Combination mode of mesh belt type dryers

A combination method and dryer technology, applied in dryer combination, dryer, progressive dryer and other directions, can solve problems such as large waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

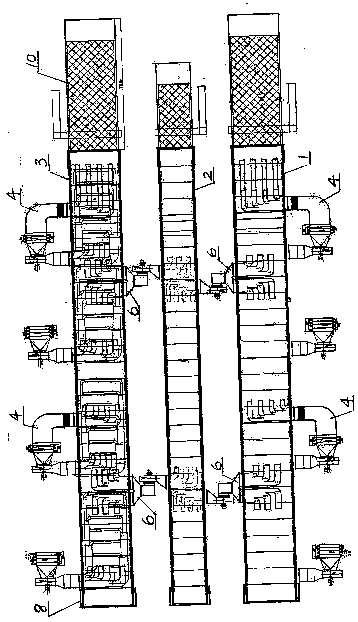

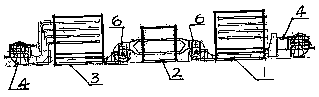

[0012] Such as figure 1 The schematic diagram shown is a block diagram of this scheme, and there are three mesh belt dryers arranged side by side, including a first main dryer 1, a second auxiliary dryer 2, and a third main dryer. Machine 3, three sets are arranged side by side, the hot air medium enters the main dryers 1 and 3 from the air inlet 4, acts on the material in the dryer and is discharged from the moisture outlet 5, and the hot air with less moisture in the lower part passes through the fan 6 It is forced to be drawn out and sent into the auxiliary dryer 2, and acts on the material again. The reason why it is required to be arranged side by side is that the connecting pipes between them are short to avoid heat loss. The rest of the numbers in the schematic diagram are: wet material inlet 7 of each dryer , Dry material outlet 8.

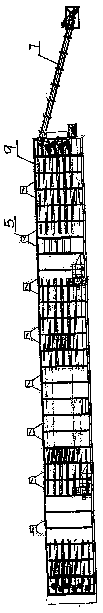

[0013] Such as figure 2 Shown is the front view of the mesh belt dryer used in this application. The whole dryer is a metal box 9 equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com