Cover film with low coating weight and good sealing and preparation method thereof

A technology with high sealing and coating volume, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of over-coating, over-packaging, etc., and achieve coating The effect of reducing the amount, heating uniformly, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

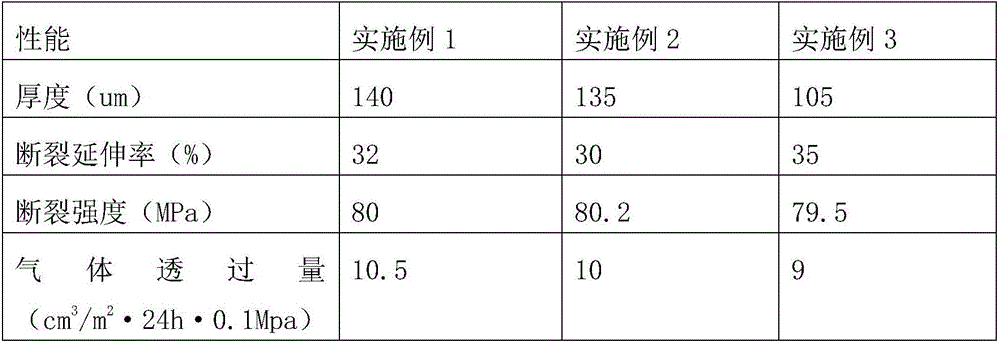

Embodiment 1

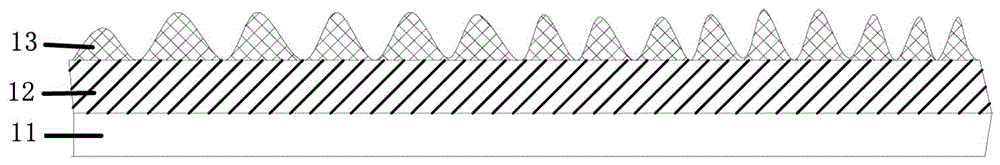

[0033] A low-coating high-sealing cover film comprises a polyester / aluminum foil composite film base material, a ternary vinyl acetate resin layer on the base material, and a heat-sealing adhesive layer on the ternary vinyl chloride resin layer.

[0034] A method for preparing a low-coating high-tightness cover film, comprising the following steps:

[0035] 1) Coating ternary vinyl acetate resin: Mix ternary vinyl acetate resin and methyl ethyl ketone at a mass ratio of 1:4 to obtain a mixed solution, and apply the mixed solution on the polyester / aluminum foil composite film base by metal gravure coating on the aluminum foil side of the material, and then put it into a hot air drying oven composed of 5 ovens for drying and cooling treatment. , the dry hot air volume of each oven is controlled at 2900m 3 / h, after leaving the oven, it is cooled by an S-type cooling water roll, and it is wound up with a coating machine to obtain a substrate / ternary vinyl chloride resin composite ...

Embodiment 2

[0038] A low-coating high-sealing cover film comprises a paper / aluminum foil composite film base material, a ternary vinyl chloride resin layer on the base material, and a heat-sealing adhesive layer on the ternary vinyl chloride resin layer.

[0039] A method for preparing a low-coating high-tightness cover film, comprising the following steps:

[0040] 1) Coating ternary vinyl acetate resin: Mix ternary vinyl acetate resin and methyl ethyl ketone at a mass ratio of 1:4.5 to obtain a mixed solution, and apply the mixed solution on the paper / aluminum foil composite film substrate by metal gravure coating On the side of the aluminum foil on the top, then put it into a hot air drying oven composed of 5 ovens for drying and cooling treatment. The temperature of the oven is set to 70°C, 100°C, 150°C, 200°C in turn, and the last section blows cold air drying section , the dry hot air volume of each oven is controlled at 2900m 3 / h, after leaving the oven, it is cooled by an S-type...

Embodiment 3

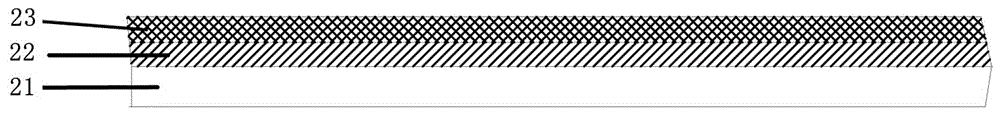

[0043] A cover film with low coating amount and high sealing performance comprises an aluminum foil base material, a three-component vinyl chloride resin layer on the base material, and a heat-sealing adhesive layer on the three-component vinyl chloride resin layer.

[0044] A method for preparing a low-coating high-tightness cover film, comprising the following steps:

[0045] 1) Coating ternary vinyl acetate resin: mix ternary vinyl acetate resin with methyl ethyl ketone in a mass ratio of 1:5 to obtain a mixed solution, and apply the mixed solution on the aluminum foil substrate by metal gravure coating, and then Put it into a hot air drying oven composed of 5 ovens for drying and cooling treatment. The temperature of the oven is set to 80°C, 110°C, 180°C, and 220°C in sequence. The air volume is controlled at 2900m 3 / h, after leaving the oven, it is cooled by an S-type cooling water roll, and it is wound up with a coating machine to obtain a substrate / ternary vinyl chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com