Patents

Literature

68results about How to "Strong touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand wallpaper and preparation method thereof

ActiveCN104452476APromote sheddingStrong adhesionCovering/liningsSpecial paperPolymer scienceAcrylic resin

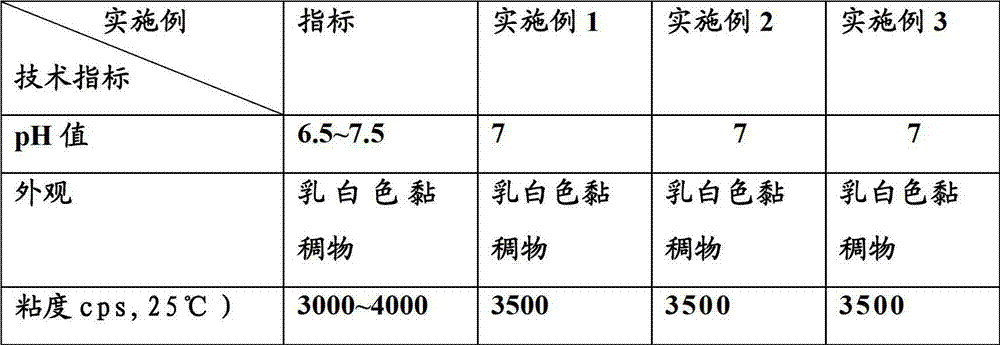

The invention relates to the technical field of wallpapers, and particularly relates to sand wallpaper and a preparation method thereof. The sand wallpaper comprises a base material layer, a printing layer and a sand layer, which are sequentially arranged, wherein the sand layer is prepared from the following raw materials in parts by weight: 100 parts of modified acrylic resin emulsion, 40-100 parts of a packing composition, 0.5-5 parts of an adhesion auxiliary and 0.1-3 parts of a thickening agent; and the packing composition is prepared from packing A, packing B and packing C at the ratio in parts by weight of (4-100) to (2-5) to 1. The sand wallpaper is simple in process, and has a distinct stereoscopic vision, a strong sense of touch, and a good three-dimensional effect.

Owner:GUANGDONG YULAN GRP

Special polyurethane resin for bright oily synthetic leather and preparation method of special polyurethane resin

ActiveCN104672740AImprove color and visual effectGood colorTextiles and paperPolyesterPolymer science

The invention relates to the technical field of leather finishing agent production, in particular to special polyurethane resin for bright oily synthetic leather and a preparation method of the special polyurethane resin. The polyurethane resin comprises components in percentage by weight as follows: 8%-20% of polyester polyol, 15%-20% of isocyanate, 2%-5% of micromolecular dihydric alcohol with the molecular weight lower than 150, 1%-5% of a chain extension modifier, 1%-5% of an acrylic acid end-capping reagent, 60%-69% of a solvent and 1%-3% of auxiliaries, wherein the auxiliaries comprise 0.1%-1% of an antioxidant, 0.05%-0.1% of a catalyst, 0.1%-1% of a high-temperature-resistant auxiliary and 0.1%-2% of a nano-powder auxiliary, and the sum of the antioxidant, the catalyst, the high-temperature-resistant auxiliary and the nano-powder auxiliary is in a range from 1% to 3%. The polyurethane resin is utilized to process a surface of a coating formed on the surface of the synthetic leather, oily gloss and brightness is strong, the hand feeling is dry and comfortable, and the problem that the polyurethane resin in the current market touches sticky especially when hands sweat in summer is solved.

Owner:JIANDE BAISHA CHEM

Aqueous decorative ink for glass printing and preparation method thereof

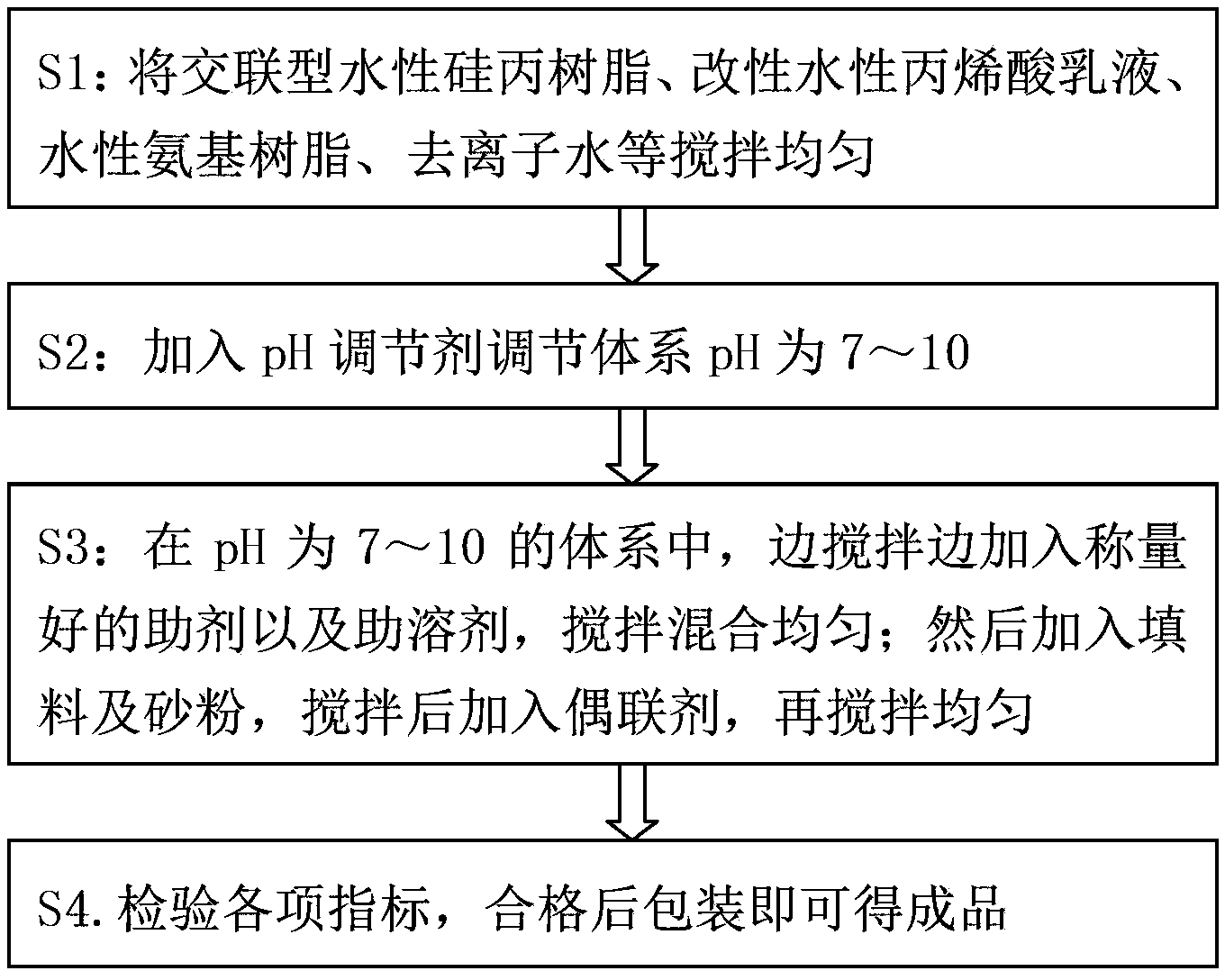

The invention provides an aqueous decorative ink for glass printing. The ink contains the following components by weight: 25%-50% of crosslinking aqueous silicone acrylate resin, 5%-15% of a modified aqueous acrylic emulsion, 10%-20% of aqueous amino resin, 5-20% of deionized water, 1%-5% of a coupling agent, 0-15% of a cosolvent, 10%-20% of a sand powder, 1-15% of a filler, 0.2%-15% of an additive and 2%-10% of a curing agent. The invention also provides a preparation method of the aqueous decorative ink for glass printing. The aqueous decorative ink for glass printing prepared through the above formula and the preparation method is subjected to heat treatment and gains good adhesion on flat toughened glass surface and good water resistance; and the coating forms a convex surface, has strong touch feeling and excellent decorative effect, also has the characteristics of environmental protection, low odor and no VOC residue, and does not cause environmental pollution or harm to the safety of operator.

Owner:王景泉

Water-borne silk-screen suede printing ink and preparation method thereof

The invention provides water-borne silk-screen suede printing ink and a preparation method thereof. The printing ink is prepared by mixing and uniformly mixing the following materials in percentage by weight (based on the total weight of the materials): 80%-83.5% of water-borne polyurethane, 2%-4% of water-borne adhesion promoting resin, 0.2%-0.3% of water-borne defoamer, 6%-8.5% of dipropylene glycol methyl ether, 1%-2% of thickener, 1.5%-2.5% of flatting agent, 5%-6% of elastic touch powder, and 0.5%-0.7% of wax powder. The water-borne silk-screen suede printing ink provided by the invention does not need V-lamp drying, and has the advantages of being more fine and smooth, strong in touch, high in thickness, outstanding in soft feeling, and the like, in comparison with the existing silk-screen printing ink such as dull-polish silk-screen printing ink, snowflake silk-screen printing ink, and the like.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

High-performance wallpaper

ActiveCN106671556AImprove mechanical propertiesGood tensile loadCovering/liningsLamination ancillary operationsTear resistanceMoisture resistance

The invention discloses a preparation method of high-performance wallpaper. The preparation method of the high-performance wallpaper comprises the steps of preparing mixed wood powder, modifying the mixed wood powder, preparing stone powder, preparing a mixed material, preparing a blank, preparing a surface material and adhering the surface material to PVC artificial leather. The wallpaper is prepared by preparing a blending material from the modified wood powder, the stone powder and polyurethane glue, cutting the blending material into soft slices and adhering the soft slices to the prepared PVC artificial leather, so the tensile strength and the tear resistance of the wallpaper are greatly improved, and the prepared wallpaper has remarkable heat-insulating and sound-insulating effects, high stain resistance, excellent printing property and high moisture resistance.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Wallpaper with hand-painting effect and manufacturing process of wallpaper

InactiveCN103483910AAvoid color distortionWith the effect of hand paintingCovering/liningsInksWater basedAcrylic resin

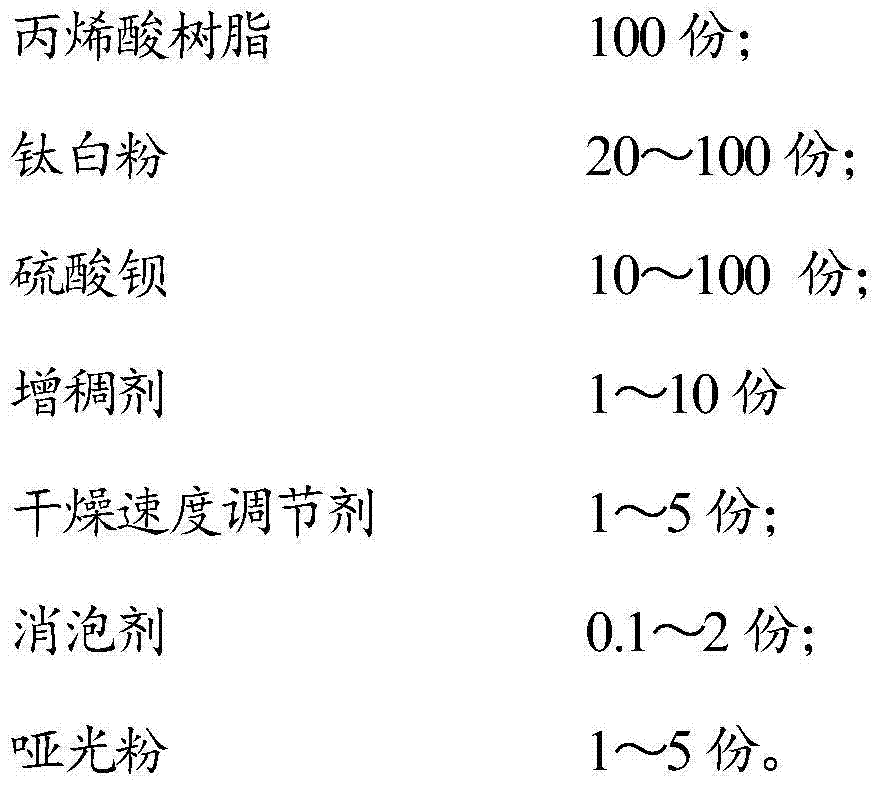

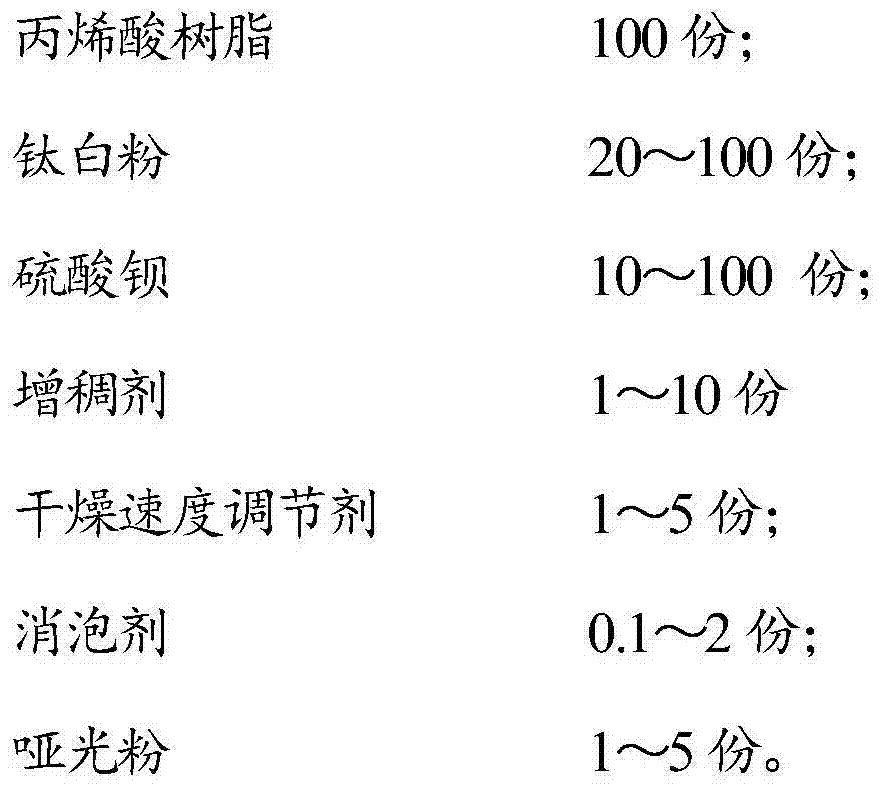

The invention discloses wallpaper with a hand-painting effect. The wallpaper comprises a bottom layer, an underpainting layer and a pattern layer, wherein the underpainting layer is formed on the bottom layer; the pattern layer is formed on the underpainting layer and formed by printing ink; and the printing ink is formed by adding organic coloring pigments to water-base resin, and the water-base resin comprises components in parts by weight as follows: 100 parts of acrylic resin, 20-100 parts of titanium dioxide, 10-100 parts of barium sulfate, 1-10 parts of a thickening agent, 1-5 parts of a drying rate conditioning agent, 0.1-2 parts of a defoaming agent and 1-5 parts of matte powder. According to the wallpaper, the printing ink used in the pattern layer is formed by adding the organic coloring pigments into the water-base resin, and the water-base resin is prepared with from proper raw materials, so that when the pattern layer is formed by the printing ink, pattern color distortion caused by secondary color and composite color problems during printing can be avoided, partial pattern surfaces are smooth and fine, the wallpaper is vividly and has the hand-painting effect, patterns can be formed through industrial production such as printing, the production efficiency is high, and the labor cost is low.

Owner:GUANGDONG YULAN GRP

Buffing burnt-feeling water-based Yangbuck foaming resin and preparation method thereof

The invention relates to a buffing burnt-feeling water-based Yangbuck foaming resin and a preparation method thereof. The water-based Yangbuck foaming resin comprises following raw material formula in part by weight: 48-52 parts of water-based acrylic resin, 43-47 parts of water, 0.5-2 parts of water-based foam killer, 2-4 parts of Yangbuck powder, 5-7 parts of water-based thickening agent, 2-4 parts of water-based rubbing-burnt paraffin powder, 2-4 parts of water-based leveling agent, 0-1 parts of disinfectant and 3-5 parts of organic bentonite. The water-based Yangbuck foaming resin provided by the invention is provided with very good scrape-resistance property, and can form strong hairy feeling by surface buffing; and at the same time the water-based Yangbuck foaming resin is also provided with strong burnt feeling and very delicate hand feeling, and the emulational effect of the leather is very good.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

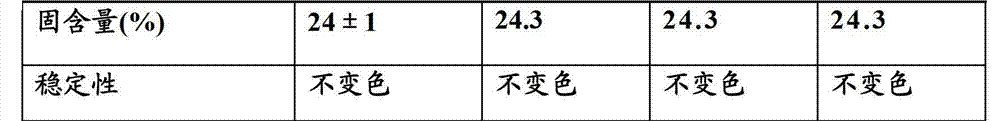

Manufacturing method of steering wheel cover as well as special mold thereof and steering wheel cover

The invention discloses a manufacturing method of a steering wheel cover, wherein the manufacturing method comprises the steps of: a. preparing raw materials; step b. putting dried raw materials into a material inlet box of an injection molding machine; step c. heating an injection molding heating system to the temperature of 180-210 DEG C, then melting the raw materials, operating the injection molding machine, and carrying out butt jointing on a mouth hole of the injection molding machine and a glue inlet hole of a molded cavity of the mold; step d. injecting the melted raw materials into the molded cavity of a steering wheel protection cover, and cooling and molding after to-be-melted materials fill up the molded cavity of the steering wheel cover; and step e. taking out a product after being molded, thus the product is manufactured, wherein the raw materials and the composition proportion of the step a are as follows: 55% of polyester polyol, 25% of water-base resin, and 20% of 1, 4-dyhydroxy hydroxy butane. The invention also discloses the steering wheel cover and a special mold thereof. The steering wheel cover provided by the invention has the advantages of good environment-friendly effect, safety, beauty and elegance, dirt prevention, easiness in cleaning, convenience in installation, comfort handfeel, high touch sense, and the like.

Owner:DONGGUAN YONGSHENG HARDWARE PLASTIC PRODS

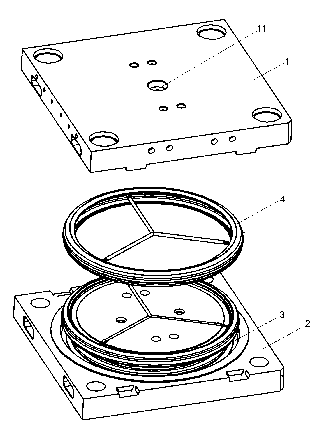

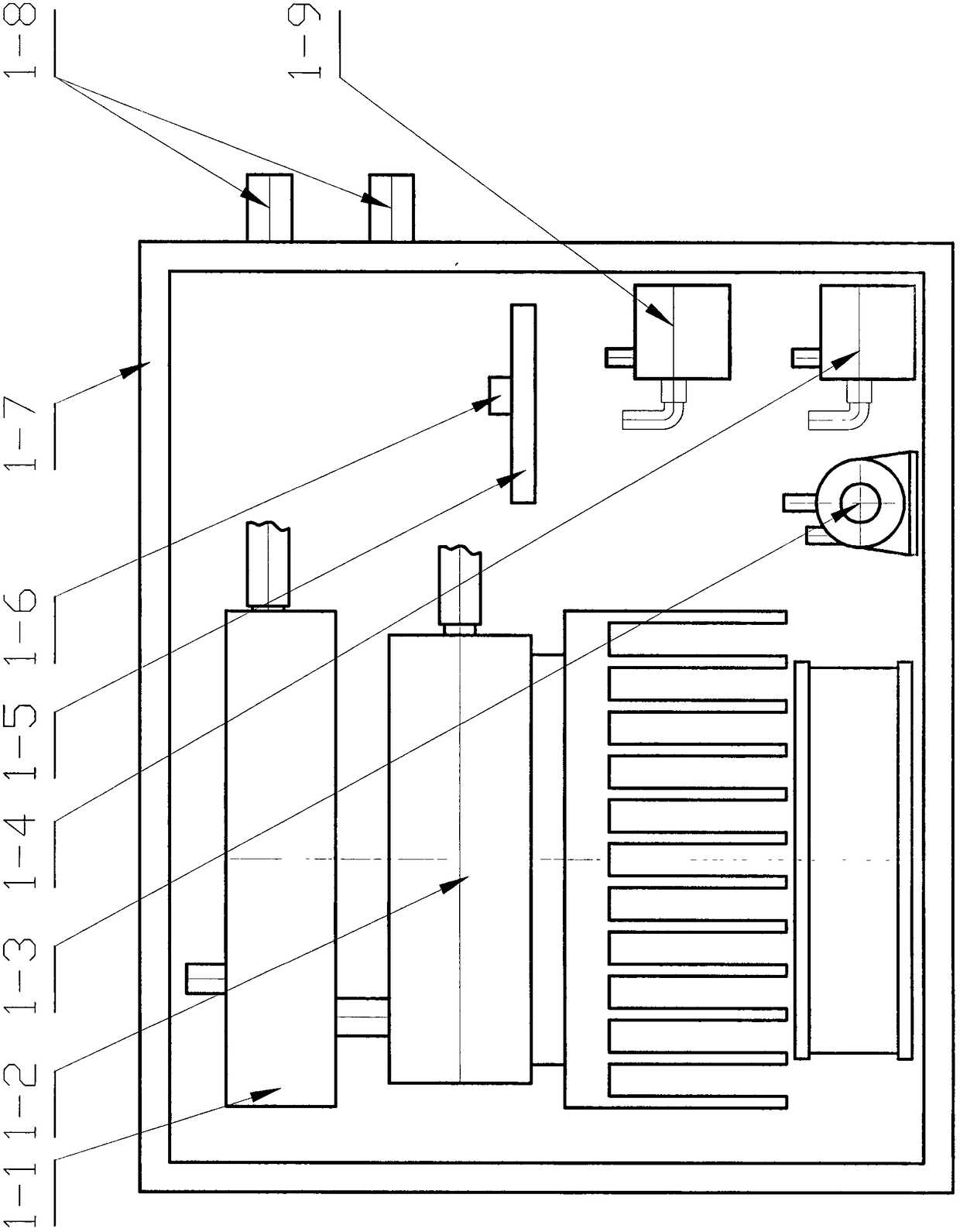

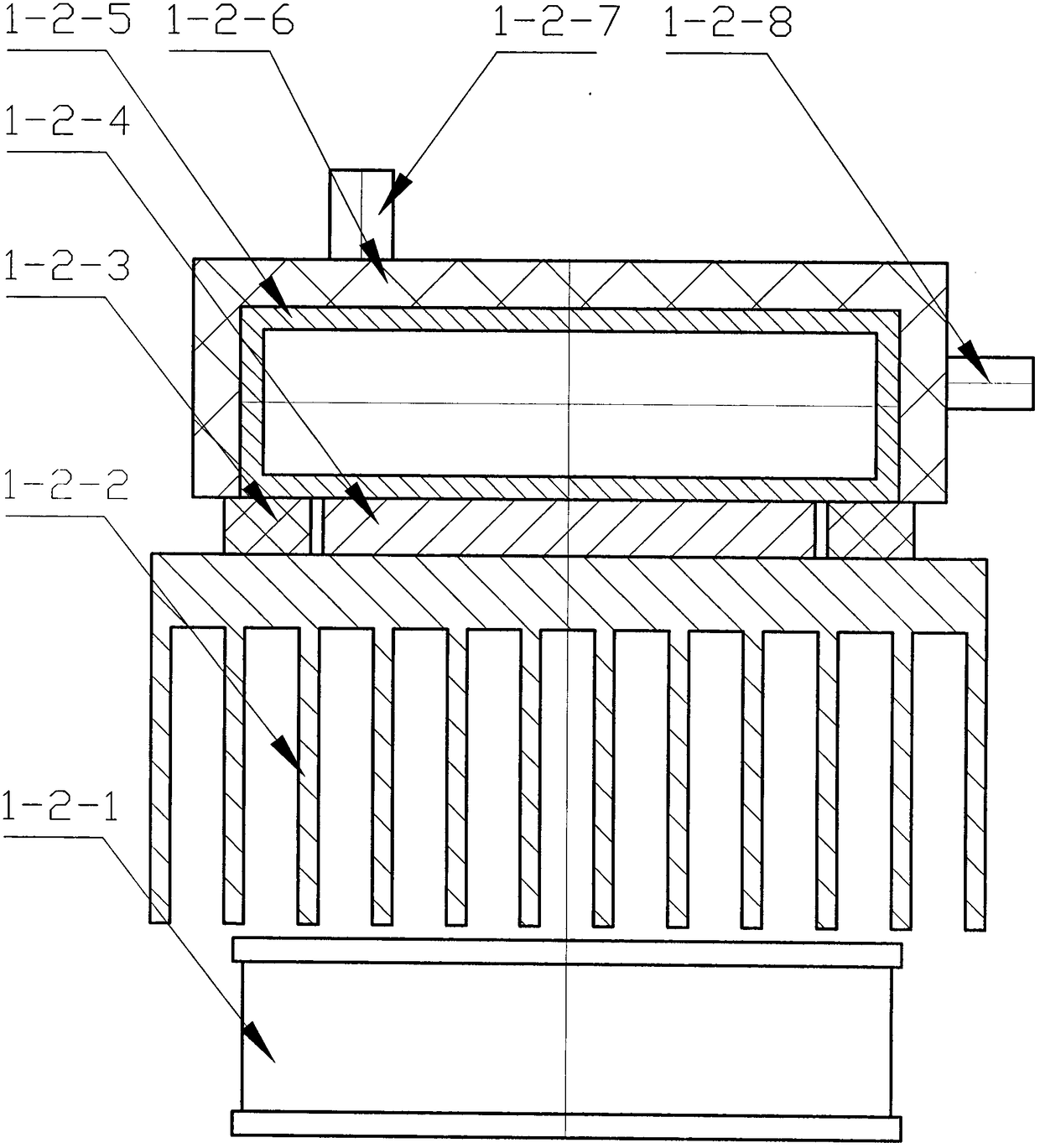

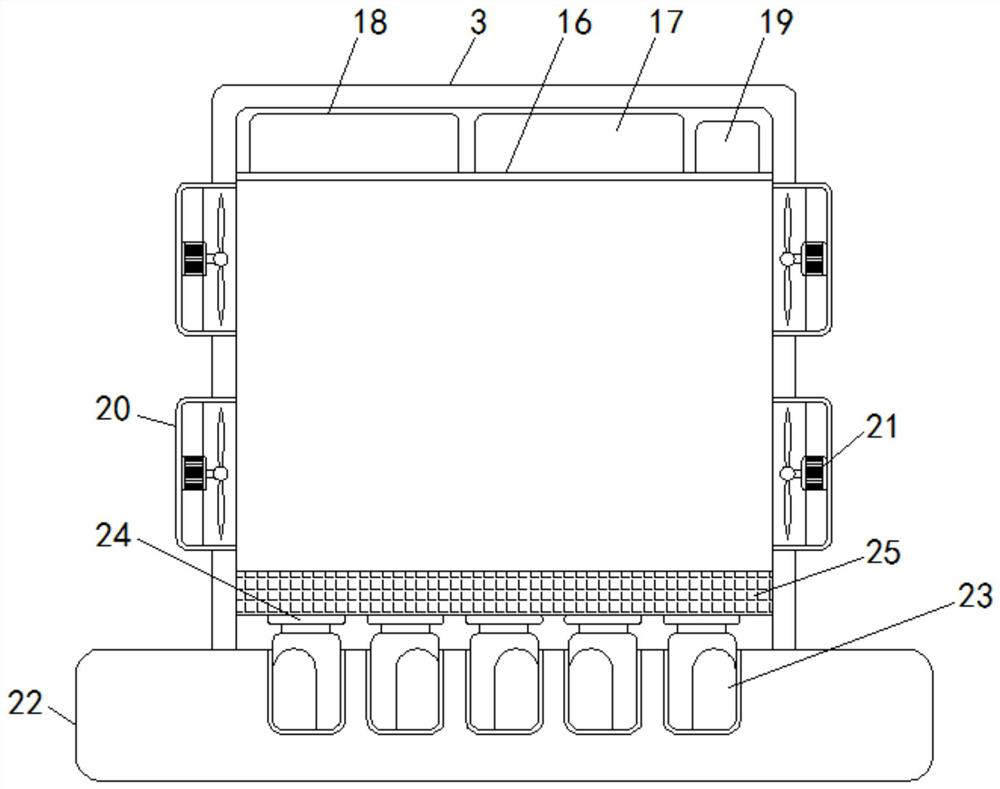

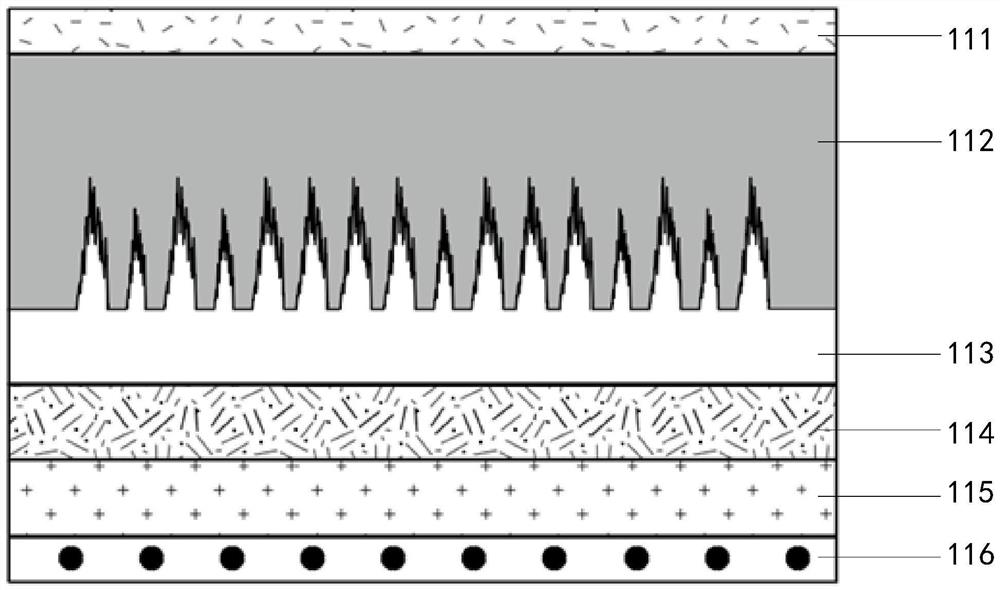

Cold and hot compress instrument for massaging by circulating pulsed water flow

PendingCN108992238APromote circulationAvoid unsightly defects that are exposedTherapeutic coolingHydraulic massageTemperature controlWater flow

The invention relates to a cold and hot compress instrument for massaging by circulating pulsed water flow. The cold and hot compress instrument is composed of a mobile host, a water bag, a water bagcover and water inlet and outlet pipes. The mobile host is composed of a refrigeration and heating assembly, a water tank, a water pump, a pulsed electromagnetic valve, a control circuit board and aninfrared receiver and the like. The circulating water is enabled to form the pulsed water flow by the pulsed electromagnetic valve. The water bag is internally provided with a plurality of longitudinal and transverse wave-shaped circulating channels, and the pulsed water flow waves are enabled to be formed on the surface of the water bag under the action of the pulsed electromagnetic valve for massaging the cold and hot compress parts of the human body. The water bag cover is composed of soft and hard plastic bodies, a temperature sensing head, a temperature control circuit board, an infraredemitter, a display screen and keys, etc. The temperature sensing head is used for detecting the surface temperature of the water bag. The cold and hot compress physical therapy effect is enabled to better by circulating pulsed water massaging. Meanwhile, the temperature measuring point is arranged at the cold and hot compress parts so as to make the cold and hot compress physical therapy more scientific. In addition, the cold and hot compress instrument is small and more convenient, universal and cost-effective.

Owner:深圳市倍力健科技有限公司 +1

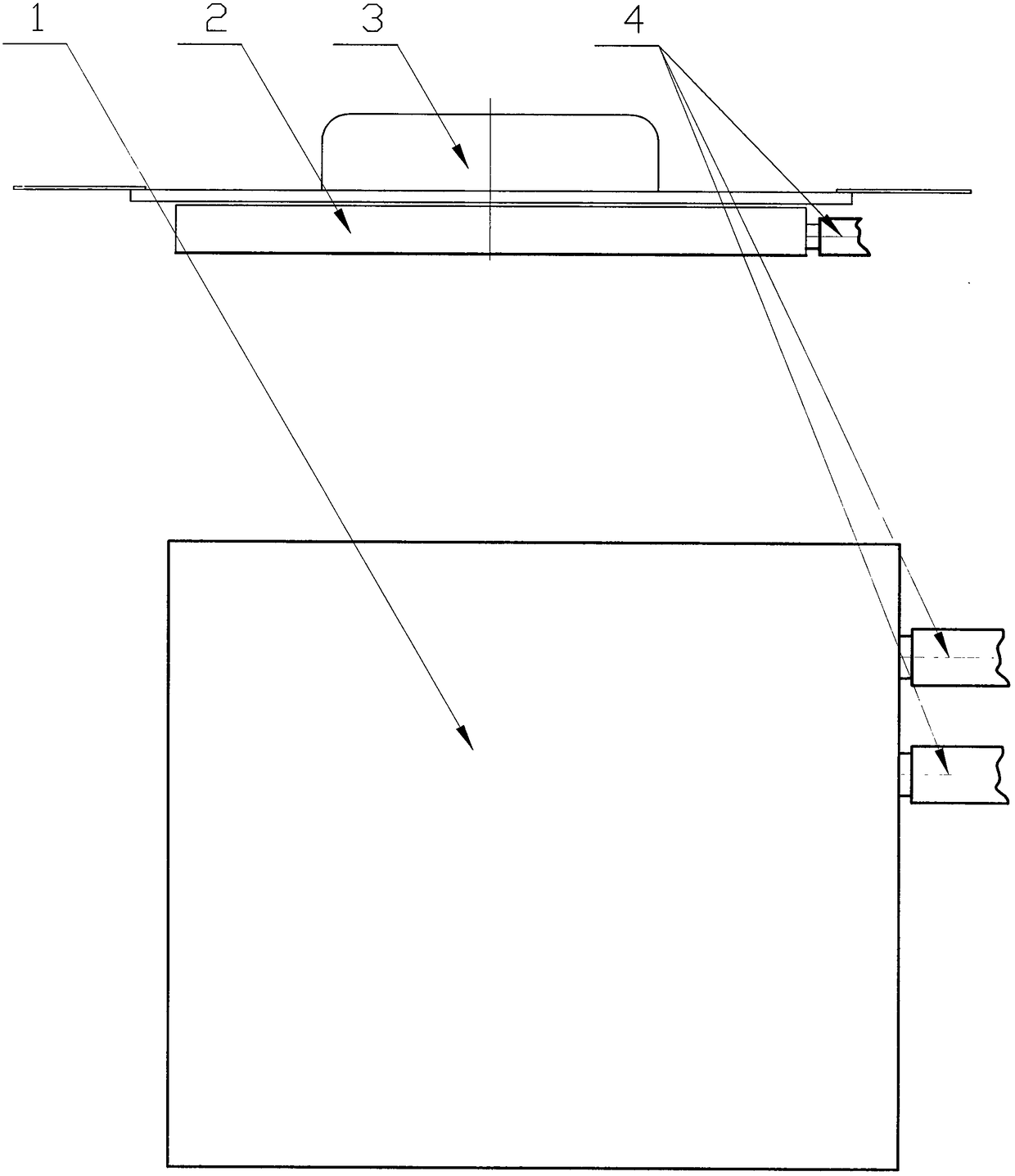

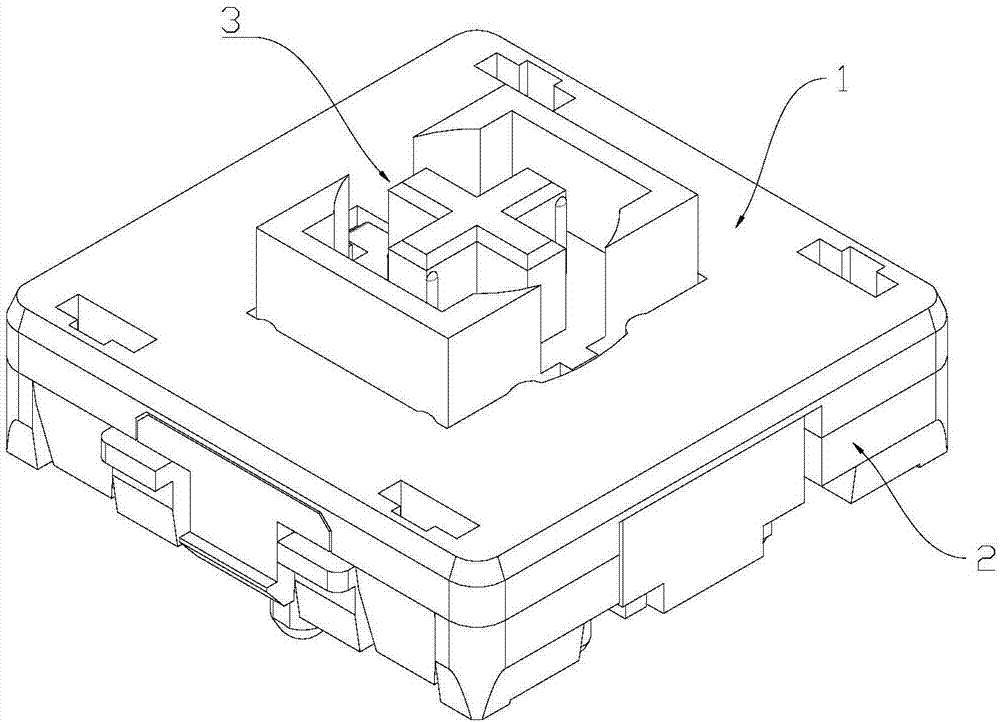

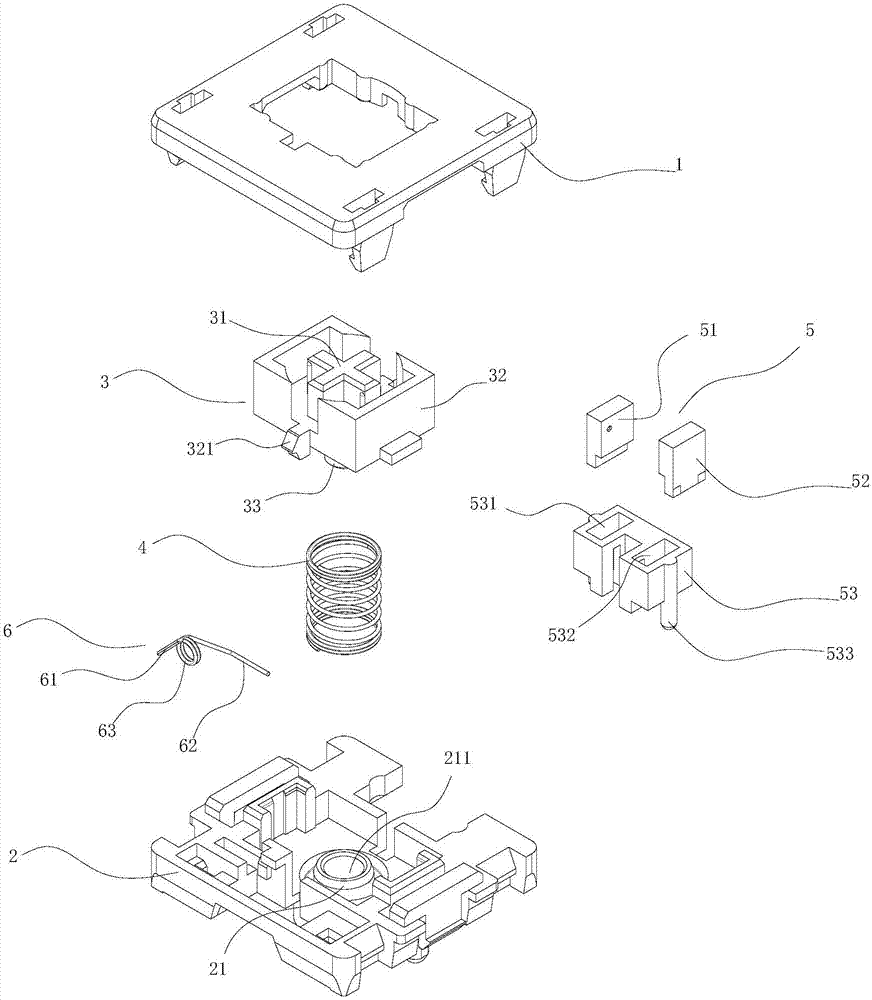

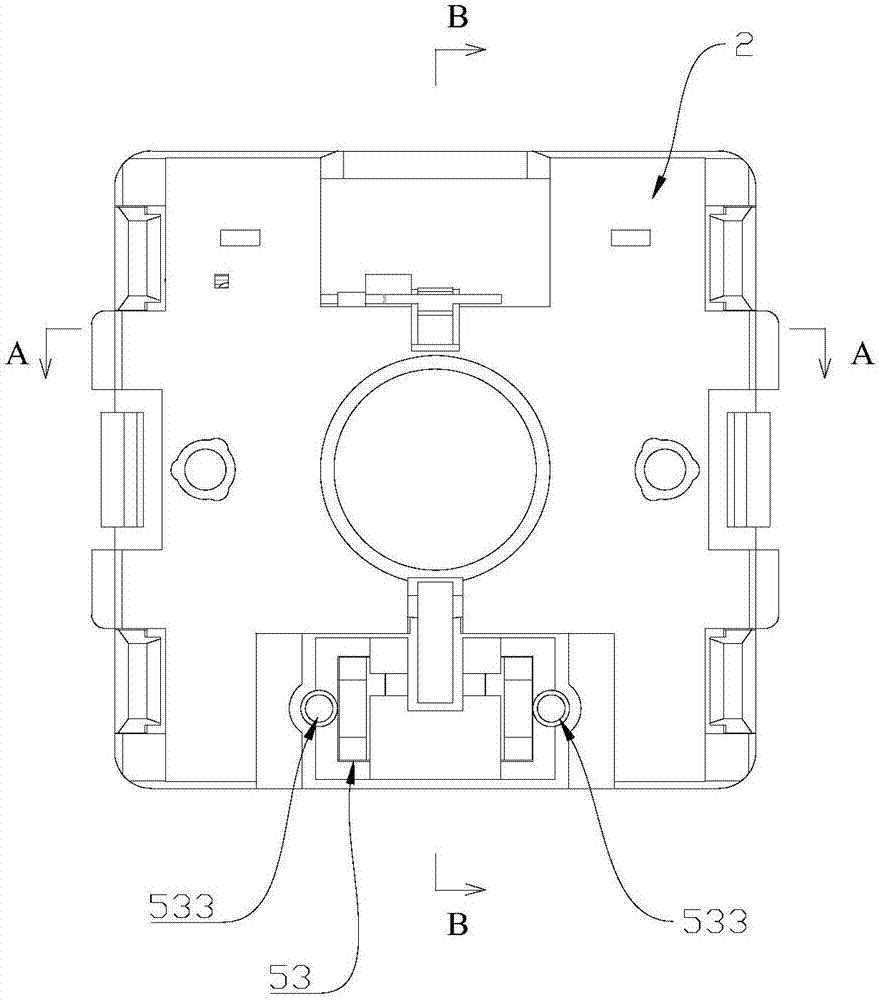

Photoelectric thin shaft mechanical keyboard switch

ActiveCN107424857AStrong touchStrong sense of paragraphElectric switchesTactile feedbackKey pressingEngineering

The invention provides a photoelectric thin shaft mechanical keyboard switch, and relates to the photoelectric keyboard switch technology field. The technical problem of the photoelectric keyboard of poor paragraph feeling during pressing of a button is solved. The photoelectric thin shaft mechanical keyboard switch comprises a cover plate, a base, a button, a reset spring, and a photoelectric coupler. The photoelectric thin shaft mechanical keyboard switch also comprises a torsional spring, which comprises a fixing arm, a barrier arm, and a spiral segment. The fixing arm is fixedly disposed on the base, and the end part of the barrier arm is disposed in the sliding path of the button, and the paragraph feeling is realized by the button sliding upwards and downwards to be contacted with the barrier arm. When a human finger presses the button downwards, the button moves downwards, and during the above mentioned process, the torsional spring is used to provide upward resistance for the button, and then when the pressure applied by the finger on the button disappears, under common springback action of the reset spring and the torsional spring, the button moves upwards quickly, and is reset, and therefore when the button moves upwards and downwards, the touch feeling of the finger is strong, and the paragraph feeling is obvious.

Owner:DONGGUAN GAOTE ELECTRONICS

Manufacturing method of suede leather polyurethane synthetic leather with high?physical properties

The invention discloses a manufacturing method of a suede leather polyurethane synthetic leather with high?physical properties. The manufacturing method includes preparation of a semi-finished product of the synthetic leather, sanding treatment and napping treatment. The preparation of semi-finished product of the synthetic leather is carried out by coating a polyurethane foaming slurry on a base cloth, and then drying by an oven. The sanding treatment is carried out by first conducting surface grinding on the semi-finished product of the synthetic leather subjected to the foaming process by a multi-roll grinding wheel, and adjusting the amount of grinding by selecting sandpaper and rotation speed of the grinding wheel. The napping treatment is carried out by conducting napping on the suede leather sanding subjected to sanding treatment by using a carbon fiber napping roller. The manufacturing method of the suede leather polyurethane synthetic leather with high?physical properties provided by the invention is simple; and coating treatment is carried out directly on the base cloth to reduce the operations of a traditional wet process, so as to substantially increase the production efficiency and effectively reduce material and energy consumption cost.

Owner:ANHUI ANLI MATERIAL TECH

Printing processing technology for decorative surface

ActiveCN103231593AImprove clarityHigh resolutionOther printing apparatusImage resolutionProduct base

The invention discloses a printing processing technology, particularly discloses a printing processing technology for a decorative surface and belongs to the technical field of manufacture of household electrical appliances. High-definition, high-resolution and textured decorative patterns can be produced on product base materials by means of the printing processing technology for the decorative surface. The printing processing technology comprises the steps of manufacturing templates with the same number as corresponding colors according to a CMYK four-color mixing principle, then using rollers to roll inks corresponding to the colors into grooves of the templates, using printing rubber heads to dip the inks in the grooves of the templates and print the ink on the decorative surfaces of cleaned products required to be printed, and finally curing the inks in a roasting mode or other modes. When a plurality of colors are required, printing of all of colors can be finished only by repeating the printing steps and curing step.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Indoor lightless flat sand-textured powder coating having skin tactility and specially used for IT products

The invention discloses an indoor lightless flat sand-textured powder coating having skin tactility and specially used for IT products. The powder coating comprises carboxyl polyester resin, epoxy resin, an acrylic flatting agent, a leveling agent, benzoin, a brightener, a special toughening agent, wear-resistant wax, a catalyst, extinction barium sulfate, calcium carbonate and carbon black. The flat sand-textured powder coating having skin tactility is prepared by matching the carboxyl polyester resin, the acrylic flatting agent and the special toughening agent, shows an extremely fine sand texture state and a strong sand feeling under a naked eye viewing condition, but has a flat tactility and strong soft skin tactility, so the powder coating is suitable for being applied to IT electronic information products and indoor furniture products, and the soft skin tactility of the powder coating is close to the fit degree, the comfort and the softness of human skins; and the powder coatingalso has excellent mechanical properties and excellent scratch resistance under a low gloss condition, and is functional new functional having the advantage of convenience in material drawing, convenience in preparation and low cost.

Owner:广东华彩粉末科技有限公司

Frosted velvet fabric and preparing process thereof

The invention discloses a frosted velvet fabric and a preparing process thereof. The frosted velvet fabric comprises a fabric body, the fabric body is woven by a warp knitting machine to form gray fabric, a bottom comb adopts 2428 semi-gloss FDY polyester yarn 45D / 24F head lines per width, a middle comb adopts 2428 semi-gloss FDY polyester yarn 45D / 24F head lines per width, and a surface comb adopts 2420 full dull FDY polyester yarn 75D / 36F head lines, and joint weaving is carried out to form the frosted velvet fabric. The frosted velvet fabric is dense in velvet feeling, strong in touch feeling and almost free of reversible velvets, and the problem that a velvet sofa generates touch traces due to the reversible velvets is solved.

Owner:桐乡市顺兴经纬编有限公司

Production process for large-particle granite imitated ceramic tile with strong touch effect

The invention relates to a production process of imitating large-grain granite tiles with a strong tactile effect, including the conventional processes of powder making, granulation, pressing brick adobe, drying and kiln firing, and is characterized in that it is used in the pulping process of the powder making process Most critically, the percentage by weight of the specific slurry required for the milling process is: 15-25% of quartz powder, 30-35% of clay, 40-55% of high-temperature sand, 0.2-0.3% of water glass, and water reducing agent 0.2 to 0.25%, sodium tripolyphosphate 0.05 to 0.1%, the ingredients are made by ball milling with ball stone: ingredients: water ratio of 2:1:0.55, using the characteristics of high temperature resistance of quartz powder to produce a surface with strong The large-grain tiles with tactile effect have the advantages of high quality, low cost and high profit, and have obvious effects and value on improving the grade of the product.

Owner:江西省石湾环球陶瓷有限公司

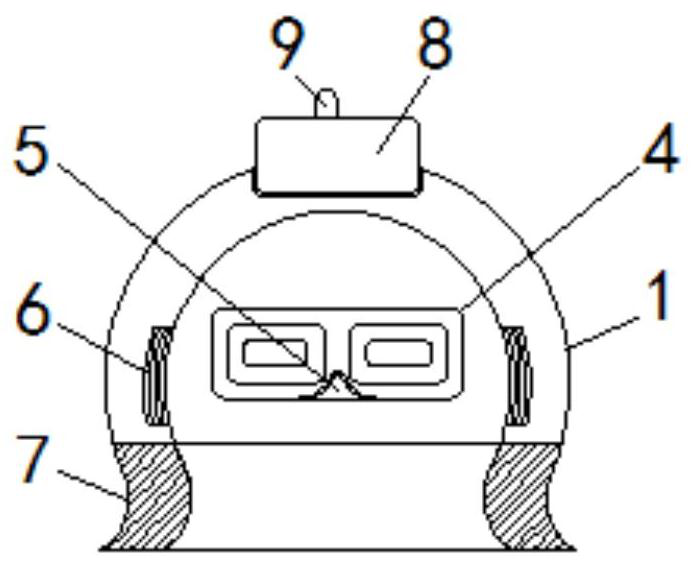

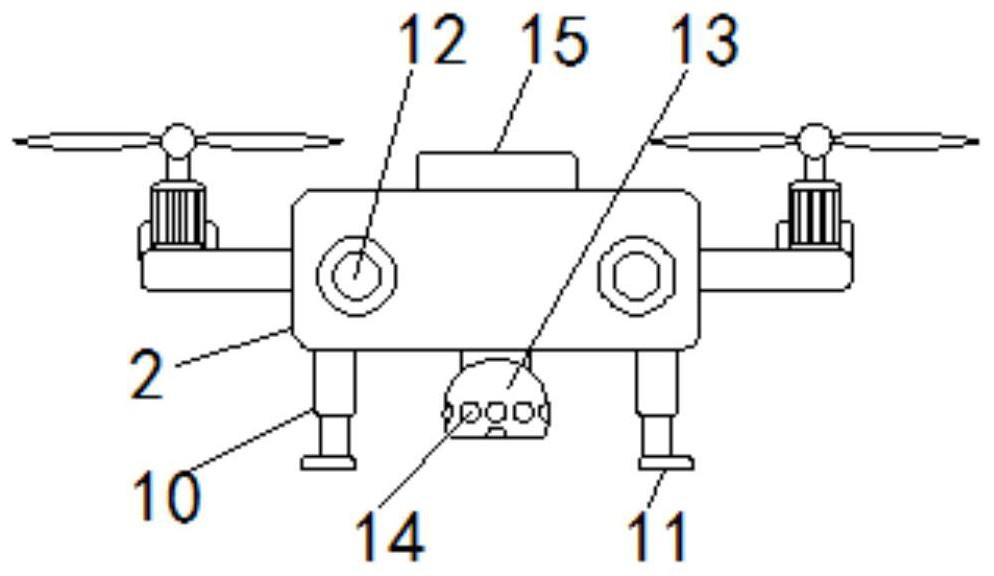

VR panoramic video shooting interactive experience device

InactiveCN111787304AMeet visual needsStrong noveltySteroscopic systemsOptical elementsPhysical medicine and rehabilitationComputer graphics (images)

The invention relates to the technical field of VR videos, and discloses a VR panoramic video shooting interactive experience device, which comprises a VR helmet, a VR shooting unmanned aerial vehicleand a VR experience room, wherein VR glasses are fixedly installed on the inner wall of the front surface of the VR helmet, and a nose protection support is fixedly installed on the bottom wall of the VR glasses. The invention discloses a VR panoramic video shooting interactive experience device. A user wears the VR helmet to carry out VR experience in the VR experience room. A mimicry fan on theside of the VR experience room and a mimicry lifting rod at the bottom of the VR experience room can be intelligently regulated and controlled through a central processing unit in the video automaticsynthesis device; the mimicry fan and the mimicry lifting rod simulate a real shooting scene; a user has a strong visual impact feeling, the body of the user has a strong touch feeling and a strong somatosensory feeling, the user truly has an immersive feeling, and the experience feeling of the user is effectively enhanced. Thus, the VR panoramic video shooting interactive experience device is put forward.

Owner:南昌市一境信息技术有限公司

Environment-friendly temperature-variable interior wall paint, and preparation method thereof

InactiveCN109929436AHigh strengthImprove hydrophobicityFireproof paintsThermosensitive paintsSolventUltimate tensile strength

The invention discloses an environment-friendly temperature-variable interior wall paint, and a preparation method thereof. The environment-friendly temperature-variable interior wall paint comprises,by weight, 40 to 50 parts of a matrix, 20 to 40 parts of a solvent, 1 to 10 parts of a thermochromic powder, 3 to 6 parts of a flame retardant, 3 to 6 parts of a lubricant, and 5 to 10 parts of a dispersing aid. The environment-friendly temperature-variable interior wall paint is prepared through four following steps: preparation of a thermochromic powder dispersion, matrix pre-curing, wet coating preparation, and wet coating curing. Compared with the prior art, the advantages are that the environment-friendly temperature-variable interior wall paint possesses strong light sensitivity, the lubricant capable of improving touch feel is added, so that excellent touch feel comfortability is achieved; excellent strength and hydrophobicity are achieved; the environment-friendly temperature-variable interior wall paint is no-toxic, is safe, is friendly to the environment, and is a novel functional paint with both the advantages of temperature variable paint and common paint; and no pollutionis caused.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

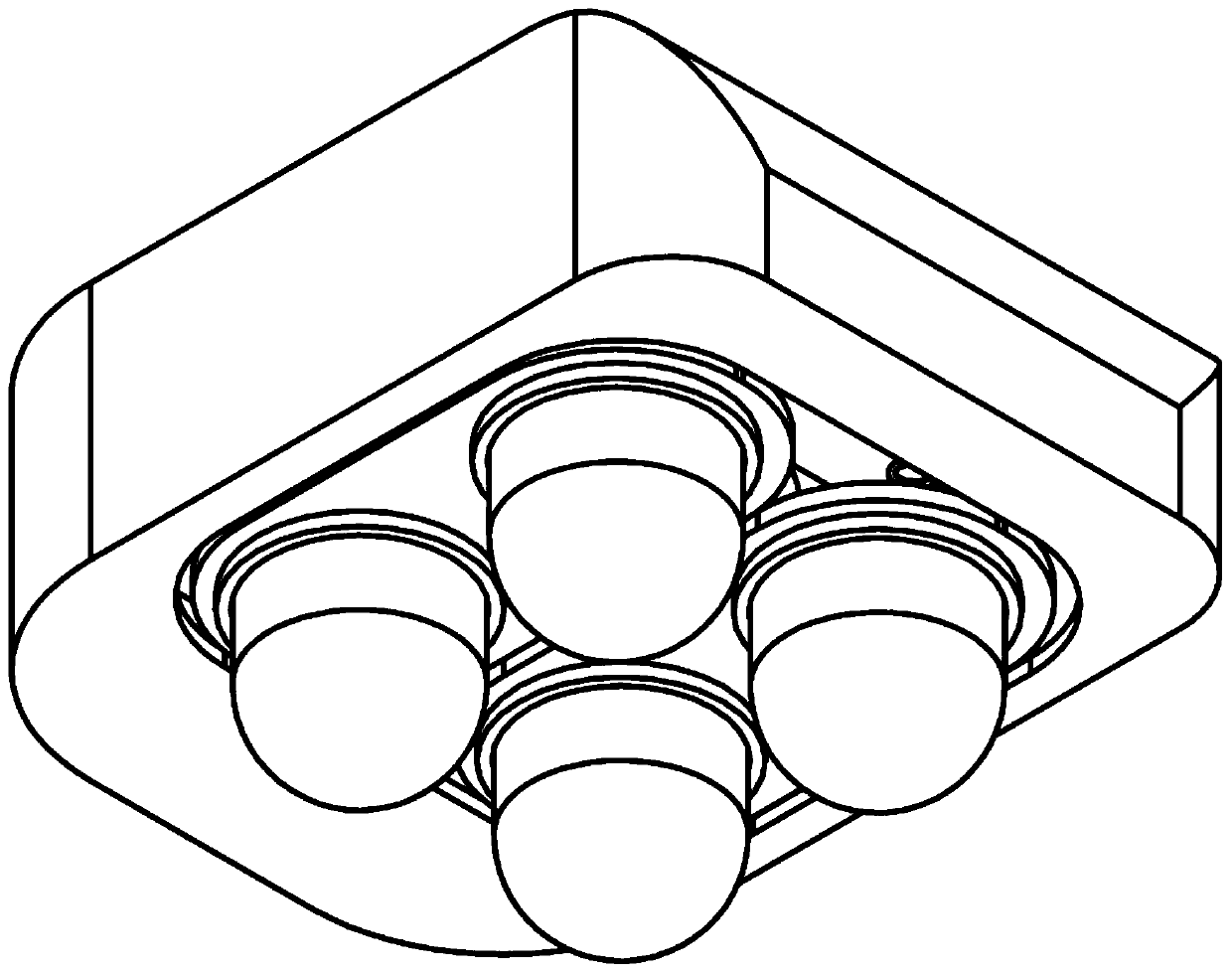

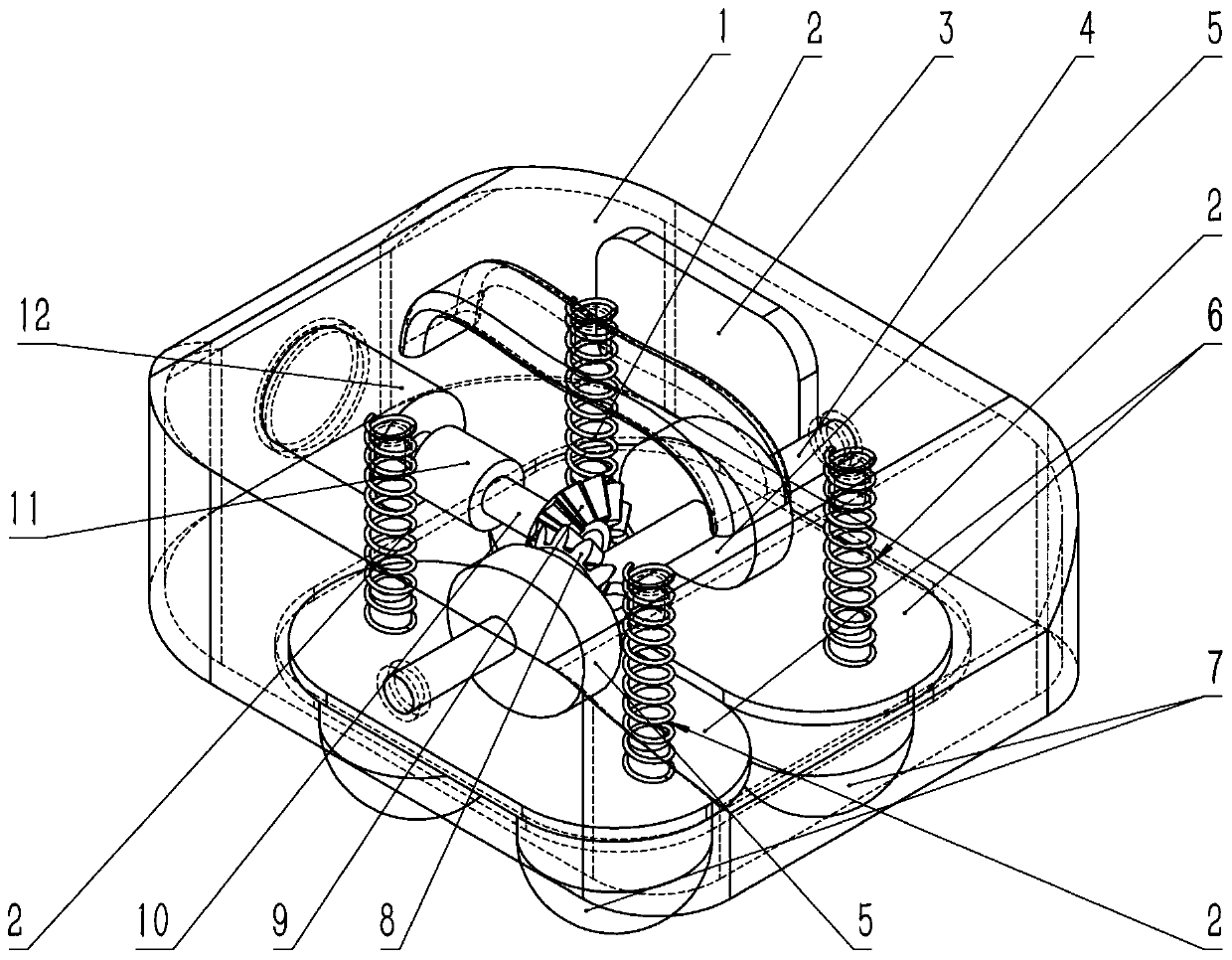

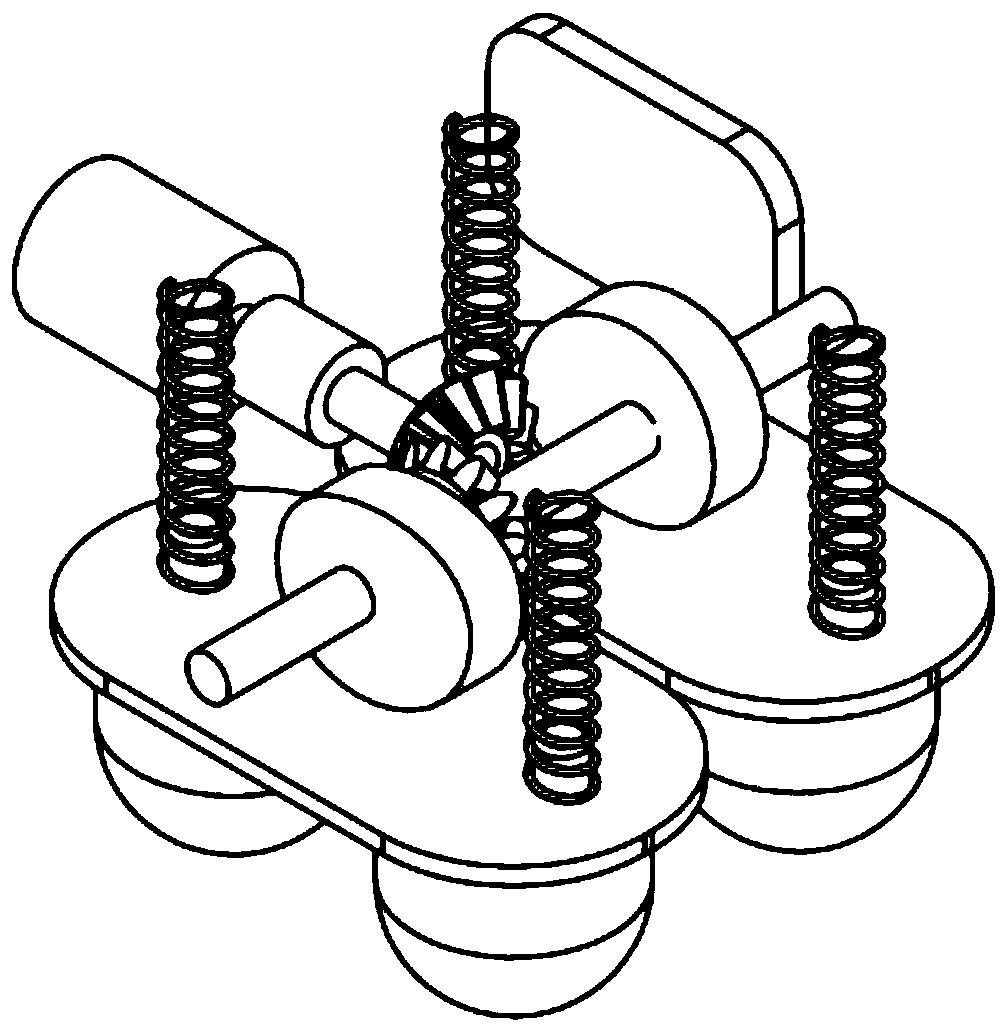

Convenient bionic massage instrument structure

The invention provides a convenient bionic massage instrument structure, which comprises an outer shell, return springs, a camshaft, cams, massage head base seats, massage heads, a driven gear, a driving gear, a gear shaft, a coupling and a motor which are arranged inside the outer shell, wherein the motor drives the driving gear through the coupling and the gear shaft, the driving gear drives thedriven gear to rotate in a vertical plane, the driven gear sleeves the camshaft, the driven gear drives the camshaft to rotate, and the cams sleeve the camshaft to rotate together with the camshaft;and one end of the return springs are connected with the outer shell, the other end of the return springs are connected with the massage head base seats, the cams contact with the massage head base seats, the cams rotate to drive the massage head base seats to move, the massage heads are connected with the massage head base seats, the massage heads move along with the massage head base seats, andthe return springs enable the massage head base seats to smoothly reset after reaching a lowest point. By using a brand-new transmission mode, the noise and vibration are obviously improved, and the active use experience of users is improved.

Owner:深圳市康瑞普斯医疗器械有限公司

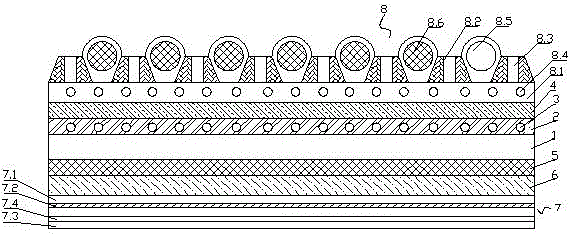

Good-handle waterproof fabric

InactiveCN105965969AThree-dimensionalAntibacterialWoven fabricsMetal layered productsActivated carbonEngineering

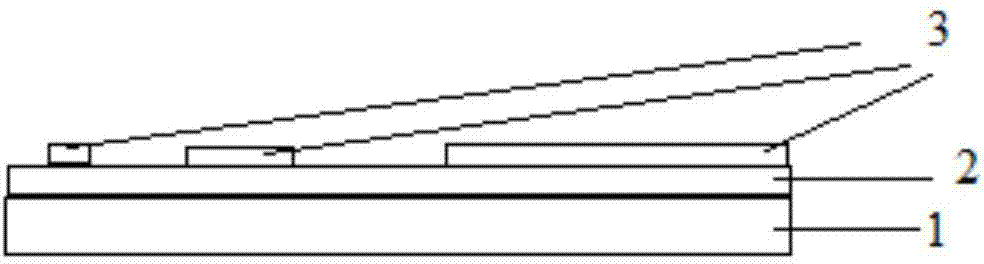

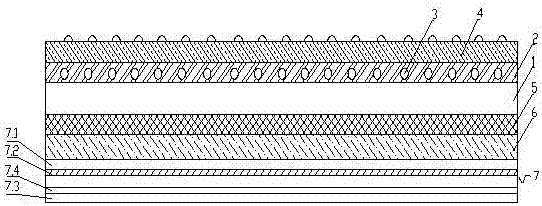

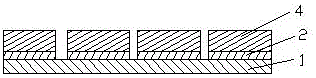

The invention relates to a waterproof fabric with strong tactility, comprising a fabric body (1), the upper surface of the fabric body is provided with a radiation-proof layer (2), and the upper surface of the radiation-proof layer (2) is sequentially provided with a reinforcement layer (4) and an upper waterproof layer (8), the lower surface of the fabric body is sequentially provided with an antibacterial layer (5), a fireproof layer (6) and a lower waterproof layer (7). The lower surface of the lower waterproof layer is provided with a lining layer. The lining layer includes a lining layer body woven by warp yarns and weft yarns. The warp yarns and weft yarns are interwoven into a three-up and three-down plain weave structure. The lining layer The upper surface of the main body is provided with a jacquard layer, and the upper surface of the jacquard layer is provided with a flocking layer; the lower surface of the lining layer body is provided with a breathable layer, the lower surface of the air-permeable layer is provided with an activated carbon cloth layer, and the lower surface of the activated carbon cloth layer is provided with a photocatalyst coating. Floor. The invention has the advantages of three-dimensional effect, antibacterial, radiation protection, fire prevention, waterproof and strong touch.

Owner:JIANGYIN YASHUN GARMENT

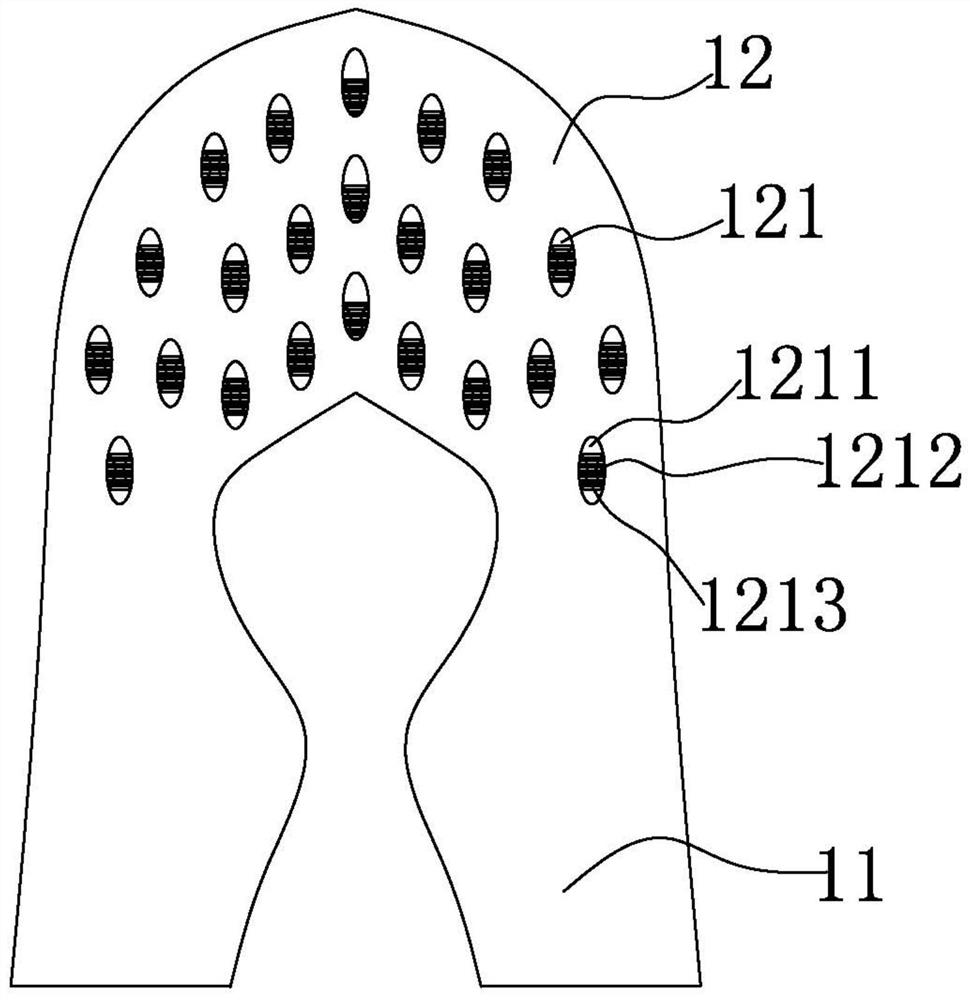

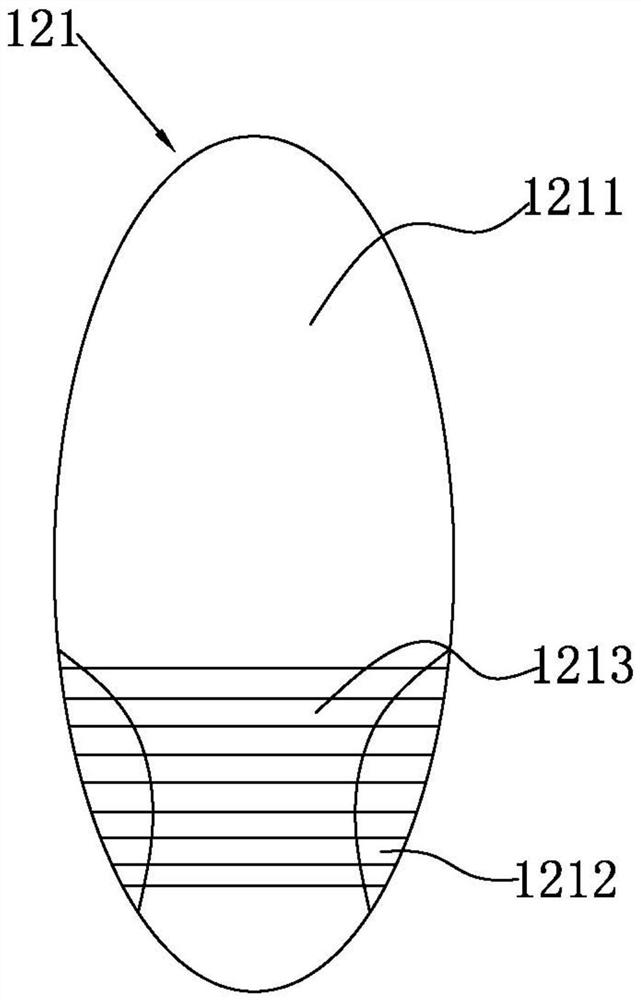

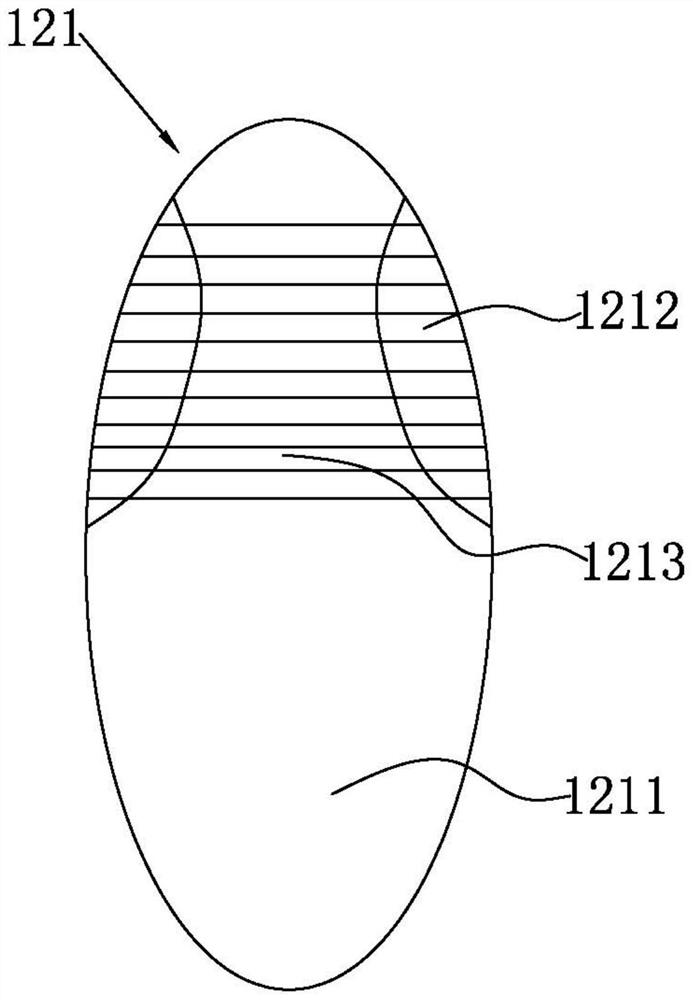

Anti-sliding baby hosiery

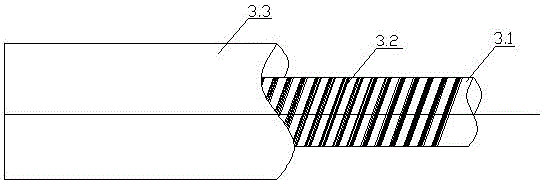

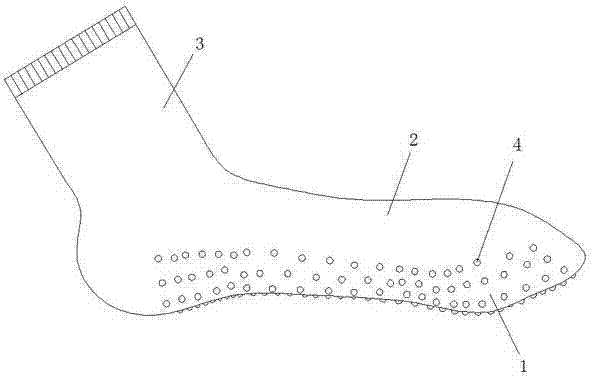

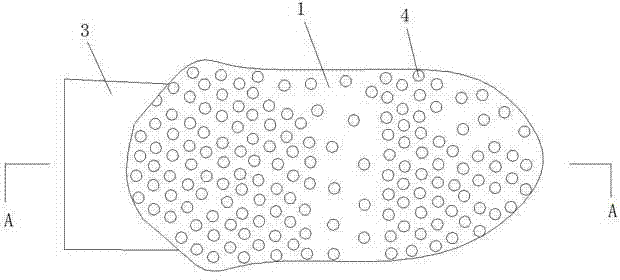

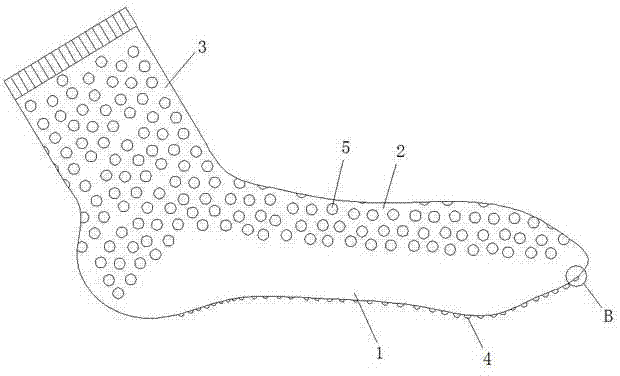

The invention relates to hosiery, in particular to anti-sliding baby hosiery. The anti-sliding baby hosiery comprises a hosiery body and a hosiery cylinder. The hosiery body comprises a sole wrapping layer and an instep wrapping layer. First anti-sliding protrusions are densely and fixedly arranged on the outer surface of the sole wrapping layer in a distributing mode. Second anti-sliding protrusions are densely and fixedly arranged both on the inner surface of the instep wrapping layer and the inner surface of the hosiery cylinder in a distributing mode. A cavity is arranged in the middle of the first anti-siding protrusions. The anti-sliding baby hosiery has the advantages of being capable of effectively increasing friction force between the bottom face of the hosiery and the ground and friction force between the hosiery and a foot portion, avoiding malposition between the hosiery and the foot portion, being capable of massaging sole acupoints on the premise that stress of the sole acupoints of a baby is not too large and the like.

Owner:ZHEJIANG MENGNA SOCKS & HOSIERY

Interior wall paint with magnetic functions, and preparation method thereof

InactiveCN109929387APlay the role of heat insulation and weight lossReduce loadFireproof paintsMagnetic paintsThermal insulationReducing bodies

The invention discloses an interior wall paint with magnetic functions, and a preparation method thereof. The interior wall paint with magnetic functions comprises following components, by weight, 40to 50 parts of a matrix, 20 to 40 parts of a solvent, 1 to 10 parts of a weight reducing body, 3 to 6 parts of a flame retardant, 3 to 6 parts of a lubricant, and 5 to 10 parts of nanometer Fe3O4. Itis prepared through four steps including preparation of a nanometer Fe3O4 dispersion, matrix pre-curing, wet coating preparation, and wet coating curing. Compared with the prior art, the advantages are that: the interior wall paint possesses strong magnetic force; the lubricant capable of improving touch feel is adopted, so that excellent comfortability is achieved; the interior wall paint possesses thermal insulation function, is non-toxic, is safe, is friendly to the environment, and is a novel functional coating with both the advantages of magnetic coating and common coating; and no pollution is caused.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

Wear-resistant fabric with good tactile properties

The invention relates to a wear-resistant fabric with strong tactility, comprising a fabric body (1), a radiation-proof layer (2) arranged on the upper surface of the fabric body, a radiation-proof strip (3) embedded in the radiation-proof layer, and a radiation-proof layer ( The upper surface of 2) is provided with a wear-resistant layer (4), the lower surface of the fabric body (1) is provided with an antibacterial layer (5), the lower surface of the antibacterial layer is provided with a fireproof layer (6), and the lower surface of the fireproof layer is provided with Waterproof layer (7). The lower surface of the waterproof layer is provided with a lining layer. The lining layer includes a lining layer body woven by warp yarns and weft yarns. The warp yarns and weft yarns are interwoven into a three-up and three-down plain weave structure. The lining layer body The upper surface is provided with a jacquard layer. The invention has the functions of antibacterial, anti-radiation, fireproof, waterproof, wear-resistant and the like. The present invention has a strong sense of touch.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

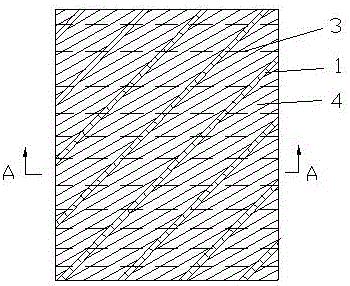

Strong-touch-sense flashing fiber villus woollen cloth

The invention relates to a fleece wool with strong touch and flashing light. It includes a woolen body (1), the front of the woolen body is provided with several protrusions (2) and flashing fibers (3), and the protrusions (2) are provided with fluff (4). The back of the woolen body is provided with a lining layer. The lining layer includes a lining layer body woven by warp yarns and weft yarns. The warp yarns and weft yarns are interwoven into a three-up and three-down plain weave structure. The surface is provided with a jacquard layer, and the upper surface of the jacquard layer is provided with a flocking layer; the lower surface of the lining layer body is provided with a breathable layer, the lower surface of the breathable layer is provided with an activated carbon cloth layer, and the lower surface of the activated carbon cloth layer is provided with a photocatalyst coating. The invention has a soft hand feeling and a sense of texture; it is visually beautiful and luxurious, and has a three-dimensional effect. The lining layer has a strong touch and breathability.

Owner:JIANGYIN YIFAN IND & TRADE

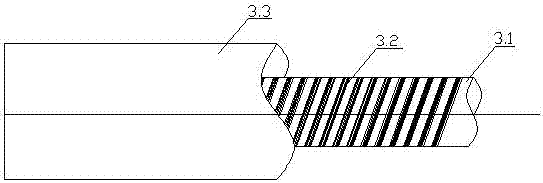

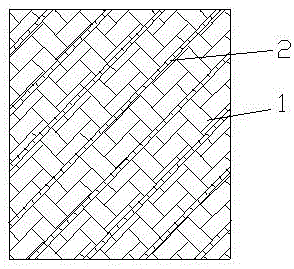

High-touch twill

The invention relates to high-touch twill. The high-touch twill comprises a fabric body (1), wherein a plurality of strip-shaped bulges (2) are formed on the outer surface of the fabric body, inclined by 45 degrees, and parallelly arranged; a lining layer is arranged at the back of the fabric body and comprises a lining layer body formed by weaving of warp yarns and weft yarns, and the warp yarns and the weft yarns are weaved into an upper-three and lower three plain structure; a jacquard layer is arranged on the upper surface of the lining layer body; a flocking layer is arranged on the upper surface of the jacquard layer. A concave-convex structure formed by the bulged strips of the high-touch twill enhances the stereoscopic impression and hand feeling of the high-touch twill, and the high-touch twill is strong in touch impression.

Owner:JIANGYIN TOPWAY TEXTILE

Fabric with warp knitting yarn diameter structure and manufacturing method thereof

PendingCN113493957AImprove support and stabilityShow strengthWarp knittingManufacturing engineeringWarp knitting

The invention relates to the technical field of fabrics, in particular to a fabric with a warp knitting yarn diameter structure and a manufacturing method thereof. The fabric with the warp knitting yarn diameter structure is integrally woven by a double-needle-bar high-speed warp knitting machine; a fabric body comprises a surface layer, a middle layer, a bottom layer and meshes; a plurality of third yarns of the middle layer are subjected to weft insertion non-looping weaving in the meshes to form a hollow structure; the plurality of third yarns are subjected to cross weaving with a plurality of second yarns of the bottom layer in the meshes to form a jacquard structure; the plurality of third yarns are subjected to cross weaving with a plurality of first yarns of the surface layer in a mesh area to form an in-mesh yarn diameter structure; and the yarn diameter change is used as a research and development breakthrough point, the lunar eclipse in the weaving meshes is changed, the fabric weaving stereoscopic impression and the threading silk-like effect are highlighted, the creel structure and the local thickness touch sense are matched, the fabric stability and supporting performance are enhanced, the force sense is shown, the diversification of the fabric thickness and the mesh effect is enriched, and the method is another new pulse for breaking through warp knitting structure weaving.

Owner:SINCETECH FUJIAN TECH CO LTD

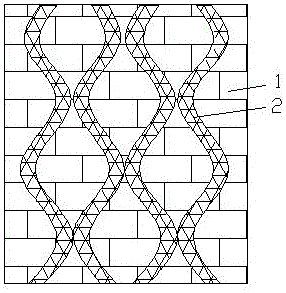

Knitting wool strip mesh fabric high in touch feeling

The invention relates to a tactile strong fleece line mesh fabric. Including the fabric body (1), the fabric body (1) is in the shape of a net, the upper surface of the fabric body (1) is provided with several coarse velvet lines, and three adjacent thick velvet lines are woven into twist-shaped decorative strips (2), and the decorative Bar (2) is serpentine. The back of the fabric body is provided with a lining layer. The lining layer includes a lining layer body woven by warp yarns and weft yarns. The warp yarns and weft yarns are interwoven into a three-up and three-down plain weave structure. The upper surface of the lining layer body is A jacquard layer is provided, the upper surface of the jacquard layer is provided with a flocking layer; the lower surface of the lining layer body is provided with a breathable layer, the lower surface of the breathable layer is provided with an activated carbon cloth layer, and the lower surface of the activated carbon cloth layer is provided with a photocatalyst coating. Twist-like decorative strips woven from thick pile threads enhance the layering of the tactile strong pile thread mesh fabric. The present invention has a strong sense of touch.

Owner:JIANGYIN CHUNLAN TEXTILE

Production method of mirror-surface metal leatherette paper

InactiveCN106368075ASimple processLow costGroup 4/14 element organic compoundsFlexible coversMetalCoating

The invention discloses a production method of mirror-surface metal leatherette paper. The method includes the steps of: selecting a raw leatherette basic paper, impregnating the raw leatherette basic paper, finishing the basic paper, performing bottom coating, performing composition, and pressing the paper to form textures. The bottom coating is carried out in a comma blade coating manner, wherein the finished paper surface is uniformly coated with a prime coating, bottom coating quantity being 15-30 g / m<2>. Drying temperature is 110-130 DEG C and machining speed is 20-30 m / min. The method is simple and has low cost. The leatherette paper has a leather texture and has a soft and loose feel, can be folded in any way and has a strong leather hand feel, has beautiful glossiness and is high-grade, can be used various high-grade packages for expensive high-grade luxury products, such as gift boxes, jewel boxes, jewelry boxes, decorative covers of books and albums, high-grade gift boxes and wine boxes, tea boxes, textbooks, etc.

Owner:安徽天艺纸业科技有限公司

Touch wire-drawing in-die transfer film and preparation method thereof

The invention discloses a touch wire-drawing in-mold transfer printing film which is of a multi-layer structure overlapped layer by layer and sequentially comprises a PET layer and a UV layer from top to bottom. A plurality of wiredrawing texture grooves are formed in the lower surface of the PET layer, the wiredrawing texture grooves are grooves which are formed in the lower surface of the PET layer and are recessed towards the PET layer, and divergent deep wiredrawing textures are arranged on the inner surfaces of the wiredrawing texture grooves; and the UV layer can fully fill and be embedded into the plurality of wiredrawing texture grooves. According to the invention, the structure of the deep wire drawing texture groove of the PET layer is designed, so that the cured UV adhesive layer fully filled in the deep wire drawing texture groove forms numerous'tentacles' embedded into the groove of the PET layer, thereby increasing the acting force between the cured UV adhesive layer and the PET layer, and enabling the cured UV adhesive layer to be better adhered to the film surface of the PET layer in a'occlusion 'manner; and meanwhile, a release layer which must be used for separating the PET layer from the coating below in the prior art is avoided, so that the film structure is simplified, and the production cost is saved.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

A high-performance wallpaper

ActiveCN106671556BImprove mechanical propertiesGood tensile loadCovering/liningsLamination ancillary operationsTear resistanceMixed materials

The invention discloses a preparation method of high-performance wallpaper. The preparation method of the high-performance wallpaper comprises the steps of preparing mixed wood powder, modifying the mixed wood powder, preparing stone powder, preparing a mixed material, preparing a blank, preparing a surface material and adhering the surface material to PVC artificial leather. The wallpaper is prepared by preparing a blending material from the modified wood powder, the stone powder and polyurethane glue, cutting the blending material into soft slices and adhering the soft slices to the prepared PVC artificial leather, so the tensile strength and the tear resistance of the wallpaper are greatly improved, and the prepared wallpaper has remarkable heat-insulating and sound-insulating effects, high stain resistance, excellent printing property and high moisture resistance.

Owner:ANHUI SOYA DECORATIVE MATERIALS

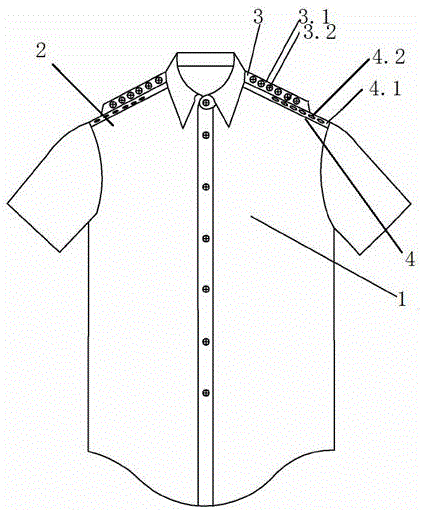

Shoulder-stretchable garment with high touch sense

InactiveCN106072932AComfortable and beautiful to wearImprove stabilityGarment special featuresProtective garmentShoulder widthTouch Senses

The invention relates to a shoulder-stretchable garment with a high touch sense. Shoulders of the garment are provided with stretchable bands and fixed bands, the shoulder width is adjusted by adjusting the numbers of loop fasteners and hook fasteners on the stretchable bands and the fixed bands, the length at hook and loop fasteners can be adjusted, a comfortable size of the shoulders can be adjusted according to the condition of a wearer, and more comfortable and beautiful effects are achieved when the wearer wears the garment; meanwhile, damage to the product can be greatly reduced, pilling can be reduced, elasticity is good, and stability is high. A lining layer is arranged on the back face of a garment body, the lining layer comprises a lining layer body formed by weaving warp yarns and weft yarns, the warp yarns and the weft yarns are interwoven into a three-upper-three-lower plain weave structure, a jacquard weave layer is arranged on the upper surface of the lining body, and a flocking layer is arranged on the upper surface of the jacquard weave layer. The shoulder-stretchable garment is high in touch sense.

Owner:JIANGYIN XINJIAMEI GARMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com