Drying method for ring-form calcining furnace

A technology of ring roaster and oven method, which is applied in the oven field of 36-chamber ring roaster, which can solve the problems of difficulty in product quality control, large amount of sinking and deformation of the starting furnace chamber, and shortening the service life of refractory bricks, etc. problems, to achieve the effect of preventing furnace chamber sinking and cracks, ensuring no deformation, and preventing excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The furnace is a 36-chamber, 8-fire channel, 7 material boxes, length*width*depth=5298*780*5496mm open type roasting furnace.

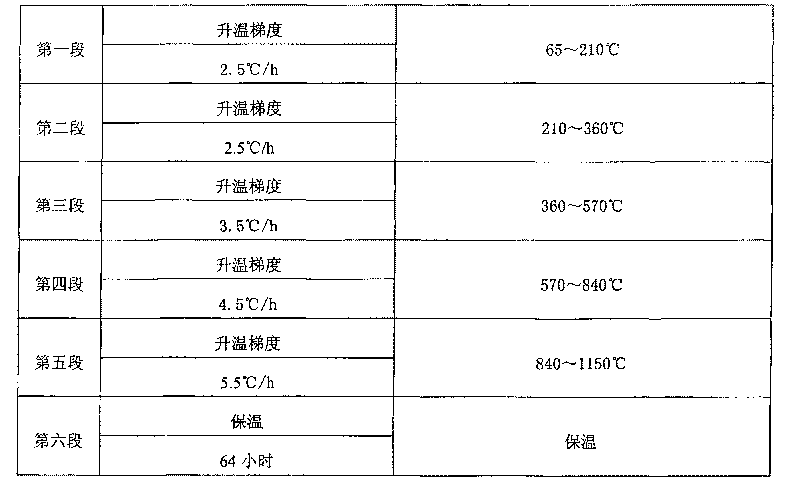

[0033] The specific method of the oven:

[0034] (1) Baking chimney: Baking with firewood at the bottom of the flue at a temperature of 150-200°C. Clean up residue after baking.

[0035] (2) Steel flue and connected fire passage: rely on special spraying equipment, send it to the working surface through high-pressure special binder, the water content is 25-30%, and the natural strength increases by 40% after natural drying for 4-8 hours %, the natural strength increases to 60-70% after 48 hours, and the strength can reach more than 80% after 100 hours over time. It is not affected in any way by the temperature profile of the overall oven. Therefore, it is required to spray the steel flue for more than 100 hours when drying the flue. Theoretically, the strength can be fully achieved within 4-6 hours when the flue gas temperature of the oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com