Steam cooling gas injection sintering machine and its control method

A control method and technology of a sintering machine, applied in the metallurgical field, can solve the problems of insignificant effect, inconspicuous effect of strengthening sintering, inability to obtain gas supplementary heat for the upper material layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention intends to solve the problem existing in the prior art that the starting point of gas injection cannot be moved forward without igniting.

[0047] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0048]In this paper, terms such as "upper, lower, inner, outer" are established based on the positional relationship shown in the accompanying drawings, and the corresponding positional relationship may also change according to different drawings. It is understood to be an absolute limitation on the scope of protection; moreover, relational terms such as "first" and "second" etc. are only used to distinguish one element of the same name from another, and do not necessarily require or Any such actual relationship or order between these components is implied.

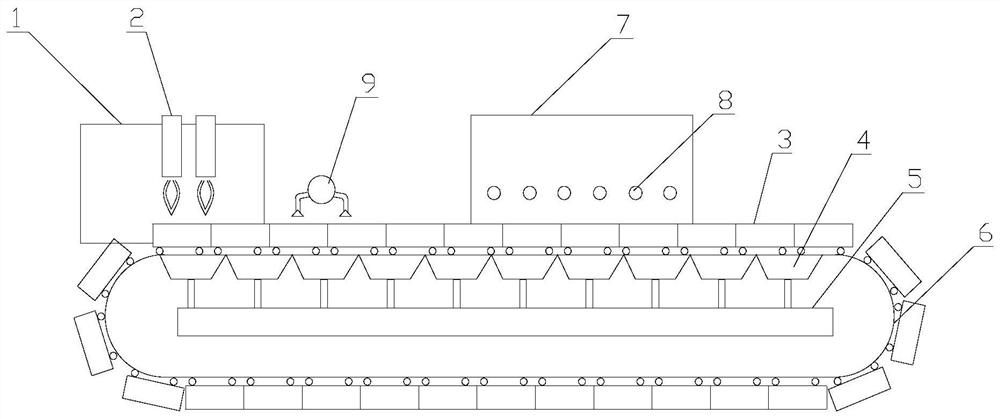

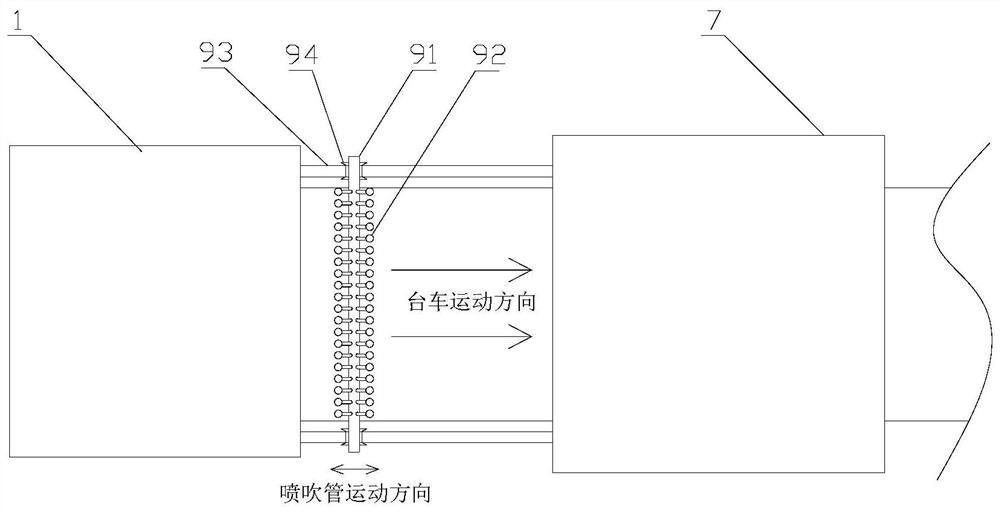

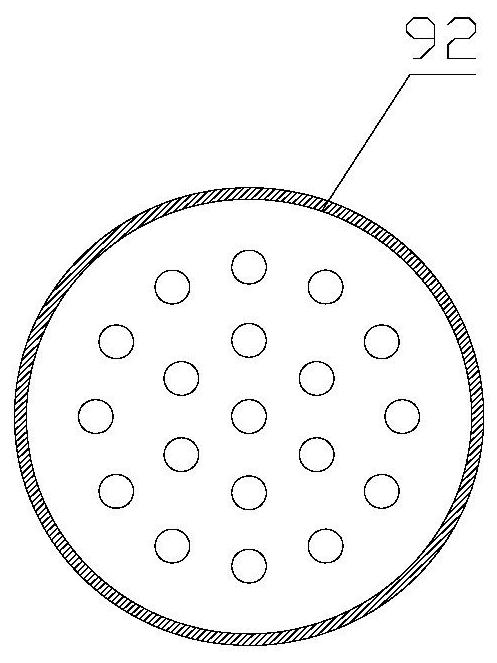

[0049] Please refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com