Wet wood shaving drying system and drying process

A drying process and drying system technology, applied in the direction of drying solid materials, drying gas layout, non-progressive dryers, etc., can solve problems such as hidden safety hazards and easy fire in the drying process, and achieve easy control, elimination of ignition factors, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

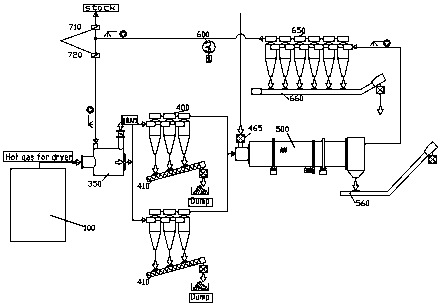

[0033] Example 1 A wet shaving drying process and its drying system

[0034] Such as figure 1 As shown, a drying system for wet shavings of the present invention includes a boiler 100, a mixing chamber 350, a hot flue gas cyclone separator 400, an ash discharge screw conveyor 410, a one-way feed trough 465, a single-channel drum dryer 500, Unloading conveyor 560, multi-pipe cyclone separator 650, small waste conveyor 660, main induced draft blower 600, bidirectional control dampers 710, 720, the drying system of the present invention is simple in structure, the price of each component is relatively low, and the manufacturing cost is low, which can widely used on a large scale.

[0035] The high-temperature flue gas in the boiler 100 enters the mixing chamber 350 through the smoke outlet for mixing and air distribution, and the mixed flue gas in the mixing chamber 350 enters the hot flue gas cyclone separator 400 for dust separation.

[0036] The temperature of the high-tempe...

Embodiment 2

[0046] Example 2 A wet shaving drying process and its drying system

[0047] Such as figure 1 As shown, a drying system for wet shavings of the present invention includes a boiler 100, a mixing chamber 350, a hot flue gas cyclone separator 400, an ash discharge screw conveyor 410, a one-way feed trough 465, a single-channel drum dryer 500, Unloading conveyor 560, multi-pipe cyclone separator 650, small waste conveyor 660, main induced draft blower 600, bidirectional control dampers 710, 720, the drying system of the present invention is simple in structure, the price of each component is relatively low, and the manufacturing cost is low, which can widely used on a large scale.

[0048] The high-temperature flue gas in the boiler 100 enters the mixing chamber 350 through the smoke outlet for mixing and air distribution, and the mixed flue gas in the mixing chamber 350 enters the hot flue gas cyclone separator 400 for dust separation.

[0049] The temperature of the high-tempe...

Embodiment 3

[0059] Example 3 A wet shaving drying process and its drying system

[0060] Such as figure 1 As shown, a drying system for wet shavings of the present invention includes a boiler 100, a mixing chamber 350, a hot flue gas cyclone separator 400, an ash discharge screw conveyor 410, a one-way feed trough 465, a single-channel drum dryer 500, Unloading conveyor 560, multi-pipe cyclone separator 650, small waste conveyor 660, main induced draft blower 600, bidirectional control dampers 710, 720, the drying system of the present invention is simple in structure, the price of each component is relatively low, and the manufacturing cost is low, which can widely used on a large scale.

[0061] The high-temperature flue gas in the boiler 100 enters the mixing chamber 350 through the smoke outlet for mixing and air distribution, and the mixed flue gas in the mixing chamber 350 enters the hot flue gas cyclone separator 400 for dust separation.

[0062] The temperature of the high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com