System and method for intermittent negative-pressure pneumatic conveying for powder

A negative pressure pneumatic conveying, intermittent technology, applied in the field of pneumatic conveying, can solve the problems of low degree of automation, damage to the system, simple structure of the feeder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

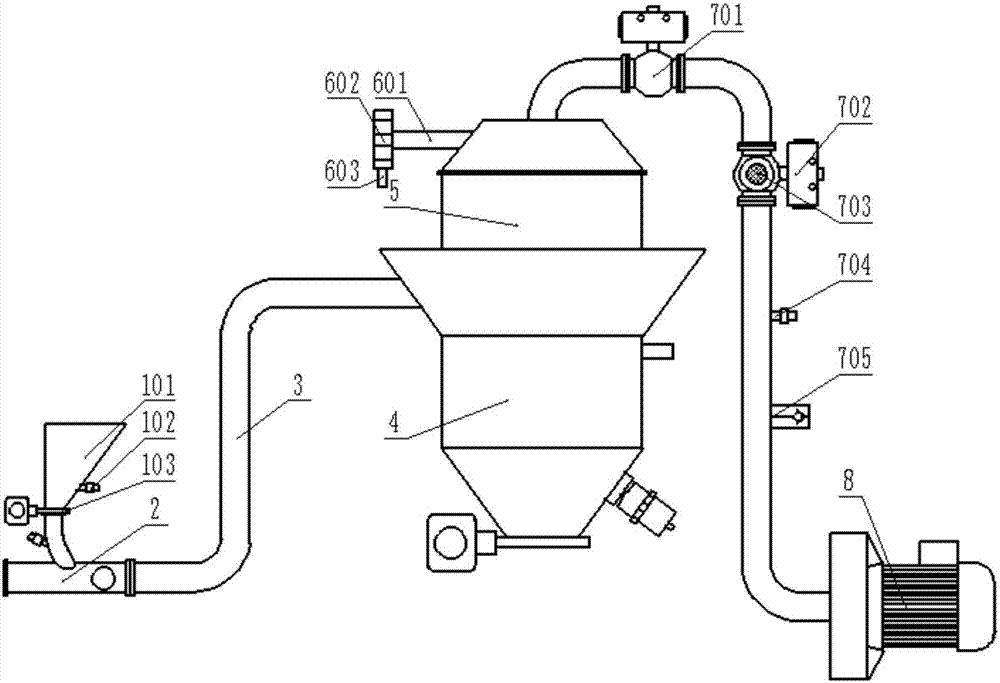

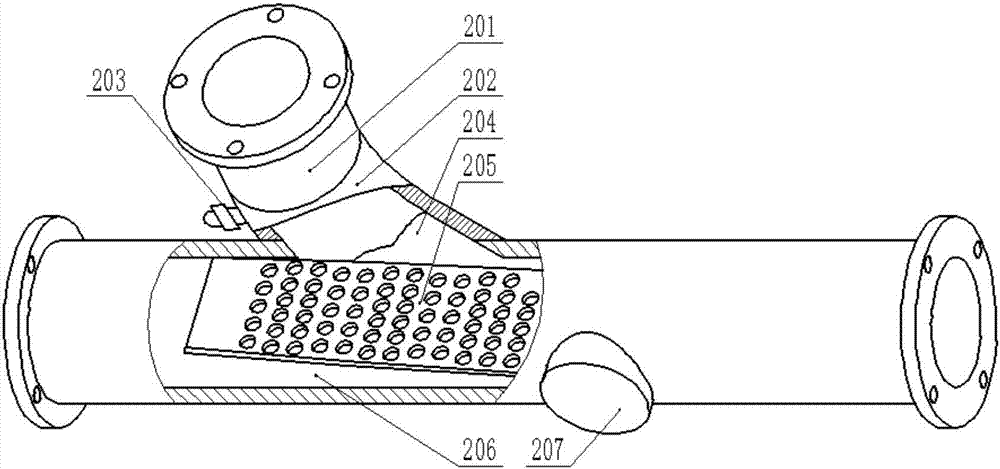

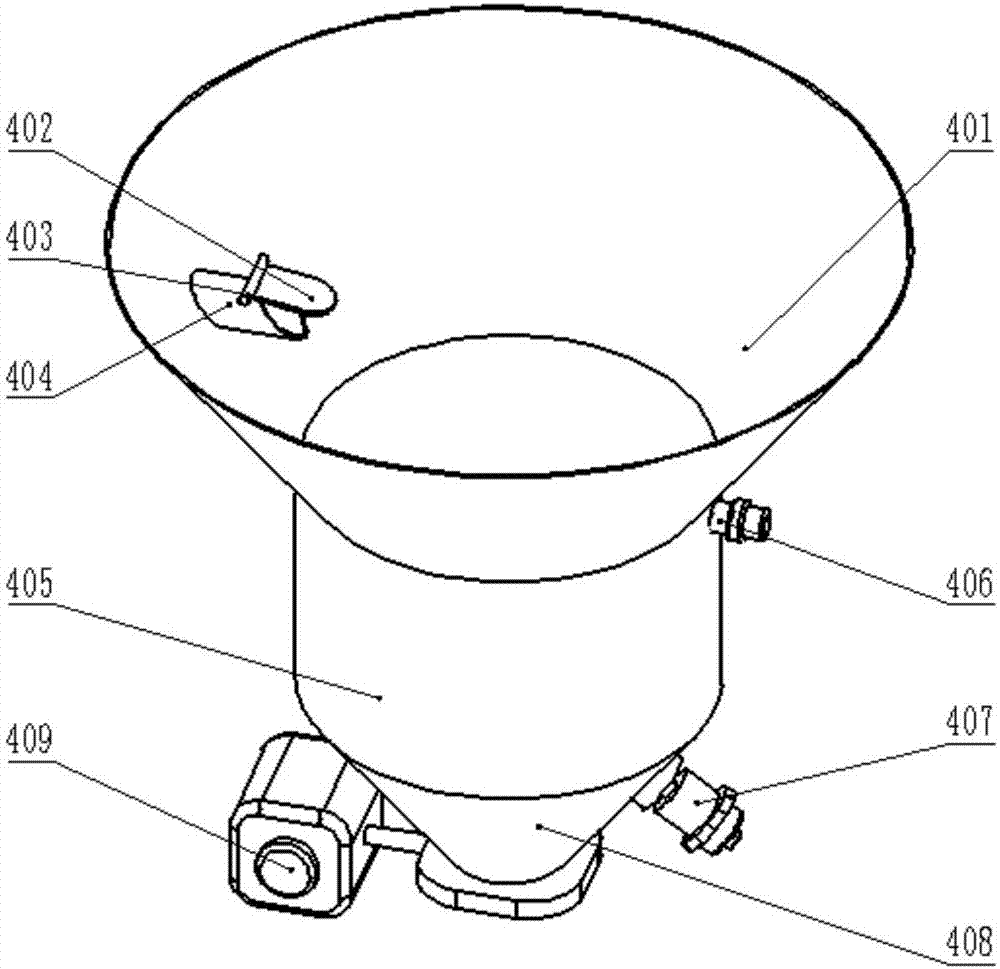

[0059] like figure 1 and Figure 7As shown, the intermittent negative pressure pneumatic conveying system of the present invention includes a feeding device, a horizontal feeder 2, a conveying pipeline 3, a separator 4, a dust collector 5, a blowback device, auxiliary equipment, and a high-pressure vortex fan 8 , Control device 9. The feeding device includes a right-angle hopper 101, an air nozzle I102, and a pneumatic butterfly valve I103; the air nozzle I102 is installed on the inclined side of the right-angle hopper 101; the pneumatic butterfly valve I103 is installed at the bottom of the right-angle hopper 101. The horizontal feeder 2 is installed below the pneumatic butterfly valve I103. The conveying pipeline 3 connects the horizontal feeder 2 and the separator 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com