Transverse folding mechanism of full-automatic towel folding machine and process thereof

A horizontal folding and folding machine technology, which is applied in the direction of folding thin materials, thin material handling, transportation and packaging, etc., can solve the problems of high labor intensity, low production efficiency, and poor folding effect, so as to improve production efficiency and reduce The effect of artificial labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

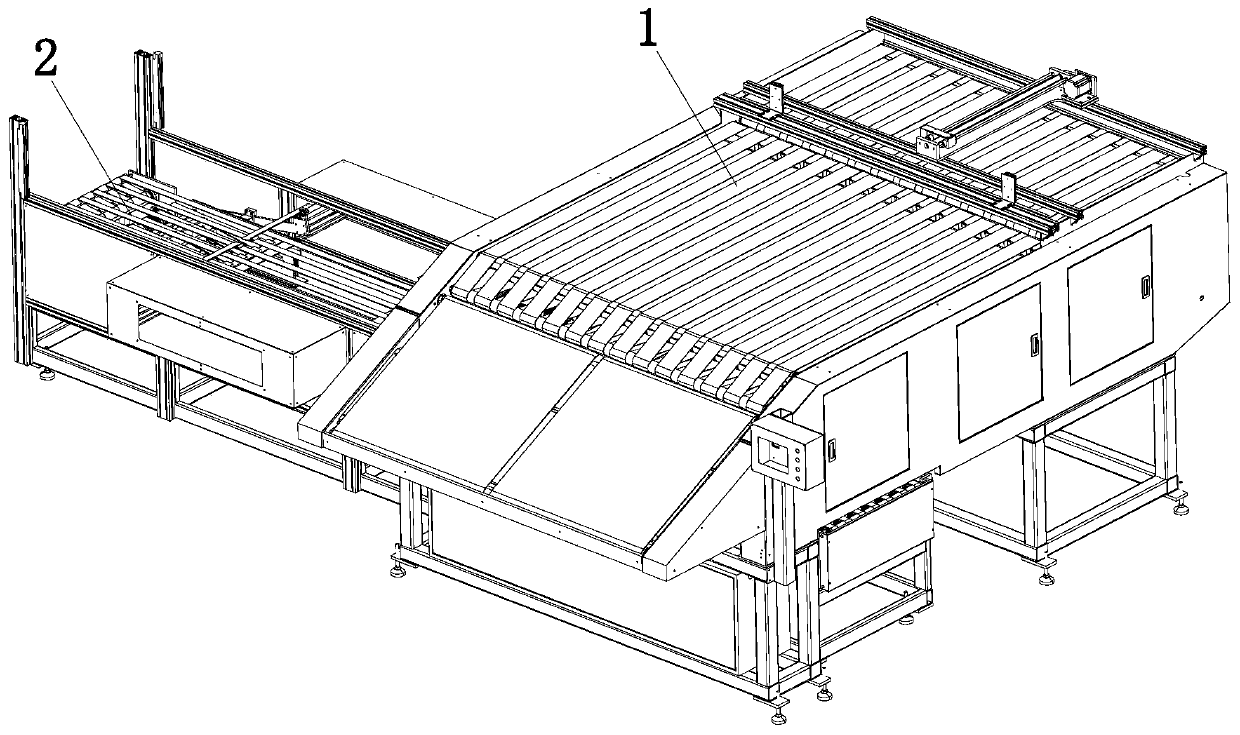

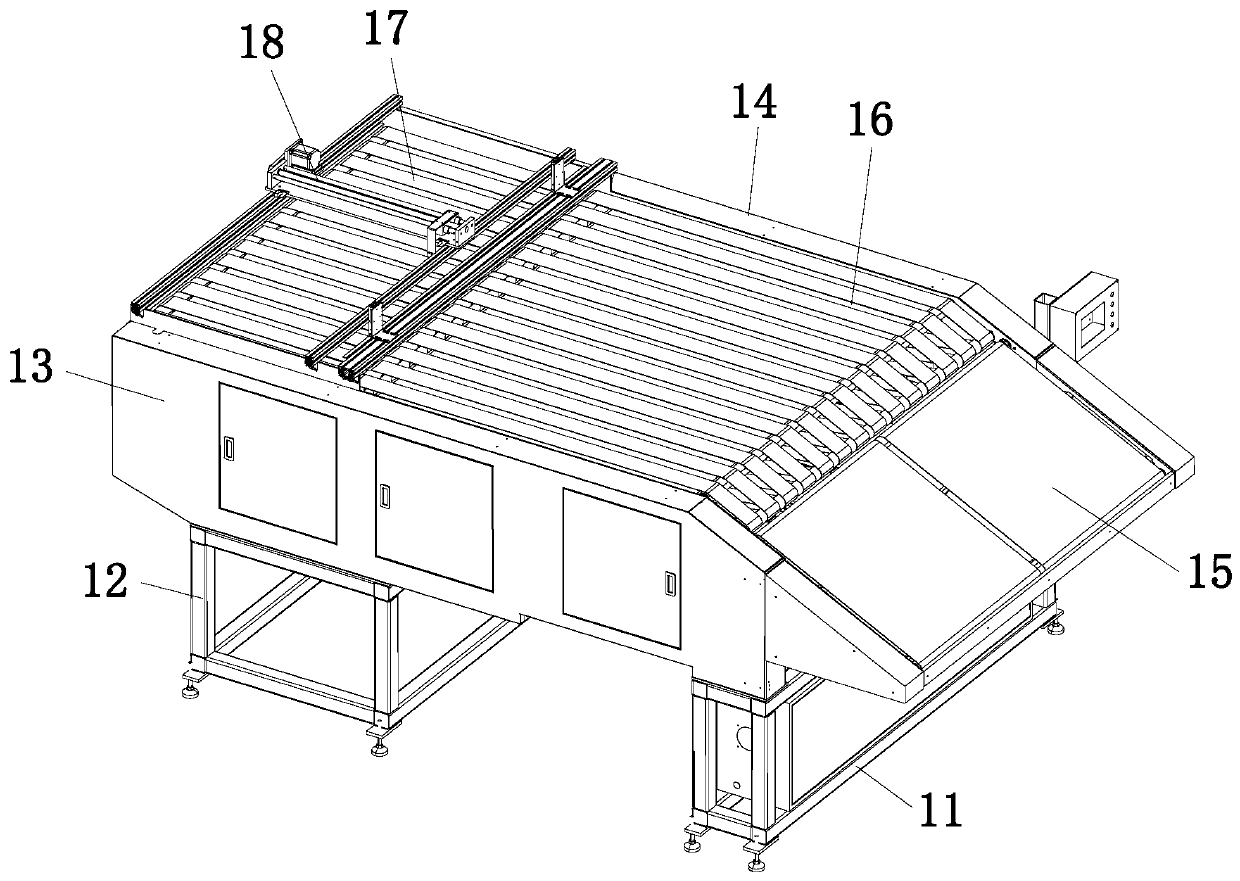

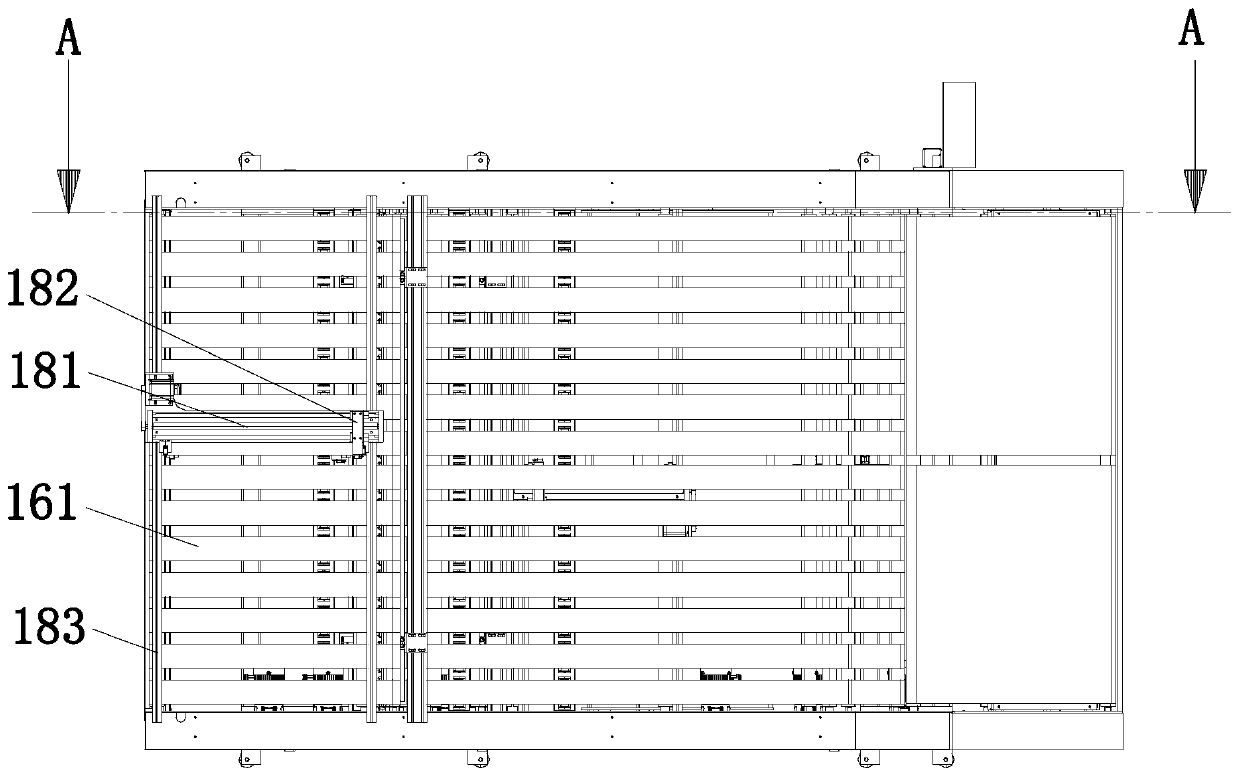

[0035] refer to Figure 1 to Figure 15 It can be seen that a fully automatic folding machine for towels is disclosed, which includes a longitudinal folding mechanism 1 and a horizontal folding mechanism 2, the output end of the longitudinal folding mechanism 1 is connected to the input end of the horizontal folding mechanism 2, and the longitudinal folding mechanism 1 includes a front Bracket 11, rear bracket 12, left side frame 13, right side frame 14, feeding conveyor belt 15, first roller split conveyor belt 16, second roller shaft split conveyor belt 17, limit assembly 18, third roller shaft split body conveyor belt 19, the fourth roller shaft split conveyor belt 111 and the fifth roller shaft split conveyor belt 112, the front bracket 11 and the rear bracket 12 are arranged at intervals, and the left side frame 13 and the right side frame 14 are installed on the front bracket 11 and the right side frame respectively. On both sides of the top of the rear support 12, the fe...

Embodiment 2

[0048] By laying the towels flat on the feeding conveyor belt 15, utilizing the feeding conveyor belt 15 to connect with the first roller shaft split conveyor belt 16, the towel is transported to the first roller shaft split conveyor belt 16, and the first roller shaft split conveyor belt 16, the towel is then conveyed to the second roller shaft split conveyor belt 17, and when the towel is positioned on the second roller shaft split conveyor belt 17 and its front end is in contact with the toggle plate 182, the toggle plate 182 is assisted, and the second roller The shaft split conveyor belt 17 is reversely driven, so that the towel is folded in half into the aisle formed between the output end of the first roller shaft split conveyor belt 16 and the second roller shaft split conveyor belt 17 to realize the longitudinal primary folding step of the towel, and then , the towel falls on the third roller shaft split conveyor belt 19, and the third roller shaft split conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com