Serpentine paper drying machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

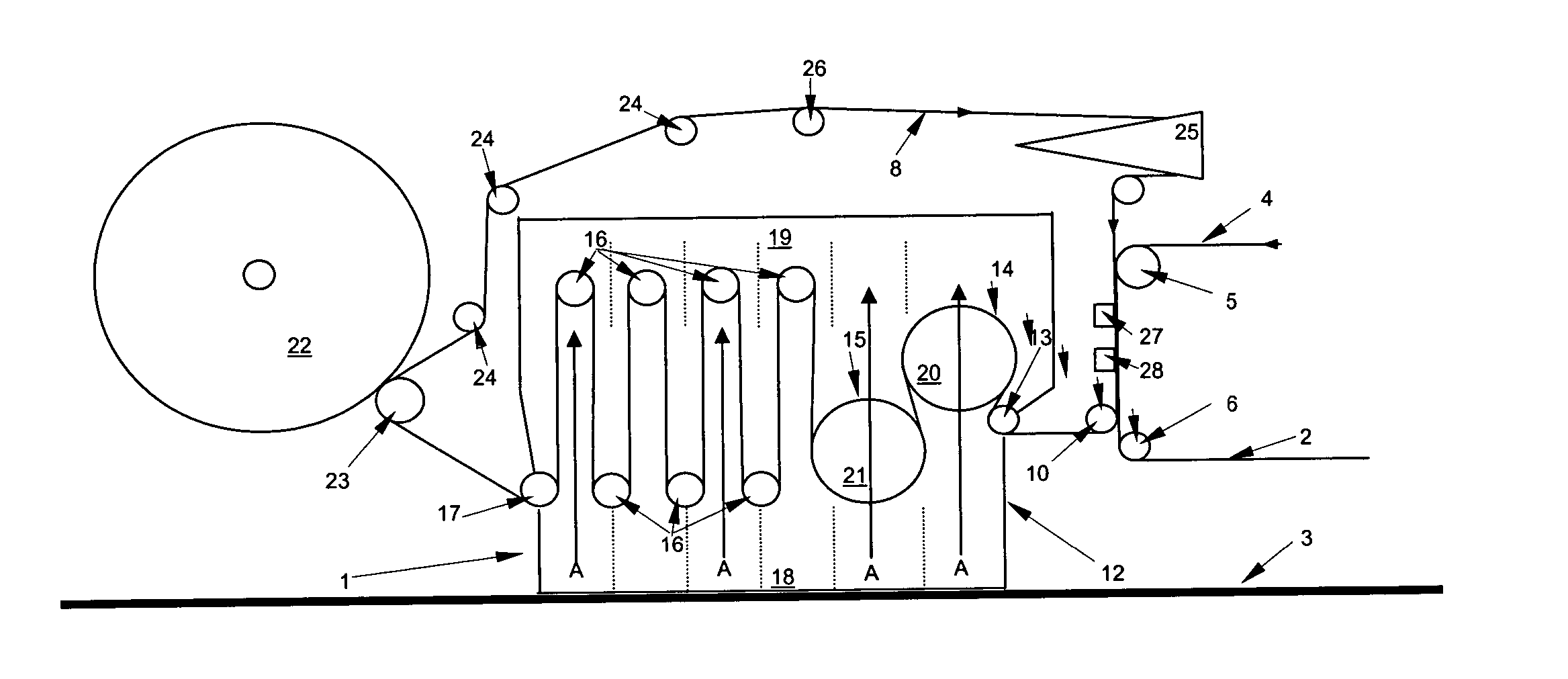

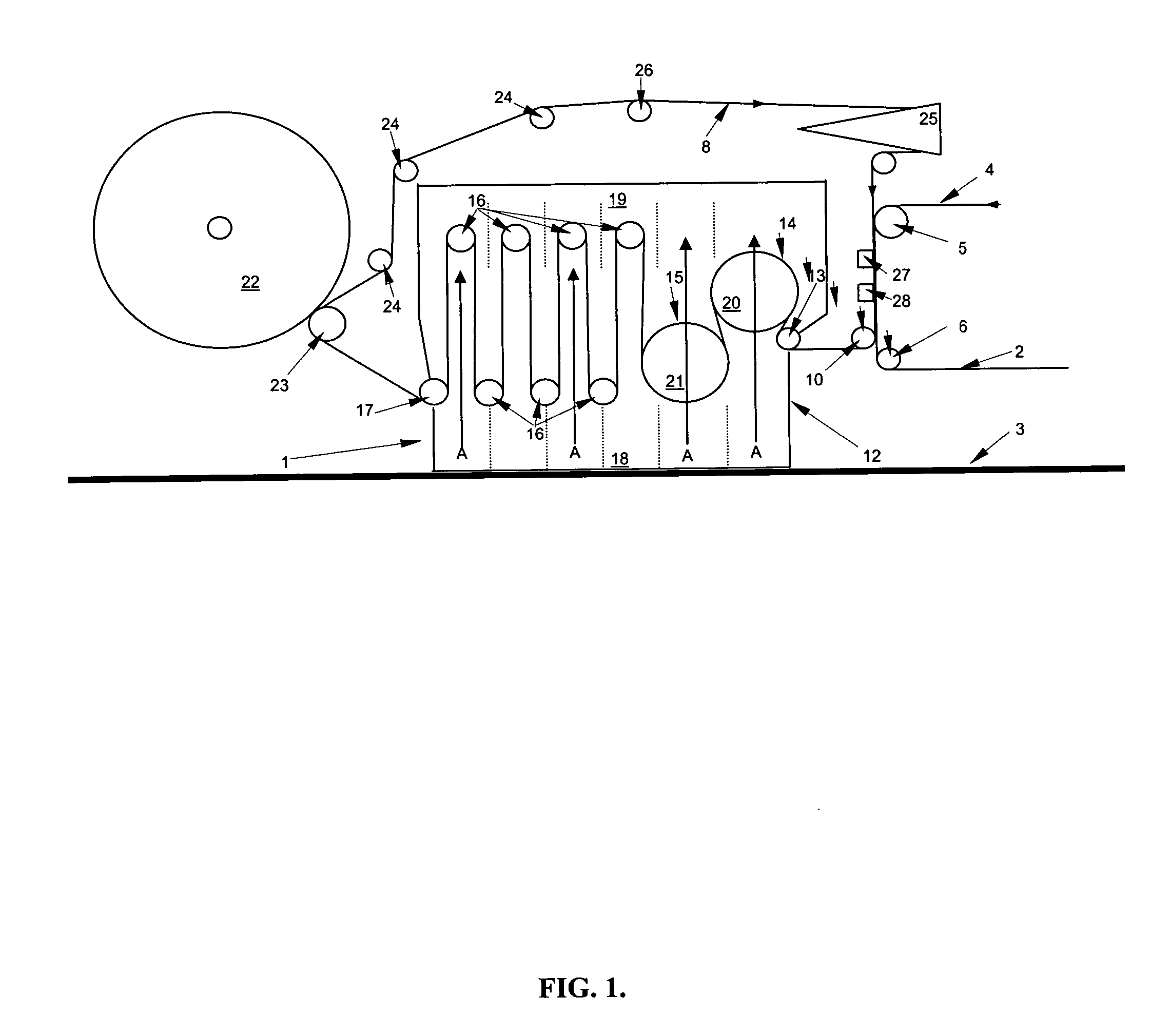

[0018] Referring now to FIG. 1, a paper drying device 1 in accordance with a preferred embodiment of the present invention is illustrated for removing moisture from a wet paper web 4, which is the product of a paper making machine, not shown here. Paper drying device 1 is supported on a floor or other surface 3. Paper web 4 is carried from a paper making process (not shown) to drying device 1 by a fabric sheet 2, wherein fabric sheet 2 travels about the perimeter of a couch roller 5 and a roller 6. In between rollers 5 and 6, paper web 4 is contacted by and transferred to a fabric sheet 8 as fabric sheet 8 passes by a pick-up device or shoe 10. Pick-up shoe 10 may comprise a transfer roller, transfer shoe or any other structure to transfer paper web 4 from fabric sheet 2 to fabric sheet 8. Such transfer devices often employ a vacuum to aid in the transfer of the paper web from one transfer fabric to another. Fabric sheet 8 conveys paper web 4 throughout drying device 1 and forms a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com