Aqueous decorative ink for glass printing and preparation method thereof

A decorative ink and water-based technology, which is applied in the field of water-based decorative ink for glass printing and its preparation, can solve the problems of difficult popularization and application, low efficiency, and high safety risk of hydrofluoric acid solution corrosion method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

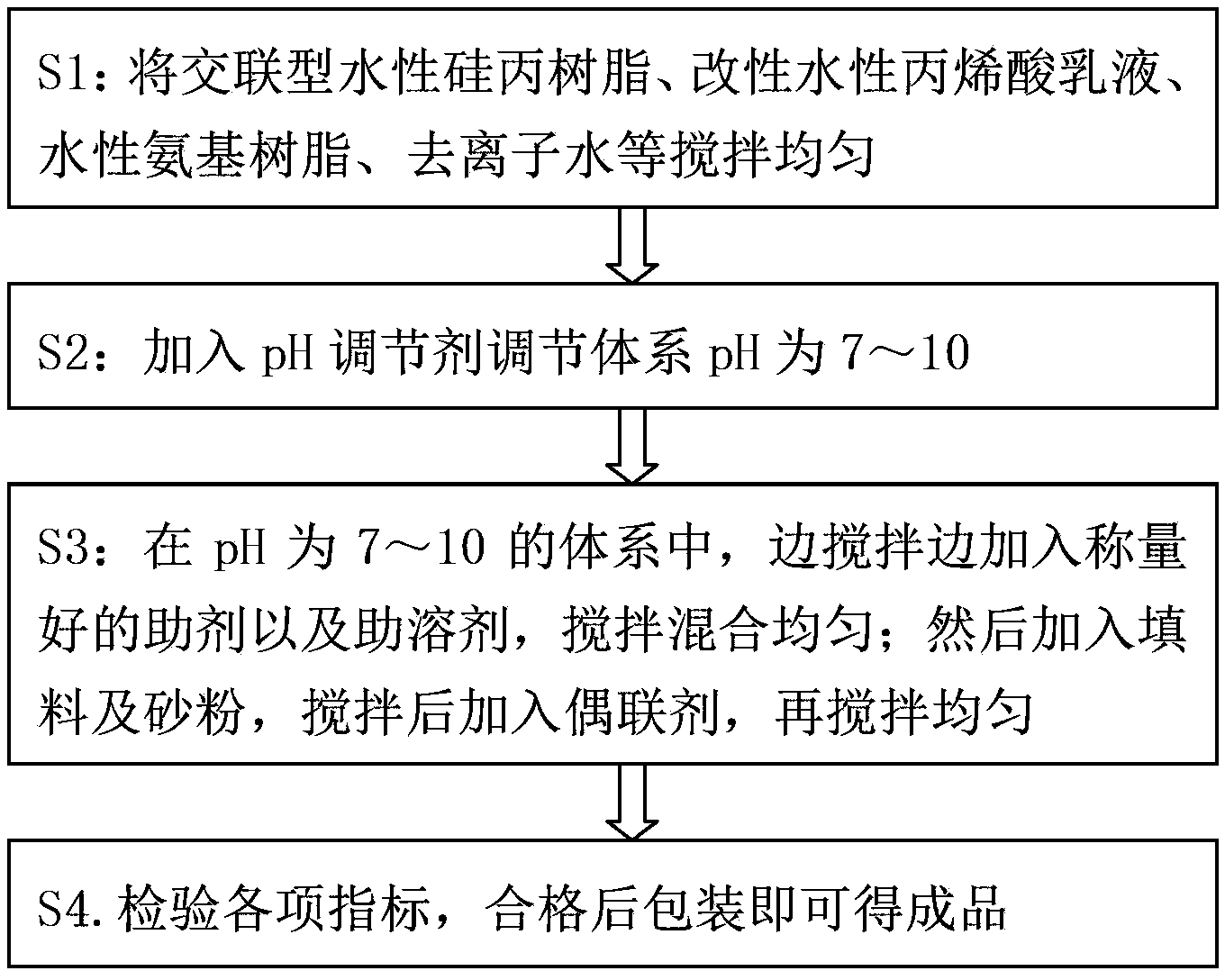

Method used

Image

Examples

Embodiment Construction

[0021] The ink of the present invention adopts cross-linked water-based silicone acrylic resin, water-based acrylic emulsion and water-based amino resin as raw materials, and prepares water-based glass ink with excellent decorative effect by matching specially selected coupling agent and curing agent.

[0022] Specifically, the components contained in the water-based decorative ink for glass printing according to an embodiment of the present invention and their respective weight percentages are: 25%-50% of cross-linked water-based silicone acrylic resin, 5%-15% of modified water-based acrylic emulsion , water-based amino resin 10%-20%, deionized water 5-20%, coupling agent 1%-5%, co-solvent 0-15%, sand powder 10%-20%, filler 1-15%, auxiliary agent 0.2% to 15%, and curing agent 2% to 10%.

[0023] Among them, the cross-linked water-based silicone acrylic resin described in this example is specially treated to introduce silicone during the synthesis process, which has both the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com