Installation-free W-shaped floor type clothes hanger

A floor-standing, installation-free technology, applied in washing devices, other drying devices, textiles and papermaking, etc., can solve the problems of inconvenient movement, inconvenient disassembly, unfriendly, etc., to increase the drying capacity and save storage space , solve the effect of occupying too much space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

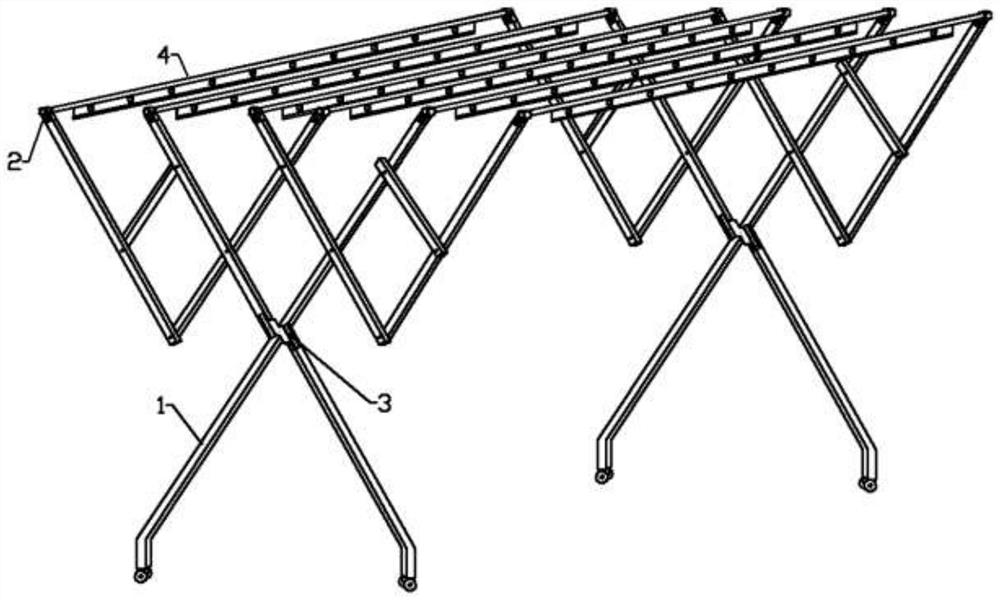

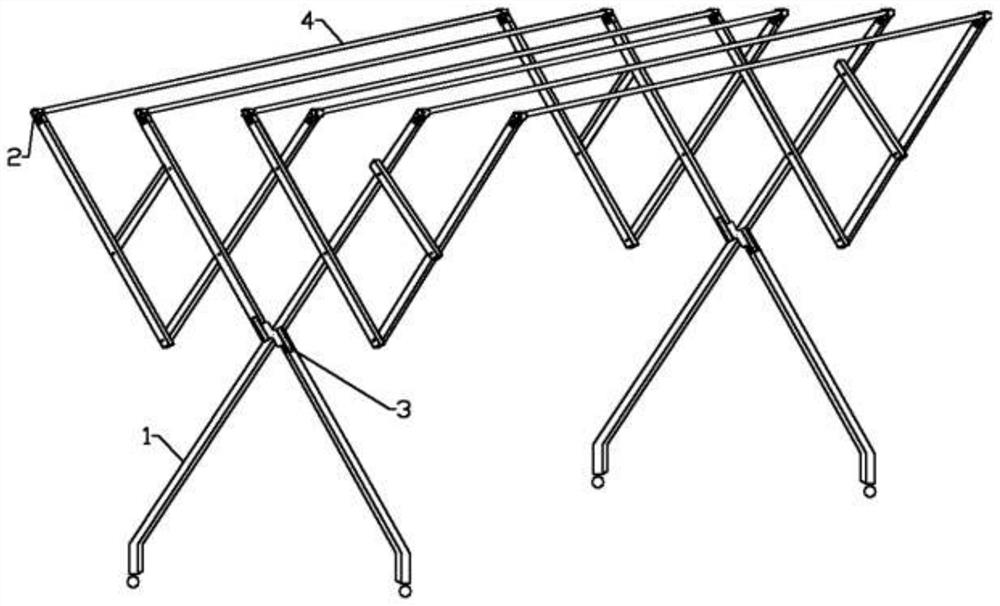

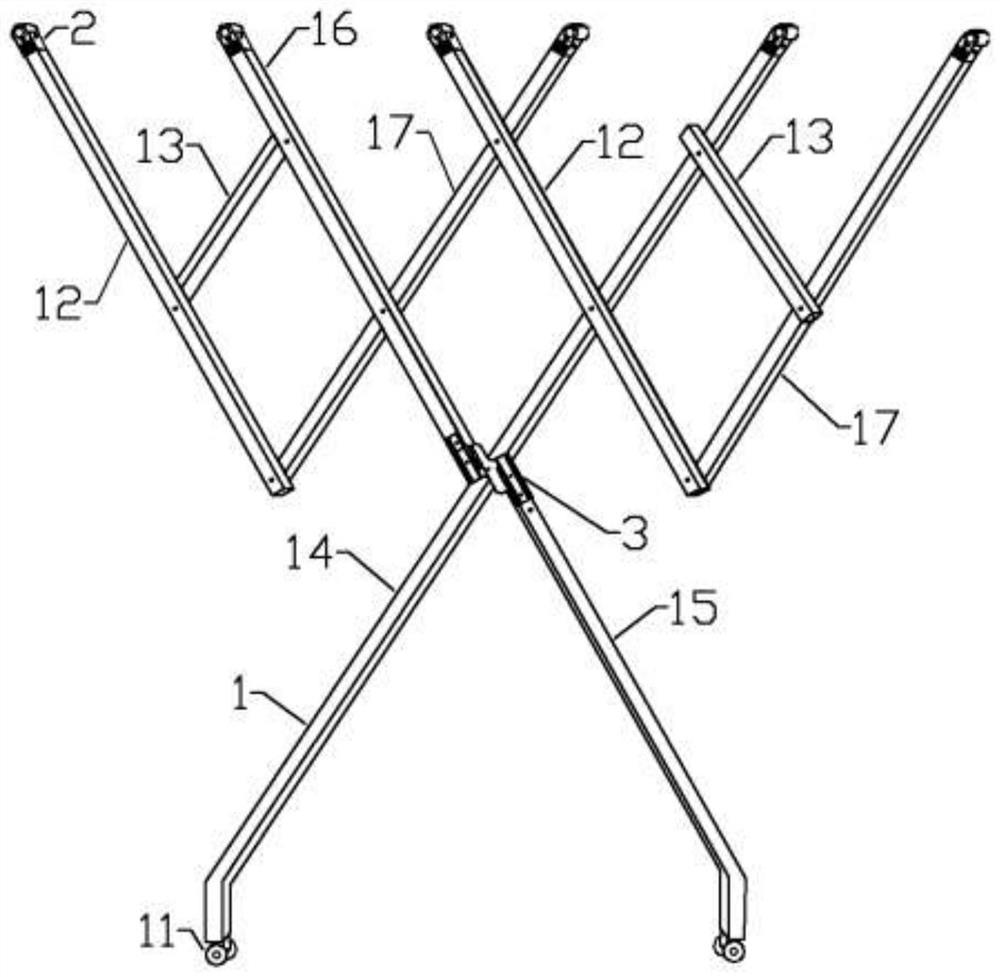

[0035] see Figure 1-5 , an installation-free W-shaped floor-standing clothes hanger, including a support frame 1, an installation connector 2, a folding block 3 and a cross bar 4, the support frame 1 has two, and the installation connector 2 is installed on the side of the support frame 1 At the top, the two ends of the crossbar 4 are fixed between the two supports 1 through the installation connector 2, which is a foldable connector; the installation connector 2 can realize the crossbar 4 from being perpendicular to the support frame 1 The position is folded to a position parallel to the support frame 1 to realize the longitudinal folding of the entire drying rack;

[0036] The support frame 1 is provided with a folding block 3, and a plurality of support rods are fixed by the folding block 3 so that the support frame 1 can be folded. The folding block 3 can realize the horizontal folding of the support frame 1, so that the space occupied by the support frame is reduced.

...

Embodiment 2

[0045] see Figure 6-7 , in order to achieve the folding effect of the installation connector 2, the installation connector 2 includes a connection clamp 21, a plastic connection sleeve 22 and a plastic connector 23, and the lower part of the connection clamp 21 can be sleeved and installed inside the plastic connection sleeve 22 , the upper part of the connecting chuck 21 is provided with a collar, and the collar can be installed with a locking nut through the locking screw hole 211 provided on the connecting chuck 21 to realize the fastening of the collar. The No. 2 connecting screw hole 212, the bottom of the plastic connecting sleeve 22 is provided with the No. 2 connecting screw hole 221, and the connecting chuck 21 is inserted into the plastic connecting sleeve 22. The next No. 2 connecting screw hole 212 is in the same position as the No. Correspondingly, the top of the plastic connector 23 is provided with a connecting head 231, and the connecting head 231 is provided ...

Embodiment 3

[0051] please participate Figure 8-10 , in order to make the overall stability of the drying rack when in use, a reinforcing rod 5 for fixing is also provided between the supporting frames 1, and the reinforcing rod 5 is installed at the middle or bottom position of the supporting frame 1.

[0052] The reinforcement rod 5 can be directly installed between the support frames 1 through bolts, and is fixed on the support rod. It is also very convenient to disassemble. When the entire drying rack needs to be used for a long time, the reinforcement rod 5 can be installed to ensure long-term use of stability.

[0053] The reinforcing bar 5 is preferably installed between the two folding blocks 3. If it is installed between the folding blocks 3, it will not have any impact on the horizontal folding of the entire clothes hanger. When it is installed in other positions, it needs to be folded Reinforcement rod 5 is removed, because reinforcement rod 5 only plays the effect of reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com