Production and calcination system of carbon anode for aluminium electrolysis and process control method of system

A carbon anode and aluminum electrolysis technology, which is applied in the field of carbon anode production system, can solve the problems of easy cracks, low waste heat utilization rate, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] First of all, it should be explained that the present invention not only discloses the production and roasting system of the carbon anode for aluminum electrolysis, but also discloses the process control method for the production and roasting of the carbon anode by using the production and roasting system of the carbon anode for aluminum electrolysis. And the gas flow and flue gas mentioned therein should be understood as the same concept, and both refer to the mixed gas flowing in the fire tube.

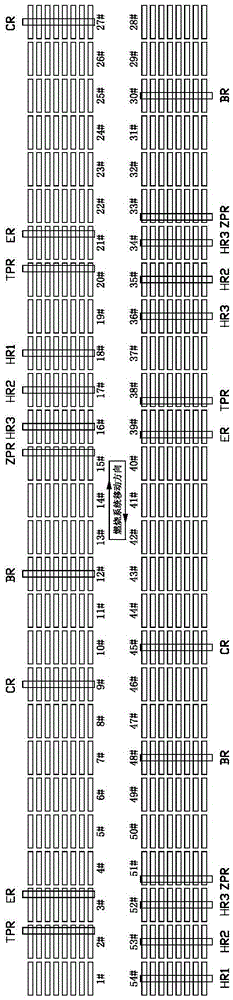

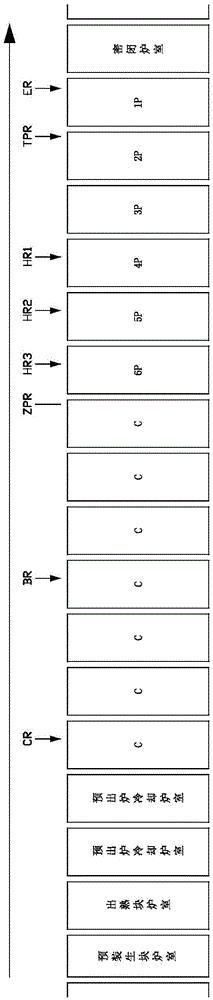

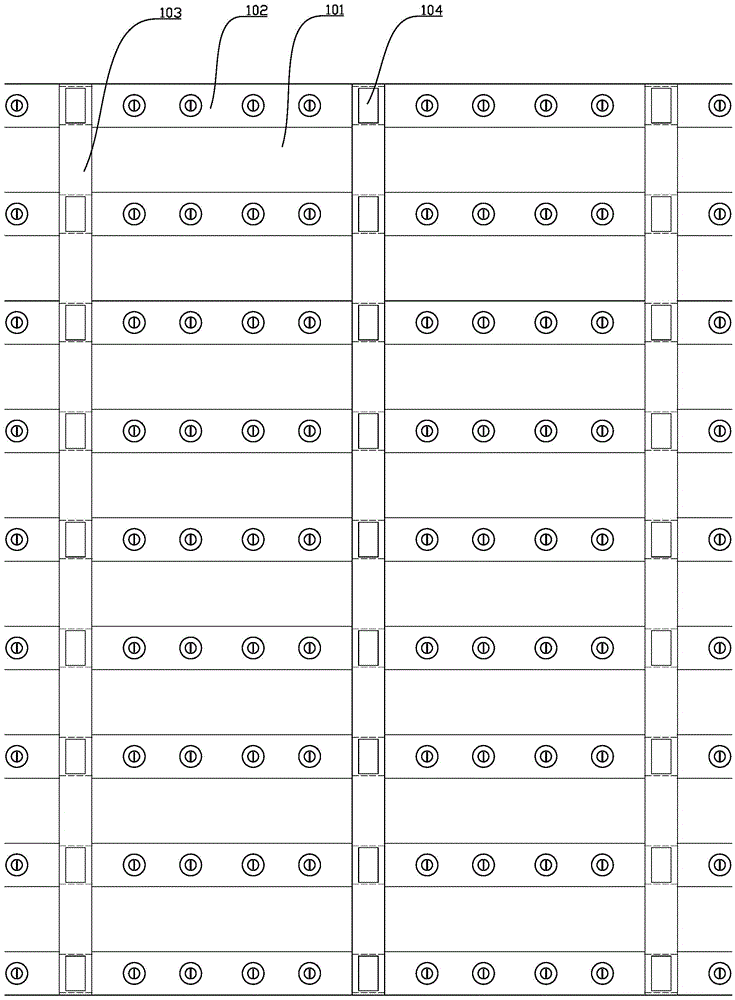

[0034] Such as Figure 3 to Figure 5 Shown is the first embodiment of the production and roasting system of a carbon anode for aluminum electrolysis of the present invention, including a circulating roasting furnace unit composed of 60 furnace chambers 1, 3 sets of flame control units composed of various control frames, and The hanging beam device used to move the control frame in the flame control unit allows each furnace chamber 1 to include a plurality of open material box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com