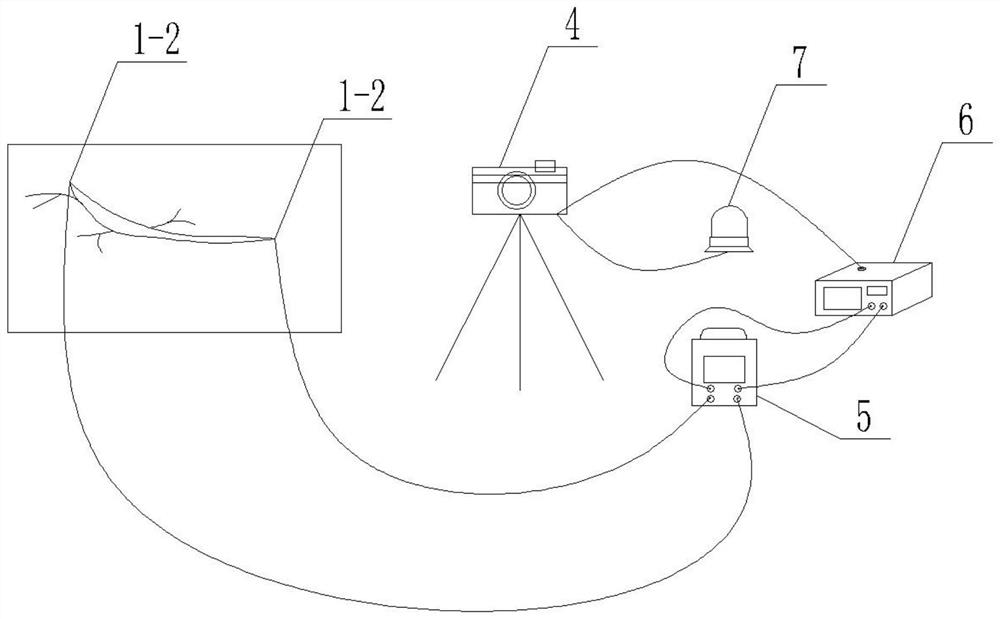

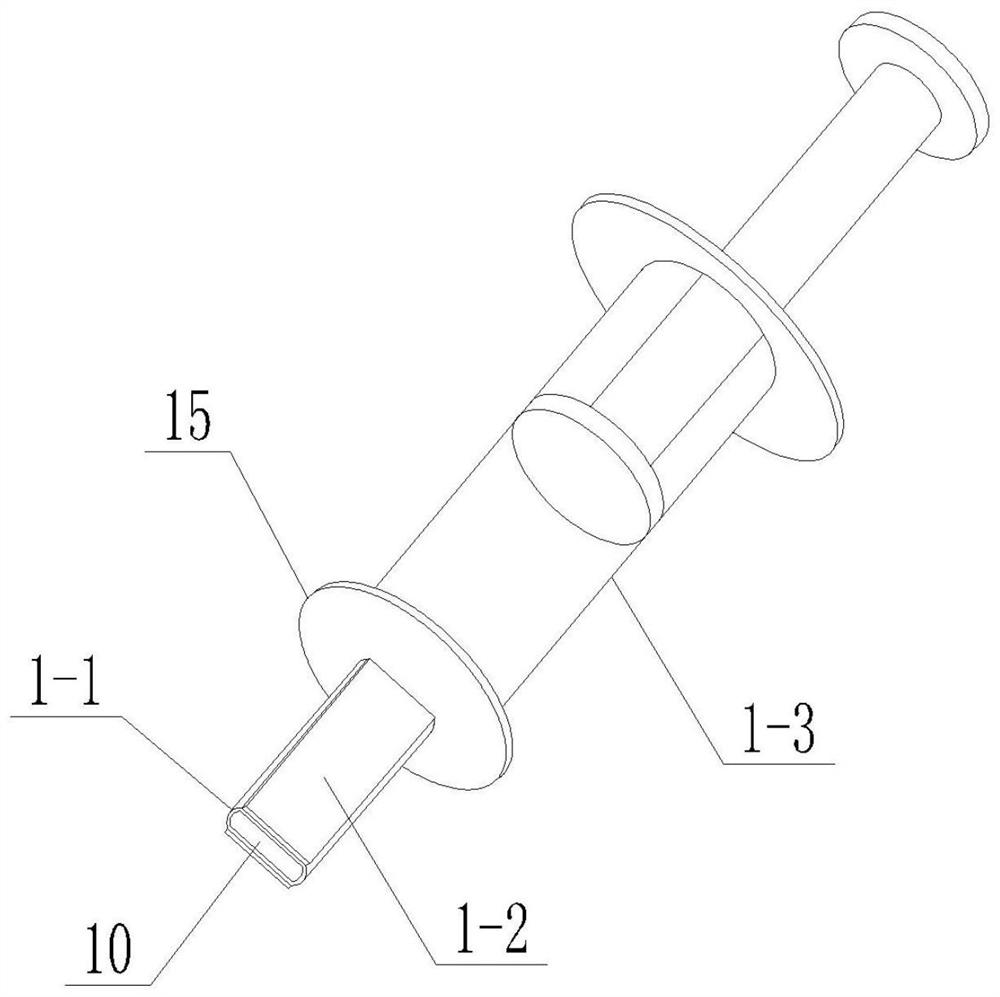

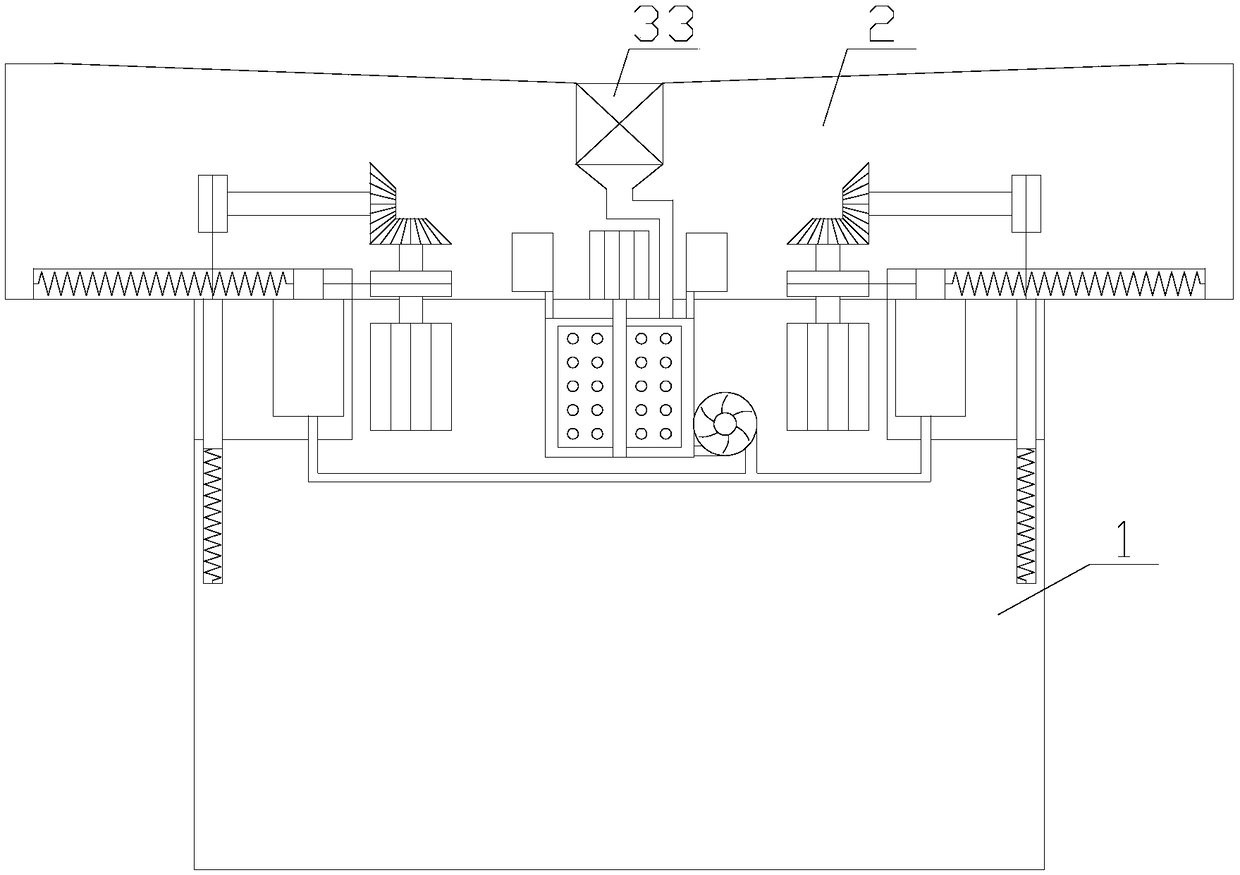

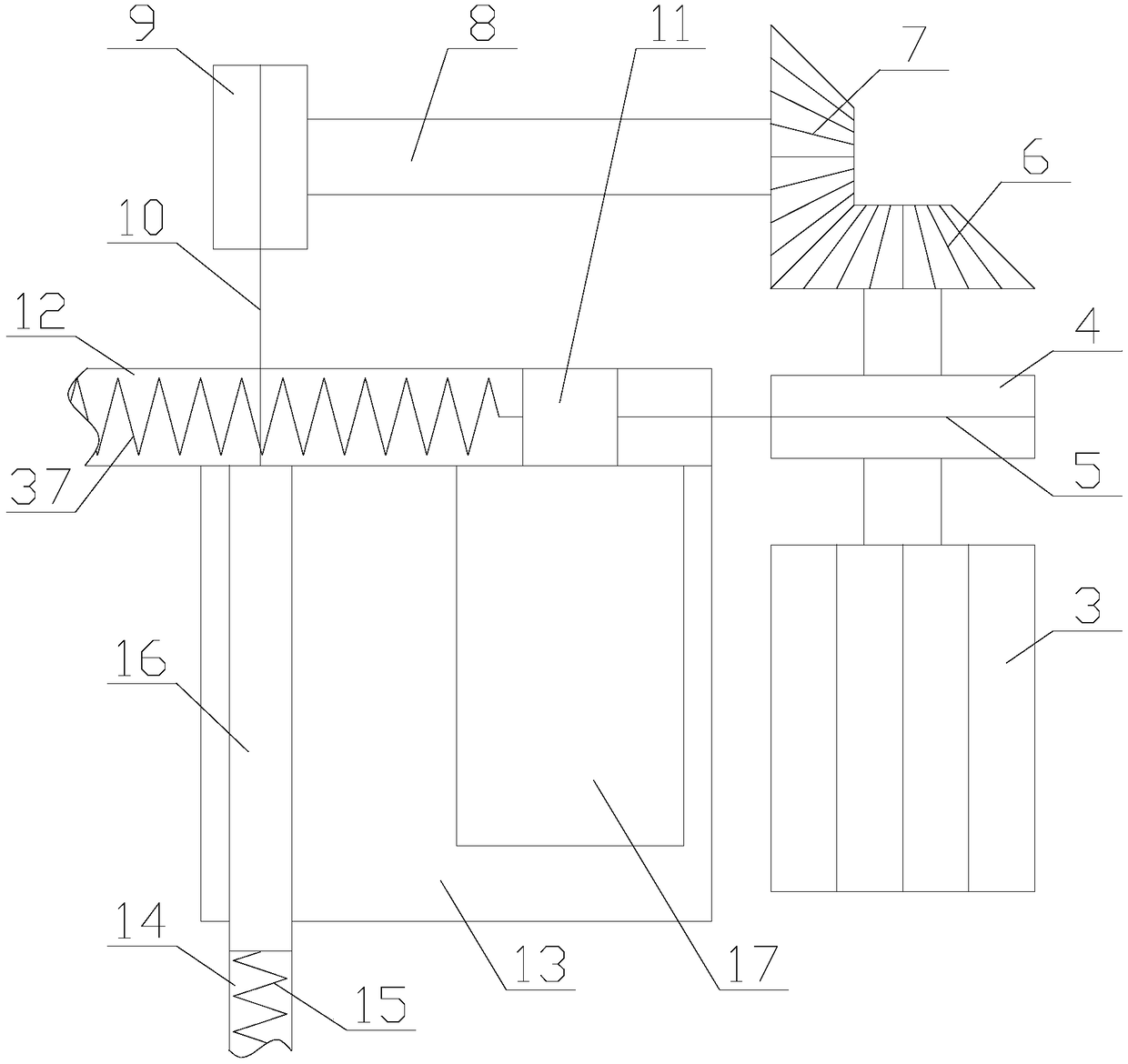

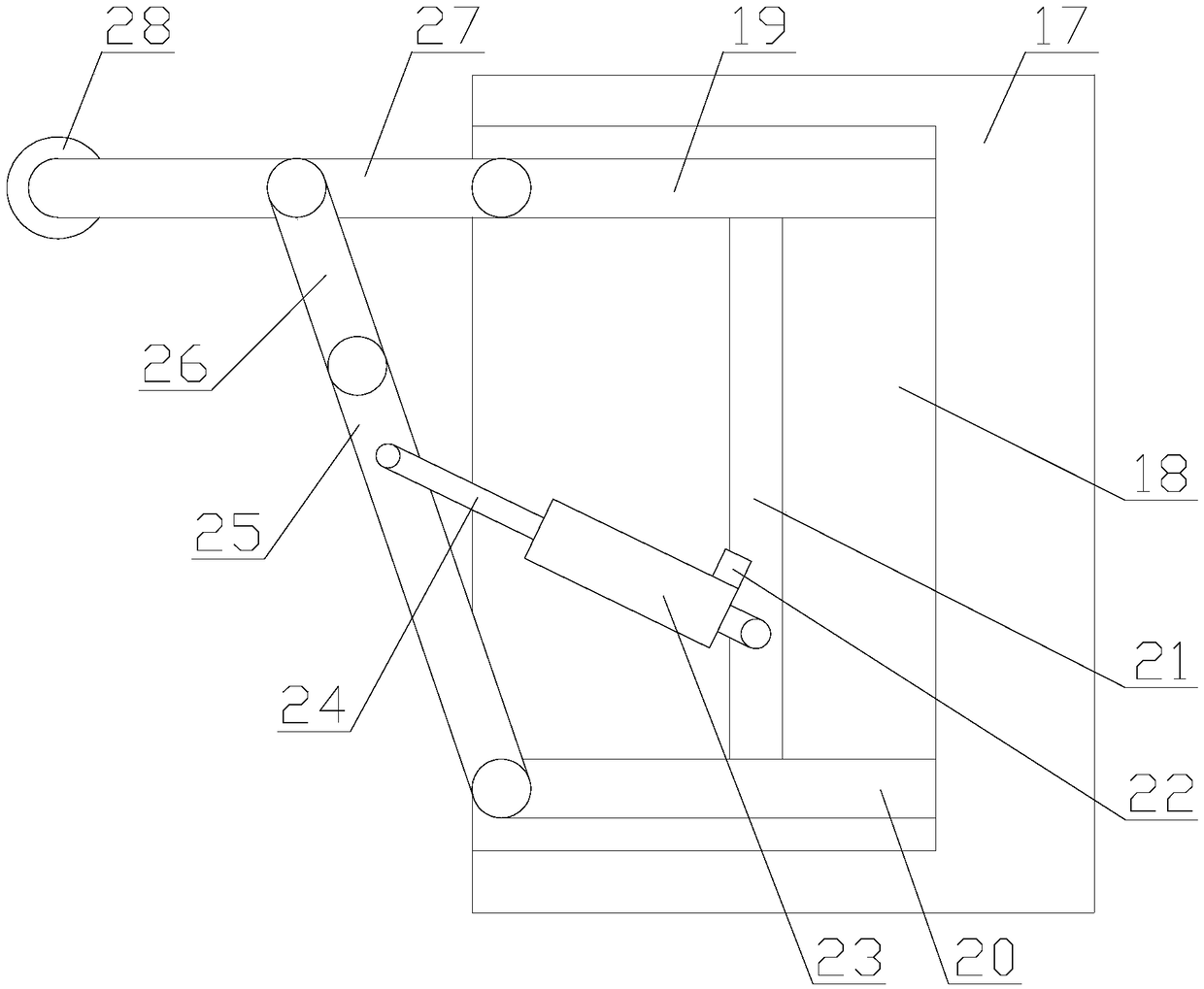

Filling type maintenance device and method for concrete crack repairing in winter in cold regions

ActiveCN112727139AEasy to useAvoid the defect of incoherent maintenance effectUnderground chambersBuilding repairsTemperature controlContinuous use

The invention discloses a filling type maintenance device and method for concrete crack repairing in winter in cold regions. The device and the method aim to overcome the defects that after a concrete structure is cracked in winter in a cold region, an existing method cannot achieve rapid repairing on site, and great problems are brought to continuous use of the structure. According to the filling type maintenance device, each electrode type injector of comprises a flat needle head, electrode plates and an injection body; the flat needle head is detachably connected to the discharging end of the injection body, a feeding port communicating with the discharging end of the injection body is machined in one end of the flat needle head, and a discharging port is machined in the other end of the flat needle head; and the electrode plates are arranged on the outer wall of the flat needle head, the injection body is filled with conductive concrete, the two electrode plates of the two electrode type injectors are electrically connected with a voltage regulator, the voltage regulator is connected with a thermal infrared imager through a temperature control switch, and the thermal infrared imager is further provided with an alarm in a matched mode. The filling type maintenance device is used for rapid repairing of the cracking part of the concrete structure in winter in the cold region.

Owner:HARBIN INST OF TECH

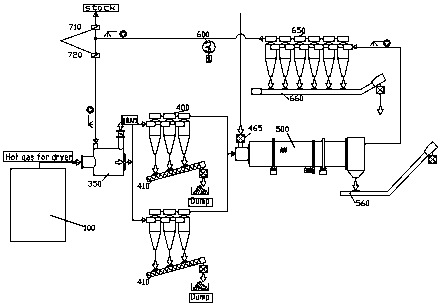

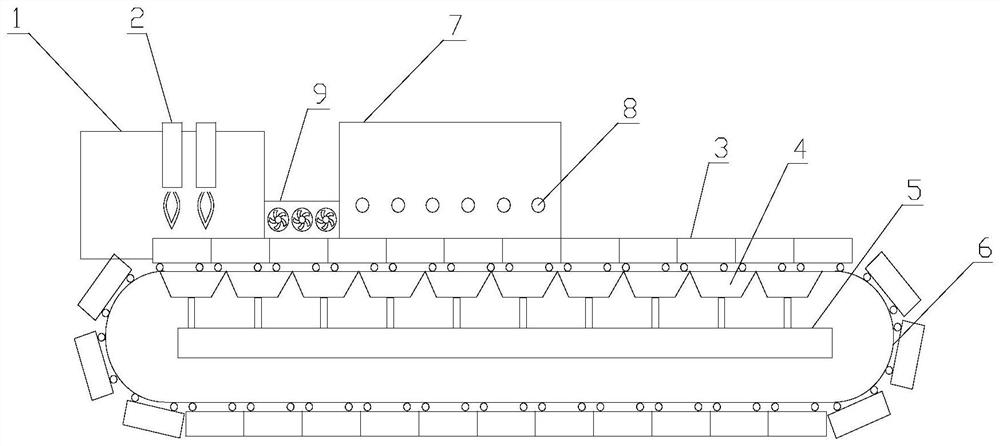

Production and calcination system of carbon anode for aluminium electrolysis and process control method of system

ActiveCN105546981AReduce consumptionRelieve pressureFurnace typesWaste heat treatmentAluminium electrolysisCalcination

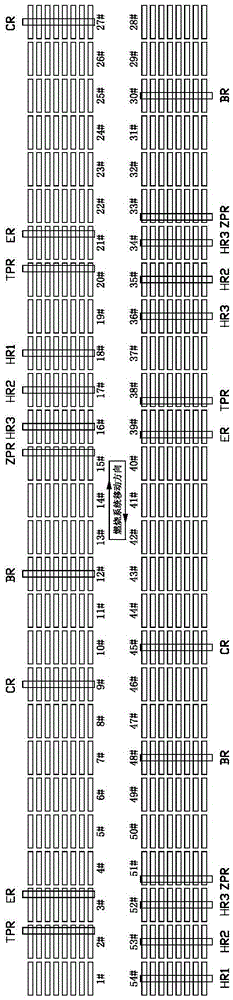

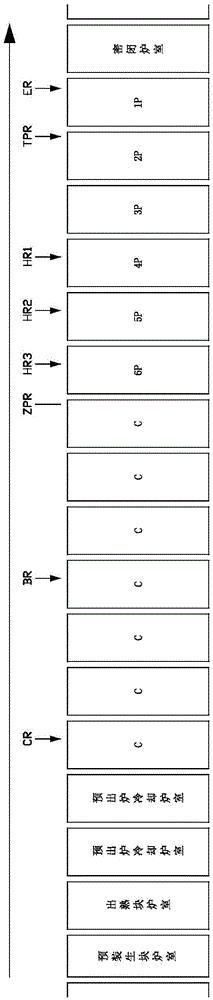

The invention discloses a production and calcination system of a carbon anode for aluminium electrolysis and a process control method of the system. The calcination system comprises a recycle calciner unit including a plurality of furnace chambers, at least one flame control unit including multiple types of control racks and a hanging beam device used for moving the flame control unit, wherein each furnace chamber comprises a plurality of open-top material boxes which are arranged side by side; a sealed flame path is arranged on each of both sides of each open-top material box; each flame control unit controls 20 / 22 furnace chambers within each flame control period and moves forwards by one furnace chamber at the end of each flame control period. The calcination system has the advantages of being simple in structure, low in cost and high in finished product ratio. According to the process control method of the system, the flue gas temperature of branch pipes of exhaust racks (ER) is controlled to be 420-480 DEG C, and the airflow negative pressure controlled by zero pressure racks (ZPR) is minus 4-0 pa; the advantages of high production efficiency, simple and convenient operation and high safety and reliability are achieved, the production rate can be effectively improved by 15% or higher, and the fuel consumption can be reduced by 10%-25%.

Owner:杨维平

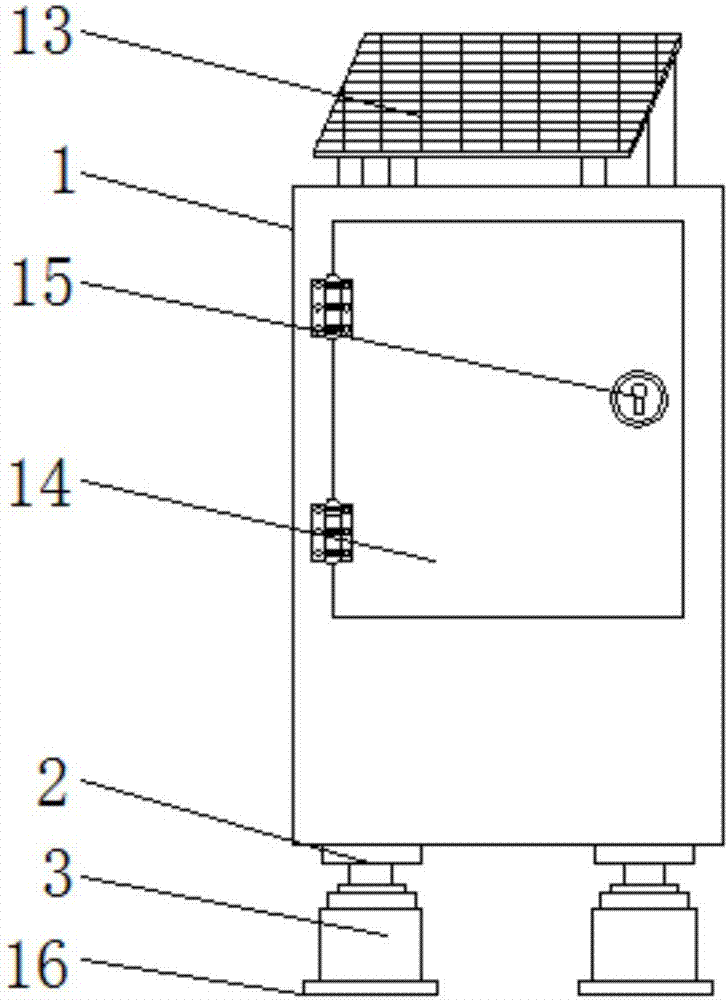

Power distribution cabinet with high safety performance

InactiveCN107394634AImprove securityGuaranteed normal operationSubstation/switching arrangement cooling/ventilationAnti-seismic devicesSlide plateEngineering

The invention discloses a power distribution cabinet with strong safety performance. Outside, the sliding board extends to the side outside the sliding board is fixedly connected with a movable board, the top of the power distribution cabinet is fixedly connected with a solar panel, and the surface of the power distribution cabinet is hinged with a cabinet door. The surface is fixedly connected with a safety lock, and the invention relates to the technical field of power distribution cabinets. The power distribution cabinet with strong safety performance is fixedly connected with the motor through the bottom side of the inner wall of the power distribution cabinet, which reduces the probability of fire and provides protection for people's personal and industrial safety. The sliding plate is connected, which greatly reduces the risk factor, so that the use of the power distribution cabinet can be carried out in a safe environment and environment, and the side of the connecting plate is fixedly connected with the bottom of the supporting plate, and the safety factor is greatly increased.

Owner:万舒

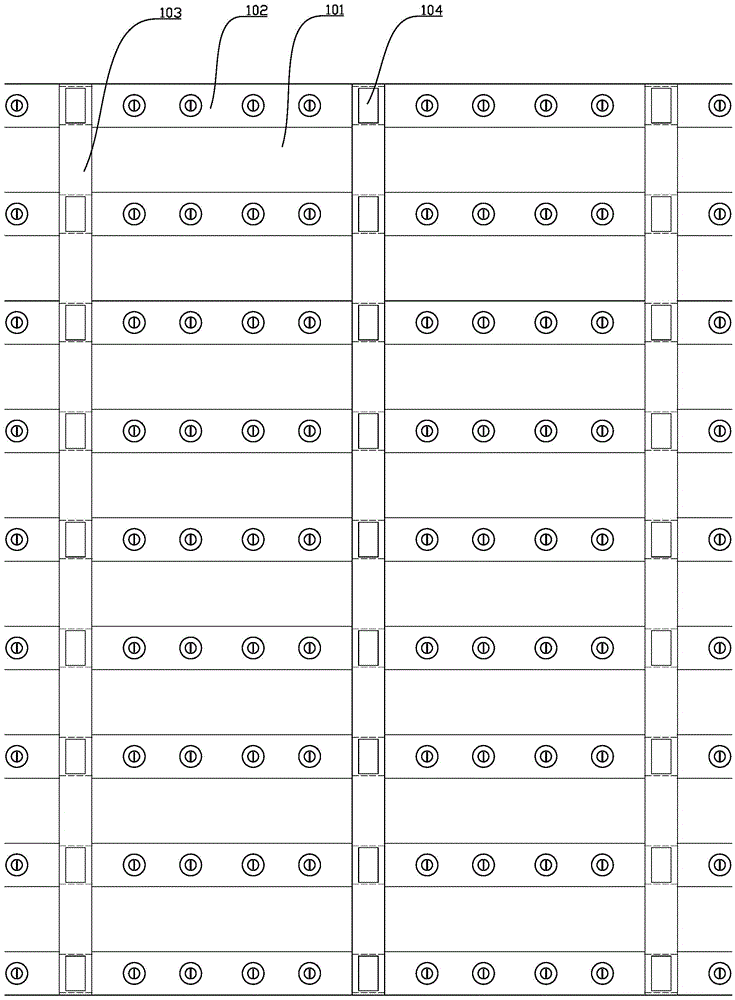

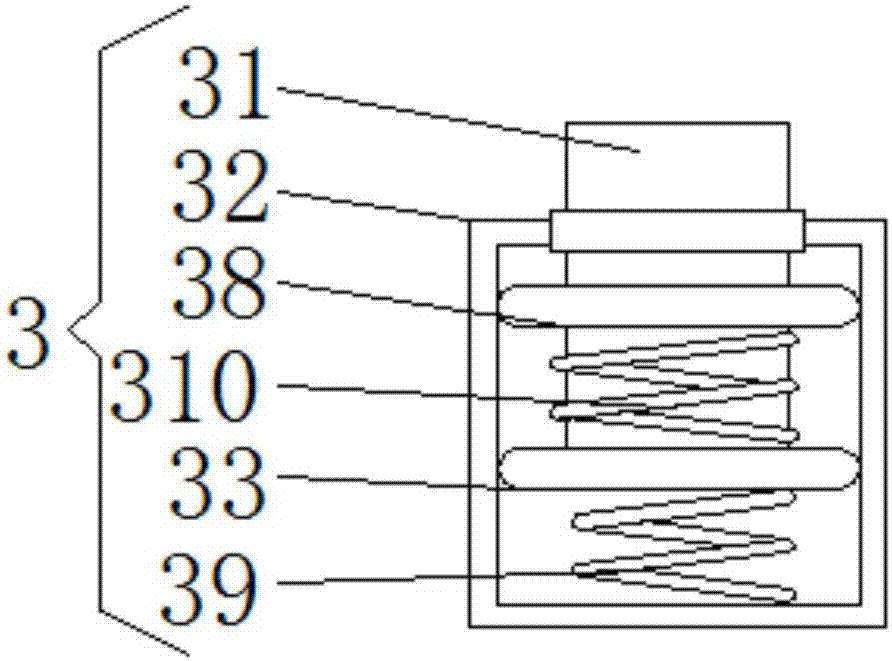

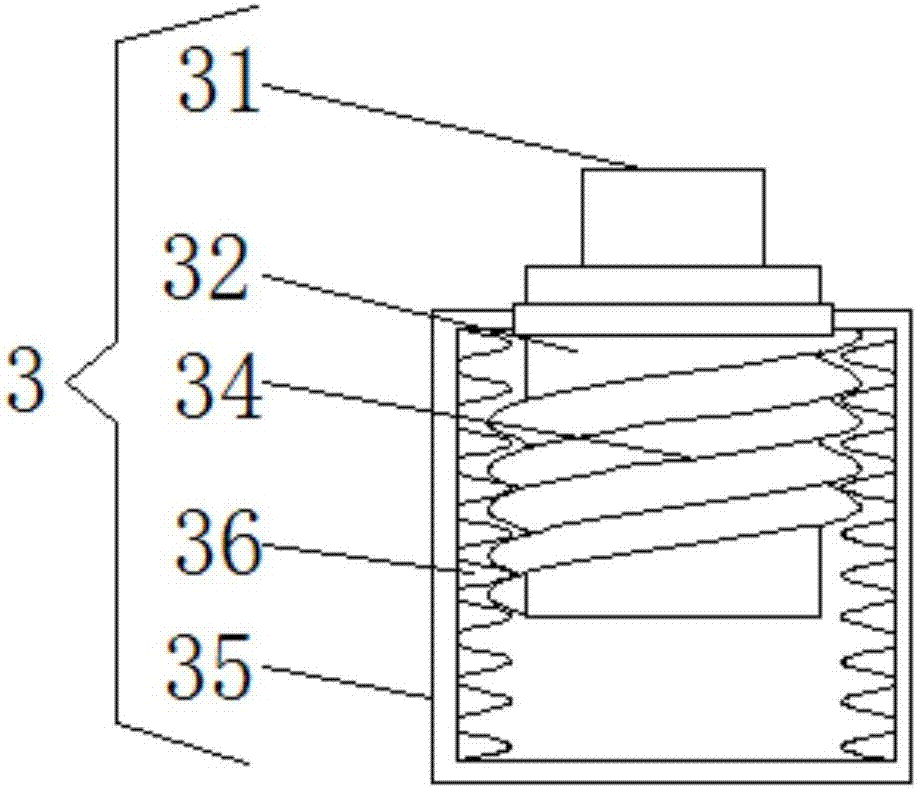

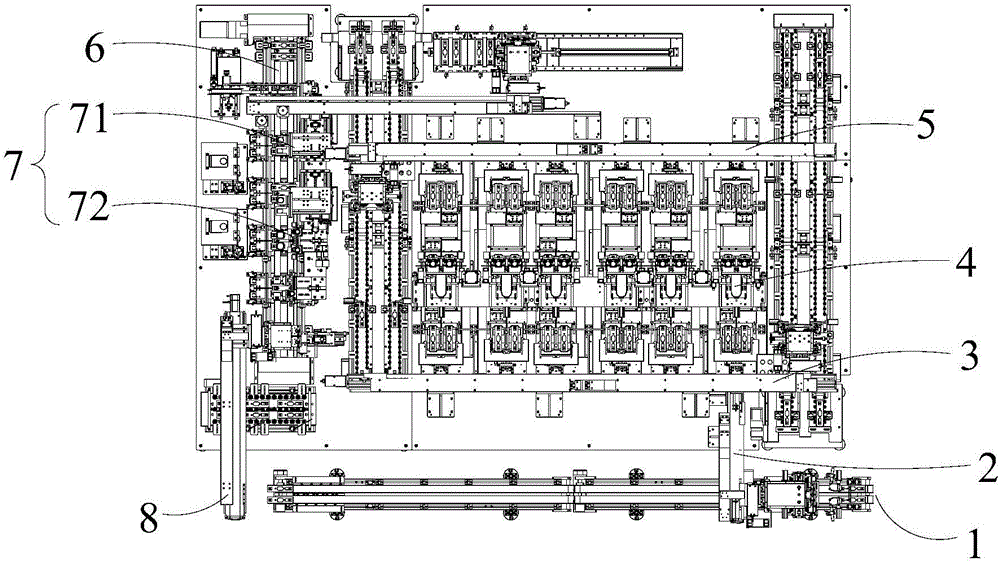

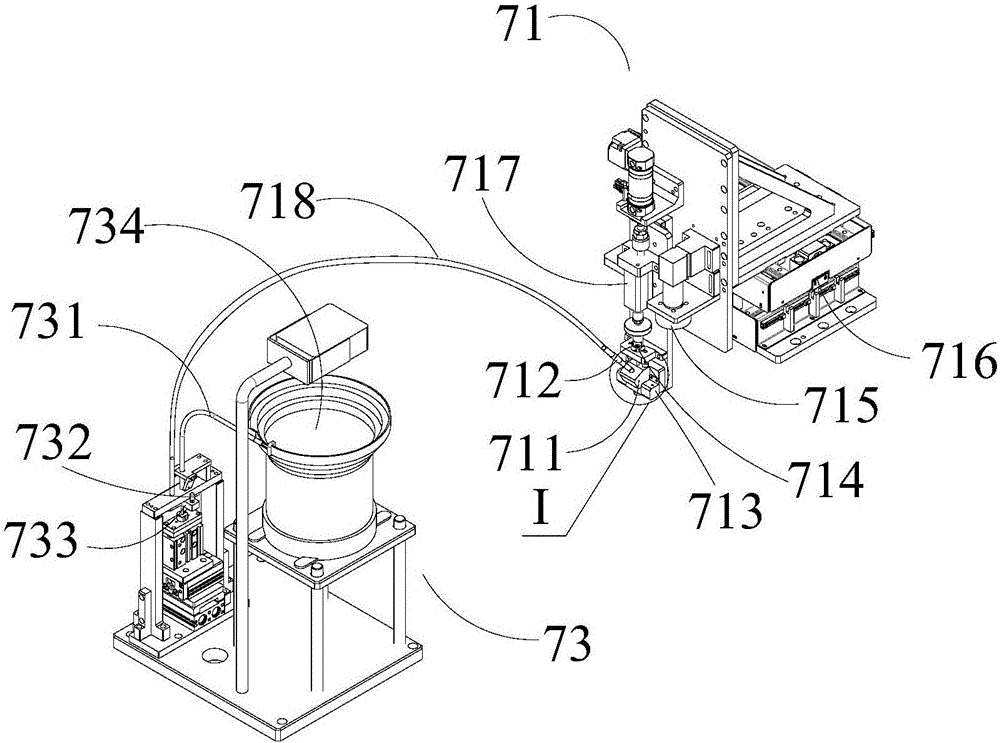

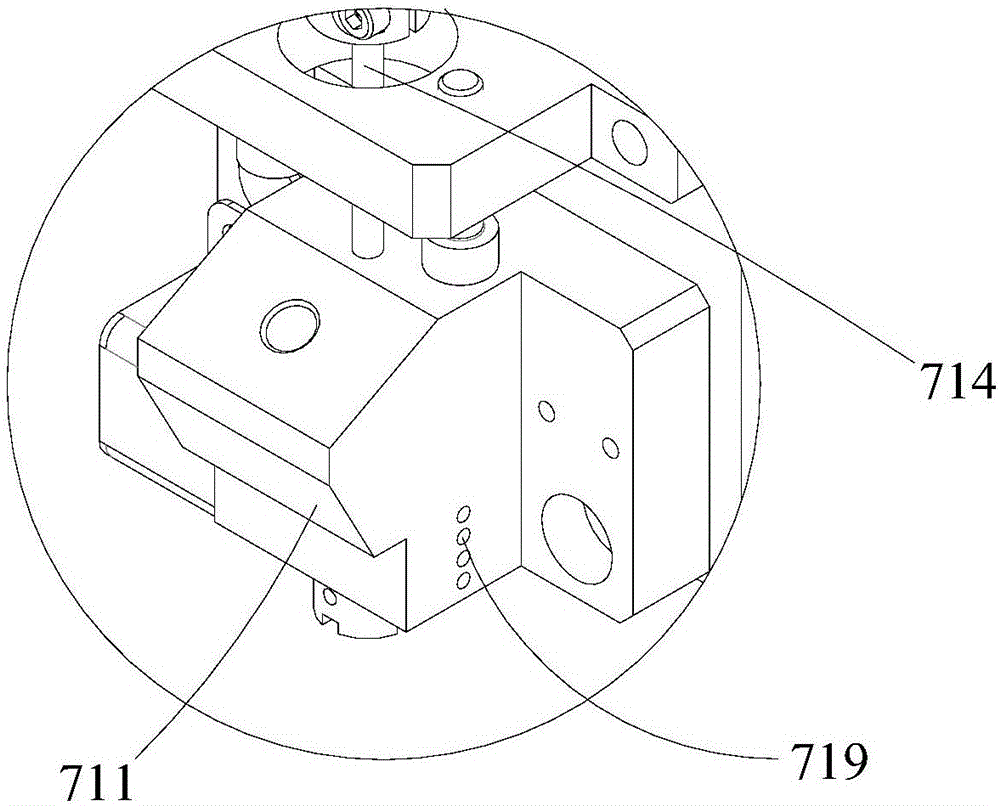

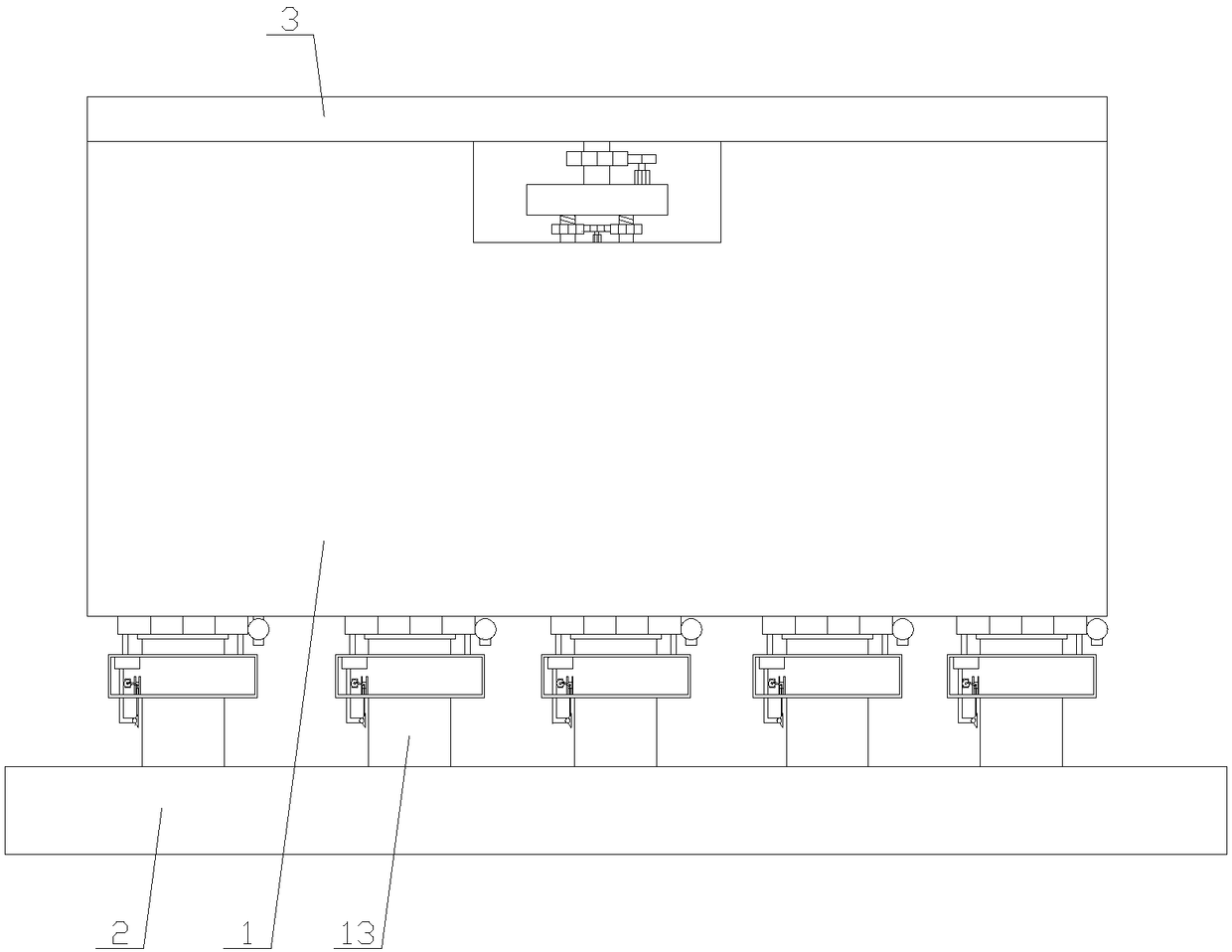

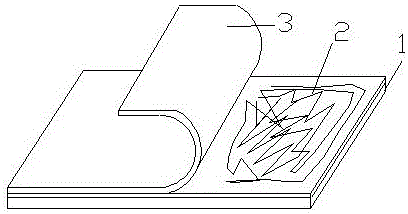

Liquid injection equipment and method

PendingCN106684310AAvoid pollutionReduce the chance of fireCell component detailsEngineeringElectrolyte

The invention relates to the technical field of production of an energy storage device, in particular to liquid injection equipment and method. The liquid injection equipment comprises a liquid injection helium-inflated module and a nailing module, wherein the liquid injection helium-inflated module and the nailing module are arranged at different stations along a transmission direction, the liquid injection helium-inflated module is used for injecting a liquid into a battery cell and inflating the battery cell with an inert gas, and the nailing module is used for pressing a sealant nail into a liquid injection hole of the battery cell so that the liquid injection hole is sealed by the sealant nail. By the liquid injection equipment, the liquid injection process and the sealant nail pressing process are respectively operated at different stations, the sealant nail directly enters the liquid injection hole and does not need to pass through a liquid injection pipe, so that the sealant nail is prevented from being polluted by an electrolyte in the liquid injection pipe, the defects such as a pinhole, an explosion point, a step and a pit occurring during the subsequent laser welding process of the sealant nail can be reduced, the probability of causing the battery cell to be on fire is reduced, and the finished rate of the battery cell is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

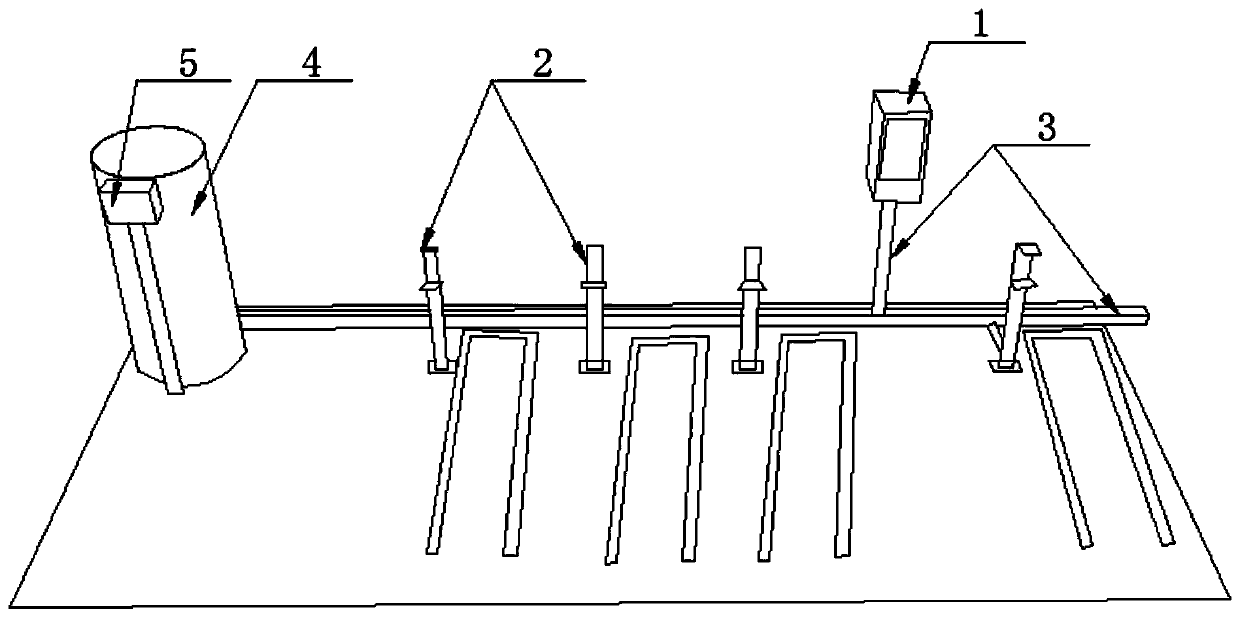

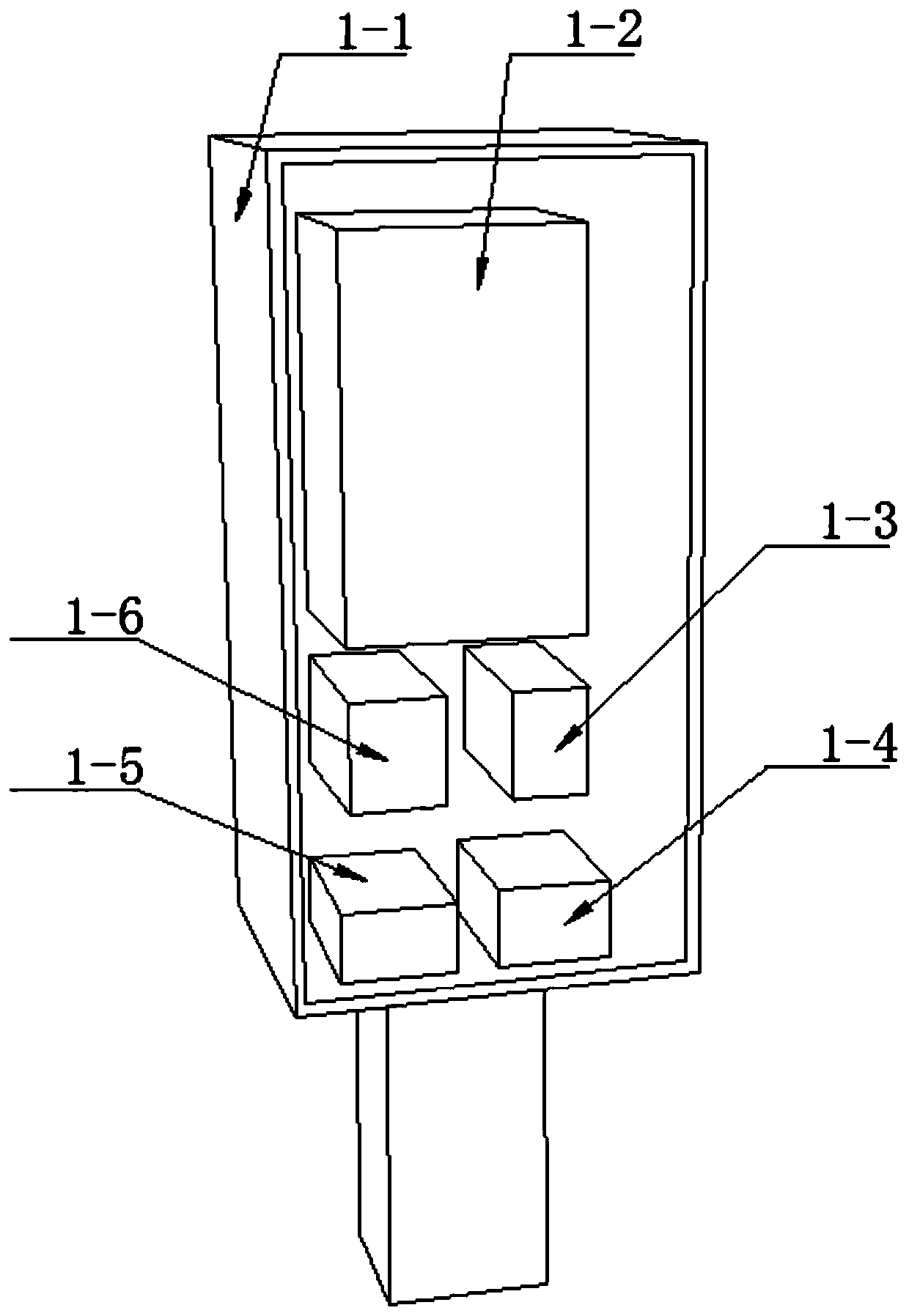

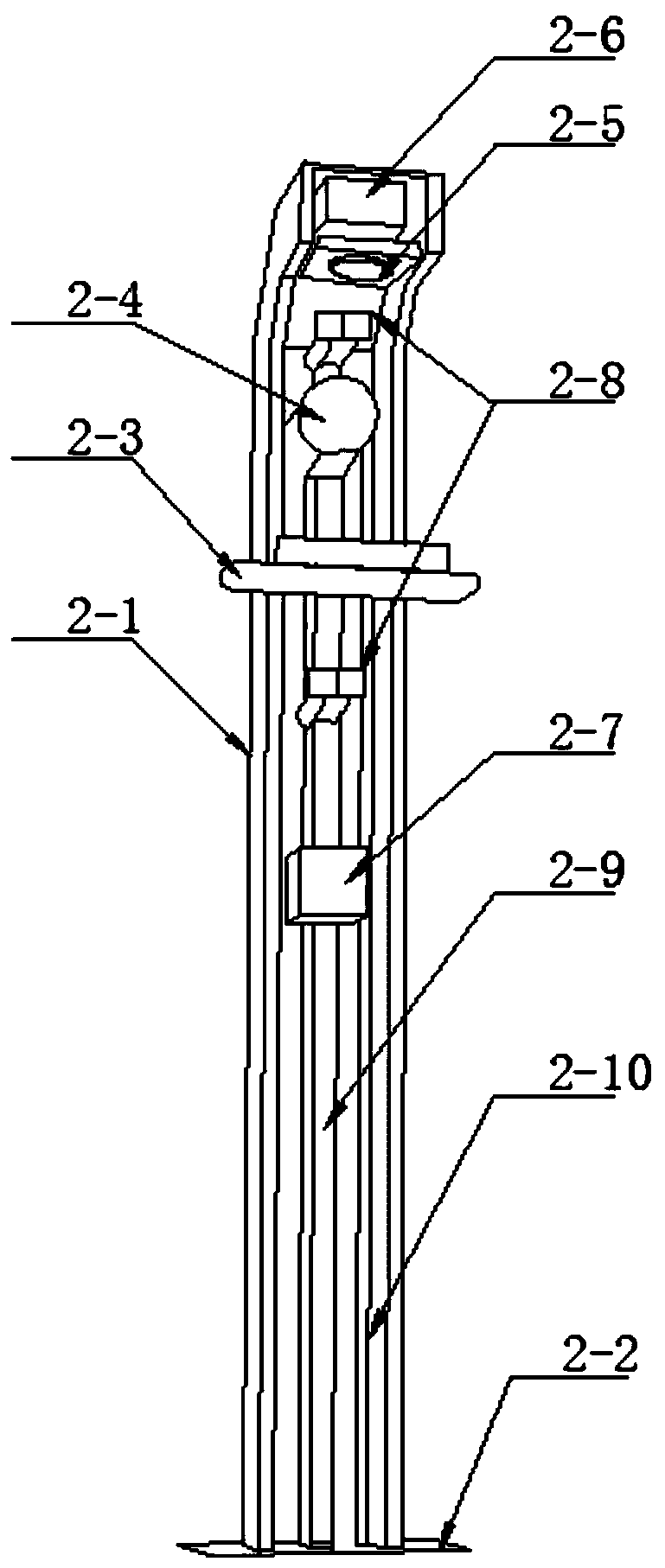

Electric vehicle charging pile with manual and automatic fire extinguishing system

InactiveCN110239385AAvoid ignitionEasy to separateCharging stationsFire rescueEngineeringElectric vehicle

The invention provides an electric vehicle charging pile with a manual and automatic fire extinguishing system, and relates to the technical field of electric vehicle charging piles. A charging pile control main case is connected with a fire extinguishing function charging pile through a fire extinguishing agent charging line laying pipeline; the fire extinguishing function charging pile is connected with a super-large-capacity fire extinguishing agent storage tank through a fire extinguishing agent charging line laying pipeline; a manual fire extinguishing control box is connected with the charging pile control main case through a fire extinguishing agent charging line laying pipeline; a temperature and smoke flame signal collecting plate is connected with a temperature and smoke flame sensor probe; and one end of an electromagnetic valve is connected with the super-large-capacity fire extinguishing agent storage tank through a fire extinguishing agent conveying pipe, and the other end of the electromagnetic valve is connected with two double-head liquid spraying heads. The charging pile is mounted and arranged beside a to-be-charged electric vehicle, and each charging pile is provided with a charger storing frame. According to the electric vehicle charging pile, chargers and the electric vehicles are separated advantageously, then the situation that the chargers are on fire abnormally and consequently the electric vehicles are ignited to burn is avoided, and the probability of being on fire caused by the chargers is reduced.

Owner:上海柜满格实业有限公司

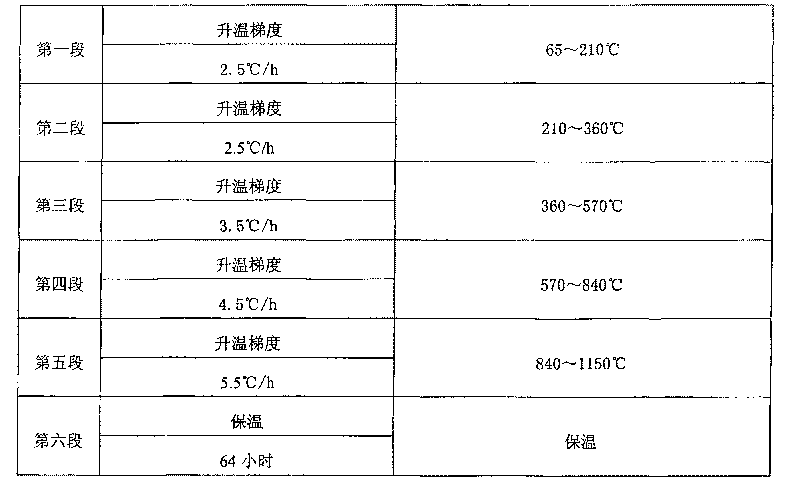

Drying method for ring-form calcining furnace

The invention is a furnace-drying method for a ring type baking furnace, relates to a furnace-drying method for a 36-chamber ring type baking furnace in aluminum prebaked anode production. The invention is characterized in 360 furnace-baking curve is selected in the baking process, waste mature anode and qualified green body are mixed after the fifth chamber, igniting for furnace drying is startedat 2# and 20# chambers, the temperature of a flue without green body furnace in the prophase of furnace drying rises in ladder form, normal furnace baking is about to finish, when the starting chamber becomes a 4P chamber, the furnace-drying curve transits to a normal curve. According to the invention, water in mortar and bricks are discharged slowly and uniformly to sinter the mortar and clay bricks integrally, so that the upper temperature and lower temperature of a furnace body is indeed unified, the furnace body is free from deformation and crackle, and the service life of the furnace isextended.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Communication base station with functions of weeding and rainwater collecting

InactiveCN108713548AHas weed controlWith rainwater harvesting functionGeneral water supply conservationWeed killersDrive wheelDrive shaft

The invention relates to a communication base station with functions of weeding and rainwater collecting. The communication base station comprises a main body, a baffle, a collecting mechanism and several weeding mechanisms; each weeding mechanism comprises a protection groove, a driving unit, a moving unit and a protection unit, each driving unit comprises a first motor, a driving wheel, a firstfixed rope, a first gear, a second gear, a transmission shaft, a transmission wheel and a second fixed rope, and each moving unit comprises a slide block, a slide groove, a second spring and a cleaning block; the collecting mechanism comprises a second motor, a mixed pool, a liquid inlet pipe, a water pump, several blades and several liquid storage boxes. By means of the communication base stationwith the functions of weeding and rainwater collecting, through the collecting mechanism, rainwater can be collected, preliminarily filtered, and stored in the mixed pool; besides, through the weeding mechanism, weeds around the communication base station can be killed, it is prevented that in autumn, the weeds wither, dry and become combustible, and the probability that fires break out at the communication base station is lowered.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

Intelligent communication machine room with snow removal and anti-snake functions

InactiveCN108343280AReduce the chance of starting a fireAvoid economic lossSnow trapsAnimal repellantsSnow removalTelecommunications equipment

The invention relates to an intelligent communication machine room with snow removal and anti-snake functions. The intelligent communication machine room comprises a main body, a base disposed at thebottom of the main body, a snow removal mechanism and an anti-snake mechanism. The snow removal mechanism includes a snow removal board, a lifting assembly and a rotating assembly. The anti-snake mechanism includes support columns, a power assembly and an oil injection assembly. According to the intelligent communication machine room with the snow removal and anti-snake functions, the snow removalmechanism is activated to remove snow from the machine room when the snow covers the top of the machine room, and the machine room is avoided from being overwhelmed by the heavy snow to cause damageto telecommunication equipment, so that power outage and other accidents are avoided to bring inconvenience to people. Secondly, when a snake tends to climb to the machine room, the anti-snake mechanism is activated to prevent the snake from climbing to the machine room, and the chance of fire caused by the snake climbing into the machine room and being electrically shocked is reduced, so that greater economic losses of people are avoided.

Owner:MAANSHAN BEIYITONG INTELLIGENT TECH CO LTD

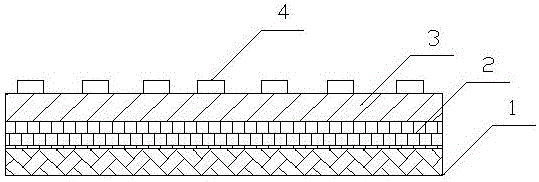

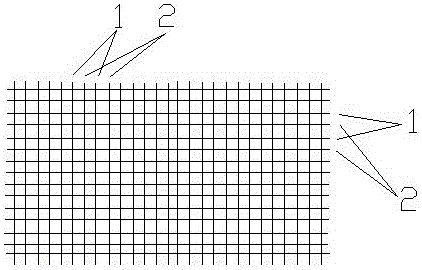

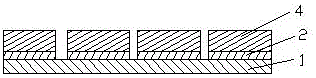

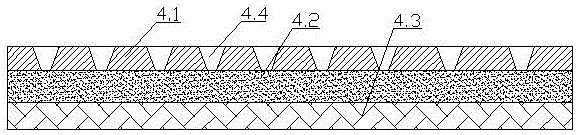

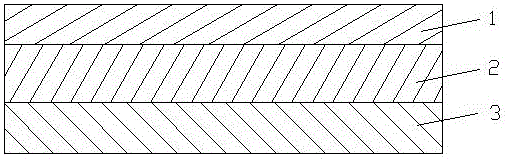

Deodorant bactericidal waterproof light-reflecting artificial leather

The invention relates to a deodorizing, sterilizing, waterproof and reflective artificial leather, which comprises a base layer (1) and a surface layer (2) bonded together, and is characterized in that the surface layer (2) is provided with a plastic film layer (3) , a plurality of reflective strips (4) are arranged on the plastic film layer (3). The back of the base layer is compounded with a lining layer. The upper and lower surfaces of the lining layer are respectively fixed with a fiber surface layer and a waterproof layer. The outer surface of the waterproof layer is fixed with a flame-retardant layer made of flame-retardant powder. The lining layer is evenly arranged with ventilation holes, and the fiber surface layer is made of warp yarns and weft yarns interwoven, and soybean fibers are woven in the warp yarns and weft yarns. The invention is deodorizing, sterilizing, waterproof and reflective.

Owner:JIANGYIN LONGSHENG PLASTIC

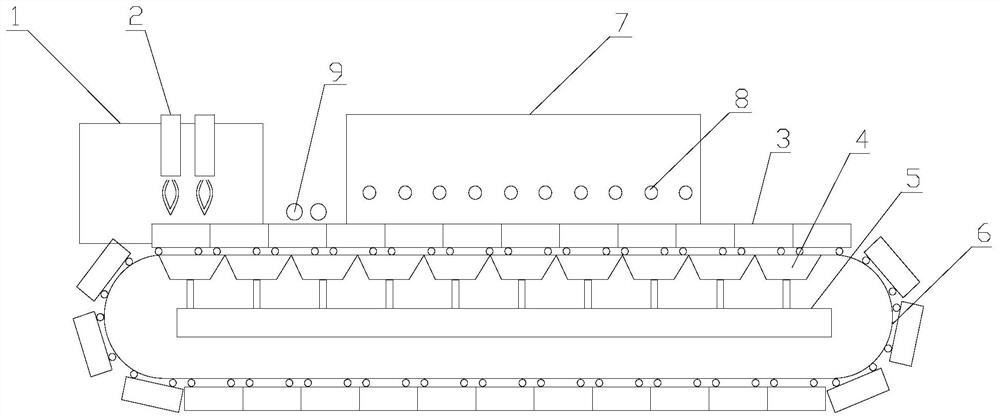

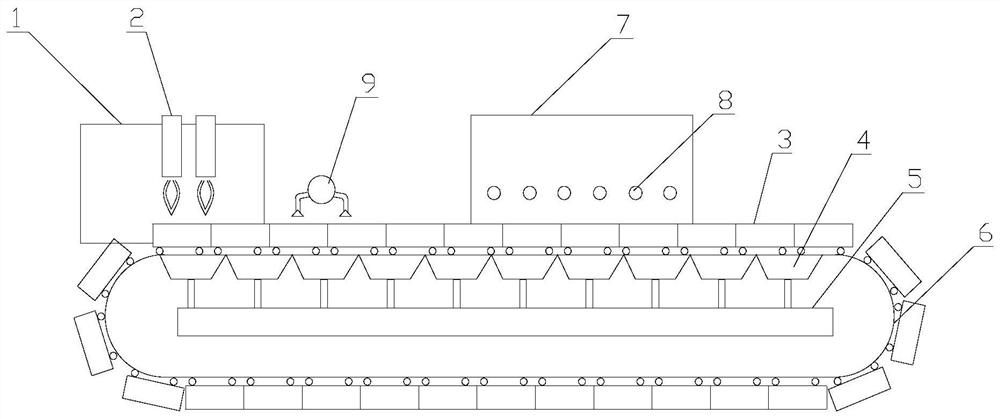

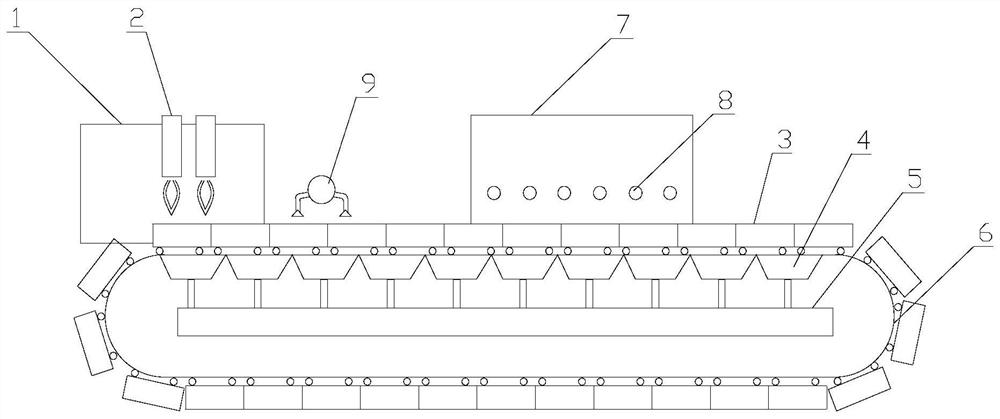

Tangential curtain cooling type gas injection sintering machine and control method thereof

ActiveCN112393599AReduce the chance of fireEnsure safetyFurnace typesFurnace coolingProcess engineeringMechanical engineering

The invention discloses a tangential curtain cooling type gas injection sintering machine and a control method thereof. The sintering machine comprises a sintering machine track, a sintering machine trolley, an ignition device and a gas injection device, wherein the fuel gas injection device is arranged at a fuel gas injection position of the sintering machine so as to inject fuel gas to the sintering material surface of the sintering machine trolley when the sintering machine trolley passes through the fuel gas injection device from the fuel gas injection position; and the sintering machine further comprises a steam blowing device, the steam blowing device is arranged between the ignition device and the fuel gas blowing device so as to blow steam to the sintering material surface of the sintering machine trolley in the form of a steam curtain when the sintering machine trolley passes through the position where the sintering machine trolley is located, and the temperature of the sintered material surface is reduced to be lower than the gas ignition temperature. The sintering machine is provided with the steam injection device, and the problems that the fuel gas injection device isprone to catching fire, unstable in production and the like can be effectively solved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

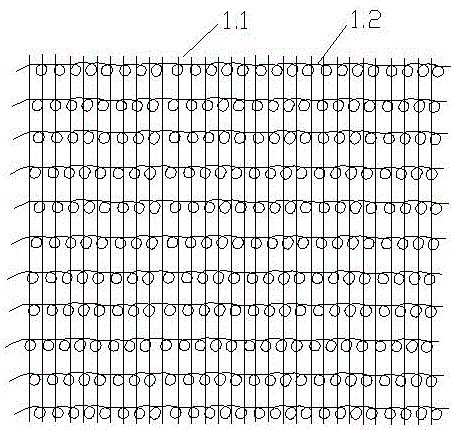

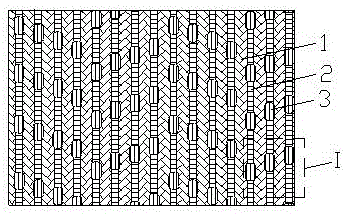

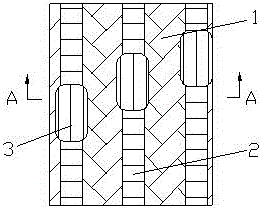

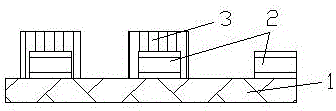

Bamboo fiber gauze kerchief deodorization, sterilization and anti-radiation fabric

InactiveCN106003867AStable supportAnti-electromagnetic radiationSynthetic resin layered productsWoven fabricsPolyesterYarn

The invention relates to a bamboo fiber gauze kerchief deodorization, sterilization and anti-radiation fabric. The fabric is formed by interweaving cotton fiber yarns (1) as warps and bamboo fiber yarns (2) as wefts, several core-spun yarns (3) are embedded into the cotton fiber yarns (1) and formed in the mode that wavy metal ion fiber is wrapped with silk. A lining layer is combined to the back face of the fabric. A fiber face layer and a waterproof layer are fixedly arranged on the upper surface and the lower surface of the lining layer respectively. An inflaming retarding layer formed through adhesion of inflaming retarding powder is fixed to the surface of the outer side of the waterproof layer, the lining layer is formed by interweaving polyester yarns, breathable holes are evenly arrayed in the lining layer, the fiber face layer is formed by interweaving warps and wefts, and soybean fiber is interwoven in the warps and the wefts. The fabric achieves deodorization, sterilization and radiation resistance.

Owner:JIANGYIN BEIYE TEXTILE

Buried anti-corrosion cable sheath material, and preparation method thereof

InactiveCN107189355AReduce flammabilityLight weightPlastic/resin/waxes insulatorsInsulated cablesEpoxyCompound organic

The invention discloses a buried anti-corrosion cable sheath material. The buried anti-corrosion cable sheath material comprises, by weight, 11 to 13 parts of polyvinyl chloride, 15 to 30 parts of polytetrafluoroethylene, 20 to 25 parts of epoxy resin, 10 to 15 parts of polyurethane, 5 to 10 parts of acrylic acid, 40 to 60 parts of a composite organic solvent, 20 to 30 parts of a fire retardant, and 20 to 35 parts of a foaming agent. The invention also discloses a preparation method of the buried anti-corrosion cable sheath material. The preparation method comprises following steps: S1, weighing of raw materials; S2, preparation of a solvent; S3, mixing of basic raw materials; S4, adding of the solvent; S5, adding of the foaming agent; S6, moulding; and S7, cooling. The buried anti-corrosion cable sheath material possesses durability and fire resistance, is light in weight, and is promising in popularization prospect.

Owner:CHONGQING EASTFUL ELECTRIC WIRE & CABLE CO LTD

Wet wood shaving drying system and drying process

InactiveCN110108101AEasy to operateEliminate the fire factorDrying gas arrangementsDrying solid materialsScrew conveyorFlue gas

The invention provides a wet wood shaving drying process and drying system. The drying system comprises a boiler, a mixing chamber, hot flue gas cyclone separators, an ash discharge screw conveyor, aone-way feed chute, a single-channel roller dryer, an unloading conveyor, a multi-pipe cyclone separator, a fine waste conveyor, a main induced draft fan and a bilateral control air valve. The temperature of high-temperature flue gas in the boiler is 680-780 DEG C. The temperature of the flue gas after air mixing and distribution is 350-450 DEG C. The oxygen content is 10-11%. The smoke dust content is 300-600 mg / m3. The wind speed of the single-channel roller dryer is 15-20 m / s. The temperature of clean flue gas is 320-450 DEG C. The rotating speed is 10-28 r / min. The outlet temperature is 100-120 DEG C. The drying system provided by the invention is reasonable in structure. The drying effect of the drying process is good. Operation is easy to control. Fire factors are eliminated. The fire rate is reduced. The problem of safety in the existing drying process is solved.

Owner:寿光市鲁丽木业股份有限公司

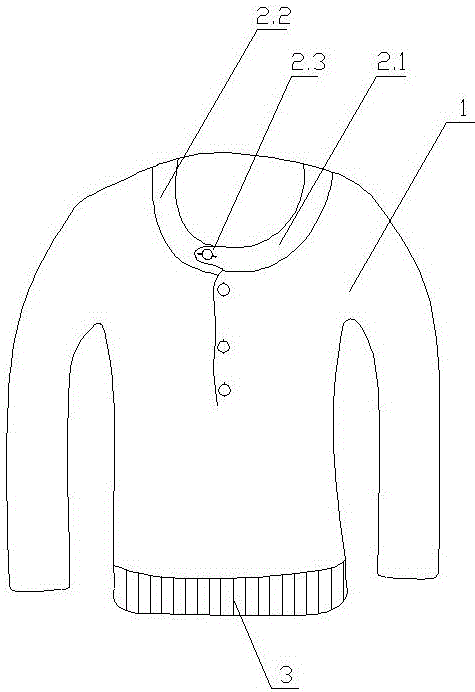

Deodorant and bactericidal clothes with far-infrared therapeutic function

InactiveCN105935162AReceive radiation in real timeAesthetically pleasingGarment special featuresLight therapyFiberPolyester

The invention relates to deodorant and bactericidal clothes with a far-infrared therapeutic function. According to the deodorant and bactericidal clothes with the far-infrared therapeutic function, a warmth keeping sheet is arranged at the collar, after a person wears the clothes, the throat can be under double warmth retention, and therefore the person does not need to keep warm by additionally wearing a scarf; meanwhile, by means of the arrangement of a lower hem and the like, the three-dimensional sense of the clothes is increased, and the attractiveness of the clothes is achieved; by means of a far-infrared chip, when the person wears the clothes, far-infrared radiation can be received in real time, and the far-infrared chip helps to achieve the health-care curative effect. The back of the clothes is provided with a lining layer, a fiber surface layer and a waterproof layer are fixedly arranged on the upper surface and the lower surface of the lining layer respectively, a flame retardant layer which is formed by adhering flame retardant powder is fixedly arranged on the surface of the outer side of the waterproof layer, the lining layer is formed by interweaving polyester yarns, air holes are formed in the lining layer in an evenly arranged mode, the fiber surface layer is formed by interweaving warp yarns and weft yarns, and soybean fibers are woven in the warp yarns and the weft yarns. The clothes have the deodorant and bactericidal effects.

Owner:JIANGYIN ZEWAN TRADE

Strong-touch-sense flashing fiber villus woollen cloth

The invention relates to a fleece wool with strong touch and flashing light. It includes a woolen body (1), the front of the woolen body is provided with several protrusions (2) and flashing fibers (3), and the protrusions (2) are provided with fluff (4). The back of the woolen body is provided with a lining layer. The lining layer includes a lining layer body woven by warp yarns and weft yarns. The warp yarns and weft yarns are interwoven into a three-up and three-down plain weave structure. The surface is provided with a jacquard layer, and the upper surface of the jacquard layer is provided with a flocking layer; the lower surface of the lining layer body is provided with a breathable layer, the lower surface of the breathable layer is provided with an activated carbon cloth layer, and the lower surface of the activated carbon cloth layer is provided with a photocatalyst coating. The invention has a soft hand feeling and a sense of texture; it is visually beautiful and luxurious, and has a three-dimensional effect. The lining layer has a strong touch and breathability.

Owner:JIANGYIN YIFAN IND & TRADE

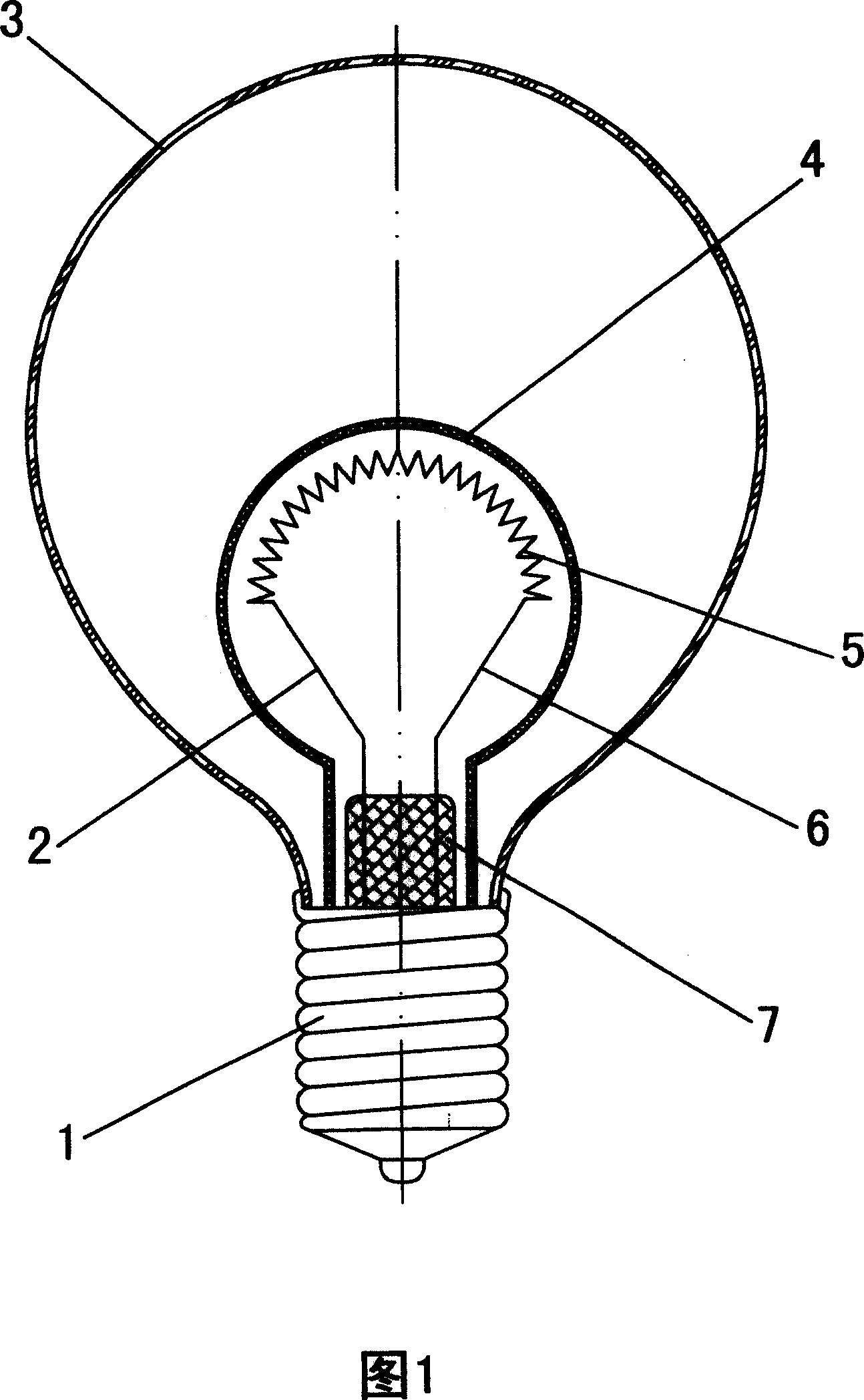

High-efficiency incandescence energy-saving lamp

InactiveCN101009201ASave electricityReasonable useIncandescent lamp energy savingIncadescent envelopes/vesselsInfraredEngineering

A high-performance power saving filament lamp includes general bulb glass shell, filament, lamp mouth, the two ends of the filament are separately connected with A electrode, B electrode; at least one layer inner lamp shell are set in the general bulb glass shell, tungsten filament is enveloped hermetically by the inner lamp shell, the material of the inner lamp shell is high-temperature transparent material which can prevent invisible light such as infrared ray traverse. The invention translates the invisible light emitted by filament into heat source of the filament; it is energy-saving, safe, environmental protection, use is wide.

Owner:田恩泽 +1

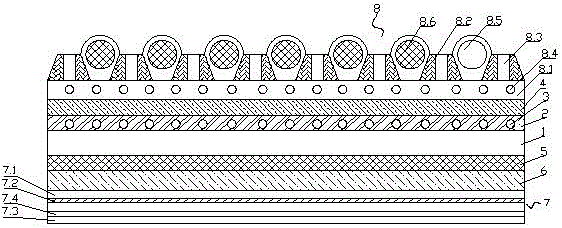

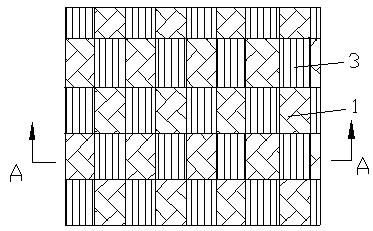

Odor-removing, anti-bacterial, wear-resistant and flame-retardant home textile fabric with high color fastness

InactiveCN106113624AFlame retardantThree-dimensionalSynthetic resin layered productsTextile decorationFiberPolyester

The invention relates to odor-removing, anti-bacterial, wear-resistant and flame-retardant home textile fabric with high color fastness. The home textile fabric comprises a fabric body (1), wherein an anti-radiation layer (2), an anti-static layer (4) and an upper waterproof layer (8) are arranged on the upper surface of the fabric body sequentially, and an anti-bacterial layer (5), a flame-retardant layer (6) and a lower waterproof layer (7) are arranged on the lower surface of the fabric body (1) sequentially. A lining layer is arranged on the lower surface of the lower waterproof layer, a fiber surface layer and a waterproof layer are fixed on the upper surface and the lower surface of the lining layer respectively, a flame-retardant layer formed through adhesion of flame-retardant powder is fixed on the surface of the outer side of the waterproof layer, the lining layer is formed by interweaving polyester yarn, air vents are uniformly arranged in the lining layer, the fiber surface layer is formed by interweaving warp yarn and weft yarn, and soybean fibers are woven in the warp yarn and the weft yarn. The home textile fabric is odor-removing, anti-bacterial, wear-resistant, flame-retardant, anti-radiation, waterproof and anti-static and has high color fastness.

Owner:JIANGSU HAIPENG SPECIAL VEHICLES

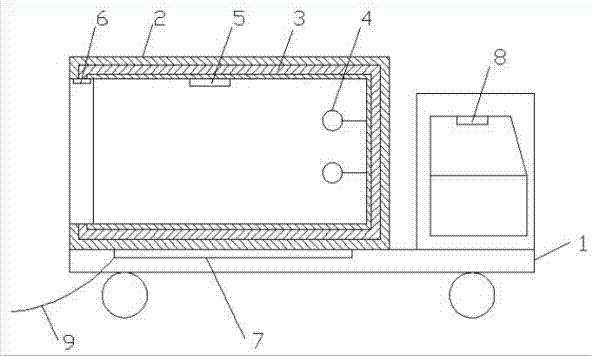

Multifunctional fireproofing express delivery vehicle

InactiveCN107009946AImprove securityImprove fire performanceItem transportation vehiclesSignalling/lighting devicesDelivery vehicleAlloy

The invention discloses a multifunctional fireproof express vehicle, which comprises a chassis and a cargo compartment, the cargo compartment is fixed above the chassis, the cargo compartment is a double-layer metal skeleton structure, the outer wall of the cargo compartment is made of cold-rolled steel plates, and the inner wall of the cargo compartment is made of aluminum alloy There is a fire-proof interlayer between the inner wall and the outer wall of the cargo compartment, and the fire-proof interlayer is filled with heat-insulating and flame-retardant materials. The front and side of the cargo compartment are equipped with fixed pull rings. Smoke alarm, the anti-theft alarm is installed above the door frame of the cargo compartment, the bottom of the cargo compartment is covered with a flame-retardant conductive static rubber sheet, and a buzzer is installed in the cab of the chassis, and the buzzer is connected with the smoke alarm and the anti-theft alarm respectively. electrical connection. The invention has high safety, good fire prevention effect, can reduce the probability of fire occurrence, and can remind delivery personnel before the fire expands, thereby greatly guaranteeing the safety of people's life and property.

Owner:TOP TRI WUXI DESIGN CONSULTANTS

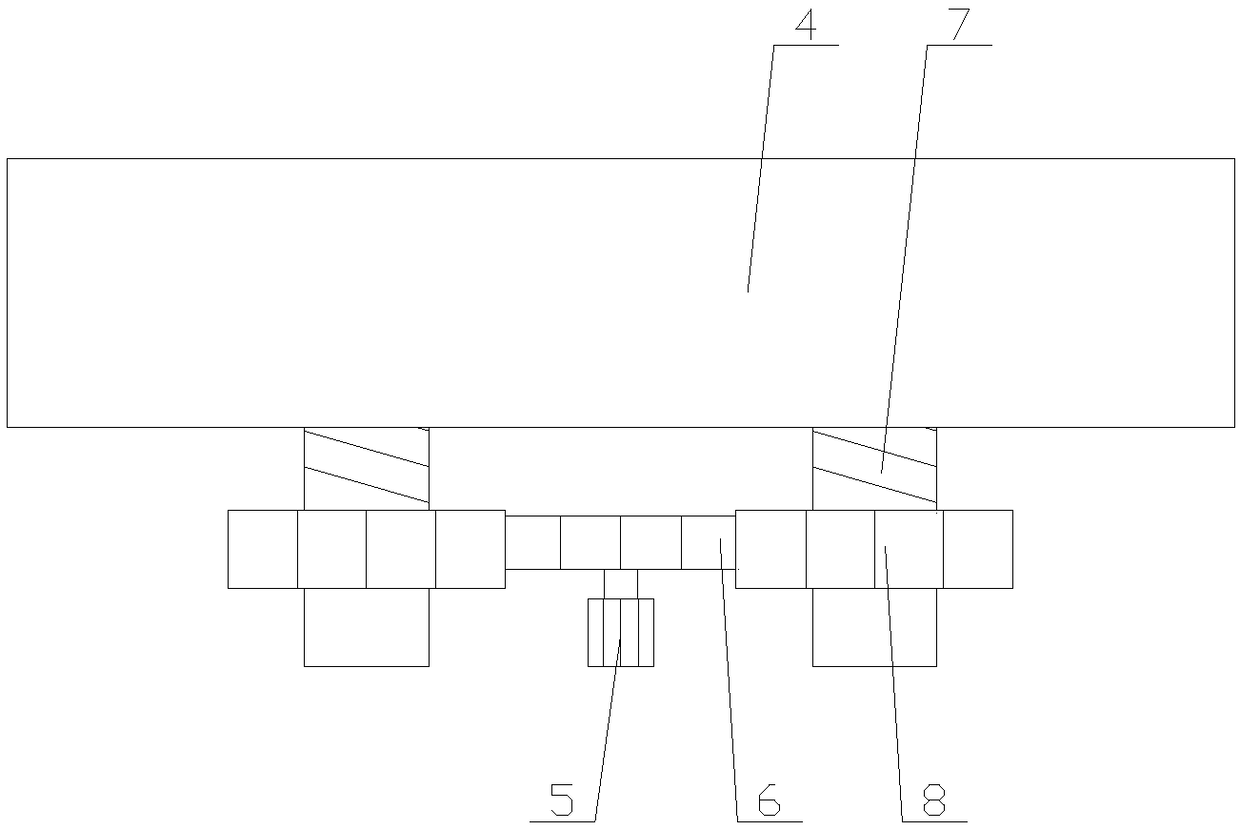

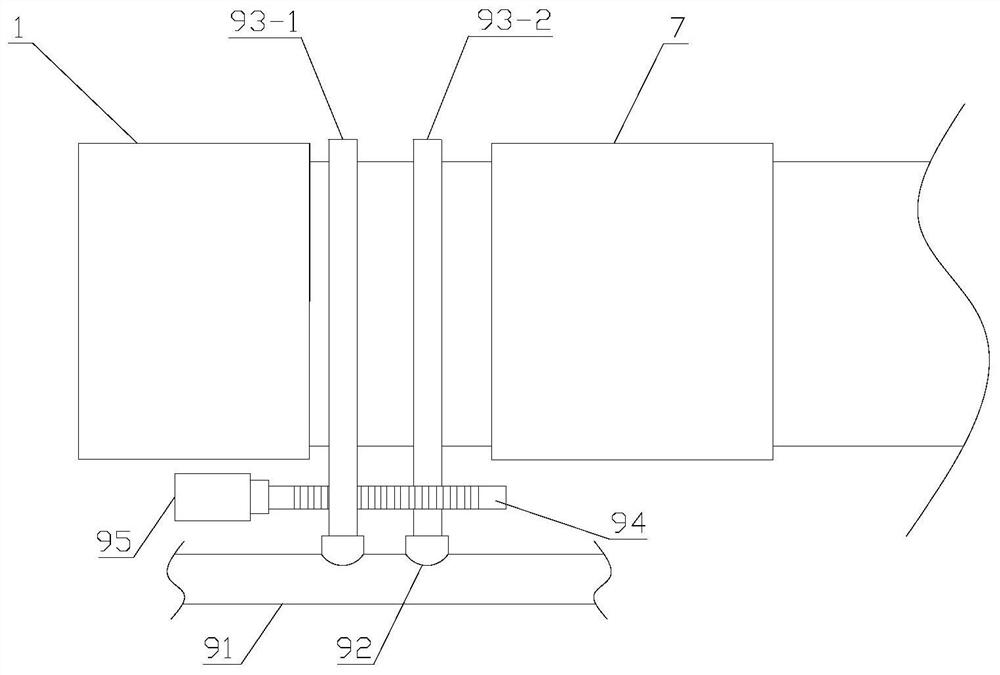

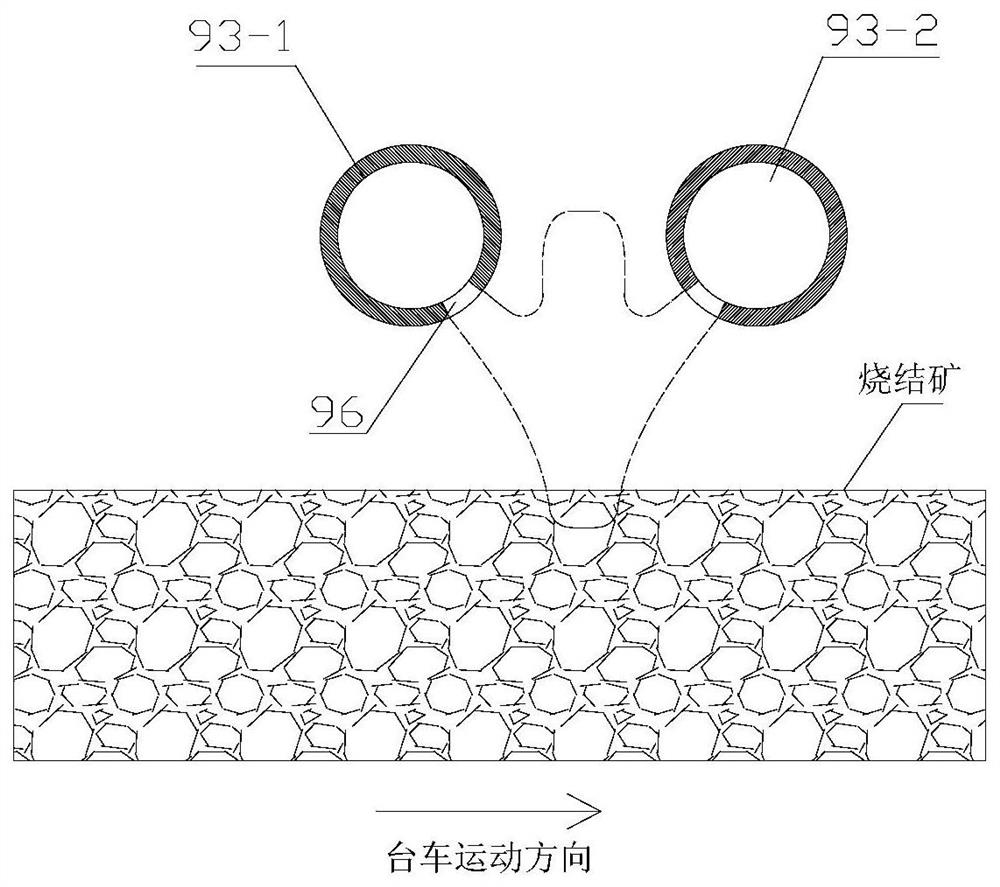

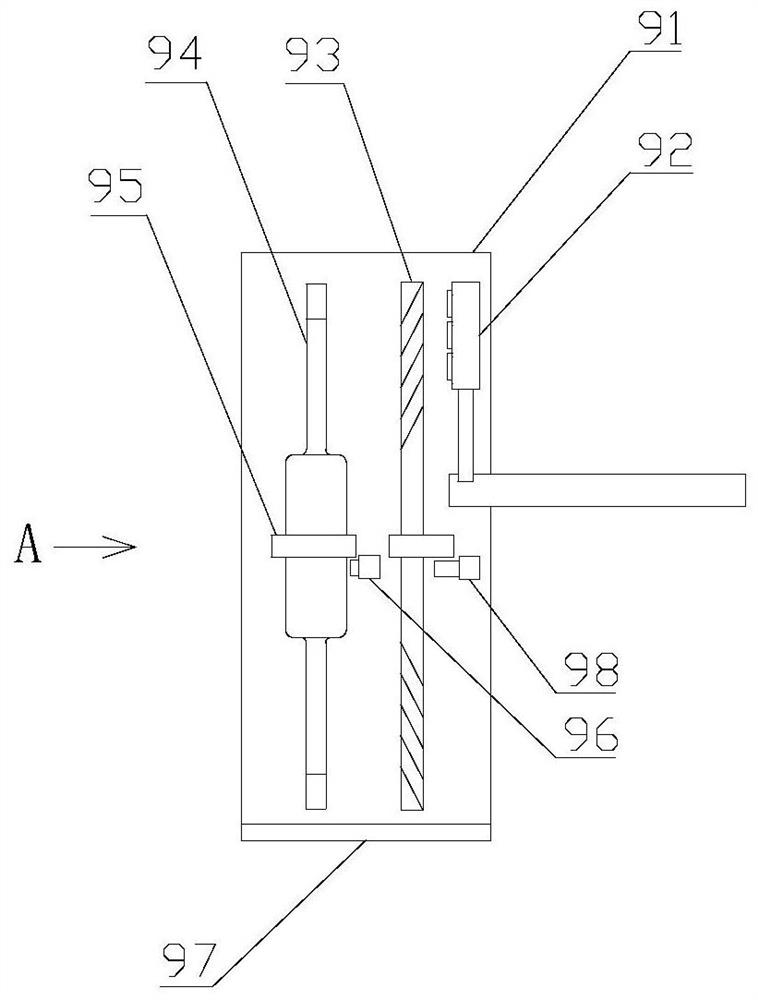

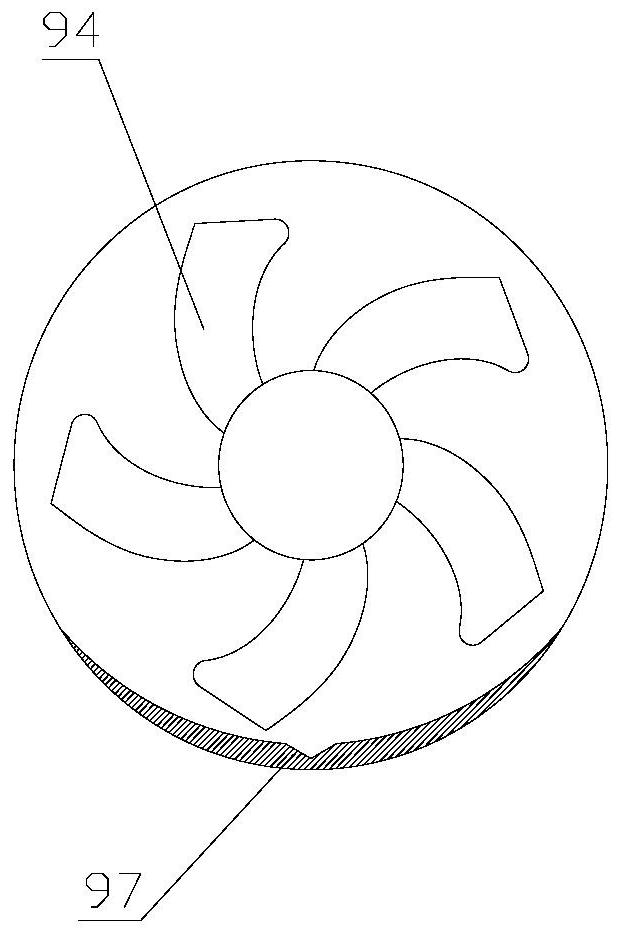

Steam cooling gas injection sintering machine and its control method

ActiveCN112393600BReduce the chance of fireEnsure safetyFurnace typesIncreasing energy efficiencyMetallurgy

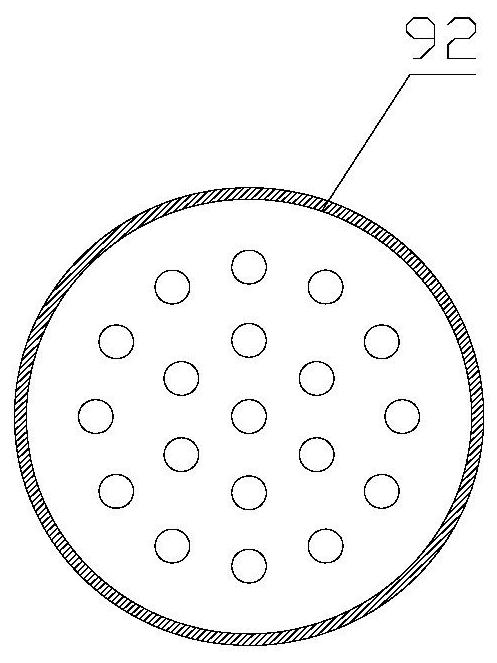

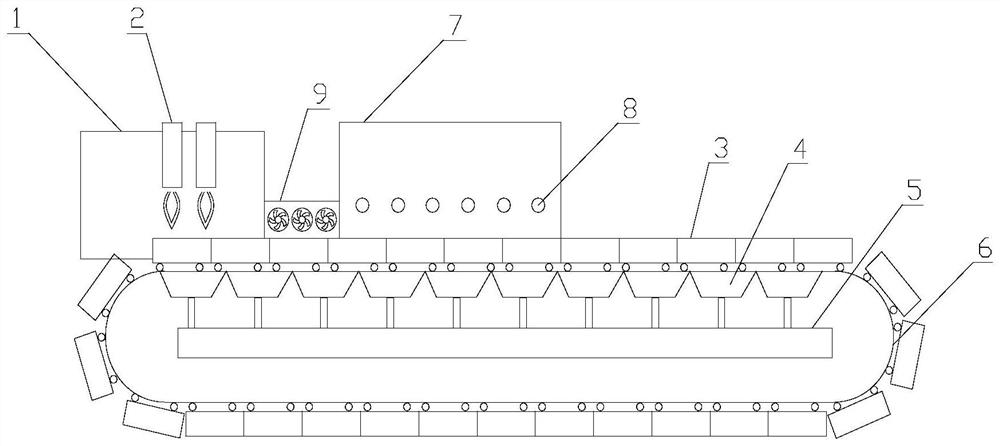

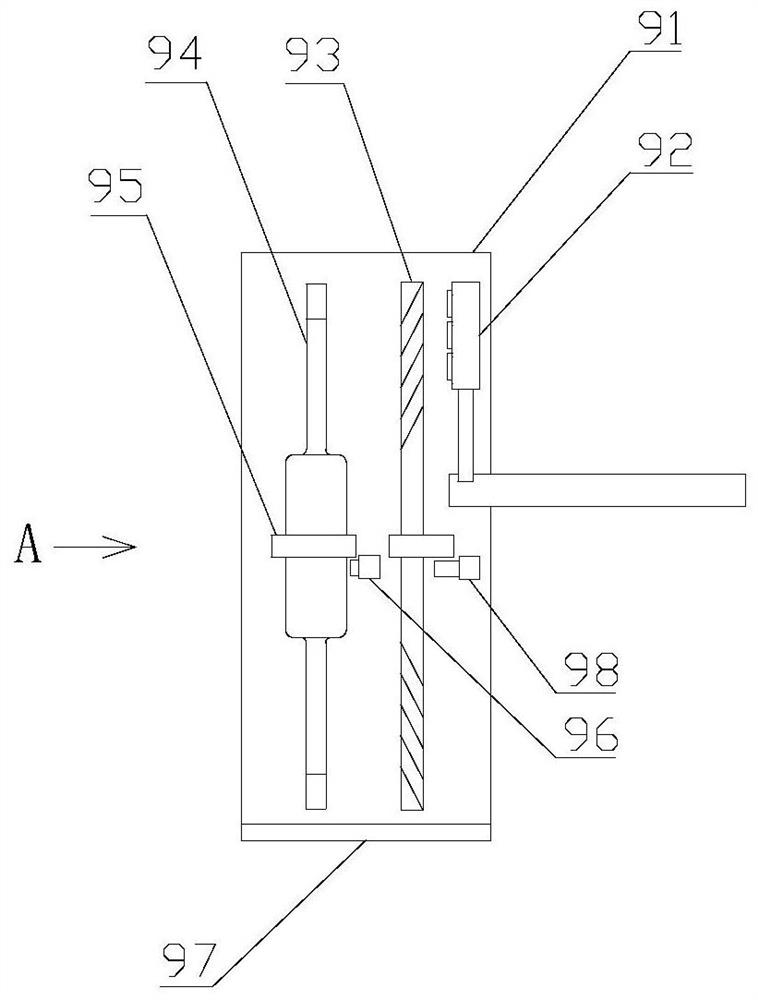

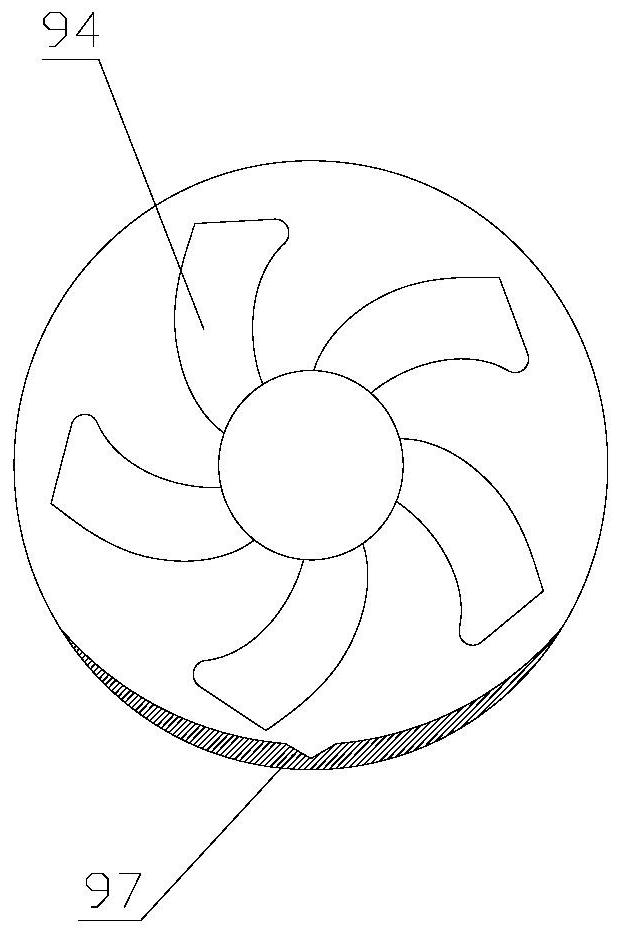

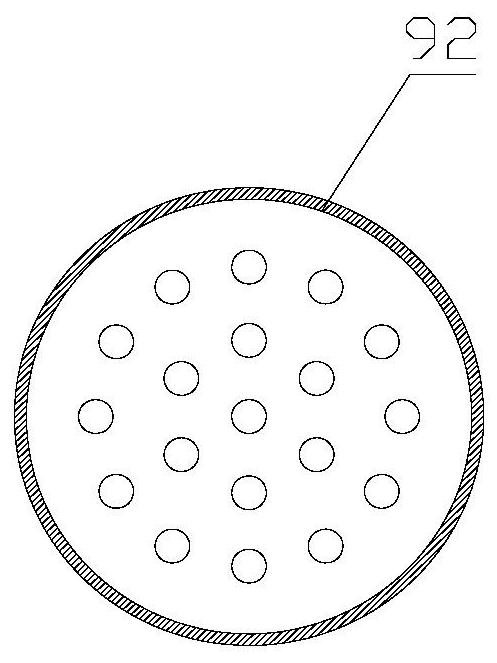

The invention discloses a steam cooling type gas injection sintering machine and a control method thereof, comprising a sintering machine track (6), a sintering machine trolley (3), an ignition device, and a gas injection device, the gas injection device Set at the gas injection position of the sintering machine to blow gas to the sintering material surface of the sintering machine trolley (3) when the sintering machine trolley (3) passes by its position; further comprising a steam cooling device (9), the steam cooling device (9) is arranged at a position between the ignition device and the gas injection device, so that when the sintering machine trolley (3) passes by its position, Steam is sprayed on the sintered material surface of the trolley (3), so that the temperature of the sintered material surface is reduced to below the ignition temperature of the gas. The sintering machine is equipped with a steam cooling device, which can effectively solve the problems of easy ignition and unstable production of the gas injection device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

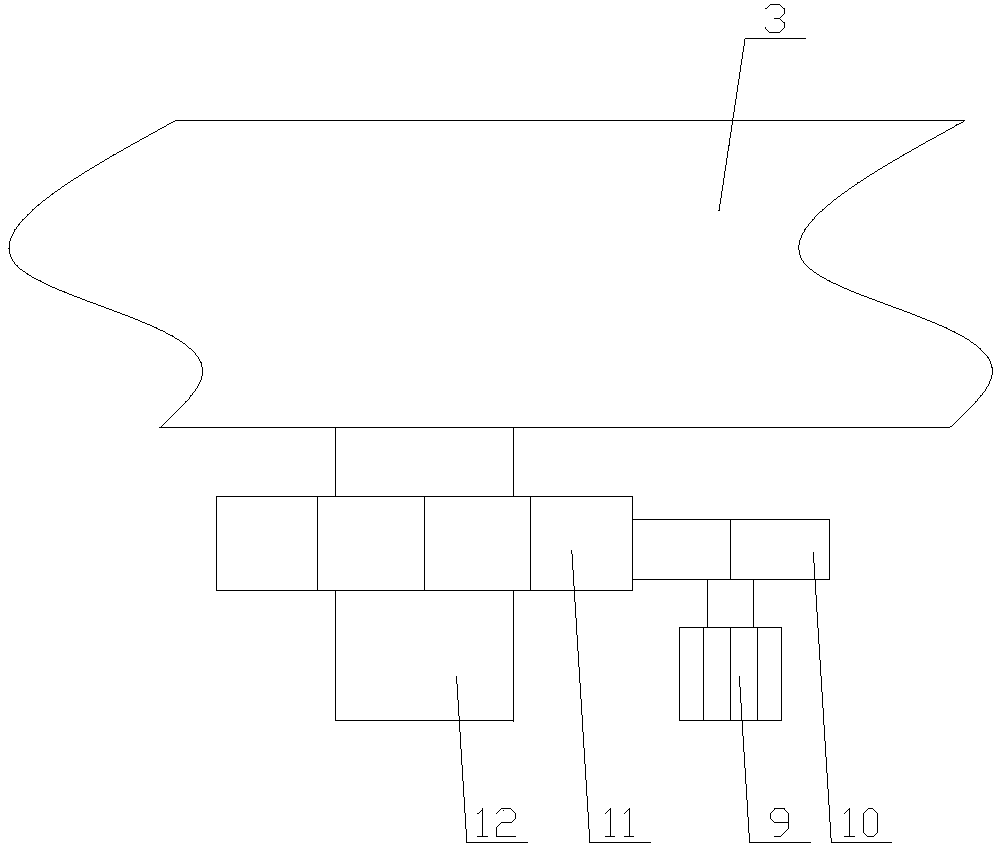

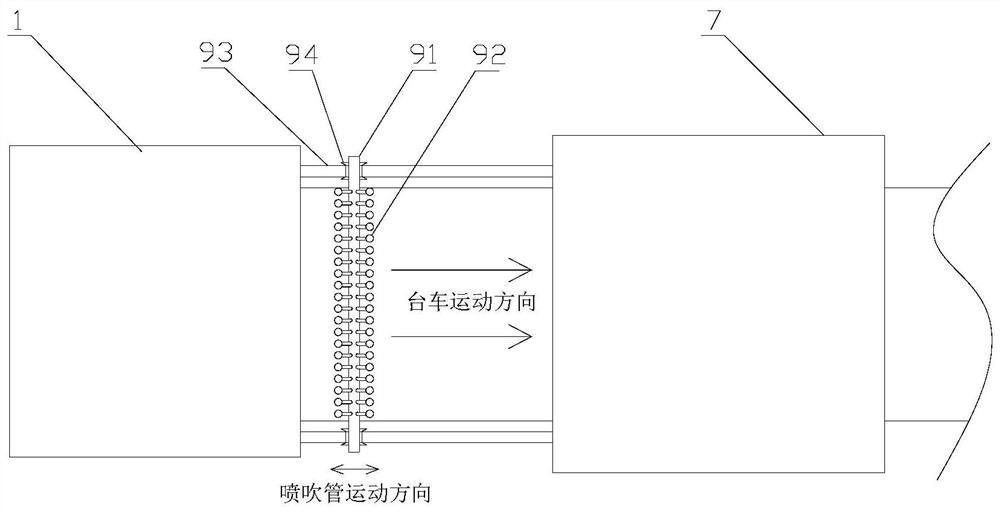

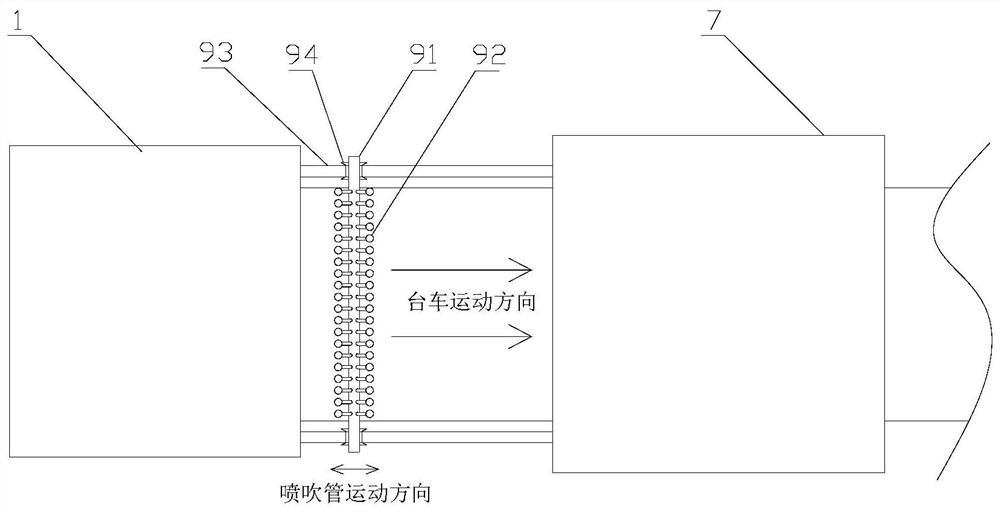

Spray cooling type fuel gas injection sintering machine and control method thereof

ActiveCN112393598AReduce the chance of fireEnsure safetyFurnace typesIncreasing energy efficiencyProcess engineeringMechanical engineering

The invention discloses a spray cooling type fuel gas injection sintering machine and a control method. The sintering machine comprises a sintering machine track, a sintering machine trolley arrangedon the sintering machine track, an ignition device located at the head of the sintering machine and a fuel gas injection device, wherein the fuel gas injection device is arranged at a fuel gas injection position of the sintering machine so as to inject fuel gas to the sintering material surface of the sintering machine trolley when the sintering machine trolley passes through the fuel gas injection device from the fuel gas injection position; and the sintering machine further comprises a spraying device, the spraying device is arranged between the ignition device and the fuel gas blowing device so that atomized water can be blown to the sintering material surface of the sintering machine trolley when the sintering machine trolley passes through the position where the sintering machine trolley is located. The sintering machine is provided with the spraying device aiming at the problems of easy ignition and unstable production of a fuel gas injection device, so that the problems can be effectively avoided.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Deodorizing disinfectant bump fluffy wool

InactiveCN107618238AFulfil requirementsSoft and comfortableSynthetic resin layered productsFiberSurface layer

The invention relates to deodorizing disinfectant bump fluffy wool. The fluffy wool includes a wool body (1), which is provided with a plurality of bumps (2), and the upper side of the bumps (2) is provided with a fluff layer. A lining layer is arranged below the wool body, and a fiber surface layer and a waterproof layer are in fixed arrangement at the upper and lower surfaces of the lining layer, wherein a flame-retardant layer made via adhesion of flame-retardant powder is in fixed arrangement at the outside surface of the waterproof layer. The lining layer is made by interweaving polyesteryarns and is internally provided with uniformly-arranged air holes. The fiber surface layer is made by interweaving warp yarns and weft yarns, both of which contain soybean fiber. The deodorizing disinfectant bump fluffy wool feels soft, is stereoscopic and fashionable, and meets the requirement of fashion clothes fabrics. The fluffy wool is deodorizing and disinfectant.

Owner:JIANGYIN QUANSHUN TEXTILE CO LTD

Wool-loop napped deodorizing and sterilizing fabric with multiple protection functions

InactiveCN105936159AFull of three-dimensional senseIncrease fashion senseGarment special featuresSynthetic resin layered productsPolyesterFiber

The invention relates to a wool-loop napped deodorizing and sterilizing fabric with multiple protection functions. The fabric comprises basic cloth (2), wool-loop fabric (1) is laminated on the front surface of the basic cloth (2); a napped layer (3) is arranged on the back surface of the basic cloth (2), and a breathable layer (4), an anti-electrostatic layer (5), and a dustproof film (6) are tightly laminated on the back surface of the napped layer (3) in sequence. A lining layer is laminated on the back surface of the dustproof film. A fiber surface layer and a waterproof layer are respectively fixed on the upper surface and lower surface of the lining layer. A flame-retardant layer, which is prepared by adhering flame-retardant powder, is fixedly arranged on the external surface of the waterproof layer. The lining layer is prepared by waving polyester filaments. The provided fabric can remove odors and kill bacteria.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Antistatic type composite flame retardant fiber and preparation method thereof

ActiveCN102108566BFunctionalImprove mechanical propertiesElectroconductive/antistatic filament manufactureFilament/thread formingFiberPolyester

The invention provides antistatic flame retardant fiber and preparation method thereof. The cross section of the fiber is a sheath-core structure; a sheath layer contains conductive powder and halogen-free flame-retardant polyamide 6; a core layer is polyester, the polyamide 6 or a polyamide 66, wherein the weight ratio of the sheath layer to the core layer is (15:85) to (25:75), and the conductive powder accounts for 5-7% of the total mass of the sheath layer. Since conductive power is added in the halogen-free flame-retardant polyamide 6, so that the fiber is endowed with the antistatic function and the flame-retardant function, particularly the electrostatic absorption of dust, caused by fiber, can be reduced because of anti-static function, and then the cleanness and favorable cleanable performance of a fiber product can be kept; and meanwhile the fiber with the sheath-core structure can still keep favorable mechanical properties and spinning property. While keeping better antistatic and flame-retardant properties and mechanical properties, the fiber reduces the production cost and improves the processing properties, thereby being more user-friendly for downstream users.

Owner:CHINESE TEXTILE ACAD

Steam cooling type fuel gas injection sintering machine and control method thereof

ActiveCN112393600AReduce the chance of fireEnsure safetyIncreasing energy efficiencyFurnace typesAutomotive engineeringProcess engineering

The invention discloses a steam cooling type fuel gas injection sintering machine and a control method thereof. The steam cooling type fuel gas injection sintering machine comprises a sintering machine rail (6), a sintering machine trolley (3), an ignition device and a fuel gas injection device, and the fuel gas injection device is arranged at a fuel gas injection position of the sintering machineso as to inject fuel gas to a sintering material surface of the sintering machine trolley (3) when the sintering machine trolley (3) passes through the fuel gas injection position; the sintering machine further comprises a steam cooling device (9), wherein the steam cooling device (9) is arranged at the position between the ignition device and the fuel gas injection device so as to blow steam tothe sintering material surface of the sintering machine trolley (3) when the sintering machine trolley (3) passes through the position where the sintering machine trolley (3) is located, so that the temperature of the sintering material surface is reduced to be lower than the fuel gas ignition temperature. The sintering machine is provided with the steam cooling device, and the problems that a fuel gas injection device is prone to catching fire, unstable in production and the like can be effectively solved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

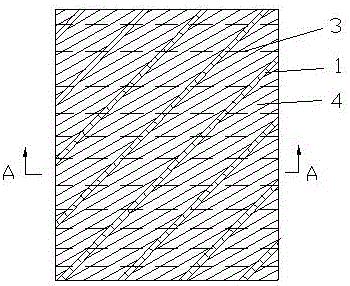

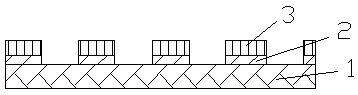

Deodorizing sterilizing artificial leather with wear-resistant pattern

InactiveCN105970651ANot easy to wearGuaranteed service lifeLayered productsWoven fabricsPolyesterFiber

The invention relates to deodorizing sterilizing artificial leather with a wear-resistant pattern, comprising a bottom base layer (1) and a top plastic layer (3) and characterized by also comprising a middle pattern layer (2), the plastic layer (3) being made with transparent plastic. A lining layer is combined to the back of the base layer, a fiber face layer and a waterproof layer are fixed respectively to upper and lower surfaces of the lining layer, a flame-retardant layer made by bonding flame-retardant powder is fixed to the outer surface of the waterproof layer, the lining layer is made by interweaving polyester yarns, air holes are evenly arranged in the lining layer, the fiber face layer is made by interweaving warps and wefts, and soybean fiber is woven in each of the warps and wefts. The artificial leather is deodorizing and sterilizing, with the pattern resistant to wear.

Owner:JIANGYIN LONGSHENG PLASTIC

Spray cooling gas injection sintering machine and its control method

ActiveCN112393598BReduce the chance of fireEnsure safetyFurnace typesIncreasing energy efficiencyProcess engineeringMechanical engineering

The invention discloses a spray cooling type gas injection sintering machine and a control method thereof. The sintering machine comprises a sintering machine rail, a sintering machine trolley arranged on the sintering machine rail, an ignition device located at the head of the sintering machine, and a gas injection blowing device, the gas injection device is set at the gas injection position of the sintering machine to blow gas to the sintering material surface of the sintering machine trolley when the sintering machine trolley passes by its position; further comprising A spraying device, the spraying device is arranged at a position between the ignition device and the gas injection device, so as to spray the sintered material surface of the sintering machine trolley when the sintering machine trolley passes by its position Blow atomized water. The sintering machine is equipped with a spray device for the problems of easy ignition and unstable production existing in the gas injection device, which can effectively avoid the above problems.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Deodorization and sterilization three-dimensional tweed

InactiveCN106182960AAdd dimensionFulfil requirementsSynthetic resin layered productsClothingsFiberPolyester

The invention relates to a deodorizing and sterilizing three-dimensional tweed. Including the woolen body (1), there are several protrusions (2) and bubbles (3) on the woolen body, the protrusions (2) are strip-shaped, and the bubbles (3) are superimposed on the protrusions (2) above. The back of the woolen body is provided with a lining layer. The upper and lower surfaces of the lining layer are respectively fixed with a fiber surface layer and a waterproof layer. The outer surface of the waterproof layer is fixed with a flame-retardant layer made of flame-retardant powder. The lining layer is made of polyester The lining layer is evenly arranged with ventilation holes, and the fiber surface layer is made of warp yarns and weft yarns, and soybean fibers are woven in the warp yarns and weft yarns. Ribs and bubbles add dimension to the tweed. The present invention deodorizes and sterilizes.

Owner:JIANGYIN DUJUAN BEADED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com